Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

1) Pier-P3

Caricato da

Venkat PalliTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

1) Pier-P3

Caricato da

Venkat PalliCopyright:

Formati disponibili

DESIGN OF PIER (P3) WITH PILE

FOUNDATION

FOR ROB AT CH. 6+472.6

INDEX

Sr. No. Items Page No.

1 Input Data 1-9

2 Seismic Coeff. Calculation 10-11

3 Horizontal Force Calculation at Bearing Level

ULS Method 12-15

Foundation Design 16-18

Stability Check 19-20

SLS Method 21-23

Centrifugal and other Forces 24-25

4 Wind Calculation 26-27

5 Stability of Foundation 28-39

6 Design of Foundation 40-51

7 Pile Cap design 52-60

8 Pier Shaft Design 61-69

9 Pier Cap Design 70-84

10 ANNEXURE-I : CWLL 85-87

11 ANNEXURE-II :ULS Check for Pile 88-91

12 ANNEXURE-III :ULS and SLS Check for Pier Shaft 92-98

13 Annexure-IV : Design of Seismic Stopper 99-104

Design Calculation ICT Input Data

Detailed Design of Substructure & Pile Foundation

Span Arrangement Left Span Right Span

c/c distance between Bearing - Left Span = 36.000 m c/c distance between Bearing -Right Span = 38.000 m

projection beyond CL of brg.-Left support = 0.725 m projection beyond CL of brg.-Left support = 0.975 m

projection beyond CL of brg.-Right support = 0.725 m projection beyond CL of brg.-Right support = 0.975 m

Total Length of Left Span = 37.450 m Total Length of Right Span = 39.950 m

Expansion Gap = 50.000 mm Expansion Gap = 50.000 mm

c/c distance between Expansion Gap - Left Span = 37.50 m c/c distance bet. Expansion Gap - Right Span = 40.00 m

Congestion Factor = 1.300 Congestion Factor = 1.300

Type of Superstructure = Steel plate Girder Type of Superstructure = Precast PSC Girder

Radius of Curvature = 0.000 m

Angle of Skew = 0 Degrees

Cos 0 = 1.000 Sin 0 = 0.000 tan 0 = 0.000

Calculation of Impact Factor AS per IRC 6:2014,Clause 208.2

Impact Factor - 70 RW = 1.182 Superstructure Impact Factor - 70 RW = 1.102 Superstructure

Impact Factor -Class A {1+9/(13.5+L)} = 1.182 Superstructure Impact Factor -Class A {1+4.5/(6+L)} = 1.102 Superstructure

Impact Factor - 70 RW = 1.182 Bearing Impact Factor - 70 RW = 1.102 Bearing

Impact Factor -Class A = 1.182 Bearing Impact Factor -Class A = 1.102 Bearing

Impact Factor - 70 RW = 1.091 Pier Cap Impact Factor - 70 RW = 1.051 Pier Cap

Impact Factor -Class A = 1.091 Pier Cap Impact Factor -Class A = 1.051 Pier Cap

Bearings

Type of Bearing = Elastomeric & Pin Bearing Type of Bearing = Elastomeric & Pin Bearing

No of Bearings/Pedestral = 5 excluding pin brgNo of Bearings/Pedestral = 4 excluding metallic guided brg

C/C Distance of Bearing in Transverse Direction= 2.500m (Skew) C/C Distance of Bearing in Transverse Direction

= 3.000m (Skew)

Details of Superstructures and Salient Reduced Levels's (RL's)

LEFT SIDE SPAN RIGHT SIDE SPAN

Deck level at Median edge = 277.300 m Deck level at Median Edge = 277.300 m

Deck level at outer edge = 277.070 m Deck level at outer edge = 277.070 m

Deck level at center line of bridge = 277.185 m Deck level at center line of bridge = 277.185 m

Soffit Level = 275.295 m Soffit Level = 274.406 m

Pier Cap Top Level = 274.895 m Pier Cap Top Level = 274.016 m

Bearing Level = 275.295 m Bearing Level = 274.376 m

C/C of span = 36.000 m C/C of span = 38.000 m

Max Depth of Superstructure = 1.831 m Max Depth of Superstructure = 2.720 m

NH-72A and NH-73 1 PIER-P3

Design Calculation ICT Input Data

Depth of Bearing+Pedestal 1 = 0.300 m Bearing Plate = 0.00 m

Depth of Bearing+Pedestal 2 = 0.350 m Depth of Bearing+Pedestal 1 = 0.300 m

Depth of Bearing+Pedestal 3 = 0.400 m Depth of Bearing+Pedestal 2 = 0.360 m

Depth of Bearing+Pedestal 4 = 0.450 m Depth of Bearing+Pedestal 3 = 0.420 m

Depth of Bearing+Pedestal 5 = 0.500 m Depth of Bearing+Pedestal 4 = 0.480 m

Depth of Bearing+Pedestal 6 = 0.000 m Depth of Bearing+Pedestal 5 = 0.000 m

Depth of Bearing+Pedestal 7 = 0.000 m Depth of Bearing+Pedestal 6 = 0.000 m

Distance of nearest girder from c.l. of bridge = 0.000 m Depth of Bearing+Pedestal 7 = 0.000 m

Depth of Bow string arch = 0.000 m Distance of nearest girder from c.l. of bridge = 1.500 m

Depth of Bow string arch = 0.000 m

Common For Both Span

Pier Cap Bottom Level = 272.216 m Thickness of Wearing Coat = 0.050 m

Pier Shaft Top Level = 272.216 m Camber slope = 2.00 %

Pier Shaft Bottom Level = 265.000 m Width of Carriageway = 11.5 m

GL/FL/LBL/Cross road level = 266.074 m Total Width of Superstructure = 12.5 m

Pile Cap Top Level = 265.000 m Nos. of Lane for design purpose = 3 LANE

Pile Cap Bottom Level = 262.700 m Dia of Pile = 1.20 m

Pile Tip Level = 236.700 m Depth of Pile Cap = 2.30 m

Cross road level = 0.000 m Length of Pile = 26.00 m

Rock level = 0.000 m Nos of Pile in Longitudinal Side in one row = = 2 Nos

Nos of Pile in Transverse Side in one row = 4 Nos m/s

Wedge over girder = 0.018 m

Cross girder depth below centre girder 0.000 m

C.G OF CRASH Barrier From Deck Top = 0.447 m C.G OF CRASH Barrier From Deck Top = 0.447 m

C.G OF Wearing Cousrse from Deck Top = 0.025 m

Dimensions of Substructure & Foundation

(i) Pier Cap

Along L-L Axis Along T-T Axis

Width of Uniform Portion = 3.750 m Right Length of Uniform Portion = 12.500 m Right

Width of Uniform Portion = 3.750 m Skew Length of Uniform Portion = 12.500 m Skew

Width of Cap at Bottom = 3.750 m Right Length of Varrying Portion at bottom = 2.200 m Skew

Height of Uniform depth = 0.900 m

Height of triangular portion = 0.900 m

SPAN-LEFT SPAN-Right Expansion Gap

C/C distance of Bearing along L-L = 0.725 + 0.975 + 0.050 = 1.750 m

C/C distance of Bearing along T-T = 3.000 m (Straight) 3.000m (Skew)

(ii) Pier Shaft

Width/Dia of pier shaft = 2.000 m No of Pier = 1 c/c distance between Piers = 0.000

Length/Dia. of Pier = 2.000 m

cut water portion(semi-circular) = 0.000 m 0.0000 Height of Pier shaft = 7.216 m

Length / Dia of pier = 2.000 m

NH-72A and NH-73 2 PIER-P3

Design Calculation ICT Input Data

(iii) Pile Cap

along L-L Axis along T-T Axis

Projection of Pile Cap on Left Side of Pier = 1.550 m Projection of Pile Cap on Footpath Side of Pier = 5.150 m

Projection of Pile Cap on Right Side of Pier= 1.550 m Projection of Pile Cap on Median Side of Pier= 5.150 m

Distance Between Piles Centre in Longitudinal Direction= 3.600 m Distance Between Piles Centre in Transverse Direction= 3.600 m

Projection of Pile Cap from C/L of piles in longitudinal direction= 0.750 m Projection of Pile Cap from C/L of piles in Transverse direction= 0.750 m

Length of Pile Cap in Longitudinal Direction= 5.100 m Projection of Pile Cap from C/L of piles in Transverse direction= 0.750 m

Length of Pile Cap in Transverse Direction= 12.300 m

Design Data & Material Specification

Pile & Pile Cap

Conc Grade = M 35

Characteristic Compressive Strength of Concrete,fck = 35.00 Mpa at 28 days

Design Compressive strength of Concrete, fcd = 15.63 Mpa at 28 days (0.67/1.5 * fck)

Tensile strength of concrete , fctm = 2.77 MPa

Strain at reaching Characteistic Strength, ec2 = 0.02

Ultimate Strain, ecu2 = 0.035

Modulus of Elasticity of Concrete ( Ec ) = 29580.40 N/mm2 ( 5000 x sqrt ( fck )

2

Ecm = 32308.250 N/mm

Steel Grade = Fe 500 D (HYSD Steel)

Yield Strength of Reinforcement, fy or fyk = 500 Mpa

Design Yield Strength of Reinforcement, fyd = 434.78 Mpa (1/1.15 * fy)

Modulus of Elasticity of Steel ( Es) = 200000.00 Mpa

Pier & Pier Cap

Conc Grade pier cap = M 40

Characteristic Compressive Strength of Concrete,fck = 40.00 Mpa at 28 days

Design Compressive strength of Concrete, fcd = 17.87 Mpa at 28 days (0.67/1.5 * fck)

Tensile strength of concrete , fctm = 3.03 MPa

Ecm = 33345.764 N/mm2

Dry weight of Concrete = 25 kN/m3

Dry unit weight of soil = 20 kN/m3

Permissible Crack Width = 0.3 mm - For Moderate Exposure Condition

Type of Soil = 2 Medium Soil Strata

NH-72A and NH-73 3 PIER-P3

Design Calculation ICT Input Data

Maximum compressive stress in concrete ( Refer Clause 12.2.1 of IRC:112-2011)

under rare combination = 16.8 N/mm2

Under Quasi-Permenant Combination = 12.6 N/mm2

Maximum tensile stress in steel = 300 N/mm2

Clear Cover to Reinforcement

Cover for pier shaft = 50 mm

Cover for pile cap and pile shaft = 75 mm

Seismic Data:

Seismic Zone = 4

Z =Zone factor = 0.24

I =Importance factor = 1.2 for important bridges

R =Response Reduction factor = 3 in Longitudinal direction For substructure except pier cap

= 3 In Transverse direction For substructure except pier cap

= 3 For Pier Cap/Beam

Vertical load capacity of pile (Normal Case) = 4513 KN From Geotechnical Report

Vertical load capacity of pile (Wind Case) = 5641 KN From Geotechnical Report multiplied by 25%

Vertical load capacity of pile ( Seismic Case) = 5641 KN From Geotechnical Report multiplied by 25%

Horizontal load capacity of pile (Normal Case) = 130.8 KN From Geotechnical Report

NH-72A and NH-73 4 PIER-P3

Design Calculation ICT DL+SIDL+LL

CALCULATION OF DEAD LOAD , SIDL , CWLL

( Note: 5% increase in DL,SIDL,Wearing course due to varies overhange)

Dead Load Reaction from Superstructure Analysis

Trans. Trans.

Ecce. (m) Ecce. (m)

LHS skew RHS skew

DL reaction on Bearing1 = 433.59 kN 5.000 DL reaction on Bearing1 1262.97

kN

= 4.500

DL reaction on Bearing2 = 433.59 kN 2.500 DL reaction on Bearing2 1312.36

kN

= 1.500

DL reaction on Bearing3 = 433.59 kN 0.000 DL reaction on Bearing3 1312.36

kN

= -1.500

DL reaction on Bearing4 = 433.59 kN -2.500 DL reaction on Bearing4 1262.97

kN

= -4.500

DL reaction on Bearing5 = 433.59 kN -5.000 DL reaction on Bearing5 0.00 kN

= 0.000

DL reaction on Bearing6 = 0.00 kN 0.000 DL reaction on Bearing4 0.00 kN

= 0.000

DL reaction on Bearing7 = 0.00 kN 0.000 DL reaction on Bearing5 0.00 kN

= 0.000

Total DL Reaction = 2167.969 kN 0.000 Total DL Reaction 5150.654 kN

= 0.000

SIDL Reaction from Superstructure Analysis (without Wearing Course )

Trans. Trans.

LHS Ecce. (m) RHS Ecce. (m)

SIDL reaction on Bearing1 = 333.731 kN 5.000 SIDL reaction on Bearing1140.000

kN= 4.500

SIDL reaction on Bearing2 = -172.725 kN 2.500 SIDL reaction on Bearing2 19.500

kN= 1.500

SIDL reaction on Bearing3 = 84.989 kN 0.000 SIDL reaction on Bearing3 19.500

kN= -1.500

SIDL reaction on Bearing4 = -172.725 kN -2.500 SIDL reaction on Bearing4140.000

kN= -4.500

SIDL reaction on Bearing5 = 333.731 kN -5.000 SIDL reaction on Bearing5 0.000

kN= 0.000

SIDL reaction on Bearing6 = 0.000 kN 0.000 SIDL reaction on Bearing4 0.000

kN= 0.000

SIDL reaction on Bearing7 = 0.000 kN 0.000 SIDL reaction on Bearing5 0.000

kN= 0.000

Total SIDL Reaction = 407.001 kN 0.000 Total SIDL Reaction 319.000 kN 0.000

Reaction due to Wearing Coat from Superstructure Analysis

Trans. Trans.

LHS Ecce. (m) RHS Ecce. (m)

WC reaction on Bearing1 = 81.400kN 5.000 WC reaction on Bearing1 126.891 kN

= 4.500

WC reaction on Bearing2 = 101.750kN 2.500 WC reaction on Bearing2 138.427 kN

= 1.500

WC reaction on Bearing3 = 101.750kN 0.000 WC reaction on Bearing3 138.427 kN

= -1.500

WC reaction on Bearing4 = 101.750kN -2.500 WC reaction on Bearing4 126.891 kN

= -4.500

WC reaction on Bearing5 = 81.400kN -5.000 WC reaction on Bearing5 0.000 kN

= 0.000

WC reaction on Bearing6 = 0.000kN 0.000 WC reaction on Bearing4 0.000 kN

= 0.000

WC reaction on Bearing7 = 0.000kN 0.000 WC reaction on Bearing5 0.000 kN

= 0.000

TOTAL REACTION ( WC ) = 468.050 kN 0.000 TOTAL REACTION ( WC 530.636

) kN

= 0.000

From Annexure-I

MAXIMUM REACTION CASE: Reduction Factor = 0.9

1-70R + 1-CLASS A

Total Reaction on LHS brg. 1185.74 kN and Corresponding Transverse moment 1792.99 kNm

Total Reaction on RHS brg. 212.86 kN and Corresponding Transverse moment 520.28 kNm

SV LOAD

Total Reaction on LHS brg. 2490.87 kN and Corresponding Transverse moment 996.35 kNm

Total Reaction on RHS brg. 2189.13 kN and Corresponding Transverse moment 875.65 kNm

MAXIMUM TRASVERSE MOMENT CASE: Reduction Factor = 1

1-70R

Total Reaction on LHS brg. 890.82 kN and Corresponding Transverse moment 2810.54 kNm

Total Reaction on RHS brg. 109.18 kN and Corresponding Transverse moment 344.46 kNm

Computation of volumes of Subsoil Components

i) Bearing Pedestal

Left Span : Trans. Ecc

Pedestal 1 = 0.300 x 0.800 x 0.800 = 0.1920 m3 5.000

3

Pedestal 2 = 0.350 x 0.800 x 0.800 = 0.2240 m 2.500

3

Pedestal 3 = 0.400 x 0.800 x 0.800 = 0.2560 m 0.000

3

Pedestal 4 = 0.450 x 0.800 x 0.800 = 0.2880 m -2.500

3

Pedestal 5 = 0.500 x 0.800 x 0.800 = 0.3200 m -5.000

4

Pedestal 6 0.000 x 0.800 x 0.800 = 0.0000 m 0.000

5

Pedestal 7 0.000 x 0.800 x 0.800 = 0.0000 m 0.000

3

1.2800 m -0.625

NH-72A and NH-73 5 PIER-P3

Design Calculation ICT DL+SIDL+LL

Right Span :

3

Pedestal 1 = 0.300 x 0.800 x 0.800 = 0.1920 m 4.500

3

Pedestal 2 = 0.360 x 0.800 x 0.800 = 0.2304 m 1.500

3

Pedestal 3 = 0.420 x 0.800 x 0.800 = 0.2688 m -1.500

3

Pedestal 4 = 0.480 x 0.800 x 0.800 = 0.3072 m -4.500

3

Pedestal 5 = 0.000 x 0.800 x 0.800 = 0.0000 m 0.000

Pedestal 6 = 0.000 x 0.800 x 0.800 = 0.0000 0.000

Pedestal 7 = 0.000 x 0.800 x 0.800 = 0.0000 0.000

3

0.9984 m -0.577

ii) Seismic Arrestor

Left Span: Nos.

3

Long. Arrestor = 0.350 x 0.850 x 0.800 0.2380 m 5

3

Transverse arrestor = 0.550 x 0.600 x 0.870 = 0.2871 m 2

Right Span:

Long. Arrestor = 0.500 x 0.650 x 0.700 = 0.2275 m3 0

Transverse Arrestor = 0.550 x 0.725 x 1.025 = 0.4087 m3 2

(iii) Pier Cap

3

Volume 1 = 12.500 x 3.750 x 0.900 = 66.994 m

+ 3.750 x ( 12.500 + 2.200 ) x 0.90

2.000

3

Volume 2 due to additional height of cap = 0.879x 1.875 x 12.500 = 20.602 m

Long. Eccentricity due to additional weight of cap = 1.875 - 0.938 = -0.938 m

(iv) Pier Shaft

3

Volume of Pier Shaft = 1.000 0.79 x 4.000 x 7.216 = 22.670 m

(v) Pile Cap

3

Volume = 5.100 x 12.300 x 2.3 = 144.279 m

(vi) Volume of Overburden Earth Over Pile Cap

3

Volume of earthfill over pile cap = ( 62.73 - 3.1 ) x 1.074 = 63.998 m

NH-72A and NH-73 6 PIER-P3

Design Calculation ICT Load Combination

Possible Load Combination

1 COMB 1: DL+SIDL-Normal Dry Case

2 COMB 2: DL+SIDL + LL(Maximum Reaction) -Normal Dry Case

NORMAL

CASE

3 COMB 3: DL+SIDL + LL(Max Transverse Moment) -Normal Dry Case

4 COMB 4 : DL+SIDL -one Span Dislodege Normal case

5 COMB 5 : COMB 2 + WL -Normal Dry Case

WIND

6 COMB 6: COMB 3 + WL -Wind Dry Case

CASE

7 COMB 7 : DL+SIDL+WL -one Span Dislodege Wind case

8 COMB 8 : COMB 1 + EQ-L -Seismic Dry Case

9 COMB 9 : COMB 1 + EQ-T -Seismic Dry Case

10 COMB 10 : COMB 2 + EQ-L -Seismic Dry Case

11 COMB 11 : COMB 2 + EQ-T -Seismic Dry Case

SEISMIC

CASE

12 COMB 12 : COMB 3 + EQ-L -Seismic Dry Case

13 COMB 13 : COMB 3 + EQ-T -Seismic Dry Case

14 COMB 14 : DL+SIDL+EQ-L -one Span Dislodege Seismic case

15 COMB 15 : DL+SIDL+EQ-T -one Span Dislodege Seismic case

NH-72A and NH-73 7 PIER-P3

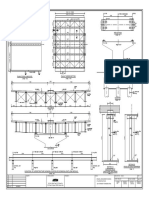

Design Calculation ICT General Elevation

FIGURE SHOWING SALIENT FEATURE OF PIER AND FOUNDATION

277.3 DECK LEVEL

WEARING COAT

SUPERSTRUCTURE SUPERSTRUCTURE

3.75

PIER CAP

PIER SHAFT

2

266.074 GROUND LEVEL

#REF! 5.1

3.6

NH-72A and NH-73 8 PIER-P3

Design Calculation ICT Load Factor

Load Factors:

Table B.2 Partial Safety Factor For Verification of Structural Strength: Ultimate Limit State

Loads Normal Case Seismic Case

Dead Laod+SIDL , Back

1.350 1.35

Fill except wearing course

SIDL ( Wearing Course

1.750 1.75

only)

CWLL ( Service ) 1.500 0.20

CWLL ( Construction) 1.350 1.00

Wind Load-accompanying 0.900 -

Seismic Effect ( during

1.50

service)

Seismic Effect ( during

0.75

construction)

Table B.3 Partial Safety Factor For Verification of Servicibilty Limit State

Quasi-

Loads Rare Case Frequent Combination Permanent

Combination

Dead Laod+SIDL 1.00 1.00 1.00

Surfacing 1.20 1.20 1.20

CWLL 1.00 0.75 0.00

Wind Load 0.60 0.50 0.00

Table B.4 Partial Safety Factor For Design of Foundation

Loads Normal Case Seismic Case

Dead Laod+SIDL except

1.350 1.35

wearing course

SIDL ( Wearing Course

1.750 1.75

only)

CWLL ( Service ) 1.500 0.75

CWLL ( Construction) 1.350 1.00

Wind Load 0.900 -

Seismic Effect ( during

1.50

service)

Seismic Effect ( during

0.75

construction)

NH-72A and NH-73 9 PIER-P3

Design Calculation ICT SEISMIC COEFF.

Seismic coefficient Calculation

(As Per IRC:6-2017 , Clause 219)

Horizontal Seismic Force For Zone - 4

Feq = Seismic forces to be resisted

Feq = Ah x (Dead load + Appropriate Live load)

Ah = horizontal seismic coefficient

= Z Sa

2 g

R

I

Z = Zone factor = 0.24

I = Importance factor = 1.20

R = Response reduction factor = 3.0 in Longitudinal direction

= 3.0 In Transverse direction

= 3.0 For Pier Cap/Beam

T = Fundamental period of the bridge member (in sec.)

or horizontal vibrations.

1/2

= 2.0 D

1000F

D = appropriate dead load of the superstructure , and live load in KN

F = Horizontal force in KN required to be applied at the center of mass of the superstructure for one mm

horizontal deflection at the top of the pier/abutment along the considered direction of horizontal force.

F = 6EI

2

x *(3L-x)

C.g. of Horizontal Force acting at a height from Foundation Level in Longitudinal direction

= 9.406 m

C.g. of Horizontal Force acting at a height from Foundation Level in Tranverse direction

= 11.632 m

Pier Cap Top Level - Pile Top Level

= 9.016 m

Dimensions of Abutment Shaft

Size of shaft = 2.00 m

Numbers of shaft = 1.00 m

Moment of Inertia , Ilongitudinal

= 0.589 m4

Moment of Inertia , Itransverse

= 0.589 m4

Ecm = 3.335E+07 kN/m2

Longitudinal Direction Transverse Direction

Force = 75.5038 KN Force = 56.023 KN

D = 9043.31 KN D = 9323.030 KN

T = 0.6922 sec T = 0.8159 sec

Medium Soil Strata

Sa/g = 1.965 Sa/g = 1.667

For Substructure except pier cap

Seismic Coeff. In Longitudinal Direction = 0.094

Seismic Coeff. In Transverse Direction = 0.080

For Pier Cap

Seismic Coeff. In Longitudinal Direction = 0.094

Seismic Coeff. In Transverse Direction = 0.080

NH-72A and NH-73 10 PIER-P3

Design Calculation ICT SEISMIC COEFF.

Summary of Horizontal and Vertical Sesmic Coeff.

For Design of Substructure

For Substructure excluding pier cap only for Pier Cap

Ah = 0.094 in Longitudinal direction Ah = 0.094

Ah = 0.080 In Transverse direction Ah = 0.080

Av = 0.063 In Vertical Direction Av = 0.063

For Design of Foundation

For Substructure excluding pier cap only for Pier Cap

Ah = 0.127 Ah = 0.127

Ah = 0.108 Ah = 0.108

Av = 0.085 Av = 0.085

During Construction ,

Importance factor = 1.00

Summary of Horizontal and Vertical Sesmic Coeff. In Dislodge Case

For Design of Substructure

For Substructure excluding pier cap only for Pier Cap

Ah = 0.079 Ah = 0.079

Ah = 0.067 Ah = 0.067

Av = 0.052 Av = 0.052

For Design of Foundation

For Substructure excluding pier cap only for Pier Cap

Ah = 0.106 Ah = 0.106

Ah = 0.090 Ah = 0.090

Av = 0.071 Av = 0.071

NH-72A and NH-73 11 PIER-P3

CALCULATION OF LONGITUDINAL HORIZONTAL FORCES DUE TO

TEMPERATURE:

Coefficent of thermal expansion = 0.000012 / oC

o

Maximum temperature = 47.5 C

o

Minimum temperature = 2.5 C

o

Bridge Temprature = 32.5 C

Longitudinal strain = 0.0004

Shrinkage coefficent = 0.0002

Total strain for longitudinal movement = 0.0006

Horizontal movement = 0.00059 x 37.45 x 1000

1

= 22.096 mm

Size of bearing = 300 x 550 x 76 mm

Strain in bearing = 22.096 = 0.29073

76

Shear modulus = 0.9 Mpa

Shear force per Bearing = 0.2907 x 0.9 x 292 x 542

= 41410.9209 N = 4.221 t

Total shear force for 5 bearings ( with 0 % increase )

= 4.221 x 5 x 1

= 21.106 t

Refer IRC : 6 clause 214.5.1.5;

10 % increase for variation in movement of span

Total shear force = 1.1 x 21.106

= 23.217 t

Design Calculation ICT HF@BRG-ULS

Horizontal Force (HL) AT Bearings in Ultimate Limit State

(Refer Clause 211.5.1.1 of IRC:6-2017 )

Type of bearing - Elastomeric & Pin Bearing

Left Span

Load

Unfactored Basic Seismic Load (Basic

Loads (Seismic

Load Comb Comb Comb)

Comb)

DL = 2167.97 1.35 1.35 2926.76 2926.76

SIDL except wc = 407.00 1.35 1.35 549.45 549.45

WC = 468.05 1.75 1.75 819.09 819.09

FPLL = 0.00 1.5 0.2 0.00 0.00

CWLLmax-

= 0.00 1.5 0.2 0.00 0.00

Reaction case

CWLLmax-

Transv. Moment 0.00 1.5 0.2 0.00 0.00

Case =

CWLLmin = 0.00 1.5 0.2 0.00 0.00

Right Span

Load

Unfactored Basic Seismic Load (Basic

Loads (Seismic

Load Comb Comb Comb)

Comb)

DL = 5150.65 1.35 1.35 6953.38 6953.38

SIDL except wc = 319.00 1.35 1.35 430.65 430.65

WC = 530.64 1.75 1.75 928.61 928.61

FPLL = 0.00 1.5 0.2 0.00 0.00

CWLLmax-

= 1185.74 1.5 0.2 1778.61 237.15 1-70R + 1-CLASS A

Reaction case

CWLLmax-

= 2490.87 1 0 2490.87 0.00 SV LOAD

Reaction case

CWLLmax-

Transv. Moment = 890.82 1.5 0.2 1336.23 178.16

Case

CWLLmin = 109.18 1.5 0.2 163.77 21.84 1-70R + 1-CLASS A

CWLLmin = 2189.13 1 0 2189.13 0.00 SV LOAD

COMB 1: DL+SIDL-Normal Dry Case

From Right Span

Fh = 0 kN

Maximum Net Horizontal Force = 232.17 kN

NH-72A and NH-73 13 PIER-P3

Design Calculation ICT HF@BRG-ULS

COMB 2: DL+SIDL + LL(Maximum Reaction) -Normal Dry Case 1-70R + 1-CLASS A

From Right Span

Fh due to braking = 0.2 x ( 1500.00 ) + 0.05 x ( 831.00 )

= 341.55 kN

Maximum Net Horizontal Force = 573.72 kN

COMB 2: DL+SIDL + LL(Maximum Reaction) -Normal Dry Case SV LOAD

From Right Span

Fh due to braking = 0.2 x ( 0.00 ) + 0.05 x ( 0.00 )

= 0.00 kN

Maximum Net Horizontal Force = 232.17 kN

COMB 3: DL+SIDL + LL(Max Transverse Moment) -Normal Dry Case

Maximum Net Horizontal Force = 573.72 kN

COMB 4 : DL+SIDL -one Span Dislodege Normal case

Maximum Net Horizontal Force = 232.17 kN

COMB 5 : COMB 2 + WL -Normal Dry Case

From Right Span Load factor

Fh due to wind = 176.971 kN x 0.9 = 159.273

Maximum Net Horizontal Force = 391.44 kN

COMB 6: COMB 3 + WL -Wind Dry Case

Maximum Net Horizontal Force = 391.44 kN

COMB 7 : DL+SIDL+WL -one Span Dislodege Wind case

From Right Span Load factor

Fh due to wind = 176.971 kN x 0.9 = 159.273

Maximum Net Horizontal Force = 232.17 kN

COMB 8 : COMB 1 + EQ-L -Seismic Dry Case

From Right Span

DL SIDL WC

Fh due to seismic = 0.094 x ( 10301.31 + 638.00 + 1061.27 )

Load factor

= 0.094 x 12000.580 x 1.50

= 1697.71

Maximum Net Horizontal Force = 1929.88 kN

COMB 9 : COMB 1 + EQ-T -Seismic Dry Case

From Right Span

Fh due to seismic = 0.3 x 848.86 = 254.657 kN

Maximum Net Horizontal Force = 486.83 kN

NH-72A and NH-73 14 PIER-P3

Design Calculation ICT HF@BRG-ULS

COMB 10 : COMB 2 + EQ-L -Seismic Dry Case

From Right Span

Fh due to seismic = 1697.71 kN

Fh due to braking = 0.2 x 200 + 0.05 x 110.8

= 45.54 kN

Total Fh = 1743.25 kN

Maximum Net Horizontal Force = 1975.42 kN

COMB 11 : COMB 2 + EQ-T -Seismic Dry Case

From Right Span

Fh due to seismic = 0.30 x 848.86 = 254.7 kN

Fh due to braking = 45.54 kN

Total Fh = 300.20 kN

Maximum Net Horizontal Force = 532.37 kN

COMB 12 : COMB 3 + EQ-L -Seismic Dry Case

Maximum Net Horizontal Force = 1975.42 kN

COMB 13 : COMB 3 + EQ-T -Seismic Dry Case

Maximum Net Horizontal Force = 532.37 kN

COMB 14 : DL+SIDL+EQ-L -one Span Dislodege Seismic case

From Right Span DL SIDL WC

Fh due to seismic = 0.079 x ( 10301.31 + 638.00 + 1061.27 )

= 0.079 x 12000.58 = 943.17

= 943.17 kN

Maximum Net Horizontal Force = 707.38 kN .75 factor have been considered

COMB 15 : DL+SIDL+EQ-T -one Span Dislodege Seismic case

From Right Span

Fh due to seismic = 0.3 x 471.59 = 141.476 kN

Maximum Net Horizontal Force = 232.17 kN .75 factor have been considered

NH-72A and NH-73 15 PIER-P3

Design Calculation ICT HF@BRG-FND. Design

Horizontal Force (HL) AT Bearings For Design of Foundation

(Refer Clause 211.5.1.1 of IRC:6-2017 )

Type of bearing - Elastomeric & Pin Bearing

Left Span

Load

Unfactored Basic Load (Basic

Loads Seismic Comb (Seismic

Load Comb Comb)

Comb)

DL = 2167.97 1.35 1.35 2926.76 2926.76

SIDL except wc = 407.00 1.35 1.35 549.45 549.45

WC = 468.05 1.75 1.75 819.09 819.09

FPLL = 0.00 1.5 0.75 0.00 0.00

CWLLmax-Reaction

= 0.00 1.5 0.75 0.00 0.00

case

CWLLmax-Transv.

= 0.00 1.5 0.75 0.00 0.00

Moment Case

CWLLmin = 0.00 1.5 0.75 0.00 0.00

Right Span

Load

Unfactored Basic Load (Basic

Loads Seismic Comb (Seismic

Load Comb Comb)

Comb)

DL = 5150.65 1.35 1.35 6953.38 6953.38

SIDL except wc = 319.00 1.35 1.35 430.65 430.65

WC = 530.64 1.75 1.75 928.61 928.61

FPLL = 0.00 1.5 0.75 0.00 0.00

CWLLmax-Reaction

= 1185.74 1.5 0.75 1778.61 889.31

case

CWLLmax-Transv.

890.82 1.5 0.75 1336.23 668.12

Moment Case

CWLLmin = 109.18 1.5 0.75 163.77 81.88

COMB 1: DL+SIDL-Normal Dry Case

From Right Span

Fh = 0 kN

Maximum Net Horizontal Force = 232.17 kN

NH-72A and NH-73 16 PIER-P3

Design Calculation ICT HF@BRG-FND. Design

COMB 2: DL+SIDL + LL(Maximum Reaction) -Normal Dry Case

From Right Span

Fh due to braking= 0.2 x ( 1500.00 ) + 0.05 x ( 831.00 )

= 341.55 kN

Maximum Net Horizontal Force = 573.72 kN

COMB 3: DL+SIDL + LL(Max Transverse Moment) -Normal Dry Case

Maximum Net Horizontal Force = 573.72 kN

COMB 4 : DL+SIDL -one Span Dislodege Normal case

Maximum Net Horizontal Force = 232.17 kN

COMB 5 : COMB 2 + WL -Normal Dry Case

From Right Span Load factor

Fh due to wind = 176.971 kN x 0.9 = 159.273

Maximum Net Horizontal Force = 391.44 kN

COMB 6: COMB 3 + WL -Wind Dry Case

Maximum Net Horizontal Force = 391.44 kN

COMB 7 : DL+SIDL+WL -one Span Dislodege Wind case

From Right Span Load factor

Fh due to wind = 176.971 kN x 0.90 = 159.273

Maximum Net Horizontal Force = 232.17 kN

NH-72A and NH-73 17 PIER-P3

Design Calculation ICT HF@BRG-FND. Design

COMB 8 : COMB 1 + EQ-L -Seismic Dry Case

From Right Span DL SIDL WC

Fh due to seismic = 0.127 x ( 10301.31 + 638.00 + 1061.27 )

Load factor

= 0.127 x 12000.580 x 1.50

= 2291.91

Maximum Net Horizontal Force = 2524.08 kN

COMB 9 : COMB 1 + EQ-T -Seismic Dry Case

From Right Span

Fh due to seismic = 0.3 x 1145.96 = 343.787 kN

Maximum Net Horizontal Force = 575.96 kN

COMB 10 : COMB 2 + EQ-L -Seismic Dry Case

From Right Span

Fh due to seismic = 2291.91

Fh due to braking = 0.2 x 200 + 0.05 x 110.8

= 45.54 kN

Total Fh = 2337.45 kN

Maximum Net Horizontal Force = 2569.62 kN

COMB 11 : COMB 2 + EQ-T -Seismic Dry Case

From Right Span

Fh due to seismic = 0.30 x 1145.96 = 343.79 kN

Fh due to braking = 45.54 kN

Total Fh = 389.33 kN

Maximum Net Horizontal Force = 621.50 kN

COMB 12 : COMB 3 + EQ-L -Seismic Dry Case

Maximum Net Horizontal Force = 2569.62 kN

COMB 13 : COMB 3 + EQ-T -Seismic Dry Case

Maximum Net Horizontal Force = 621.50 kN

COMB 14 : DL+SIDL+EQ-L -one Span Dislodege Seismic case

From Right Span DL SIDL WC

Fh due to seismic = 0.1061 x ( 10301.31 + 638.00 + 1061.27 )

= 0.106 x 12000.580 = 1273.28

= 1273.28 kN

Maximum Net Horizontal Force = 954.96 kN

COMB 15 : DL+SIDL+EQ-T -one Span Dislodege Seismic case

From Right Span

Fh due to seismic = 0.3 x 636.64 = 190.993 kN

Maximum Net Horizontal Force = 232.17 kN

NH-72A and NH-73 18 PIER-P3

Design Calculation ICT HF@BRG-Stabilty Check

Horizontal Force (HL) AT Bearings For Stability of Foundation

(Refer Clause 211.5.1.1 of IRC:6-2017)

Type of bearing - POT-PTFE

Left Span

Load

Unfactored Basic Load (Basic

Loads Seismic Comb (Seismic

Load Comb Comb)

Comb)

DL = 2167.97 1 1 2167.97 2167.97

SIDL except wc = 407.00 1 1 407.00 407.00

WC = 468.05 1 1 468.05 468.05

FPLL = 0.00 1 1 0.00 0.00

CWLLmax-Reaction

= 0.00 1 1 0.00 0.00

case

CWLLmax-Transv.

0.00 1 1 0.00 0.00

Moment Case

CWLLmin = 0.00 1 1 0.00 0.00

Right Span

Load

Unfactored Basic Load (Basic

Loads Seismic Comb (Seismic

Load Comb Comb)

Comb)

DL = 5150.65 1 1 5150.65 5150.65

SIDL except wc = 319.00 1 1 319.00 319.00

WC = 530.64 1 1 530.64 530.64

FPLL = 0.00 1 1 0.00 0.00

CWLLmax-Reaction

= 1185.74 1 1 1185.74 1185.74 1-70R + 1-CLASS A

case

CWLLmax-Reaction

= 2490.87 1 0 2490.87 0.00 SV LOAD

case

CWLLmax-Transv.

890.82 1 1 890.82 890.82

Moment Case

CWLLmin = 109.18 1 1 109.18 109.18 1-70R + 1-CLASS A

CWLLmin = 2189.13 1 0 2189.13 0.00 SV LOAD

COMB 1: DL+SIDL-Normal Dry Case

From Right Span

Fh = 0 kN

Maximum Net Horizontal Force = 232.17 kN

COMB 2: DL+SIDL + LL(Maximum Reaction) -Normal Dry Case 1-70R + 1-CLASS A

From Right Span

Fh due to braking = 0.2 x ( 1000.00 ) + 0.05 x ( 554.00 )

= 227.70 kN

Maximum Net Horizontal Force = 459.87 kN

COMB 2: DL+SIDL + LL(Maximum Reaction) -Normal Dry Case SV LOAD

From Right Span

Fh due to braking = 0.2 x ( 0.00 ) + 0.05 x ( 0.00 )

= 0.00 kN

Maximum Net Horizontal Force = 232.17 kN

COMB 3: DL+SIDL + LL(Max Transverse Moment) -Normal Dry Case

Maximum Net Horizontal Force = 459.87 kN

COMB 4 : DL+SIDL -one Span Dislodege Normal case

Maximum Net Horizontal Force = 232.17 kN

NH-72A and NH-73 19 PIER-P3

Design Calculation ICT HF@BRG-Stabilty Check

COMB 5 : COMB 2 + WL -Normal Dry Case

From Left Span

mR = 152.15 kN

From Right Span Load factor

Fh due to wind = 176.971 kN x 1.00 = 176.971

Maximum Net Horizontal Force = 409.14 kN

COMB 6: COMB 3 + WL -Wind Dry Case

Maximum Net Horizontal Force = 409.14 kN

COMB 7 : DL+SIDL+WL -one Span Dislodege Wind case

From Right Span Load factor

Fh due to wind = 176.971 kN x 1 = 176.971

Maximum Net Horizontal Force = 232.17 kN

COMB 8 : COMB 1 + EQ-L -Seismic Dry Case

From Right Span DL SIDL WC

Fh due to seismic = 0.1273 x ( 10301.31 + 638.00 + 1061.27 )

Load factor

= 0.13 x 12000.58 = 1527.94 x 1.00

= 1527.94

DL SIDL WC

Maximum Net Horizontal Force = 1760.11 kN

COMB 9 : COMB 1 + EQ-T -Seismic Dry Case

From Right Span

Fh due to seismic = 0.3 x 763.97 = 229.191 kN

Maximum Net Horizontal Force = 461.36 kN

COMB 10 : COMB 2 + EQ-L -Seismic Dry Case

From Right Span

Fh due to seismic = 1527.94

Fh due to braking = 0.2 x 200 + 0.05 x 110.8

= 45.54 kN

Total Fh = 1573.48 kN

Maximum Net Horizontal Force = 1805.65 kN

COMB 11 : COMB 2 + EQ-T -Seismic Dry Case

From Right Span

Fh due to seismic = 0.30 x 763.97 = 229.2 kN

Fh due to braking = 45.54 kN

Total Fh = 274.73 kN

Maximum Net Horizontal Force = 506.90 kN

COMB 12 : COMB 3 + EQ-L -Seismic Dry Case

Maximum Net Horizontal Force = 1805.65 kN

COMB 13 : COMB 3 + EQ-T -Seismic Dry Case

Maximum Net Horizontal Force = 506.90 kN

COMB 14 : DL+SIDL+EQ-L -one Span Dislodege Seismic case

From Right Span DL SIDL WC

Fh due to seismic = 0.106 x ( 10301.31 + 638.00 + 1061.27 )

Load factor

= 0.11 x 12000.580 = 1273.28 x 0.50

= 636.64 kN

Maximum Net Horizontal Force = 636.64 kN

COMB 15 : DL+SIDL+EQ-T -one Span Dislodege Seismic case

From Right Span

Fh due to seismic = 0.3 x 318.32 = 95.496 kN

Maximum Net Horizontal Force = 232.17 kN

NH-72A and NH-73 20 PIER-P3

Design Calculation ICT HF@BRG-SLS

Horizontal Force (HL) AT Bearings For Servicibilty Limit State

(Refer Clause 211.5.1.1 of IRC:6-2017 )

Type of bearing - POT-PTFE

Left Span

Quasi- Load Load (Quasi-

Unfactored Rare Frequent Load (Rare

Loads Permanent (Frequent Permanent

Load Comb Comb Comb)

Comb Comb) Comb)

DL = 2167.97 1 1 1 2167.97 2167.97 2167.97

SIDL except wc = 407.00 1 1 1 407.00 407.00 407.00

WC = 468.05 1 1 1 468.05 468.05 468.05

FPLL = 0.00 1 0.75 0 0.00 0.00 0.00

CWLLmax-Reaction

= 0.00 1 0.75 0 0.00 0.00 0.00

case

CWLLmax-Transv.

0.00 1 0.75 0 0.00 0.00 0.00

Moment Case

CWLLmin = 0.00 1 0.75 0 0.00 0.00 0.00

Right Span

Quasi- Load Load (Quasi-

Unfactored Rare Frequent Load (Rare

Loads Permanent (Frequent Permanent

Load Comb Comb Comb)

Comb Comb) Comb)

DL = 5150.65 1 1 1 5150.65 5150.65 5150.65

SIDL except wc = 319.00 1 1 1 319.00 319.00 319.00

WC = 530.64 1 1 1 530.64 530.64 530.64

FPLL = 0.00 1 0.75 0 0.00 0.00 0.00

CWLLmax-Reaction

= 1185.74 1 0.75 0 1185.74 889.31 0.00

case

CWLLmax-Transv.

890.82 1 0.75 890.82 668.12 0.00

Moment Case

CWLLmin = 109.18 1 0.75 0 109.18 81.88 0.00

COMB 1: DL+SIDL-Normal Dry Case -Rare Combination

From Right Span

Fh = 0 kN

Maximum Net Horizontal Force = 232.17 kN

COMB 2: DL+SIDL + LL(Maximum Reaction) -Normal -Rare Combination

Dry Case

From Right Span

Fh due to braking = 0.2 x ( 1000.00 ) + 0.05 x ( 554.00 )

= 227.70 kN

NH-72A and NH-73 21 PIER-P3

Design Calculation ICT HF@BRG-SLS

Maximum Net Horizontal Force = 459.87 kN

COMB 3: DL+SIDL + LL(Max Transverse Moment) -Normal

-Rare Dry

Combination

Case

Maximum Net Horizontal Force = 459.87 kN

COMB 5 : COMB 2 + WL -Normal Dry Case -Rare Combination

From Right Span Load factor

Fh due to wind = 176.971 kN x 0.60 = 106.182 kN

Maximum Net Horizontal Force = 338.35 kN

COMB 6: COMB 3 + WL -Wind Dry Case -Rare Combination

Maximum Net Horizontal Force = 338.35 kN

FREQUENT COMBINATION

COMB 1: DL+SIDL-Normal Dry Case FREQUENT COMBINATION

From Right Span

Fh = 0 kN

Maximum Net Horizontal Force = 232.17 kN

COMB 2: DL+SIDL + LL(Maximum Reaction) -Normal FREQUENT

Dry Case COMBINATION

From Right Span

Fh due to braking = 0.2 x ( 1000.00 ) + 0.05 x ( 554.00 )

= 227.70 kN

NH-72A and NH-73 22 PIER-P3

Design Calculation ICT HF@BRG-SLS

Maximum Net Horizontal Force = 459.87 kN

COMB 3: DL+SIDL + LL(Max Transverse Moment) -Normal

FREQUENT

Dry Case

COMBINATION

Maximum Net Horizontal Force = 459.87 kN

COMB 5 : COMB 2 + WL -Normal Dry Case FREQUENT COMBINATION

From Right Span Load factor

Fh due to wind = 176.971 kN x 0.50 = 88.485 kN

Maximum Net Horizontal Force = 320.66 kN

COMB 6: COMB 3 + WL -Wind Dry Case FREQUENT COMBINATION

Maximum Net Horizontal Force = 320.66 kN

1. Normal Case - ( DL+SIDL)-Quasi-Permanent Combination

From Right Span

Fh = 0 kN

Maximum Net Horizontal Force = 232.17 kN

2. Normal One Span Dislodged Case - ( DL+SIDL)-Quasi-Permanent Combination Left Span Dislodge

Maximum Horizontal Force

Fh = 232.17 kN

NH-72A and NH-73 23 PIER-P3

Design Calculation ICT centrifugal force

Centrifugal Force Calculation

As per clause 212 of IRC:6-2017

CENTRIFUGAL FORCE C = W V2

127 R

Normal Case Seismic Case

Design Speed V = 80.00 kmph 80.00 kmph

Live Load W = 139.86 t 27.97 t

Radius of Curvature R = 0.00 m 0.00 m

CENTRIFUGAL FORCE C = 0.00 t 0.00 t

= 0.00 kN 0.00 kN

NH-72A and NH-73 24 PIER-P3

Design Calculation ICT Vertical Reaction_Braking

Calculation of Vertical Reaction Due to Braking Force

Braking Force = 0.2 x ( 1000 ) + 0.05 x ( 554.00 )

= 227.7 kN

Deck Lvl. At

Centre of Soffit Level

Bridge

C.g. Of Force = 1.2 + ( 277.185 - 274.406 )

= 3.98 m

Moment due to Braking

= 906.02 kNm

Force

Span = 38 m

Vertical Reaction = 23.843 kN Upward

= -23.843 kN Downward

NH-72A and NH-73 25 PIER-P3

Design Calculation ICT Wind Calc

Wind Calculation ( As Per Clause 209 of IRC:6-2017 )

basic wind speed = 47 m/s (As per IRC 6:2017 , Fig. 10)

Maximum Height of Bridge from Ground Surface = 11.226 m

As per Table 4 of IRC 6:2017

Basic wind speed = 33 m/s

Vz = 29.2 m/s

2

Pz = 512.5 N/m

modified value of Hourly mean wind speed and wind pressure for this bridge are as per below

Vz,design = Vz x 1.42 = 41.59 m/s

2

Pz,design = Pz x 2.03 = 1039.59 N/m

AS per Clause 209.3.7 of IRC 6:2017

Since Design Mean wind speed of 39.59 m/s exceed wind speed of 36 m/s, hence no Live load to be considered in wind load case

Design Wind Force on Superstructure

FT = Pz x A1 x G x Cd as per IRC 6:2017, Caluse 209.3.3

2

Where , Pz = 1039.59 N/m

Area ( A1) in Elevation

Left Side Span

Span Length = 37.500 m

Depth of superstructure = 1.831 m

Crash Barrier = 1.100 m

Area A1 = 109.913 m2

Right Side Span

Span Length = 40.000 m

Depth of superstructure = 2.720 m

Anticrash Railing = 1.100 m

Area A1 = 152.800 m2

Gust factor , G = 2.0 as per Clause 209.3.3

Left Span

Precast I-Girder

Width of Girder b = 900 mm

Depth of Girder d = 1831 mm

Ratio b/d = 0.492

Drag Coeff. Cd = 2.250

RightSpan

Precast I-Girder

Width of Girder b = 900 mm

Depth of Girder d = 2720 mm

Ratio b/d = 0.331

Drag Coeff. Cd = 2.250

FT = 257093.63 N from Left span

N acting at Level = 276.7605 m

Parallel to Span FT sin (q ) = 0.00 N acting at Level = 275.195 m

Perpendicular to span FT cos (q ) = 257093.63 N acting at Level = 276.7605 m

FT = 357410.72 N from Right Span

acting at 276.316 m

Parallel to Span FT sin (q ) = 0.00 N acting at Level = 274.316 m

Perpendicular to span FT cos (q ) = 357410.72 N acting at Level = 276.316 m

Wind Force on Live Load

Drag Coeff. Cd = 1.450

Exposed Area A1 = 38.750 x 3

2

= 116.250 m

FT = 350471.47 N

NH-72A and NH-73 26 PIER-P3

Design Calculation ICT Wind Calc

AS per clause 209.3.4

Longitudinal Wind Force

FL = 25% FT = 64273.407 N from Left span

N acting at Level = 275.195 m

Parallel to Span FL cos (q ) = 64273.41 N acting at Level = 275.195 m

Perpendicular to span FL sin (q ) = 0.00 N acting at Level = 276.7605 m

FL = 25% FT = 176970.547 N from Right Span +live load

N acting at Level = 274.316 m

Parallel to Span FL cos (q ) = 176970.55 N acting at Level = 274.316 m

Perpendicular to span FL sin (q ) = 0.00 N acting at Level = 276.316 m

Total Wind Force in Longitudinal Direction FL = FT sin (q ) + FL cos (q ) from Left span

= 0.00 + 64273.41

= 64273.41 N acting at Level = 275.195 m

FL = FT sin (q ) + FL cos (q ) from Right Span

= 0.00 + 176970.55

= 176970.55 N acting at Level = 274.32 m

Total Wind Force in Transverse Direction FT = FT cos (q ) + -FL sin (q ) from Left span

= 257093.63 + 0.0

= 257093.63 N acting at Level = 276.761 m

FT = FT cos (q ) + -FL sin (q ) from Right Span

= 357410.72 + 0.0

= 357410.72 N acting at Level = 276.316 m

Toatl FT = 614504.35 N acting at Level = 276.502 m

Upward / Downward Wind Vertical Load ( Fv)

Fv = Pz x A3 x G x CL as per IRC 6:2014, Caluse 209.3.5

Where ,

A3 = Area in Plan ( m2) = 12.5 x 37.50

2

= 468.750 m from Left span

A3 = 12.5 x 40.00

2

= 500.0 m from Right Span

CL = 0.75

Fv = 365480.5 N from Left span

-365480.5 N Upward

Fv = 389845.9 N from Right Span

-389845.9 N upwrad

Design Wind Force on Subtsructure AS per clause 209.4 , IRC 6:2014

Pier Cap

FT = Pz x A2 x G x Cd

2

Projected area of cap in elevation A2 = 6.750 m

H/b = 0.480 & d/b= 1.96

Correspo to H/b and d/b ratio fro Table 6 Cd = 0.900

FT = 12631.0 N

Parallel to Span FT sin (q ) = 0.0 N acting at Level = 273.6 m

Perpendicular to span FT cos (q ) = 12631.0 N acting at Level = 273.6 m

Pier Shaft

2

Projected area of shaft in elevation A2 = 12.284 m

H/b = 3.1 & d/b= 1

Cd = 0.7 For circular section

FT = 17878.4 N

Parallel to Span FT sin (q ) = 0.0 N acting at Level = 269.145 m

Perpendicular to span FT cos (q ) = 17878.4 N acting at Level = 269.145 m

NH-72A and NH-73 27 PIER-P3

Design Calculation ICT Stability of Foundation

Calculation of Forces For Foundation Base Pressure Check

Pile Cap Bottom Lvl = 262.70 Bearing top Level = 274.85 m

COMB 1: DL+SIDL-Normal Dry Case

Unit

Load Volume Vertical Load( Long. Ecc. Transv. Ecc.

Loads Weights FL (kN) FT (kN) ML = PxeL MT = PxeT

Factor (m3) P ) kN. (eL) (m) (eT) (m)

(kN/m3)

Superstructure-Left Span

Dead Load 1 2167.969 -0.875 0.000 -1896.973 0.000

SIDL except Wearing Course 1 407.001 -0.875 0.000 -356.126 0.000

Wearing Course 1 468.050 -0.875 0.000 -409.544 0.000

Superstructure-Right Span

Dead Load 1 5150.654 0.875 0.000 4506.822 0.000

SIDL except Wearing Course 1 319.000 0.875 0.000 279.125 0.000 `

Wearing Course 1 530.636 0.875 0.000 464.306 0.000

Bearing Pedestal : Left Span 1 25 1.280 32.000 -0.875 -0.625 -28.000 -20.000

Bearing Pedestal : Right Span 1 25 0.998 24.960 0.875 -0.577 21.840 -14.400

Seismic arrestor: Left Span

Long. Arrestor 1 25 1.190 29.750 0.000 0.000 0.000 0.000

Transverse arrestor 1 25 0.574 14.355 0.000 0.000 0.000 0.000

Seismic arrestor: Right Span

Long. Arrestor 1 25 0.000 0.000 0.875 0.000 0.000 0.000

Transverse arrestor 1 25 0.817 20.436 0.000 0.000 0.000 0.000

Substructure

Pier Cap 1 25 66.994 1674.844 0.000 0.000 0.000 0.000

Additional weight of cap 1 25 20.602 515.039 -0.938 0.000 -482.849 0.000

Pier Shaft 1 25 22.670 566.743 0.000 0.000 0.000 0.000

Pile Cap 1 25 144.279 3606.975 0.000 0.000 0.000 0.000

Earth fill on pile cap 1 20 63.998 1279.959 0.000 0.000 0.000 0.000

Net Horizontal Force at Bearing 232.171 0.000 2820.998 0.000

Total 16808.371 232.171 0.000 4919.6 -34.400

COMB 2: DL+SIDL + LL(Maximum Reaction) -Normal Dry Case

Unit

Load Volume Vertical Load( Long. Ecc. Transv. Ecc.

Loads Weights FL (kN) FT (kN) ML = PxeL MT = PxeT

Factor 3 (m3) P ) kN. (eL) (m) (eT) (m)

(kN/m )

Forces from Case 1 except

horizontal forces due to 16808.371 0.000 0.000 2098.602 -34.400

superstructure

CWLL from left span 1 0.00 -0.875 0.000 0.000

CWLL(MAX) with Braking

1 1209.584 0.875 1058.386 1792.995

Vertical Reaction

Net Horizontal Force at Bearing 459.871 0.000 5587.666 0.000

Total 18017.955 459.871 0.000 8744.655 1758.595

NH-72A and NH-73 28 PIER-P3

Design Calculation ICT Stability of Foundation

COMB 3: DL+SIDL + LL(Max Transverse Moment) -Normal Dry Case

Unit

Load Volume Vertical Load( Long. Ecc. Transv. Ecc.

Loads Weights FL (kN) FT (kN) ML = PxeL MT = PxeT

Factor 3 (m3) P ) kN. (eL) (m) (eT) (m)

(kN/m )

Forces from Case 1 except

horizontal forces due to 16808.371 0.000 0.000 2098.602 -34.400

superstructure

CWLL from left span 1 0.00 -0.875 0.000 0.000

CWLL(MAX) with Braking

1 914.664 0.875 800.331 2810.540

Vertical Reaction

Net Horizontal Force at Bearing 459.871 0.000 5587.666 0.000

Total 17723.034 459.871 0.000 8486.599 2776.140

COMB 4 : DL+SIDL -one Span Dislodege Normal case

Unit

Load Volume Vertical Load( Long. Ecc. Transv. Ecc.

Loads Weights FL (kN) FT (kN) ML = PxeL MT = PxeT

Factor (m3) P ) kN. (eL) (m) (eT) (m)

(kN/m3)

Superstructure-Right Span

Dead Load 1 5150.654 0.875 0.000 4506.822 0.000

SIDL except Wearing Course 1 319.000 0.875 0.000 279.125 0.000

Wearing Course 1 530.636 0.875 0.000 464.306 0.000

Bearing Pedestal : Right Span 1 25 0.998 24.960 0.875 -0.577 21.840 -14.400

Seismic arrestor 1 64.541 0.000 0.000 0.000 0.000

Substructure

Pier Cap 1 25 66.994 1674.844 0.000 0.000 0.000 0.000

Additional weight of cap 1 25 20.602 515.039 -0.938 0.000 -482.849 0.000

Pier Shaft 1 25 22.670 566.743 0.000 0.000 0.000 0.000

Pile Cap 1 25 144.279 3606.975 0.000 0.000 0.000 0.000

Earth fill on pile cap 1 20 63.998 1279.959 0.000 0.000 0.000 0.000

Net Horizontal Force at Bearing 232.171 0.000 2820.998 0.000

Total 13733.351 232.171 0.000 7610.242 -14.400

COMB 5 : COMB 2 + WL -Normal Dry Case Long. Moment Trans. Moment

Unit

Load Volume Vertical Load( C.g. of Long. Ecc. Transv. Ecc. MT due to

Loads Weights FL (kN) FT (kN) ML = PxeL ML due to FL MT = PxeT

Factor (m3) P ) kN. Force (m) (eL) (m) (eT) (m) FT

(kN/m3)

Superstructure-Left Span

Dead Load 2167.969 -0.875 0.000 -1896.973 0.000

SIDL except Wearing Course 407.001 -0.875 0.000 -356.126 0.000

Wearing Course 468.050 -0.875 0.000 -409.544 0.000

CWLL 0.000 -0.875 0.000 0.000

Superstructure-Right Span

Dead Load 5150.654 0.875 0.000 4506.822 0.000

SIDL except Wearing Course 319.000 0.875 0.000 279.125 0.000

Wearing Course 530.636 0.875 0.000 464.306 0.000

CWLL 1209.584 0.875 1058.386 2810.540

Bearing Pedestal : Left Span 32.000 -0.875 -0.625 -28.000 -20.000

Bearing Pedestal : Right Span 24.960 0.875 -0.577 21.840 -14.400

Seismic arrestor 64.541 0.000 0.000 0.000 0.000

Substructure

Pier Cap 1674.844 0.000 12.631 273.556 0.000 0.000 0.000 0.00 0.000 137.12

Additional weight of cap 515.039 -0.938 0.000 -482.849 0.000

Pier Shaft 566.743 0.000 17.878 269.145 0.000 0.000 0.000 0.00 0.000 115.23

Pile Cap 3606.975 0.000 0.000 0.000 0.000

Earth fill on pile cap 1279.959 0.000 0.000 0.000 0.000

Wind Load 409.142 614.504 276.502 4971.278 8481.36934

Wind Down from Left Span 365.481 -0.875 -319.795

Wind down from Right Span 389.846 0.875 341.115

Wind UP from Left Span -365.481 -0.875 319.795

Wind UP from Right Span -389.846 0.875 -341.115

Total Down 18773.281 409.142 645.014 3178.308 4971.278 2776.140 8733.712

Up 17262.628 3135.669

NH-72A and NH-73 29 PIER-P3

Design Calculation ICT Stability of Foundation

COMB 6: COMB 3 + WL -Wind Dry Case

Hence Design forces will same as Load Combination 5 Long. Moment Trans. Moment

Unit

Load Volume Vertical Load( C.g. of Long. Ecc. Transv. Ecc. MT due to

Loads Weights FL (kN) FT (kN) ML = PxeL ML due to FL MT = PxeT

Factor (m3) P ) kN. Force (m) (eL) (m) (eT) (m) FT

(kN/m3)

Total down 18773.281 409.142 645.014 3178.308 4971.278 2776.140 8733.712

UP 17262.628 3135.669

COMB 7 : DL+SIDL+WL -one Span Dislodege Wind case Left Span Dislodge Long. Moment Trans. Moment

Unit

Load Volume Vertical Load( C.g. of Long. Ecc. Transv. Ecc. MT due to

Loads Weights FL (kN) FT (kN) ML = PxeL ML due to FL MT = PxeT

Factor (m3) P ) kN. Force (m) (eL) (m) (eT) (m) FT

(kN/m3)

Superstructure-Right Span

Dead Load 1 5150.654 0.875 0.000 4506.822 0.000

SIDL except Wearing Course 1 319.000 0.875 0.000 279.125 0.000

Wearing Course 1 530.636 0.875 0.000 464.306 0.000

Bearing Pedestal : Left Span 32.000 -0.875 -0.625 -28.000 -20.000

Bearing Pedestal : Right Span 24.960 0.875 -0.577 21.840 -14.400

Seismic arrestor 64.541 0.000 0.000 0.000 0.000

Substructure

Pier Cap 1 25 66.994 1674.844 0.000 12.631 273.556 0.000 0.000 0.000 0.00 0.000 137.12

Additional weight of cap 515.039 -0.938 0.000 -482.849 0.000

Pier Shaft 1 25 22.670 566.743 0.000 17.878 269.145 0.000 0.000 0.000 0.00 0.000 115.23

Pile Cap 1 25 144.279 3606.975 0.000 0.000 0.000 0.000

Earth fill on pile cap 1 20 63.998 1279.959 0.000 0.000 0.000 0.000

Wind Load 1 232.171 614.504 276.502 2820.997626 8481.369

Wind down from Right Span 389.846 0.875 341.115

Wind UP from Right Span -389.846 0.875 -341.115

Total Down 14155.197 232.171 645.014 5102.360 2820.998 -34.400 8733.712

UP 13375.505 4420.129

NH-72A and NH-73 30 PIER-P3

Design Calculation ICT Stability of Foundation

COMB 8 : COMB 1 + EQ-L -Seismic Dry Case

For Substructure Excluding Pier Cap For Pier Cap

Seismic Effect Factor = 1 αh= 0.127 in Longitudinal direction

αh= 0.127 in Longitudinal direction αh= 0.108 In Transverse direction

αh= 0.108 In Transverse direction αv= 0.085 In Vertical Direction

αv= 0.085 In Vertical Direction

Long. Moment Trans. Moment

Unit Fv = 0.3 x C.g. of

Load Volume Vertical Load( FL = αh x P FT = 0.3 x αh Long. Ecc. Transv. Ecc. MLs due to MTs due to

Loads Weights αv x P Force in ML = PxeL MLs due to FL MT = PxeT

Factor (m3) P ) kN. (kN) x P (kN) (eL) (m) (eT) (m) Fv FT

(kN/m3) (kN) Trans. (m)

Superstructure-Left Span

Dead Load 1 2167.969 70.253 55.206 276.516 -0.875 0.000 -1896.973 -48.305 0.000 970.589

SIDL except Wearing Course 1 407.001 13.189 10.364 277.632 -0.875 0.000 -356.126 -9.069 0.000 196.937

Wearing Course 1 468.050 15.167 11.919 277.210 -0.875 0.000 -409.544 -10.429 0.000 220.075

Superstructure-Right Span

Dead Load 1 5150.654 166.906 131.159 276.219 0.875 0.000 4506.822 114.764 0.000 2256.463

SIDL except Wearing Course 1 319.000 10.337 8.123 277.632 0.875 0.000 279.125 7.108 0.000 154.356

Wearing Course 1 530.636 17.195 13.512 277.210 0.875 0.000 464.306 11.823 0.000 249.502

Bearing Pedestal : Left Span 32.000 -0.875 -0.625 -28.000 -20.000

Bearing Pedestal : Right Span 24.960 0.875 -0.577 21.840 -14.400

Seismic Arrestor 64.541 0.000 0.000 0.000 0.000

Substructure

Pier Cap 1 25 66.994 1674.844 213.245 54.273 42.649 273.556 0.000 0.000 0.000 2314.881 0.000 0.000 589.162

Additional weight of cap 515.039 65.576 16.690 13.115 273.556 -0.938 0.000 -482.849 711.860 0.000 181.176

Pier Shaft 1 25 22.670 566.743 72.159 18.365 14.432 269.145 0.000 0.000 0.000 465.065 0.000 0.000 118.364

Pile Cap 1 25 144.279 3606.975 459.249 116.884 91.850 263.850 0.000 0.000 0.000 528.136 0.000 134.416

Earth fill on pile cap 1 20 63.998 1279.959 0.000 0.000 0.000 0.000

Net Horizontal Force at Bearing 1760.113 0.000 21386.256 0.000

TOTAL 16808.371 2570.342 499.259 392.329 2098.602 25406.198 65.892 -34.400 5071.040

-392.329 -65.892

COMB 9 : COMB 1 + EQ-T -Seismic Dry Case Long. Moment Trans. Moment

Unit Fv = 0.3 x C.g. of

Load Volume Vertical Load( FL = 0.3x αh FT = αh x P Long. Ecc. Transv. Ecc. MLs due to MTs due to

Loads Weights αv x P Force in ML = PxeL MLs due to FL MT = PxeT

Factor (m3) P ) kN. x P (kN) (kN) (eL) (m) (eT) (m) Fv FT

(kN/m3) (kN) Trans. (m)

Superstructure-Left Span

Dead Load 1 2167.969 234.176 55.206 276.516 -0.875 0.000 -1896.973 -48.305 0.000 3235.297

SIDL except Wearing Course 1 407.001 43.963 10.364 277.632 -0.875 0.000 -356.126 -9.069 0.000 656.457

Wearing Course 1 468.050 50.557 11.919 277.210 -0.875 0.000 -409.544 -10.429 0.000 733.582

Superstructure-Right Span

Dead Load 1 5150.654 556.355 131.159 276.219 0.875 0.000 4506.822 114.764 0.000 7521.543

SIDL except Wearing Course 1 319.000 34.457 8.123 277.632 0.875 0.000 279.125 7.108 0.000 514.519

Wearing Course 1 530.636 57.317 13.512 277.210 0.875 0.000 464.306 11.823 0.000 831.674

Bearing Pedestal : Left Span 32.000 -0.875 -0.625 -28.000 -20.000

Bearing Pedestal : Right Span 24.960 0.875 -0.577 21.840 -14.400

Seismic Arrestor 64.541 0.000 0.000 0.000 0.000

Substructure

Pier Cap 1 25 66.994 1674.844 63.974 180.910 42.649 273.556 0.000 0.000 0.000 694.464 0.000 0.000 1963.873

Additional weight of cap 515.039 19.673 55.633 13.115 273.556 -0.938 0.000 -482.849 213.558 0.000 603.920

Pier Shaft 1 25 22.670 566.743 21.648 61.218 14.432 269.145 0.000 0.000 0.000 139.520 0.000 0.000 394.547

Pile Cap 1 25 144.279 3606.975 137.775 389.612 91.850 263.850 0.000 0.000 0.000 158.441 0.000 448.054

Earth fill on pile cap 1 20 63.998 1279.959 0.000 0.000 0.000 0.000

Net Horizontal Force at Bearing 461.363 0.000 5605.786 0.000

TOTAL 16808.371 704.431 1664.197 392.329 2098.602 6811.769 65.892 -34.400 16903.465

-392.329 -65.892

NH-72A and NH-73 31 PIER-P3

Design Calculation ICT Stability of Foundation

COMB 10 : COMB 2 + EQ-L -Seismic Dry Case

Unit Fv = 0.3 x C.g. of

Load Volume Vertical Load( FL = αh x P FT = 0.3 x αh Long. Ecc. Transv. Ecc. MLs due to MTs due to

Loads Weights αv x P Force in ML = PxeL MLs due to FL MT = PxeT

Factor (m3) P ) kN. (kN) x P (kN) (eL) (m) (eT) (m) Fv FT

(kN/m3) (kN) Trans. (m)

Forces from Case 8 except

horizontal forces due to 16808.371 810.229 499.259 392.329 2098.602 4019.943 65.892 -34.400 5071.040

superstructure

CWLL from left span 1 0.000 0.000 0.000 278.385 -0.875 0.000 0.000 0.000 0.000 0.000

CWLL(MAX) with Braking

1 241.917 7.839 6.160 278.385 0.875 211.677 5.390 1792.995 122.959

Vertical Reaction

Net Horizontal Force at Bearing 1805.653 0.000 21939.590 0.000

Total 17050.287 2615.882 507.099 398.489 2310.279 25959.532 71.282 1758.595 5193.999

-398.489 -71.282

COMB 11 : COMB 2 + EQ-T -Seismic Dry Case

Unit Fv = 0.3 x C.g. of

Load Volume Vertical Load( FL = 0.3x αh FT = αh x P Long. Ecc. Transv. Ecc. MLs due to MTs due to

Loads Weights αv x P Force in ML = PxeL MLs due to FL MT = PxeT

Factor (m3) P ) kN. x P (kN) (kN) (eL) (m) (eT) (m) Fv FT

(kN/m3) (kN) Trans. (m)

Forces from Case 9 except

horizontal forces due to 16808.371 243.069 1664.197 392.329 2098.602 1205.983 65.892 -34.400 16903.465

superstructure

CWLL from left span 1 0.000 0.000 0.000 278.385 -0.875 0.000 0.000 0.000 0.000 0.000

CWLL(MAX) with Braking

1 241.917 26.131 6.160 278.385 0.875 211.677 5.390 1792.995 409.864

Vertical Reaction

Net Horizontal Force at Bearing 506.903 0.000 6159.120 0.000

Total 17050.287 749.971 1690.328 398.489 2310.279 7365.103 71.282 1758.595 17313.329

-398.489 -71.282

COMB 12 : COMB 3 + EQ-L -Seismic Dry Case

Unit Fv = 0.3 x C.g. of

Load Volume Vertical Load( FL = αh x P FT = 0.3 x αh Long. Ecc. Transv. Ecc. MLs due to MTs due to

Loads Weights αv x P Force in ML = PxeL MLs due to FL MT = PxeT

Factor (m3) P ) kN. (kN) x P (kN) (eL) (m) (eT) (m) Fv FT

(kN/m3) (kN) Trans. (m)

Forces from Case 8 except

horizontal forces due to 16808.371 810.229 499.259 392.329 2098.602 4019.943 65.892 -34.400 5071.040

superstructure

CWLL from left span 1 0.000 0.000 0.000 278.385 -0.875 0.000 0.000 0.000 0.000 0.000

CWLL(MAX) with Braking

1 182.933 5.928 4.658 278.385 0.875 160.066 4.076 2810.540 92.979

Vertical Reaction

Net Horizontal Force at Bearing 1805.653 0.000 21939.590 0.000

Total 16991.303 2615.882 505.187 396.987 2258.668 25959.532 69.968 2776.140 5164.019

-396.987 -69.968

COMB 13 : COMB 3 + EQ-T -Seismic Dry Case

Unit Fv = 0.3 x C.g. of

Load Volume Vertical Load( FL = 0.3x αh FT = αh x P Long. Ecc. Transv. Ecc. MLs due to MTs due to

Loads Weights αv x P Force in ML = PxeL MLs due to FL MT = PxeT

Factor (m3) P ) kN. x P (kN) (kN) (eL) (m) (eT) (m) Fv FT

(kN/m3) (kN) Trans. (m)

Forces from Case 9 except

horizontal forces due to 16808.371 243.069 1664.197 392.329 2098.602 1205.983 65.892 -34.400 16903.465

superstructure

CWLL from left span 1 0.000 0.000 0.000 278.385 -0.875 0.000 0.000 0.000 0.000 0.000

CWLL(MAX) with Braking

1 182.933 19.760 4.658 278.385 160.066 4.076 2810.540 309.931

Vertical Reaction 0.875

Net Horizontal Force at Bearing 506.903 0.000 6159.120 0.000

Total 16991.303 749.971 1683.957 396.987 2258.668 7365.103 69.968 2776.140 17213.396

-396.987 -69.968

NH-72A and NH-73 32 PIER-P3

Design Calculation ICT Stability of Foundation

Note: In Seismic Condition , Seismic Effect becomes 50% = 0.5

COMB 14 : DL+SIDL+EQ-L -one Span Dislodege Seismic case Left Span Dislodge Long. Moment Trans. Moment

Unit Fv = 0.3 x C.g. of

Load Volume Vertical Load( FL = αh x P FT = 0.3 x αh Long. Ecc. Transv. Ecc. MLs due to MTs due to

Loads Weights αv x P Force in ML = PxeL MLs due to FL MT = PxeT

Factor 3 (m3) P ) kN. (kN) x P (kN) (eL) (m) (eT) (m) Fv FT

(kN/m ) (kN) Trans. (m)

Superstructure-Right Span

Dead Load 1 5150.654 83.453 65.579 276.219 0.875 0.000 4506.822 57.382 0.000 1128.231

SIDL except Wearing Course 1 319.000 5.169 4.062 277.632 0.875 0.000 279.125 3.554 0.000 77.178

Wearing Course 1 530.636 8.598 6.756 277.210 0.875 0.000 464.306 5.912 0.000 124.751

Bearing Pedestal : Right Span 24.960 0.875 -0.577 21.840 -14.400

Seismic Arrestor 64.541 0.000 0.000 0.000 0.000

Substructure

Pier Cap 1 25 66.994 1674.844 106.623 27.137 21.325 273.556 0.000 0.000 0.000 1157.441 0.000 0.000 294.581

Additional weight of cap 515.039 32.788 8.345 6.558 273.556 -0.938 0.000 -482.849 355.930 0.000 90.588

Pier Shaft 1 25 22.670 566.743 36.080 9.183 7.216 269.145 0.000 0.000 0.000 232.533 0.000 0.000 59.182

Pile Cap 1 25 144.279 3606.975 229.624 58.442 45.925 263.850 0.000 0.000 0.000 264.068 0.000 67.208

Earth fill on pile cap 1 20 63.998 1279.959 0.000 0.000 0.000 0.000

Net Horizontal Force at Bearing 636.642 0.000 7735.524 0.000

TOTAL 13733.351 1041.757 200.325 157.420 4789.244 9745.496 66.847 -14.400 1841.719

-157.420 -66.847

COMB 15 : DL+SIDL+EQ-T -one Span Dislodege Seismic case Left Span Dislodge Long. Moment Trans. Moment

Unit Fv = 0.3 x C.g. of

Load Volume Vertical Load( FL = 0.3 x αh FT = αh x P Long. Ecc. Transv. Ecc. MLs due to MTs due to

Loads Weights αv x P Force in ML = PxeL MLs due to FL MT = PxeT

Factor 3 (m3) P ) kN. x P (kN) (kN) (eL) (m) (eT) (m) Fv FT

(kN/m ) (kN) Trans. (m)

Superstructure-Right Span

Dead Load 1 5150.654 278.177 65.579 276.219 0.875 0.000 4506.822 57.382 0.000 3760.771

SIDL except Wearing Course 1 319.000 17.229 4.062 277.632 0.875 0.000 279.125 3.554 0.000 257.259

Wearing Course 1 530.636 28.659 6.756 277.210 0.875 0.000 464.306 5.912 0.000 415.837

Bearing Pedestal : Right Span 24.960 0.875 -0.577 21.840 -14.400

Seismic Arrestor 64.541 0.000 0.000 0.000 0.000

Substructure

Pier Cap 1 25 66.994 1674.844 31.987 90.455 21.325 273.556 0.000 0.000 0.000 347.232 0.000 0.000 981.937

Additional weight of cap 515.039 9.836 27.816 6.558 273.556 -0.938 0.000 -482.849 106.779 0.000 301.960

Pier Shaft 1 25 22.670 566.743 10.824 30.609 7.216 269.145 0.000 0.000 0.000 69.760 0.000 0.000 197.273

Pile Cap 1 25 144.279 3606.975 68.887 194.806 45.925 263.850 0.000 0.000 0.000 79.220 0.000 224.027

Earth fill on pile cap 1 20 63.998 1279.959 0.000 0.000 0.000 0.000

Net Horizontal Force at Bearing 232.171 0.000 2820.998 0.000

TOTAL 13733.351 353.706 667.751 157.420 4789.244 3423.989 66.847 -14.400 6139.065

-157.420 -66.847

NH-72A and NH-73 33 PIER-P3

Design Calculation ICT Stability of Foundation

Centrifugal Force : Normal Case

Centrifugal Force (C.F.) = 1.00 x 0.00 = 0.00 KN

Transverse Moment due to C.F. = 0.000 x ( 278.500 - 262.700 ) = 0.00 kNm

Centrifugal Force : Seismic Case

Centrifugal Force (C.F.) = 1.00 x 0.00 = 0.000 KN

Transverse Moment due to C.F. = 0.000 x ( 278.500 - 262.700 ) = 0.000 kNm

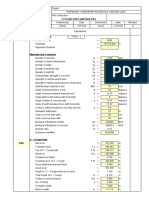

Summary of Forces at Pile Cap Bottom For Stability of Foundation

Resultant

CASE LOAD COMBINATION P (kN) ML (kNm) MT (kNm) FL (kN) FT (kN)

Force

COMB 1: DL+SIDL-Normal Dry Case 16808.4 4919.6 -34.4 232.17 0.00 232.17

Normal Case

COMB 2: DL+SIDL + LL(Maximum Reaction) -Normal Dry Case 18018.0 8744.7 1758.6 459.87 0.00 459.87

COMB 3: DL+SIDL + LL(Max Transverse Moment) -Normal Dry Case 17723.0 8486.6 2776.1 459.87 0.00 459.87

COMB 4 : DL+SIDL -one Span Dislodege Normal case 13733.4 7610.2 -14.4 232.17 0.00 232.17

COMB 5 : COMB 2 + WL -Normal Dry Case Down 18773.3 8149.6 11509.9 409.14 645.01 763.83

Up 17262.6 8106.9 11509.9

Wind Case

COMB 6: COMB 3 + WL -Wind Dry Case Down 18773.3 8149.6 11509.9 409.14 645.01 763.83

Up 17262.6 8106.9 11509.9

COMB 7 : DL+SIDL+WL -one Span Dislodege Wind case Down 14155.2 7923.4 8699.3 232.17 645.01 685.53

Up 13375.5 7241.1 8699.3

COMB 8 : COMB 1 + EQ-L -Seismic Dry Case Down 17200.7 27570.7 5036.6 2570.34 499.26 2618.38

Up 16416.0 27438.9 5036.6

COMB 9 : COMB 1 + EQ-T -Seismic Dry Case Down 17200.7 8976.3 16869.1 704.43 1664.20 1807.15

Up 16416.0 8844.5 16869.1

COMB 10 : COMB 2 + EQ-L -Seismic Dry Case Down 17448.8 28341.1 6952.6 2615.88 507.10 2664.58

Up 16651.8 28198.5 6952.6

Seismic Case

COMB 11 : COMB 2 + EQ-T -Seismic Dry Case Down 17448.8 9746.7 19071.9 749.97 1690.33 1849.23

Up 16651.8 9604.1 19071.9

COMB 12 : COMB 3 + EQ-L -Seismic Dry Case Down 17388.3 28288.2 7940.2 2615.88 505.19 2664.22

Up 16594.3 28148.2 7940.2

COMB 13 : COMB 3 + EQ-T -Seismic Dry Case Down 17388.3 9693.7 19989.5 749.97 1683.96 1843.41

Up 16594.3 9553.8 19989.5

COMB 14 : DL+SIDL+EQ-L -one Span Dislodege Seismic case Down 13890.8 14601.6 1827.32 1041.76 200.33 1060.84

Up 13575.9 14467.9 1827.32

COMB 15 : DL+SIDL+EQ-T -one Span Dislodege Seismic caseDown 13890.8 8280.1 6124.66 353.71 667.75 755.64

Up 13575.9 8146.4 6124.66

NH-72A and NH-73 34 PIER-P3

Design Calculation ICT Stability of Foundation

Calculation of Reaction at Pile

Arrangement of Vertical Pile Shaft

Nos. of Piles = 8 Nos. 0.75 1.8 1.8 0.75 PILE CAP

Pile No rLs rTs

1 1.800 5.400 0.75

2 1.800 1.800

3 1.800 -1.800 5 1

4 1.800 -5.400 12.30

5 -1.800 5.400 3.60 PILE

6 -1.800 1.800 L S 6

7 -1.800 -1.800 e p 2 R S

8 -1.800 -5.400 f a i p

t

9 0.000 0.000 t n 3.60 g a

10 0.000 0.000 h n

11 0.000 0.000

12 0.000 0.000 S rLs^2 = 25.920 m^2

13 0.000 0.000 S rTs^2 = 129.600 m^2

14 0.000 0.000 7 3

15 0.000 0.000

3.60

8 4

Load on each pile = P + MLs .rLs + MTs .rTs

n S rL^2 S rT^2 0.75

5.10

NH-72A and NH-73 35 PIER-P3

Design Calculation ICT Stability of Foundation

LOADS ON EACH PILE

Design Forces at Bottom of Cap Load on Each Pile Top

CASE LOAD COMBINATION P ML MT P1 P2 P3 P4 P5 P6 P7 P8

Normal Case

COMB 1: DL+SIDL-Normal Dry Case 16808 4920 -34 2441 2442 2443 2444 1758 1759 1760 1761

COMB 2: DL+SIDL + LL(Maximum Reaction) -Normal Dry Case 18018 8745 1759 2933 2884 2835 2786 1718 1669 1621 1572

COMB 3: DL+SIDL + LL(Max Transverse Moment) -Normal Dry Case 17723 8487 2776 2920 2843 2766 2689 1742 1665 1587 1510

COMB 4 : DL+SIDL -one Span Dislodege Normal case 13733 7610 -14 2245 2245 2245 2246 1188 1188 1188 1189

COMB 5 : COMB 2 + WL -Normal Dry Case Down 18773 8150 11510 3392 3072 2753 2433 2260 1941 1621 1301

Wind Case

Up 17263 8107 11510 3200 2881 2561 2241 2074 1755 1435 1115

COMB 6: COMB 3 + WL -Wind Dry Case Down 18773 8150 11510 3392 3072 2753 2433 2260 1941 1621 1301

Up 17263 8107 11510 3200 2881 2561 2241 2074 1755 1435 1115

COMB 7 : DL+SIDL+WL -one Span Dislodege Wind case Down 14155 7923 8699 2682 2440 2199 1957.2 1582 1340 1098 857

Up 13376 7241 8699 2537 2296 2054 1812.3 1532 1290 1048 807

COMB 8 : COMB 1 + EQ-L -Seismic Dry Case Down 17201 27571 5037 4275 4135 3995 3855 445 305 166 26

Up 16416 27439 5037 4167 4027 3888 3748 356 216 77 -63

COMB 9 : COMB 1 + EQ-T -Seismic Dry Case Down 17201 8976 16869 3476 3008 2539 2071 2230 1761 1292 824

Up 16416 8844 16869 3369 2900 2432 1963 2141 1672 1204 735

COMB 10 : COMB 2 + EQ-L -Seismic Dry Case Down 17449 28341 6953 4439 4246 4053 3860 503 310 116 -77

Up 16652 28199 6953 4329 4136 3943 3750 413 220 27 -166

Seismic Case

COMB 11 : COMB 2 + EQ-T -Seismic Dry Case Down 17449 9747 19072 3653 3123 2593 2063 2299 1769 1239 710

Up 16652 9604 19072 3543 3013 2484 1954 2209 1679 1150 620

COMB 12 : COMB 3 + EQ-L -Seismic Dry Case Down 17388 28288 7940 4469 4248 4028 3807 540 319 99 -122

Up 16594 28148 7940 4360 4139 3919 3698 450 230 9 -211

COMB 13 : COMB 3 + EQ-T -Seismic Dry Case Down 17388 9694 19990 3680 3124 2569 2014 2333 1778 1223 667

Up 16594 9554 19990 3571 3015 2460 1905 2244 1688 1133 578

COMB 14 : DL+SIDL+EQ-L -one Span Dislodege Seismic case Down 13891 14602 1827 2826 2776 2725 2674 798 748 697 646

Up 13576 14468 1827 2778 2727 2676 2626 768 718 667 616

COMB 15 : DL+SIDL+EQ-T -one Span Dislodege Seismic caseDown 13891 8280 6125 2567 2396 2226 2056 1417 1246 1076 906

Up 13576 8146 6125 2518 2348 2178 2008 1386 1216 1046 876

NH-72A and NH-73 36 PIER-P3

Design Calculation ICT Stability of Foundation

Load on Each Pile Top

Check For Check For Check For

Max Min Max

CASE LOAD COMBINATION Vertical Min Reaction Uplift Resultant Force Max Horizontal

Reaction Reaction Reaction

Capacity Capacity (kN) Capacity

Normal Case

COMB 1: DL+SIDL-Normal Dry Case 2444 1758 29

COMB 2: DL+SIDL + LL(Maximum Reaction) -Normal Dry Case 2933 1572 57

2933 SAFE 1188 SAFE 57 SAFE

COMB 3: DL+SIDL + LL(Max Transverse Moment) -Normal Dry Case 2920 1510 57

COMB 4 : DL+SIDL -one Span Dislodege Normal case 2246 1188 29

COMB 5 : COMB 2 + WL -Normal Dry Case Down 3392 1301 95

Wind Case

Up 3200 1115

COMB 6: COMB 3 + WL -Wind Dry Case Down 3392 1301 95

3392 SAFE 807 SAFE 95

Up 3200 1115

COMB 7 : DL+SIDL+WL -one Span Dislodege Wind case Down 2682 857 86

Up 2537 807

COMB 8 : COMB 1 + EQ-L -Seismic Dry Case Down 4275 26 327

Up 4167 -63

COMB 9 : COMB 1 + EQ-T -Seismic Dry Case Down 3476 824 226

Up 3369 735

COMB 10 : COMB 2 + EQ-L -Seismic Dry Case Down 4439 -77 333

Up 4329 -166

Seismic Case

COMB 11 : COMB 2 + EQ-T -Seismic Dry Case Down 3653 710 231

3543 620 4469 SAFE -211 SAFE 333

COMB 12 : COMB 3 + EQ-L -Seismic Dry Case Down 4469 -122 333

4360 -211

COMB 13 : COMB 3 + EQ-T -Seismic Dry Case Down 3680 667 230

3571 578

COMB 14 : DL+SIDL+EQ-L -one Span Dislodege Seismic case Down 2826 646 133

Up 2778 616

COMB 15 : DL+SIDL+EQ-T -one Span Dislodege Seismic case Down 2567 906 94

Up 2518 876

As this pier is in vicinity of rail track, the approximate 15% load on pile to cater the load from rail has been considered

Hence Maximum Reaction of the pile = 1.15 x 2933 KN = 3372.70 KN SAFE Normal Case

Max Rection on Pile = 3541.34 Normal Case 5 % Extra load has been considered

= 4692.27 Seismic Case

NH-72A and NH-73 37 PIER-P3

Design Calculation ICT Length of Fixity

Computation for length of fixity As per IS : 2911 (part 1/ sec2)

Le = Embedded length of pile below Pile cap bottom = 262.700 - 236.700 = 26.000 m

Pile cap

bottom MSL

Exposed length L1 = 262.700 0.000 = 0.00 m 0 cm

For 1.2 m dia piles

I = p x 120.00 ^4 = 10178760 cm^4

64

Material Properties:

2

Grade of Concrete = M 35 fck= 35.00 N/mm

2

Grade of Steel = Fe 500 fyk= 500.00 N/mm

2 2

E = 29580.40 N/mm = 301533 Kg/cm

2

E = 5000 x 35 = 29580 N/mm^2 = 301533 Kg/cm

E is the Young's modulus of the pile material in kg/cm^2

I is the Moment of Inertia of the pile cross section in cm^4

Length of Fixity as per (Appendix C) cl. 5.5.2 of IS :2911(Part I/Sec 2)-2010

For Sandy Strata

N = 19.000

nh = 0.269 Kg/cm3 (Medium Sand-Dry)

T = 4.09 m

Avg. Cohesion, C = 0.84 Kg/cm2 As per Geotechnical Report

3

Unconfined Compressive strength = 1.68 Kg/cm

K1 = 30.00 Kg/cm2 clayey

K = K1 / 1.5 x 0.3 / D = 5.000

Stiffnes Factor , R = 4.087

Governing Value of T/R = 4.09 (Medium Sand-Dry)

For Rock Strata

Pile cap bottom level = 262.70 m

Rock level = 0.00 m

Length of pile in soil, Ls = 262.70 m

Ls/R = 64.27 > 4

Q Q

2.3 FREE HEAD PILE

L1 = L1

FIXED HEAD PILE

2.1 Le

Le

1.9 FOR PILES IN SANDS

AND NORMALLY LOADED CLAYS

Lf /R OR Lf/T

1.7

1.5

FOR PILES IN PRELOADED CLAYS

1.3

0 2 4 6 8 10

L1 /R OR L1 /T

NH-72A and NH-73 38 PIER-P3

Design Calculation ICT Length of Fixity

For L1 /T OR L1/R = 0.00 (Medium Sand-Dry)

Hence from above Fig.

Lf/T = 2.190 For Fixed Head Pile

Lf = 2.1900 x 4.09 = 8.95 m

Governing Lf = 8.95 m

Lf = 8.952 x 100.00 = 895.16 cm

Equivalent length of cantilever = L1+ Lf = 0.00 + 895.16 = 8.95 m

cm cm

A = p x 120.00 ^2 = 11309.7 cm^2

4

Least radius of gyration = I = 30 cm

A

Effective length = 895.16 cm

Resultant Horizontal Force= 57 KN

Deflection at Pile Tip = 1.120 mm

Deflection at Scouring Level = 1.120 mm

< 12mm OK

NH-72A and NH-73 39 PIER-P3

Design Calculation ICT Forces For Found. Design

Calculation of Forces For Foundation Design

Pile Cap bottom Lvl = 262.70 m Bearing top Level = 274.851 m

COMB 1: DL+SIDL-Normal Dry Case

Unit Vertical

Volume Long. Ecc. Transv. Ecc.

Loads Load Factor Weights Load( P ) FL (kN) FT (kN) ML = PxeL MT = PxeT

(m3) (eL) (m) (eT) (m)

(kN/m3) kN.

Superstructure-Left Span

Dead Load 1.35 2926.758 -0.875 0.000 -2560.913 0.000

SIDL except Wearing Course 1.35 549.451 -0.875 0.000 -480.770 0.000

Wearing Course 1.75 819.088 -0.875 0.000 -716.702 0.000

Superstructure-Right Span

Dead Load 1.35 6953.383 0.875 0.000 6084.210 0.000

SIDL except Wearing Course 1.35 430.650 0.875 0.000 376.819 0.000

Wearing Course 1.75 928.613 0.875 0.000 812.536 0.000

Bearing Pedestal : Left Span 1.35 25 1.280 43.200 -0.875 -0.625 -37.800 -27.000

Bearing Pedestal : Right Span 1.35 25 0.998 33.696 0.875 -0.577 29.484 -19.440

Seismic arrestor: Left Span

Long. Arrestor 1.35 25 1.190 40.163 0.000 0.000 0.000 0.000

Transverse arrestor 1.35 25 0.574 19.379 0.000 0.000 0.000 0.000

Seismic arrestor: Right Span

Long. Arrestor 1.35 25 0.000 0.000 0.875 0.000 0.000 0.000

Transverse arrestor 1.35 25 0.817 27.589 0.000 0.000 0.000 0.000

Substructure

Pier Cap 1.35 25 66.994 2261.039 0.000 0.000 0.000 0.000

Additional weight of cap 1.35 25 20.602 695.303 -0.938 0.000 -651.846 0.000

Pier Shaft 1.35 25 22.670 765.103 0.000 0.000 0.000 0.000

Pile Cap 1.35 25 144.279 4869.416 0.000 0.000 0.000 0.000

Earth fill on pile cap 1.35 20 63.998 1727.945 0.000 0.000 0.000 0.000

Net Horizontal Force at Bearing 232.171 0.000 2820.998 0.000

Total 23090.775 232.171 0.000 5676.016 -46.440

COMB 2: DL+SIDL + LL(Maximum Reaction) -Normal Dry Case

Unit Vertical

Volume Long. Ecc. Transv. Ecc.

Loads Load Factor Weights Load( P ) FL (kN) FT (kN) ML = PxeL MT = PxeT

3 (m3) (eL) (m) (eT) (m)

(kN/m ) kN.

Forces from Case 1 except

horizontal forces due to 23090.775 0.000 0.000 2855.018 -46.440

superstructure

CWLL from left span 1.5 0.00 -0.875 0.000 0.000

CWLL(MAX) with Braking

1.5 1814.376 0.875 1587.579 2689.492

Vertical Reaction

Net Horizontal Force at Bearing 573.721 0.000 6971.001 0.000

Total 24905.151 573.721 0.000 11413.598 2643.052

NH-72A and NH-73 40 PIER-P3

Design Calculation ICT Forces For Found. Design

COMB 3: DL+SIDL + LL(Max Transverse Moment) -Normal Dry Case

Unit Vertical

Volume Long. Ecc. Transv. Ecc.

Loads Load Factor Weights Load( P ) FL (kN) FT (kN) ML = PxeL MT = PxeT

3 (m3) (eL) (m) (eT) (m)

(kN/m ) kN.

Forces from Case 1 except

horizontal forces due to 23090.775 0.000 0.000 2855.018 -46.440

superstructure

CWLL from left span 1.5 0.00 -0.875 0.000 0.000

CWLL(MAX) with Braking

1.5 1371.995 0.875 1200.496 4215.811

Vertical Reaction

Net Horizontal Force at Bearing 573.721 0.000 6971.001 0.000

Total 24462.770 573.721 0.000 11026.515 4169.371

COMB 4 : DL+SIDL -one Span Dislodege Normal case

Unit Vertical

Volume Long. Ecc. Transv. Ecc.

Loads Load Factor Weights Load( P ) FL (kN) FT (kN) ML = PxeL MT = PxeT

(m3) (eL) (m) (eT) (m)

(kN/m3) kN.

Superstructure-Right Span

Dead Load 1.35 6953.383 0.875 0.000 6084.210 0.000

SIDL except Wearing Course 1.35 430.650 0.875 0.000 376.819 0.000

Wearing Course 1.75 928.613 0.875 0.000 812.536 0.000

Bearing Pedestal : Right Span 1.35 25 0.998 33.696 0.875 -0.577 29.484 -19.440

Seismic arrestor 1.35 27.589 0.000 0.000 0.000 0.000

Substructure

Pier Cap 1.35 25 66.994 2261.039 0.000 0.000 0.000 0.000

Additional weight of cap 1.35 25 20.602 695.303 -0.938 0.000 -651.846 0.000

Pier Shaft 1.35 25 22.670 765.103 0.000 0.000 0.000 0.000

Pile Cap 1.35 25 144.279 4869.416 0.000 0.000 0.000 0.000

Earth fill on pile cap 1.35 20 63.998 1727.945 0.000 0.000 0.000 0.000

Net Horizontal Force at Bearing 232.171 0.000 2820.998 0.000

Total 18692.736 232.171 0.000 9472.200 -19.440

NH-72A and NH-73 41 PIER-P3

Design Calculation ICT Forces For Found. Design

COMB 5 : COMB 2 + WL -Normal Dry Case Long. Moment Trans. Moment

Unit Vertical Transv.

Volume C.g. of Long. Ecc. ML due to MT due to

Loads Load Factor Weights Load( P ) FL (kN) FT (kN) Ecc. (eT) ML = PxeL MT = PxeT

(m3) Force (m) (eL) (m) FL FT

(kN/m3) kN. (m)

Superstructure-Left Span

Dead Load 1.35 2926.758 -0.875 0.000 -2560.913 0.000

SIDL except Wearing Course 1.35 549.451 -0.875 0.000 -480.770 0.000

Wearing Course 1.75 819.088 -0.875 0.000 -716.702 0.000

Superstructure-Right Span

Dead Load 1.35 6953.383 0.875 0.000 6084.210 0.000

SIDL except Wearing Course 1.35 430.650 0.875 0.000 376.819 0.000

Wearing Course 1.75 928.613 0.875 0.000 812.536 0.000

Bearing Pedestal : Left Span 1.35 25 1.280 43.200 -0.875 -0.625 -37.800 -27.000

Bearing Pedestal : Right Span 1.35 25 0.998 33.696 0.875 -0.577 29.484 -19.440

Seismic arrestor 1.35 87.130 0.000 0.000 0.000 0.000

Substructure

Pier Cap 1.35 2261.039 0.000 11.368 273.56 0.000 0.000 0.000 0.00 0.000 123.40

Additional weight of cap 1.35 25 20.602 695.303 -0.938 0.000 -651.846 0.000

Pier Shaft 1.35 765.103 0.000 16.091 269.15 0.000 0.000 0.000 0.00 0.000 103.70

Pile Cap 1.35 4869.416 0.000 0.000 0.000 0.000

Earth fill on pile cap 1.35 1727.945 0.000 0.000 0.000 0.000

Wind Load 0.9 391.445 553.054 276.50 4756.250 7633.232

Wind Down from Left Span 328.932 -0.875 -287.816