Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pinned Base Plate (Rs Shear Key)

Caricato da

winlugue3059Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pinned Base Plate (Rs Shear Key)

Caricato da

winlugue3059Copyright:

Formati disponibili

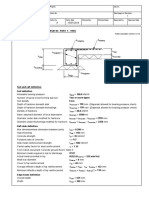

Pinned Base Plate Design

DESIGN PHILOSOPHY

Bolts are designed for tension only. Shear key is provided to resist the shear. Shear resistance by

grout is considered while designing for shear key. Bolts are anchored in concrete pedestal. Pullout

strength from concrete is considered while arriving at length of the anchor bolt. Bolt lengths are shown

in TR Document no . 30.99.75.1610.( Anchor bolt & Fixings).Full strength of bolt is considered while

checking thickness of base plate in tension.

INPUT FROM STAAD

Horizontal Vertical Horizontal

Node L/C Fx kN Fy kN Fz kN

Max Fx 31 112 DS(1.2)+DO(1.2)+LL(1.2)+T-(1.2)+FF(-1.2)+AF(-1.2)+WX(-1.2)

127.2 478.9 4.4

Min Fx 32 110 DS(1.2)+DO(1.2)+LL(1.2)+T-(1.2)+FF(1.2)+AF(1.2)+WX(1.2)

-127.8 448.6 9.8

Max Fy 15 111 DS(1.2)+DO(1.2)+LL(1.2)+T+(1.2)+FF(-1.2)+AF(-1.2)+WX(-1.2)

68.4 528.0 6.9

Min Fy 32 116 DS(1.2)+DE(1.2)+LL(1.2)+FF(-1.2)+AF(-1.2)+WX(-1.2)+CR(1.2)+EM(1.2)

111.0 -165.5 -2.2

Max Fz 1 101 DS(1.4)+DO(1.6)+LL(1.6)+

-23.5 T+

159.8

(1.2)+FF(1.6)+ AF(1.6)+CR(1.4)+BL(1)

24.9

Min Fz 34 103 DS(1.4)+DO(1.6)+LL(1.6)+T+(1.2)+FF(-1.6)+AF(-1.6)+CR(1.4)+BL(1)

22.7 159.8 -26.1

COLUMN SECTION UC 356x368x129

Depth of section,h = 356 mm.

Flange width,b = 369 mm.

Web thickness, s = 10 mm.

Flange thickness,t = 18 mm.

clear spacing between the holes 124 mm.

70 Provide Base plate 440 x 420 x 25 with 4 no´s of

24 dia of bolts of grade 4.6

440 150

368.6 8 mm.

Dia of the bolt M 24

Grade of the bolt 4.6

355.6

230 clear spacing between the holes

45 45 204

420

CHECK FOR TENSION CAPACITY OF HOLDING DOWN BOLTS

Tension in each bolt = 41 kN

Tension capacity ,Pt = 68 kN Bolts are safe in Tension

Pt = 0 .8 p t A t

(Clause. 6.3.4.2 BS5950-1:2000)

where:

Pt = tension capacity in holding down bolts

pt = tension strength of bolt (clause. 6.3.4.2 BS5950-1:2000 pp.138)

At = tensile stress area specified in appropriate bolt standard

CHECK FOR BEARING STRESS ON CONCRETE

Characteristic cube strength of concrete, fcu = 40 N/sq.mm.

Bearing strength of concrete, 0.6fcu (clause 4.13.1 of BS 5950-1:2000) = 24 N/sq.mm.

Bearing stress on to the concrete = Fc/(Area provided ) = 2.9 N/sq.mm

Area of base plate provided = 184800 sq.mm. Safe in Bearing on Pedestal

Area of base plate required = 22000 sq.mm.

CHECK FOR THICKNESS OF BASE PLATE IN COMPRESSION

Effective area

For axial forces applied concentrically to the base plate, the thickness of the baseplate should not be

less than tp given by

[

t p = c 3w/ pyp ]

0.5

= 1 mm. (clause 4.13.2.2. of BS 5950-1:2000)

where

c is the larget perpendicular distance from the edge of effective portion of the baseplate to

the face of the column cross section , as shown in the figure above = 3 mm.

p yp is the design strength of the base plate (Table 9 BS 5950-1:2000) = 265 N/sq.mm.

T is the flange thickness(or maximum thickness of the column;

w is the pressure undere the baseplate, based on an assumed uniform distribution of

pressure through out the effective portion = 24 N/sq.mm.

Effective area in mm = 2 * { (2c+b) (2c+t) } + { (2c+s) * [ h - 2 * (c+t) ] }

= (after 22000

solving for c by equating with area provided)

CHECK FOR THICKNESS OF BASE PLATE IN TENSION

Tension capacity of the holding down bolt used,Pt = 68 kN

df = 45 mm. should not be less than 36 (Clause 6.2.2 of BS 5950-1:2000)

dw = 70 mm. should not be less than 36 (Clause 6.2.2 of BS 5950-1:2000)

Bending moment about flange ,M = Pt x df = 3070 kN-mm.

Thickness of the base plate with M about flange= √( (6xM)/(pyp x(b/2)) = 19 mm.

Bending moment about web ,M = 2 x Pt x dw = 9462 kN-mm.

Thickness of the base plate with M about web = √( (6xM)/(pyp xh)) = 25 mm.

Provide baseplate thickness = 25 mm.

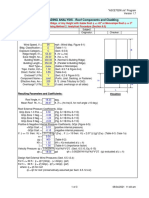

CHECK FOR WELDING

Design strength of the weld = 220 N/sq.mm. (Table 37 of BS5950-1:2000)

Weld size = 8 mm. (Table 5.8 of AWS D 1.1)

Throat thickness for the fillet weld = 6 mm. (Clause 6.8.7.1 of BS 5950-1:2000)

Shear force is acting through CG of the weld

Hence shear capacity of the weld = weld length x throat thickness of the weld x design strength

Check for shear capacity of weld along web of column

Shear

Resultant strength of

shear (kN) weld (kN) Check

Max Fx 127 876 Safe in shear

Min Fx 128 876 Safe in shear

Max Fy 69 876 Safe in shear

Min Fy 111 876 Safe in shear

Max Fz 34 876 Safe in shear

Min Fz 35 876 Safe in shear

Check for shear capacity of weld along flange of column

Shear

Resultant strength of

shear (kN) weld (kN) Check

Max Fx 127 1816 safe in shear

Min Fx 128 876 safe in shear

Max Fy 69 876 safe in shear

Min Fy 111 876 safe in shear

Max Fz 34 876 safe in shear

Min Fz 35 876 safe in shear

x

DESIGN FOR SHEAR KEY

ROLLED SECTION PROVIDED AS SHEAR KEY z

Shear Key section = UC 152x152x23 Staad Notation

Depth of section,h = 152 mm.

base plate shear key

Width of section,b = 152 mm.

Web thickness, s = 6 mm.

Flange thickness,t = 7 mm. column

Plastic Modulus about major axis = 182000 cu.mm.

Plastic Modulus about minor axis = 80200 cu.mm. Grout

Design strength = 265 N/sq.mm.

Depth of shearkey ds = 150 mm. g

Thickness of grout,g = 25 mm. ds

Elastic neutral axis of section, Cy = #N/A

CHECK FOR BEARING Section B-B

6

Bearing strength of concrete, 0.6fcu = 24 N/sq.mm. (clause 4.13.1 of BS 5950-1:2000)

Bearing pressure on concrete

In Z-direction shear force,Fz = 476

Fz / (h* (ds-g)) = 25 N/sq.mm. Change section

In X-direction shear force Fx = 130

Fx / (b*(ds-g) = 7 N/sq.mm. Safe in bearing on concrete

CHECK FOR SHEAR

Shear capacity Pv is given by Pv = 0 .6 p y A v (clause 4.2.3 of BS 5950-1:2000)

Shear Resistance offer by grout = 0.45 x Fy

check for shear along the depth of the web

Vertical Shear

resistance Shear

Resultant by grout Net shear force to be Capacity of

shear (kN) Fy (kN) (kN) taken by shear key (kN) the key (kN) Check

Max Fx 127 479 216 0 141 Safe in shear

Min Fx 128 449 202 0 141 Safe in shear

Max Fy 69 528 238 0 141 Safe in shear

Min Fy 111 -166 0 111 141 Safe in shear

Max Fz 34 160 72 0 141 Safe in shear

Min Fz 35 160 72 0 141 Safe in shear

shear force along the flange. of the section

Resultant Vertical Shear Net shear force to be Shear

shear (kN) Fy (kN) resistance taken by shear key (kN) Capacity of Check

Max Fx 127 479 216 0 329 Safe in shear

Min Fx 128 449 202 0 329 Safe in shear

Max Fy 69 528 238 0 329 Safe in shear

Min Fy 111 -166 0 111 329 Safe in shear

Max Fz 34 160 72 0 329 Safe in shear

Min Fz 35 160 72 0 329 Safe in shear

CHECK FOR BENDING STRESS

Moment about X-axis = Fz x ((ds-g)/2+g) = 42 kN-m.

Bending stress about minor axis of key = 519 N/sq.mm.

Moment about Z-axis = Fx x ((ds-g)/2+g) = 11 kN-m.

Bending stress about minor axis of key = 63 N/sq.mm.

Biaxial bending stress on ratio 2.2 Change section

CHECK FOR WELDING

Design strength of the weld = 220 N/sq.mm. (Table 37 of BS5950-1:2000)

Weld size = 6 mm. (Table 5.8 of AWS D 1.1)

Throat thickness for the fillet weld = 4 mm. (Clause 6.8.7.1 of BS 5950-1:2000)

Shear force is acting through CG of the weld

Hence shear capacity of the weld = weld length x throat thickness of the weld x design strength

Check for shear capacity of weld along depth of web

Vertical Shear

resistance Shear

Resultant by grout Net shear force to be strength of

shear (kN) Fy (kN) (kN) taken by shear key (kN) weld (kN) Check

Max Fx 127 479 216 0 282 Safe in shear

Min Fx 128 449 202 0 282 Safe in shear

Max Fy 69 528 238 0 282 Safe in shear

Min Fy 111 -166 0 111 282 Safe in shear

Max Fz 34 160 72 0 282 Safe in shear

Min Fz 35 160 72 0 282 Safe in shear

Check for shear capacity of weld along width of flange

Vertical Shear

resistance Shear

Resultant by grout Net shear force to be strength of

shear (kN) Fy (kN) (kN) taken by shear key (kN) weld (kN) Check

Max Fx 127 479 216 0 552 safe in shear

Min Fx 128 449 202 0 552 safe in shear

Max Fy 69 528 238 0 552 safe in shear

Min Fy 111 -166 0 111 552 safe in shear

Max Fz 34 160 72 0 552 safe in shear

Min Fz 35 160 72 0 552 safe in shear

DESIGN FOR SHEAR KEY Staad Notation

PLATE SECTION PROVIDED AS SHEAR KEY x

Width of shear key plate, Ws = 250 mm. z

Length of shear kay plate, Ls = 150 mm. Ls

baseplate

Thickness of shear key,ts = 20 mm.

Grout

Plastic Modulus about z - axis = 325500 cu.mm. Ws

Plastic Modulus about x - axis = 135500 cu.mm. A A

Design strength (Table 9 of BS 5950-1:2000) = 265 N/sq.mm. Plan shearkey

Depth of shearkey ds = 160 mm. g ds

Thickness of grout,g = 25 mm.

Section A-A

8

CHECK FOR BEARING ON CONCRETE

Bearing strength of concrete, 0.6fcu = 24 N/sq.mm. (clause 4.13.1 of BS 5950-1:2000)

Bearing pressure on concrete

In Z-direction shear force,Fz = 101

Fz / (Ws* (ds-g)) = 3 N/sq.mm. Safe in Bearing on concrete

In X-direction shear force Fx = 217

Fx / (Ls*(ds-g) = 11 N/sq.mm. Safe in Bearing on concrete

CHECK FOR SHEAR

Shear capacity Pv is given by Pv = 0 .6 p y A v (clause 4.2.3 of BS 5950-1:2000)

Shear Resistance offer by grout = 0.45 x Fy

check for shear along Width of shear key

Vertical Shear

resistance Shear

Resultant by grout Net shear force to be Capacity of

shear (kN) Fy (kN) (kN) taken by shear key (kN) the key (kN) Check

Max Fx 127 479 216 0 795 Safe in Shear

Min Fx 128 449 202 0 795 Safe in Shear

Max Fy 69 528 238 0 795 Safe in Shear

Min Fy 111 -166 0 111 795 Safe in Shear

Max Fz 34 160 72 0 795 Safe in Shear

Min Fz 35 160 72 0 795 Safe in Shear

check for shear along Length of shear key

Vertical Shear

resistance Shear

Resultant by grout Net shear force to be Capacity of

shear (kN) Fy (kN) (kN) taken by shear key (kN) the key (kN) Check

Max Fx 127 479 216 0 477 Safe in shear

Min Fx 128 449 202 0 477 Safe in shear

Max Fy 69 528 238 0 477 Safe in shear

Min Fy 111 -166 0 111 477 Safe in shear

Max Fz 34 160 72 0 477 Safe in shear

Min Fz 35 160 72 0 477 Safe in shear

CHECK FOR BENDING STRESS

Moment about X-axis = Fz x ((ds-g)/2+g) = 9 kN-m.

Bending stress about x - axis of shear key = 69 N/sq.mm.

Moment about Z-axis = Fx x ((ds-g)/2+g) = 20 kN-m.

Bending stress about z - axis of shear key = 62 N/sq.mm.

Biaxial bending stress on ratio 0.5 Safe in bending

CHECK FOR WELDING

Design strength of the weld = 220 N/sq.mm. (Table 37 of BS5950-1:2000)

Weld size = 8 mm. (Table 5.8 of AWS D 1.1)

Throat thickness for the fillet weld = 6 mm. (Clause 6.8.7.1 of BS 5950-1:2000)

Shear force is acting through CG of the weld

Hence shear capacity of the weld = weld length x throat thickness of the weld x design strength

Check for shear capacity of weld along Width of shear key

Vertical

Shear

resistance Shear

Resultant by grout Net shear force to be strength of

shear (kN) Fy (kN) (kN) taken by shear key (kN) weld (kN) Check

Max Fx 127 479 216 0 616 Safe in shear

Min Fx 128 449 202 0 616 Safe in shear

Max Fy 69 528 238 0 616 Safe in shear

Min Fy 111 -166 0 111 616 Safe in shear

Max Fz 34 160 72 0 616 Safe in shear

Min Fz 35 160 72 0 616 Safe in shear

Check for shear capacity of weld along Length of shear key

Vertical Shear

resistance Shear

Resultant by grout Net shear force to be strength of

shear (kN) Fy (kN) (kN) taken by shear key (kN) weld (kN) Check

Max Fx 127 479 216 0 370 safe in shear

Min Fx 128 449 202 0 370 safe in shear

Max Fy 69 528 238 0 370 safe in shear

Min Fy 111 -166 0 111 370 safe in shear

Max Fz 34 160 72 0 370 safe in shear

Min Fz 35 160 72 0 370 safe in shear

Potrebbero piacerti anche

- Footing Design Result-RcdcDocumento360 pagineFooting Design Result-RcdcJoseph Cloyd L. LamberteNessuna valutazione finora

- M3D - SampleProblemSet ACI PDFDocumento6 pagineM3D - SampleProblemSet ACI PDFasaisenthilNessuna valutazione finora

- Foundation DesignDocumento18 pagineFoundation Designhemantkle2uNessuna valutazione finora

- Crack WidthDocumento6 pagineCrack Widthnitin400Nessuna valutazione finora

- Embedded PlateDocumento38 pagineEmbedded PlateAnonymous pD2ymRUguNessuna valutazione finora

- Design of Substation Building FoundationDocumento9 pagineDesign of Substation Building FoundationManan MansoorNessuna valutazione finora

- Basic Data:: Calculation of Gust Effect FactorDocumento1 paginaBasic Data:: Calculation of Gust Effect FactorYaser ShabasyNessuna valutazione finora

- Bolt Design (Blodget)Documento4 pagineBolt Design (Blodget)Mayuresh KudveNessuna valutazione finora

- Design of Base PlateDocumento3 pagineDesign of Base Plateravi4paperNessuna valutazione finora

- Slab Foundation Design 1Documento6 pagineSlab Foundation Design 1Renato ZanescoNessuna valutazione finora

- Rectangular Spread Footing DesignDocumento42 pagineRectangular Spread Footing DesignJedidiah MelakuNessuna valutazione finora

- PAEC2017 - Slab On Grade InvestigationDocumento2 paginePAEC2017 - Slab On Grade InvestigationSayavi Nicole Sayavi NickNessuna valutazione finora

- Staad Foundation - Heat ExchangerDocumento13 pagineStaad Foundation - Heat ExchangerKritashna KjNessuna valutazione finora

- "Footings" - Spread Footing Analysis: Program DescriptionDocumento22 pagine"Footings" - Spread Footing Analysis: Program Descriptionmuh2006Nessuna valutazione finora

- Wind Load Calculation For Multiple Framed Open Structures Design Wind PressureDocumento2 pagineWind Load Calculation For Multiple Framed Open Structures Design Wind Pressurechirag01020% (1)

- Spreadsheets To BS 8110Documento11 pagineSpreadsheets To BS 8110NitinShepurNessuna valutazione finora

- Extended Fin Plate Connection - LRFDDocumento22 pagineExtended Fin Plate Connection - LRFDkalpanaadhiNessuna valutazione finora

- Sample Shear ConnectionDocumento1 paginaSample Shear ConnectionmaheshbandhamNessuna valutazione finora

- Wind CalculatorDocumento12 pagineWind Calculatorilyasmd7Nessuna valutazione finora

- Check For Punching Shear:: Pile Cap Design (PC3a)Documento6 pagineCheck For Punching Shear:: Pile Cap Design (PC3a)Sheikh Mizanur RahmanNessuna valutazione finora

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part2-Breakout Strength in TensionDocumento6 pagineConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part2-Breakout Strength in TensionVenu GopalNessuna valutazione finora

- ASD-Insert Plate CheckDocumento12 pagineASD-Insert Plate CheckJvv GudboyNessuna valutazione finora

- 00 UBZ C 51 101 001 (Rev.X0)Documento95 pagine00 UBZ C 51 101 001 (Rev.X0)Amr AbdeinNessuna valutazione finora

- Base Plate Design Metric UnitsDocumento5 pagineBase Plate Design Metric UnitsD SRINIVASNessuna valutazione finora

- Vent Stack Foundation CalDocumento11 pagineVent Stack Foundation CalBenedict OgbaghaNessuna valutazione finora

- Column Properties:-: Due To UplitDocumento2 pagineColumn Properties:-: Due To UplitRohit SinghNessuna valutazione finora

- 4 Anchor Bolts Base PlateDocumento285 pagine4 Anchor Bolts Base Platetitir bagchiNessuna valutazione finora

- Stability Analysis - Direct Analysis Method - Staad Pro AISC 360Documento4 pagineStability Analysis - Direct Analysis Method - Staad Pro AISC 360chidsalazarNessuna valutazione finora

- Base Plate p1Documento128 pagineBase Plate p1Pranav PrabhakarNessuna valutazione finora

- Ring Wall FoundationDocumento6 pagineRing Wall Foundationraghav abudhabiNessuna valutazione finora

- ACI Deflection MOD MotiurDocumento5 pagineACI Deflection MOD Motiurbasum matNessuna valutazione finora

- Lecture Machine FoundationDocumento10 pagineLecture Machine FoundationvijaystructuralNessuna valutazione finora

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part7-Pryout Strength in ShearDocumento4 pagineConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part7-Pryout Strength in ShearVenu GopalNessuna valutazione finora

- Compressor Shelter: Velocity of PressureDocumento3 pagineCompressor Shelter: Velocity of PressurerohitnrgNessuna valutazione finora

- Pinned Base Design Calculation: (Aisc 360-05 - LRFD Design Method) GeometryDocumento4 paginePinned Base Design Calculation: (Aisc 360-05 - LRFD Design Method) GeometryTuanQuachNessuna valutazione finora

- ACI BendDocumento3 pagineACI Bendمصطفى عبدالرحيمNessuna valutazione finora

- Breeder House FoundationDocumento16 pagineBreeder House FoundationRobbyTeresaNessuna valutazione finora

- Tank Foundation RingwallDocumento10 pagineTank Foundation RingwallabguyNessuna valutazione finora

- Isolated Footing DesignDocumento15 pagineIsolated Footing DesignAzzirrenNessuna valutazione finora

- Structural Design - General Provisions and Load CombinationsDocumento18 pagineStructural Design - General Provisions and Load CombinationssaravanaNessuna valutazione finora

- AG Base Plate With Moment Axial CompressionDocumento4 pagineAG Base Plate With Moment Axial Compressionsivaguruswamy thangarajNessuna valutazione finora

- ReportTank 12.0m DiaDocumento17 pagineReportTank 12.0m DiasuheilbugsNessuna valutazione finora

- Isolated Footing Design For Pipe Supports/Sliding Supports (SS) Serial NoDocumento11 pagineIsolated Footing Design For Pipe Supports/Sliding Supports (SS) Serial NoNazeer NNessuna valutazione finora

- Ast For MomentDocumento1 paginaAst For MomenteramitdhanukaNessuna valutazione finora

- E.Naldoza Design of Singly Reinforced Rectangular Section-ACI-318M-14 (NSCP 2015) - v2.1.1Documento2 pagineE.Naldoza Design of Singly Reinforced Rectangular Section-ACI-318M-14 (NSCP 2015) - v2.1.1Johny Mark AsuncionNessuna valutazione finora

- Vertical Vessel Foundation Design GuideDocumento52 pagineVertical Vessel Foundation Design GuideIsrael AGNessuna valutazione finora

- Design Criteria: Seismic Design For Buckling-Restrained Braced Frames Based On AISC 360-10/16 & AISC 341-10/16Documento6 pagineDesign Criteria: Seismic Design For Buckling-Restrained Braced Frames Based On AISC 360-10/16 & AISC 341-10/16Ridho ZiskaNessuna valutazione finora

- Pinned Base Plate - 03SF01Documento15 paginePinned Base Plate - 03SF01vivekNessuna valutazione finora

- Steeltek ConnectionDocumento5 pagineSteeltek ConnectioncadsultanNessuna valutazione finora

- WIND LOADING ANALYSIS - Roof Components and CladdingDocumento3 pagineWIND LOADING ANALYSIS - Roof Components and CladdingdantevariasNessuna valutazione finora

- 1 Input Data: Profis Anchor 2.7.3Documento7 pagine1 Input Data: Profis Anchor 2.7.3RamadanNessuna valutazione finora

- Insert Plate DesignDocumento8 pagineInsert Plate DesignPiyushNessuna valutazione finora

- (WWW - Indowebster.com) - Microsoft Word - TUGAS AKHIR LIFTINGDocumento36 pagine(WWW - Indowebster.com) - Microsoft Word - TUGAS AKHIR LIFTINGsholehamikNessuna valutazione finora

- Seismic Load Calculation 3.5: Page 15 of 152Documento3 pagineSeismic Load Calculation 3.5: Page 15 of 152phanikrishnabNessuna valutazione finora

- Larsen & Toubro Ltd. Rev Ltem Structural Design Calculations of Radiant SectionDocumento24 pagineLarsen & Toubro Ltd. Rev Ltem Structural Design Calculations of Radiant SectionAkshay Patil100% (1)

- Wind Load DesignDocumento1 paginaWind Load Designkumsbams0% (1)

- Design of Block Foundation For Low Frequency ReciprocatingDocumento13 pagineDesign of Block Foundation For Low Frequency ReciprocatingHemant SonawadekarNessuna valutazione finora

- Moment Connection: Supporting Column UC254X254X89 Supported Beam UC203X203X71Documento3 pagineMoment Connection: Supporting Column UC254X254X89 Supported Beam UC203X203X71massive85Nessuna valutazione finora

- BASEDocumento10 pagineBASESrikanth SikhaNessuna valutazione finora

- Hunch Splice-10bolts-2 Row PatternDocumento5 pagineHunch Splice-10bolts-2 Row PatternSrikanth SikhaNessuna valutazione finora

- Learn Abaquss Script in One HourDocumento12 pagineLearn Abaquss Script in One HourbaspopNessuna valutazione finora

- 36 PSV 8003 Thermal ExpansionDocumento4 pagine36 PSV 8003 Thermal Expansionwinlugue3059Nessuna valutazione finora

- 36 PSV 8001 Thermal ExpansionDocumento4 pagine36 PSV 8001 Thermal Expansionwinlugue3059Nessuna valutazione finora

- 36 PSV 8002 Thermal ExpansionDocumento3 pagine36 PSV 8002 Thermal Expansionwinlugue3059Nessuna valutazione finora

- Integrated Finite Elements Analysis and Design of StructuresDocumento50 pagineIntegrated Finite Elements Analysis and Design of Structuresaeiou321Nessuna valutazione finora

- Residential Construction: 14.1 General RemarksDocumento3 pagineResidential Construction: 14.1 General RemarksDiego RojasNessuna valutazione finora

- AISC LRFD Column DesignDocumento4 pagineAISC LRFD Column Designwinlugue3059Nessuna valutazione finora

- Israel Blast Design PDFDocumento0 pagineIsrael Blast Design PDFMike Karl BenzNessuna valutazione finora

- 11 - Introduction Retaining Walls-1Documento23 pagine11 - Introduction Retaining Walls-1Nomade Voyageur100% (2)

- Mechanics of Pile Cap and Pile GroupDocumento69 pagineMechanics of Pile Cap and Pile Grouppk100% (1)

- Basis For Tubular Joint DesignDocumento11 pagineBasis For Tubular Joint Designwinlugue3059Nessuna valutazione finora

- Steel TanksDocumento75 pagineSteel TanksAnonymous b3NKZUbNessuna valutazione finora

- Slab Thickness Design For Industrial Concrete Floors On GradeDocumento16 pagineSlab Thickness Design For Industrial Concrete Floors On GradeHung Nguyenthe88% (8)

- Trig Cheat SheetDocumento2 pagineTrig Cheat SheetDino97% (77)

- BS3974Documento20 pagineBS3974winlugue3059Nessuna valutazione finora

- Welded ConnectionsDocumento26 pagineWelded Connectionswinlugue3059Nessuna valutazione finora

- Computer Analysis & Reinforced Concrete Design of BeamsDocumento129 pagineComputer Analysis & Reinforced Concrete Design of BeamsMANDARAW100% (1)

- D1 9manciniDocumento80 pagineD1 9manciniIgnatius PathulaNessuna valutazione finora

- Chapter 9 - Force and Laws of Motion Revision Notes PDFDocumento13 pagineChapter 9 - Force and Laws of Motion Revision Notes PDFAbhishekNessuna valutazione finora

- ch25 PDFDocumento11 paginech25 PDFTomNessuna valutazione finora

- General Approach To Wave Guide AnalysisDocumento8 pagineGeneral Approach To Wave Guide AnalysisMukesh Kumar MeenaNessuna valutazione finora

- Netting Drag CoeDocumento6 pagineNetting Drag CoeAndyNessuna valutazione finora

- Assignment2014 3Documento2 pagineAssignment2014 3gokuler137Nessuna valutazione finora

- AP Physics 1 Week 16 MC Review AnswersDocumento11 pagineAP Physics 1 Week 16 MC Review AnswersAnonymous 2vwEXJNessuna valutazione finora

- Steel DesignDocumento180 pagineSteel DesignAndrick Alvarez100% (2)

- 2022 - Pete 350 - Part B - 2Documento35 pagine2022 - Pete 350 - Part B - 2Alexander AntwiNessuna valutazione finora

- Ch10 صور 5 8waste WaterDocumento4 pagineCh10 صور 5 8waste WaterAljebre MohmedNessuna valutazione finora

- Revision Worksheet 1 Force and PressureDocumento6 pagineRevision Worksheet 1 Force and PressureDhruvi SinghNessuna valutazione finora

- Steve's Handy Guide To Orbits: by Steven M. Schultheis, P.E. Houston, Texas U.S.ADocumento25 pagineSteve's Handy Guide To Orbits: by Steven M. Schultheis, P.E. Houston, Texas U.S.ASonu MishraNessuna valutazione finora

- Module 28 Solution Brittle Coulomb Mohr TheoryDocumento2 pagineModule 28 Solution Brittle Coulomb Mohr TheoryWolf LordNessuna valutazione finora

- Programs Hp35sDocumento16 paginePrograms Hp35sRodolfo Sergio Cruz FuentesNessuna valutazione finora

- Ee Electrical Measurements InstrumentatiDocumento93 pagineEe Electrical Measurements InstrumentatiSiva GowthamNessuna valutazione finora

- Edexcel Mechanical Principles H2 Unit 5 - NQF Level 4 Outcome 4 - Power Transmission Tutorial 2 - BalancingDocumento14 pagineEdexcel Mechanical Principles H2 Unit 5 - NQF Level 4 Outcome 4 - Power Transmission Tutorial 2 - BalancingSam AnuNessuna valutazione finora

- Thermodynamic Calculations For Propene HydrogenationDocumento3 pagineThermodynamic Calculations For Propene HydrogenationSukaran SinghNessuna valutazione finora

- CH 03 HWDocumento36 pagineCH 03 HWClayton KwokNessuna valutazione finora

- Mechanics SolDocumento2 pagineMechanics SolAldrin M. Villanueva Jr.Nessuna valutazione finora

- Fulltext PDFDocumento17 pagineFulltext PDFEl Youbi MohammedNessuna valutazione finora

- Waves: Srichaitanya Educational Institutions - Nagole - CoDocumento20 pagineWaves: Srichaitanya Educational Institutions - Nagole - CoGopal PenjarlaNessuna valutazione finora

- 1 Semester, 2013/2014Documento2 pagine1 Semester, 2013/2014pseudobbNessuna valutazione finora

- NSK TrustDocumento138 pagineNSK TrustoktovaNessuna valutazione finora

- Solution: Chapter 5, Practice Problem 5/039Documento13 pagineSolution: Chapter 5, Practice Problem 5/039陳台Nessuna valutazione finora

- AMEE202 Lab - Venturi MeterDocumento5 pagineAMEE202 Lab - Venturi Meterengineer63Nessuna valutazione finora

- Spin - Field GeneratorDocumento10 pagineSpin - Field GeneratorMelanie MartinssonNessuna valutazione finora

- Chapter 3 - Motion in A Straight Line WORKSHEETDocumento3 pagineChapter 3 - Motion in A Straight Line WORKSHEETHrishith SavirNessuna valutazione finora

- EOCQ - Ans - 17 2Documento1 paginaEOCQ - Ans - 17 2Куаныш ЖанадилNessuna valutazione finora

- 546 - PHE-02 - ENG D18 - Compressed PDFDocumento4 pagine546 - PHE-02 - ENG D18 - Compressed PDFDominator GamingNessuna valutazione finora

- Strength, Elasticity and Toughness of Wood: InformationDocumento2 pagineStrength, Elasticity and Toughness of Wood: InformationHernan Felipe Rodriguez AndaurNessuna valutazione finora