Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

API 11P Vs API 618

Caricato da

luis100%(3)Il 100% ha trovato utile questo documento (3 voti)

2K visualizzazioni2 pagineAPI 11P vs API 618

Titolo originale

API 11P vs API 618

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoAPI 11P vs API 618

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

100%(3)Il 100% ha trovato utile questo documento (3 voti)

2K visualizzazioni2 pagineAPI 11P Vs API 618

Caricato da

luisAPI 11P vs API 618

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

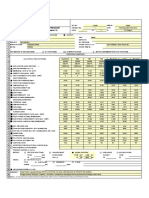

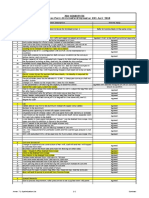

API SPEC 11P - Packaged High-Speed Separable Engine-Driven Reciprocating Gas API STD 618- Reciprocating Compressors for

sors for General Refinery Services

Compressors

1. Discharge temperature - Limited to 176.7°C (350°F). 1. Discharge temperature - Limited to 148.9°C (300°F).

2. Vibration and critical speeds - No requirements. 2. Vibration and critical speeds

a. No torsional natural frequencies within 10 percent of any shaft speed and 5

percent of twice any shaft speed.

b. Vendor states all critical speeds.

3. Compressor cylinders 3. Compressor cylinders

a. Must be rated the greater of 10 percent or 103.4 kPa (15 psi) above discharge a. Must be rated the greater of 10 percent or 103.4 kPa (15 psi) above discharge

pressure. pressure.

b. Replaceable liners preferred, but not required. b. Horizontal cylinders with bottom discharge for saturated gases.

c. Replaceable liners preferred, but not required.

d. Cylinder heads, stuffing boxes, clearance pockets, and valve covers mounted

with studs.

4. Cylinder cooling - As per manufacturer. 4. Cylinder cooling

a. Static cooling if T d 87.8°C (190°F) and _T 83.3°C (150°F).

b. Thermosiphon if 87.8°C (190°F) T d 98.9°C (210°F) and _T 83.3°C (150°F).

c. Forced liquid if T d > 98.9°C (210°F), _T> 83.3°C (150°F), or cylinder runs

unloaded.

d. Coolant system designed for P > 517.1 kPa (75 psig), _P 68.9 kPa (10 psi), _T

5.6°C (10°F) and fouling factor = 0.002.

5. Pistons and piston rods - Rods shall be SAE 4140. 5. Pistons and piston rods

a. Pistons attached to rod by shoulder and lock nut.

b. Rod positively locked to crosshead.

c. Bearing load of fluorocarbon wear rings 34.5 kPa (5 psi).

d. Rods shall be SAE 4140 with 50 Rockwell C hardness.

e. Rod finishing specified.

f. Rod load reversal required.

6. Crankshafts - No requirements. 6. Crankshafts

a. Forged or cast in one piece.

b. For power > 112 kW (BHP > 150) use forged steel.

c. Dynamically balanced if speed > 800 rpm.

7. Crossheads - No requirements. 7. Crossheads

a. For power > 112 kW (BHP > 150) use forged or cast steel.

b. Replaceable slides.

8. Bearings - No requirements. 8. Bearings

a. For power > 112 kW (BHP > 150) use replaceable main and crank.

b. Replaceable bushings for crosshead pins.

9. Distance pieces 9. Distance pieces

a. Drain and vent required. a. Drain and vent required.

b. Two compartment distance pieces required if crankcase and lube oil system b. Packing vent required.

materials not resistant to attack from compressed gas.

c. No packing vent required.

10. Packing - No requirements. 10. Packing

a. Packing glands bolted on and made of steel.

b. Cooling criteria for packing gland set.

11. Lubrication 11. Lubrication

a. Pressure system not required for frame. a. For power > 112 kW (BHP > 150) use pressure system for frame.

b. Cooler - provide if necessary. b. Auxiliary pump required

c. Filter - full flow if pressure lubricated. c. Cooler details specified.

d. Forced-feed mechanical lubricators for cylinder and packing with reservoir. d. Filter:

1. Full flow filter.

2. 25 microns for babbitt bearings.

3. 10 microns for aluminum or microbabbitt bearings.

4. Clean _P 34.5 kPa (5 psi).

5. Maximum design _P > 344.7 kPa (50 psi).

e. Forced-feed mechanical lubricators for cylinder and packing with sight flow

lubrication, check valve, and 30-hour reservoir capacity.

12. Guards 12. Guards

a. Required on all moving parts. a. Required on all moving parts.

b. No requirements for outdoor guards. b. Outdoor guards weatherproofed and ventilated.

13. Piping and pressure codes 13. Piping and pressure codes

a. Piping per ASME B31.3. a. Piping designed to ASME B31.3.

b. Lube oil piping cleaned and oiled. b. Charpy test for material and welds for T -28.9°C (-20°F).

c. Screwed hydrocarbon piping 1«-in and less shall be Sch 60. c. Stainless lube oil piping downstream of filter; carbon piping pickled upstream.

d. Misc. piping details specified. d. Threaded connections seal welded with two passes.

e. Pulsation bottles per ASME SEC VIII. e. Cast iron and malleable iron pipe, fittings, valves, strainers not allowed in

f. Air coolers, shell and tube exchanger design details given (TEMA, ASME, API pressurized flammable or toxic service.

STD 661 not required). f. Piping 1« in and less shall be Sch 80.

g. Miscellaneous piping details specified.

h. Pulsation bottles designed to ASME B31.3.

i. Shell-and-tube exchangers in accordance with TEMA Class B, C or R. For

flammable or toxic gases ASME, Section VIII, Div. 1.

j. Air coolers per API STD 661.

14. Instrumentation 14. Instrumentation

a. Gauges a. Gauges

1. Oil pressure. 1. Bearing oil header pressure.

2. Gas temperature at discharge only of each cylinder. 2. Gas temperature at inlet and discharge of each stage.

3. No gas pressure required. 3. Gas pressure at inlet and discharge of each stage.

4. No oil cooler temperatures required. 4. Oil cooler inlet and outlet oil temperatures.

5. Differential pressure for lube oil filter. September 1992 Page 81

6. No water temperatures required. 5. Differential pressure for lube oil filter.

b. Shutdowns 6. Water temperatures in and out of coolers.

1. Low oil pressure b. Alarms or shutdowns

2. Low suction pressure. 1. Low oil pressure - shutdown.

3. High suction. 2. High discharge temperature if handling air or oxygen - alarm.

4. High discharge pressure. c. Relief valves - As required per API STD 510.

5. Cooler vibration.

6. High scrubber level.

7. High discharge temperature each stage.

c. Relief valves - No requirements.

15. Materials 15. Materials

a. Cylinder - manufacturer's standard. a. Cylinder - gray iron (ASTM A278) or nodular iron (ASTM A395) for MAWP up to

b. Pressure vessels - per ASME SEC VIII. 6895 kPa (1,000 psig).

c. No corrosion allowance required on bottles. b. Cast steel (ASTM A216) for MAWP up to 17,237 kPa (2,500 psig).

d. No miscellaneous casting requirements. c. Forged steel for MAWP greater than 17,237 kPa (2,500 psig).

d. Pressure vessels - per ASME SEC VIII.

e. Welding - per ASME SEC IX.

f. Pulsation bottles - 1/8 in corrosion allowance.

g. Miscellaneous casting requirements.

16. Tests 16. Tests

a. Tests per code requirements. a. Hydrostatic with water to 1 1/2 MAWP for cylinders, cooling jackets, piping

b. No helium test. pressure vessels, filters, coolers, etc.

b. Helium test at MAWP if MW of gas 12 or more than 0.1 mol percent H 2S in

addition to hydrostatic test.

c. Test maintained for 30 minutes.

17. Pulsation design 17. Pulsation design

a. Bottles with 5 times piston displacement, if nothing else specified. a. Purchaser must specify design approach.

b. No criteria established. b. Criteria established for each approach.

18. Guarantees 18. Guarantees - No negative tolerance on capacity; that is, as a minimum, the

a. Capacity 3 percent with P s > 5 psig compressor must meet specified condition of th

b. Capacity 6 percent with P s 5 psig

19. Miscellaneous items

a. Specifies scrubber design details.

Potrebbero piacerti anche

- 04-Unit - Force Feed Lubrication SystemDocumento38 pagine04-Unit - Force Feed Lubrication SystemKavi BhandariNessuna valutazione finora

- Reciprocating Compressor Discharge TemperatureDocumento6 pagineReciprocating Compressor Discharge TemperaturesalleyNessuna valutazione finora

- Hoerbiger Hydrocom SystemDocumento21 pagineHoerbiger Hydrocom Systemabhik1790% (1)

- Reciprocating Compressor High Medium Speed Vs Slow SpeedDocumento56 pagineReciprocating Compressor High Medium Speed Vs Slow SpeedAlfredoNessuna valutazione finora

- Pages From 05-01269 Regeneration API-617-datasheet-rev11 PDFDocumento1 paginaPages From 05-01269 Regeneration API-617-datasheet-rev11 PDFalikajbafNessuna valutazione finora

- Air Volume and Pressure Guidelines For VHP GL Engines With TDI Air StartersDocumento2 pagineAir Volume and Pressure Guidelines For VHP GL Engines With TDI Air StartersMuhammad AsadNessuna valutazione finora

- Asme PTC 10 PDFDocumento191 pagineAsme PTC 10 PDFnampdpeec3Nessuna valutazione finora

- Reciprocating Compressor 11p Vs 618Documento4 pagineReciprocating Compressor 11p Vs 618karehmanNessuna valutazione finora

- Centrifugal Compressor Settle Out Conditions TutorialDocumento5 pagineCentrifugal Compressor Settle Out Conditions TutorialJHOEARGNessuna valutazione finora

- Introduction To DGSDocumento58 pagineIntroduction To DGSAan Sarkasi AmdNessuna valutazione finora

- 10 Gas Conditioning SystemDocumento24 pagine10 Gas Conditioning SystemRavi Sankar VenkatesanNessuna valutazione finora

- Unloader Selection For Recip CompressorsDocumento10 pagineUnloader Selection For Recip CompressorsAnonymous KpVxNXsNessuna valutazione finora

- Flowserve Mechanical Seal PlanDocumento56 pagineFlowserve Mechanical Seal PlanAnonymous 1XHScfCINessuna valutazione finora

- Cameron Ajax Package Service Manual PDFDocumento829 pagineCameron Ajax Package Service Manual PDFAlfredo100% (1)

- Waukesha Gas Engines VHP P9390GSIDocumento2 pagineWaukesha Gas Engines VHP P9390GSIrohizat100% (1)

- Api 617 CameronDocumento31 pagineApi 617 CameronMachineryengNessuna valutazione finora

- Presentation: Reliability of Hydrogen Area Diaphragm CompressorDocumento43 paginePresentation: Reliability of Hydrogen Area Diaphragm CompressorBiju_Pottayil100% (1)

- Unit 8 Reciprocatng Compressors: StructureDocumento26 pagineUnit 8 Reciprocatng Compressors: StructureRakeshKrNessuna valutazione finora

- API Recip Compressor Best Practices 0300 - 060814Documento25 pagineAPI Recip Compressor Best Practices 0300 - 060814daniel adamNessuna valutazione finora

- HPRT - PresentationDocumento19 pagineHPRT - PresentationMehrzad AlizadehNessuna valutazione finora

- Ariel Training Hoerbiger Valves 2012Documento100 pagineAriel Training Hoerbiger Valves 2012sithulibra100% (8)

- GPSA Engineering Data Book 14th Edition: Revision Date Reason (S) For RevisionDocumento51 pagineGPSA Engineering Data Book 14th Edition: Revision Date Reason (S) For RevisionJuan Sebastian OrozcoNessuna valutazione finora

- Instrument Air Consumption CalculationDocumento3 pagineInstrument Air Consumption CalculationVenkatesan N0% (1)

- Parallel Compressor Load SharingDocumento2 pagineParallel Compressor Load Sharingejzuppelli8036Nessuna valutazione finora

- Filtro PECO Gas CombustibleDocumento4 pagineFiltro PECO Gas CombustibleEdgar CanelasNessuna valutazione finora

- Data Sheet For Cooling Tower:, Cti CertifiedDocumento2 pagineData Sheet For Cooling Tower:, Cti CertifiedHemanti SharmaNessuna valutazione finora

- Att2 Baretti InternalsDocumento36 pagineAtt2 Baretti InternalsAli MetinNessuna valutazione finora

- JGR JGJ enDocumento137 pagineJGR JGJ enKarlosant MJ100% (1)

- Online Monitoring of Recip Compressors, 2004Documento20 pagineOnline Monitoring of Recip Compressors, 2004peach5Nessuna valutazione finora

- Bypass Method For Recip Compressor Capacity ControlDocumento4 pagineBypass Method For Recip Compressor Capacity Controlel mouatez billah messiniNessuna valutazione finora

- API 676 Datasheet PDFDocumento6 pagineAPI 676 Datasheet PDFPierre Norris0% (1)

- FTA157 Piping Plan PosterDocumento1 paginaFTA157 Piping Plan PosterGloria HamiltonNessuna valutazione finora

- Centrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)Documento4 pagineCentrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)Carlos Felipe Reyes MartínezNessuna valutazione finora

- Pressure Packing PresentationDocumento20 paginePressure Packing PresentationVIJAYIOCL100% (2)

- L7042GDocumento2 pagineL7042GRose MarieNessuna valutazione finora

- Beginner's Guide To Centrifugal Compressor Design and SimulationDocumento17 pagineBeginner's Guide To Centrifugal Compressor Design and Simulationvijay_jvNessuna valutazione finora

- Compressor Performance Test Procedure Shaybah Rev.2 BorsigDocumento23 pagineCompressor Performance Test Procedure Shaybah Rev.2 BorsigMachineryengNessuna valutazione finora

- Rod ReversalDocumento21 pagineRod ReversalandresNessuna valutazione finora

- Baker Hughes HPump Operation and Maintenance Manual PDFDocumento144 pagineBaker Hughes HPump Operation and Maintenance Manual PDFluis_seczonNessuna valutazione finora

- Maintenance & Repair Manual: Ariel CorporationDocumento169 pagineMaintenance & Repair Manual: Ariel CorporationMuhammad Rosihan100% (1)

- Difference Between API 611 and API 612 - Mechanical Engineering SiteDocumento8 pagineDifference Between API 611 and API 612 - Mechanical Engineering SiteAlfredo VelasquezNessuna valutazione finora

- 0904 Data Sheet Marine Loading Arm - USADocumento2 pagine0904 Data Sheet Marine Loading Arm - USAImran100% (1)

- 2012-11-43 Anti-Surge Valves For Dynamic CompressorsDocumento5 pagine2012-11-43 Anti-Surge Valves For Dynamic Compressorssourcemenu100% (2)

- 02-Gas Compression Fundamentals-1Documento47 pagine02-Gas Compression Fundamentals-1Muhammad Asad100% (1)

- Waukesha Knock Index Power CurveDocumento1 paginaWaukesha Knock Index Power CurveparathasiNessuna valutazione finora

- API 619 (97) PD CompressorsDocumento118 pagineAPI 619 (97) PD CompressorsMuhammadAwais100% (1)

- 002 - Reciprocating CompressorDocumento16 pagine002 - Reciprocating CompressorMuhammad TariqNessuna valutazione finora

- API 610 2018 12th PreviewDocumento7 pagineAPI 610 2018 12th PreviewJulio Hernández GarciaNessuna valutazione finora

- Burgmann Gas SealDocumento47 pagineBurgmann Gas SealGeorge J Alukkal100% (1)

- API - STD - 521 Fire Gas ExpansionDocumento3 pagineAPI - STD - 521 Fire Gas Expansioneliealtawil100% (1)

- Ajax Cause & EffectDocumento3 pagineAjax Cause & EffectgustavoespinosamNessuna valutazione finora

- Pump Specification Data SheetDocumento3 paginePump Specification Data SheetMelvin MagbanuaNessuna valutazione finora

- 1970 Dodge Challenger - Dart - Cooling System PDFDocumento12 pagine1970 Dodge Challenger - Dart - Cooling System PDFHenry SilvaNessuna valutazione finora

- Annex 7.1 Optimization ListDocumento5 pagineAnnex 7.1 Optimization Listabdullah amanullahNessuna valutazione finora

- Chiller Tech2 - EIL DelhiDocumento4 pagineChiller Tech2 - EIL DelhibmanojNessuna valutazione finora

- CR Spec SheetDocumento3 pagineCR Spec SheetGustavo HernandezNessuna valutazione finora

- Chapter 1 - Main Propulsion 0102 Gear Box (HAT/SAT) ObjectiveDocumento4 pagineChapter 1 - Main Propulsion 0102 Gear Box (HAT/SAT) ObjectiveSaTiz ZeE100% (1)

- API 510. Daily Exam-1 (Closed Book)Documento6 pagineAPI 510. Daily Exam-1 (Closed Book)Mohammed Shakil100% (2)

- Unit Test-1 SEM.-I: Subjects - Aerodynamic Batech-06Documento7 pagineUnit Test-1 SEM.-I: Subjects - Aerodynamic Batech-06mauryapiaeNessuna valutazione finora

- API 510. Daily Exam-1 (Closed Book)Documento6 pagineAPI 510. Daily Exam-1 (Closed Book)DAMIAN ALEJANDRO100% (1)

- 303-05A+Accessory+DriveDocumento5 pagine303-05A+Accessory+DriveP HandokoNessuna valutazione finora

- Question Set 1 PDFDocumento6 pagineQuestion Set 1 PDFSeljen AceNessuna valutazione finora

- Hoja Técnica Roto Xtend Duty Fluid PDFDocumento2 pagineHoja Técnica Roto Xtend Duty Fluid PDFFederico Liaudat100% (2)

- CH1Documento34 pagineCH1none5402Nessuna valutazione finora

- Tut-371 No.2Documento8 pagineTut-371 No.2fletusdiabloiNessuna valutazione finora

- DPR TemplateDocumento5 pagineDPR TemplateSantoshkumar GurmeNessuna valutazione finora

- Deformacao AxialDocumento31 pagineDeformacao AxialANTONIONessuna valutazione finora

- Shear Strenght ExampleDocumento11 pagineShear Strenght ExamplealvinNessuna valutazione finora

- Enthalpy - Thermodynamics Questions and Answers - SanfoundryDocumento8 pagineEnthalpy - Thermodynamics Questions and Answers - SanfoundryBhardwaj Rajinder SippyNessuna valutazione finora

- MEC331 - Revision Gear FinalDocumento9 pagineMEC331 - Revision Gear FinalDiana PinkyNessuna valutazione finora

- Fleetguard Recycled Coolant: Fleetcool™ Recycled EG PremixDocumento48 pagineFleetguard Recycled Coolant: Fleetcool™ Recycled EG PremixCesar G.Nessuna valutazione finora

- Seleccion de RejillaDocumento4 pagineSeleccion de RejillaCarlos Eduardo Arista FloresNessuna valutazione finora

- Owner's Manual For Porsgrunn Rotary Vane Steering Gear S-1995Documento124 pagineOwner's Manual For Porsgrunn Rotary Vane Steering Gear S-1995O olezhaod100% (4)

- Project Report On SS Tube MillDocumento8 pagineProject Report On SS Tube MillEIRI Board of Consultants and Publishers0% (1)

- Suspension For Electrathon VehicleDocumento55 pagineSuspension For Electrathon VehicleJulius RojoNessuna valutazione finora

- WTP Process DiagramDocumento1 paginaWTP Process DiagramKumar AbhishekNessuna valutazione finora

- Levers in Musculoskeletal SystemDocumento22 pagineLevers in Musculoskeletal SystemGlenn JohnstonNessuna valutazione finora

- MG UniversityDocumento2 pagineMG UniversityVaisakVenugopalNessuna valutazione finora

- Computational Fluid Dynamics (CFD) Modeling of Grain-Water Suspensions in TubeDocumento15 pagineComputational Fluid Dynamics (CFD) Modeling of Grain-Water Suspensions in TubebhuniakanishkaNessuna valutazione finora

- Decorative Metal (MS - FL)Documento10 pagineDecorative Metal (MS - FL)walid abou kachfeNessuna valutazione finora

- Determination of Blockage Correction in Open-Jet Wind TunnelDocumento6 pagineDetermination of Blockage Correction in Open-Jet Wind Tunnelmoro1381100% (1)

- Slab Analysis of Ring Rolling AssumingConstantShearFrictionDocumento7 pagineSlab Analysis of Ring Rolling AssumingConstantShearFrictionMatteo Dalla Vecchia100% (1)

- Facts at Your Fingertips-201104-Hopper Inserts For Improved Solids FlowDocumento1 paginaFacts at Your Fingertips-201104-Hopper Inserts For Improved Solids Flowonizuka-t2263Nessuna valutazione finora

- 2p36907 SwivelDocumento42 pagine2p36907 SwivelIFI ARGENTINA S.A.Nessuna valutazione finora

- Hydraulic Fan System 966Documento4 pagineHydraulic Fan System 966Ahmed Rezk100% (2)

- Screws Self-DrillingDocumento22 pagineScrews Self-DrillingSamra DukićNessuna valutazione finora

- Agrofarm 410 420 430 LP EN 02 12Documento119 pagineAgrofarm 410 420 430 LP EN 02 12Lacatusu Mircea100% (1)

- P - Delta Effect in Reinforced Concrete Structures of Rigid Joint-LibreDocumento8 pagineP - Delta Effect in Reinforced Concrete Structures of Rigid Joint-LibrePunithan PunithanNessuna valutazione finora

- Lecture 2 UpdateDocumento80 pagineLecture 2 Updateماجد مدحت سعيدNessuna valutazione finora

- List of Transferred ASME StandardsDocumento3 pagineList of Transferred ASME StandardsShakeel AhmedNessuna valutazione finora