Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Microsoft Word - Why Study Flexible Manufacturing System

Caricato da

murty99Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Microsoft Word - Why Study Flexible Manufacturing System

Caricato da

murty99Copyright:

Formati disponibili

Why Study Flexible Manufacturing System

Reason 1:Flexible manufacturing systems are regarded as one of the most efficient

methods to employ in reducing or eliminating problems in manufacturing

industries.

Reason 2:FMS originated in London, England, in the 1960s when David Williamson

came up with a flexible machining system call System 24 to operate

unmanned 24 hours a day under computer control. Broader applications

developed and continue to be developed in the areas of injection molding,

metal forming andf abr ic

ating,anda s

sembl y;the y’rebybr oade ni

ngt he

name to flexible manufacturing systems.

Reason 3:De f

initionsofFMSva ryde pendingoni ndus t

ryt ypea ndt heus e

r ’

spointof

view.

Reason 4:Many FMS principles and practices apply regardless of industry type,

business objectives, or line of product.

Reason 5:FMS brings flexibility and responsiveness to the manufacturing floor.

Reason 6:Since the 1970s there has been explosive growth in system controls and

operational enhancements, which have allowed FMS to grow, develop,

and gain wider acceptance.

Reason 7:FMS enables manufacturing to machine a wide variety of workpieces on

few machines with low staffing levels, productively, reliably, and

predictably.

Reason 8:FMS is made up of hardware elements (machine tools, movable pallets,

material- handling equipment, coordinate measuring machines, computer

hardware equipment, and the like) and software elements (NC programs,

inspection programs, work-order files, and FMS software).

Reason 9:A true FMS can handle a wide variety of different parts, producing them

one at a time in random order.

Reason 10:FMS is not an end in itself, but a means to an end and the natural partner

to integrate to existing CAD/CAM systems and progress toward CIM.

Reason 11:Machine tools in many manufacturing industries are woefully

underutilized due to equipment not being used on second and third shifts,

and decreasing availability of skilled personnel, and day to day

disturbances.

Reason 12:FMS shortens the manufacturing process through improved operational

control, round-the-clock availability of automated equipment, increased

machine utilization and responsiveness, and reduction of human

intervention.

Potrebbero piacerti anche

- CIM – Mechanical Aspects: State of the Art ReportDa EverandCIM – Mechanical Aspects: State of the Art ReportGareth EvansNessuna valutazione finora

- Flexible Manufacturing: Reference For BusinessDocumento5 pagineFlexible Manufacturing: Reference For BusinessSREYA HAZRANessuna valutazione finora

- The FMS: Md. WasifDocumento15 pagineThe FMS: Md. WasifKumar ShankarNessuna valutazione finora

- Management Information Systems: ITEC-3119Documento12 pagineManagement Information Systems: ITEC-3119Shahid IqbalNessuna valutazione finora

- CH 1 - Introduction To FMS-MNFGDocumento47 pagineCH 1 - Introduction To FMS-MNFGAshenafi DressNessuna valutazione finora

- FMS & CimsDocumento9 pagineFMS & Cimsmanjeet_virkNessuna valutazione finora

- Flexible ManufacturingDocumento18 pagineFlexible ManufacturingharshNessuna valutazione finora

- Flexible Manufacturing SystemDocumento11 pagineFlexible Manufacturing SystemSapari VelNessuna valutazione finora

- Project On Automatedprocesses-Fms: Flexible Manufacturing SystemDocumento12 pagineProject On Automatedprocesses-Fms: Flexible Manufacturing SystemMOHD.ARISHNessuna valutazione finora

- Material Unit - 3Documento60 pagineMaterial Unit - 3gnanamanola sNessuna valutazione finora

- Acknowledgement: Mrs - Maneet Kaur, LimDocumento21 pagineAcknowledgement: Mrs - Maneet Kaur, LimKhalid ShahNessuna valutazione finora

- Performance Analysis of A Flexible Manufacturing SDocumento6 paginePerformance Analysis of A Flexible Manufacturing SAbhijeet desavaleNessuna valutazione finora

- Flexible Manufacturing System: Click To Add TextDocumento46 pagineFlexible Manufacturing System: Click To Add Textpranav sharmaNessuna valutazione finora

- Flexible Manufacturing SystemDocumento16 pagineFlexible Manufacturing SystemManish JainNessuna valutazione finora

- Flexible Manufacturing Systems (FMS)Documento4 pagineFlexible Manufacturing Systems (FMS)BHAGYESH JHANWARNessuna valutazione finora

- Flexible Manufacturing System A Modern Approach To Manufacturing TechnologyDocumento8 pagineFlexible Manufacturing System A Modern Approach To Manufacturing TechnologySid BramhankarNessuna valutazione finora

- Flexible Manufacturing SystemDocumento19 pagineFlexible Manufacturing SystemAmir FauziNessuna valutazione finora

- Experiment No. - 6Documento11 pagineExperiment No. - 6jay_v9Nessuna valutazione finora

- "Flexible Manufacturing System": Department of Mechanical EngineeringDocumento32 pagine"Flexible Manufacturing System": Department of Mechanical EngineeringGoutham ReddyNessuna valutazione finora

- Flexible: Manufacturing SystemsDocumento26 pagineFlexible: Manufacturing SystemsSarthakNessuna valutazione finora

- FLEXIBLE - MANUFACTURING SYS - PPT (Compatibility Mode)Documento25 pagineFLEXIBLE - MANUFACTURING SYS - PPT (Compatibility Mode)Ramees KpNessuna valutazione finora

- Flexible Manufacturing System (FMS)Documento19 pagineFlexible Manufacturing System (FMS)purushothamkr100% (1)

- Flexible Manufacturing FinalDocumento23 pagineFlexible Manufacturing Finalashok_abclNessuna valutazione finora

- Improvement Maintenance Processes Through CMMS System-Case StudyDocumento7 pagineImprovement Maintenance Processes Through CMMS System-Case StudyRamzul Irham RizaNessuna valutazione finora

- MFG Chapter 11Documento19 pagineMFG Chapter 11Thanakrit RUNGRUANGSATENessuna valutazione finora

- Advantages: 1.3 Basic Components of FmsDocumento4 pagineAdvantages: 1.3 Basic Components of FmsBoy LiverpoolNessuna valutazione finora

- Flexible Manufacturing SystemDocumento19 pagineFlexible Manufacturing Systemtamilselvan nNessuna valutazione finora

- Modeling and Analysis of Flexible Manufacturing System With FlexSimDocumento6 pagineModeling and Analysis of Flexible Manufacturing System With FlexSimInternational Journal of computational Engineering research (IJCER)Nessuna valutazione finora

- Adaptive Production Control System For A Flexible Manufacturing Cell Using Support Vector Machine-Based ApproachDocumento13 pagineAdaptive Production Control System For A Flexible Manufacturing Cell Using Support Vector Machine-Based ApproachMd AkhtarNessuna valutazione finora

- Ubiquitous ManufacturingDocumento7 pagineUbiquitous ManufacturingSeveriano CarvalhoNessuna valutazione finora

- Lecture Notes On Flexible Manufacturing System (ETMT-428)Documento40 pagineLecture Notes On Flexible Manufacturing System (ETMT-428)Deepak Kumar100% (1)

- Flexible Manufacturing Systems 2Documento6 pagineFlexible Manufacturing Systems 2examen7071Nessuna valutazione finora

- Physical FacilitiesDocumento18 paginePhysical FacilitiesChristine Apolo100% (2)

- Introduction To RCM by L.cherifDocumento37 pagineIntroduction To RCM by L.cherifKhalid Mahmood100% (1)

- Reconfigurable Tooling For Airframe AssemblyDocumento21 pagineReconfigurable Tooling For Airframe AssemblyDennis Padec BwochengoNessuna valutazione finora

- Process Selection and Facility LayoutDocumento43 pagineProcess Selection and Facility LayoutLEIGHANNE ZYRIL SANTOSNessuna valutazione finora

- FMS Ans Key PDFDocumento7 pagineFMS Ans Key PDFPrakash MNessuna valutazione finora

- Flexible Manufacturing SystemDocumento16 pagineFlexible Manufacturing Systemm_er100Nessuna valutazione finora

- Om (TRM Papr)Documento6 pagineOm (TRM Papr)pallav_rish07Nessuna valutazione finora

- Unit VDocumento30 pagineUnit VSai Syam RallabhandiNessuna valutazione finora

- Flexible Manufacturing SystemsDocumento12 pagineFlexible Manufacturing Systemssanketsavaliya7605Nessuna valutazione finora

- Unit 6 Flexible Manufacturing SystemDocumento60 pagineUnit 6 Flexible Manufacturing SystemKajal MishraNessuna valutazione finora

- EMM 508 Flexible Manufacturing SystemDocumento60 pagineEMM 508 Flexible Manufacturing SystemKEVIN MUTURINessuna valutazione finora

- Chapter 4 Flexible - Manufacturing - SystemsDocumento24 pagineChapter 4 Flexible - Manufacturing - SystemsDeltaKill 112Nessuna valutazione finora

- Ready in 2003Documento7 pagineReady in 2003vaibhav dhandeNessuna valutazione finora

- Flexible Manufacturing System and Industrial AutomationDocumento32 pagineFlexible Manufacturing System and Industrial AutomationBizuayehu TadesseNessuna valutazione finora

- CCA NOTES Module 3 and 4Documento66 pagineCCA NOTES Module 3 and 4shiv sharmaNessuna valutazione finora

- Applsci 12 10617 v3Documento29 pagineApplsci 12 10617 v3Ariel CespedNessuna valutazione finora

- Flexible Manufacturing SystemsDocumento40 pagineFlexible Manufacturing SystemsHanoz Patel100% (1)

- Group Technology in Design of Manufacturing Systems-A ReviewDocumento6 pagineGroup Technology in Design of Manufacturing Systems-A ReviewMarwanNessuna valutazione finora

- Business Driven Information Systems 4th Edition Paige Baltzan Test Bank DownloadDocumento156 pagineBusiness Driven Information Systems 4th Edition Paige Baltzan Test Bank DownloadDawna Miles100% (19)

- Flexible Manufacturing Systems: Saurabh Avinash DeshmukhDocumento16 pagineFlexible Manufacturing Systems: Saurabh Avinash DeshmukhSaurabh DeshmukhNessuna valutazione finora

- A Digital Twin-Based Flexible Cellular Manufacturing For Optimization of Air Conditioner LineDocumento14 pagineA Digital Twin-Based Flexible Cellular Manufacturing For Optimization of Air Conditioner Line孫ウィーユNessuna valutazione finora

- Flexible Manufacturing SystemsDocumento38 pagineFlexible Manufacturing SystemsUsman AliNessuna valutazione finora

- Cim PDFDocumento32 pagineCim PDFVarshaNessuna valutazione finora

- Accounting Information System Issues of FMS: Ram S. SriramDocumento6 pagineAccounting Information System Issues of FMS: Ram S. SriramNor Masidayu Binti Mat ZinNessuna valutazione finora

- An RFID-Enabled Distributed Control and Monitoring System For A Manufacturing SystemDocumento6 pagineAn RFID-Enabled Distributed Control and Monitoring System For A Manufacturing SystemPriyatham GangapatnamNessuna valutazione finora

- Golandaz Nazim HasanDocumento15 pagineGolandaz Nazim HasanArshad KhanNessuna valutazione finora

- CH 1 CIM IntroductionDocumento53 pagineCH 1 CIM IntroductionElias GebrekirosNessuna valutazione finora

- Digital DocumentDocumento11 pagineDigital Documentmurty99Nessuna valutazione finora

- Mathes 8Documento64 pagineMathes 8murty99100% (1)

- Set Up Navigation Between Your Web PagesDocumento5 pagineSet Up Navigation Between Your Web Pagesmurty99Nessuna valutazione finora

- XI Math Sets FormulaeDocumento3 pagineXI Math Sets Formulaemurty99Nessuna valutazione finora

- Page View UiDocumento12 paginePage View Uimurty99Nessuna valutazione finora

- Quantitative Aptitude Shortcuts-Gr8AmbitionZDocumento3 pagineQuantitative Aptitude Shortcuts-Gr8AmbitionZDesperado Manogaran MNessuna valutazione finora

- Math FormulaDocumento34 pagineMath FormulaJames HoNessuna valutazione finora

- A Geometric Example:: Number of SidesDocumento246 pagineA Geometric Example:: Number of Sidesmurty99Nessuna valutazione finora

- 871 BookDocumento4 pagine871 Bookmurty99Nessuna valutazione finora

- Ch10-Motion Study PDFDocumento7 pagineCh10-Motion Study PDFmurty99Nessuna valutazione finora

- Calcium Channel PDFDocumento10 pagineCalcium Channel PDFmurty99Nessuna valutazione finora

- SurdsDocumento3 pagineSurdsmurty99Nessuna valutazione finora

- Tara Balam - Table: Nakshatra On The Day of MuhurthaDocumento1 paginaTara Balam - Table: Nakshatra On The Day of Muhurthamurty99Nessuna valutazione finora

- BBD Ccbs FullDocumento20 pagineBBD Ccbs FullWallnut StreetNessuna valutazione finora

- Novopen 4Documento15 pagineNovopen 4murty99Nessuna valutazione finora

- Buisness StudiesDocumento32 pagineBuisness Studiesmurty99Nessuna valutazione finora

- Ayurveda IntroductionDocumento5 pagineAyurveda IntroductionsrbmentalNessuna valutazione finora

- Tiru MalaDocumento1 paginaTiru Malamurty99Nessuna valutazione finora

- Ch02 Manual Work 2Documento7 pagineCh02 Manual Work 2murty99Nessuna valutazione finora

- Calcium Full Report PDFDocumento20 pagineCalcium Full Report PDFmurty99Nessuna valutazione finora

- Numerology and MarriagesDocumento6 pagineNumerology and Marriagesmurty99100% (5)

- Inter 1b SyllabusDocumento3 pagineInter 1b SyllabusSriram_VNessuna valutazione finora

- Calcium ChannelDocumento10 pagineCalcium Channelmurty99Nessuna valutazione finora

- Great Hack LanDocumento65 pagineGreat Hack Lanmurty99Nessuna valutazione finora

- Gmcks Arhatic Yoga Senior Retreat A.P - 2014: (No Installments Please)Documento1 paginaGmcks Arhatic Yoga Senior Retreat A.P - 2014: (No Installments Please)Srinivaasa MurtyNessuna valutazione finora

- Chronic DiseasesDocumento156 pagineChronic DiseasesSchmetterling123Nessuna valutazione finora

- C Shock Press KitDocumento10 pagineC Shock Press KitSusan LiNessuna valutazione finora

- Grade 8 Science Unit 1 Force, Motion and EnergyDocumento68 pagineGrade 8 Science Unit 1 Force, Motion and EnergyKeil Morada73% (26)

- Demo On Tableau DesktopDocumento46 pagineDemo On Tableau DesktopDeepak GuptaNessuna valutazione finora

- Bit DefenderDocumento130 pagineBit Defendermarius_brkt6284Nessuna valutazione finora

- Analytics For Sustainable BusinessDocumento6 pagineAnalytics For Sustainable BusinessDeloitte AnalyticsNessuna valutazione finora

- Tesla Case PDFDocumento108 pagineTesla Case PDFJeremiah Peter100% (1)

- P 1075 Basic E 03 - 08Documento2 pagineP 1075 Basic E 03 - 08Marco Andres Saldias SagredoNessuna valutazione finora

- ProceedingDocumento7 pagineProceedingnoor hafizzatul izzahNessuna valutazione finora

- Online Indian Astrology, Indian Vedic Astrology, Future Predictions, Horoscopes, Astrological Remedies, Astrological Solutions 271015Documento5 pagineOnline Indian Astrology, Indian Vedic Astrology, Future Predictions, Horoscopes, Astrological Remedies, Astrological Solutions 271015jaithilagarajNessuna valutazione finora

- Print Drawings To PDFDocumento10 paginePrint Drawings To PDFhuyxpkissNessuna valutazione finora

- IB Source CatalogDocumento145 pagineIB Source Catalogeibsource100% (2)

- Preparation of Instructional MaterialsDocumento28 paginePreparation of Instructional MaterialsMara Quila-Verzo86% (7)

- Linguistic VariablesDocumento2 pagineLinguistic VariablesShankhyaneel SarkarNessuna valutazione finora

- 8086 Microprocessor Interfacing MCQ SDocumento4 pagine8086 Microprocessor Interfacing MCQ SDeepak Ahlawat67% (3)

- Cs 1410Documento2 pagineCs 1410David DengNessuna valutazione finora

- SynopsisDocumento25 pagineSynopsisKartik KhannaNessuna valutazione finora

- Module 4 - Instruction Set Architecture (ISA) v2 (Student) PDFDocumento49 pagineModule 4 - Instruction Set Architecture (ISA) v2 (Student) PDFnedunilavanNessuna valutazione finora

- Forced Convection Over A Flat Plate by Finite Difference MethodDocumento5 pagineForced Convection Over A Flat Plate by Finite Difference MethodNihanth WagmiNessuna valutazione finora

- How To Improve Your MemoryDocumento2 pagineHow To Improve Your MemoryAlejandro GalvisNessuna valutazione finora

- BOC Develop A Strategic Communication Plan of The Transformation Roadmap Phase 2Documento25 pagineBOC Develop A Strategic Communication Plan of The Transformation Roadmap Phase 2Mario FranciscoNessuna valutazione finora

- Ecdsa PDFDocumento56 pagineEcdsa PDFMarcos CariNessuna valutazione finora

- Humanities Social Sciences DistinctionsDocumento3 pagineHumanities Social Sciences DistinctionsDavid0% (1)

- Offshore Engineering Tension Leg Platform Part 1/2Documento4 pagineOffshore Engineering Tension Leg Platform Part 1/2Yeho ShuaNessuna valutazione finora

- DC LAB Report#11Documento8 pagineDC LAB Report#11rajasafeelNessuna valutazione finora

- Fatigue Assessment Analysis of Offshore Structures With Application To An Existing Platform in Suez Gulf, EgyptDocumento21 pagineFatigue Assessment Analysis of Offshore Structures With Application To An Existing Platform in Suez Gulf, EgyptthuanNessuna valutazione finora

- Substation DiaryDocumento50 pagineSubstation Diaryrajat123sharmaNessuna valutazione finora

- Oracle OTL Timecard Layout CustomicationDocumento138 pagineOracle OTL Timecard Layout CustomicationFoolIshNessuna valutazione finora

- Subaltern Voice in The Novel of Anita Nair's Lessons in Forgetting: A Female PerspectiveDocumento2 pagineSubaltern Voice in The Novel of Anita Nair's Lessons in Forgetting: A Female PerspectiveIJELS Research JournalNessuna valutazione finora

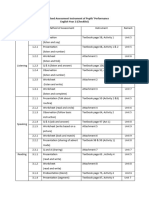

- Penyelarasan Instrumen Pentaksiran PBD Tahun 2 2024Documento2 paginePenyelarasan Instrumen Pentaksiran PBD Tahun 2 2024Hui YingNessuna valutazione finora

- An Inspector Calls Character Notes Key Quotations Key Language & Structural Features Priestley's IdeasDocumento8 pagineAn Inspector Calls Character Notes Key Quotations Key Language & Structural Features Priestley's IdeasPNessuna valutazione finora