Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Plate Girder

Caricato da

Anonymous sfkedkymDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Plate Girder

Caricato da

Anonymous sfkedkymCopyright:

Formati disponibili

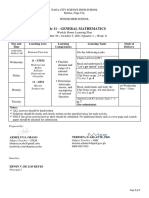

WIDTH

FLANGE WEB I XX Z XX R XX I YY RYY

8 DESIGNATION WEIGHT AREA DEPTH OF J

THK THK

FLANGE

T/m cm² mm mm mm mm cm4 cm3 cm cm4 cm cm4

1 2 3 4 5 6 7 8 9 10 11 12 13 14

1 ISWB 600 0.1423 184.9 600 250 23.6 11.8 115626.6 3854.2 25.01 5298.3 5.35 249.3

2 ISMB 600 0.121 156.2 600 210 20.8 12 91813 3060.4 24.24 2651 4.12 158.1

3 ISWB 550 0.1104 143.3 550 250 17.6 10.5 73906.1 2723.9 22.86 3740.6 5.11 110.7

4 ISLB 600 0.0976 126.7 600 210 15.5 10.5 72867.6 2428.9 23.98 1821.9 3.79 74.1

5 ISMB 550 0.0107 132.1 550 190 19.3 11.2 64893.6 2359.8 22.16 1833.8 3.73 115

6 ISWB 500 0.0934 121.2 500 250 14.7 9.2 52290.9 2091.6 20.77 2987.8 4.96 68.2

7 ISLB 550 0.0847 110 550 190 15 9.9 53161.6 1933.2 21.99 1335.1 3.48 59.6

8 ISMB 500 0.0852 110.7 500 180 17.2 10.2 45218.3 1808.7 20.21 1369.8 3.52 77.5

9 ISWB 450 0.0779 101.2 450 200 15.4 9.2 35057.6 1558.4 18.63 1706.7 4.11 59.6

10 ISLB 500 0.0736 95.5 500 180 14.1 9.2 38579 1543.2 20.1 1063.9 3.34 45.9

11 ISMB 450 0.071 92.27 450 150 17.4 9.4 30390.8 1350.7 18.15 834 3.01 64.2

12 ISLB 450 0.0641 83.14 450 170 13.4 8.6 27536.1 1223.8 18.2 853 3.2 36.2

13 ISWB 400 0.0654 85.01 400 200 13 8.6 23426.7 1171.3 16.6 1388 4.04 37.2

14 ISMB 400 0.0604 78.46 400 140 16 8.9 20458.4 1022.9 16.15 622.1 2.82 46.9

15 ISLB 400 0.0558 72.43 400 165 12.5 8 19306.3 965.3 16.33 716.4 3.15 27.9

16 ISWB 350 0.0558 72.5 350 200 11.4 8 15521.7 887 14.63 1175.9 4.03 25.3

17 ISMB 350 0.0514 66.71 350 140 14.2 8.1 13630.3 778.9 14.29 537.7 2.84 32.4

18 ISLB 350 0.0486 63.01 350 165 11.4 7.4 13158.3 751.9 14.45 631.9 3.17 20.7

19 ISWB 300 0.0472 61.33 300 200 10 7.4 9821.6 654.8 12.66 990.1 4.02 17.1

20 ISLB 325 0.0423 54.9 325 165 9.8 7 9874.4 6.7.7 13.41 510.8 3.05 13.8

21 ISMB 300 0.0452 56.26 300 140 12.4 7.5 8603.6 573.6 12.37 453.9 2.84 21.7

22 ISLB 300 0.037 48.08 300 150 9.4 6.7 7332.9 488.9 12.35 376.2 2.8 11.1

23 ISWB 250 0.0401 52.05 250 200 9 6.7 5943.1 475.4 10.69 857.5 4.06 12

24 ISMB 250 0.0365 47.55 250 125 12.5 6.9 5131.6 410.5 10.39 334.5 2.65 18.7

25 ISLB 275 0.0324 42.02 275 140 8.8 6.4 5375.3 392.4 11.31 287 2.61 8.6

26 ISWB 225 0.0333 43.24 225 150 9.9 6.4 3920.5 348.6 9.52 448.6 3.22 11.5

27 ISMB 225 0.0306 39.72 225 110 11.8 6.5 3441.8 305.9 9.31 218.3 2.34 13.9

28 ISLB 250 0.0274 35.53 250 125 8.2 6.1 3717.8 297.4 10.23 193.4 2.33 6.4

29 ISWB 200 0.0283 36.71 200 140 9 6.1 2624.5 262.5 8.46 382.8 2.99 8.2

30 ISMB 200 0.0249 32.33 200 100 10.8 5.7 2235.4 223.5 8.32 150 2.15 9.5

31 ISLB 225 0.0231 29.92 225 100 8.6 5.8 2501.9 222.4 9.15 112.7 1.94 5.6

WIDTH

FLANGE WEB I XX Z XX R XX I YY RYY

8 DESIGNATION WEIGHT AREA DEPTH OF J

THK THK

FLANGE

T/m cm² mm mm mm mm cm4 cm3 cm cm4 cm cm4

1 2 3 4 5 6 7 8 9 10 11 12 13 14

32 ISWB 175 0.0217 28.11 175 125 7.4 5.8 1509.4 172.5 7.33 188.6 2.59 4.4

33 ISLB 200 0.0194 25.27 200 100 7.3 5.4 1696.6 169.7 8.19 115.4 3.13 3.6

34 ISBM 175 0.0191 24.62 175 90 8.6 5.5 1272 145.3 7.19 85 1.86 4.7

35 ISLB 175 0.0164 21.3 175 90 6.9 5.1 1096.2 125.3 7.17 79.6 1.93 2.7

36 ISJB 225 0.0126 16.28 225 80 5 3.7 1308.5 116.3 8.97 43.5 1.58 1

37 ISWB 150 0.0167 21.67 150 100 7 5.4 839.1 111.9 6.22 94.8 2.09 3

38 ISMB 150 0.0146 19 150 80 7.6 4.8 726.4 96.9 6.18 52.6 1.66 2.8

39 ISLB 150 0.0139 18.08 150 80 6.8 4.8 688.2 91.8 6.17 55.2 1.75 2.2

PLEASE INPUT SECTIONAL PROPORTIES:

INPUT DATA IN

ISMB 500 GREEN CELLS

ONLY

MAIN MEMBER NO

BC1

AX Cross Sectional Area (cm )

2

= 110.74

D Depth of the Section (cm) = 50.00

TD Thickness of Web (cm) = 1.02

B Width of Section (cm) = 18.00

TB Flange thickness (cm) = 1.72 d1 = 180.00

IZ Moment of Inertia about zz axis (cm )

4

= 45218.30 t = 10.20

IY Moment of Inertia about yy axis (cm )

4

= 1369.80 d1 / t = 17.64706

IX Torsional Inertia (cm )

4

= 77.50

SZ Section Modulus about local zz axis (cm3) = 1808.70

SY Section Modulus about local yy axis (cm3) = 152.20

Rmin of Main Component (cm) = 3.52

LENGTH OF MEMBER = 4 (m)

MAXIMUM AXIAL FORCE = 4 (T)

MOMENT = 40 (T-m)

Rivets Connecting

1. Angles with Vertical Plates = 22 (mm)

Yield Stress of Steel = 23.6 (Kg/mm2)

P = (Table - III, IRC: 24) = 16.5 (Kg/mm2)

m, Load Factor, IRC 24, Cl. 504.4.1 = 1.82

E, IRC 24, Cl. 504.4.1 = 21100 (Kg/mm2)

Permissible Compressive Stress = 1410 (Kg/cm2)

Permisssible Bending Stress = 1500.00 (Kg/cm2)

mm

mm

DESIGN OF PLATE GIRDER

Axial Load (Tensile) = 4000 Kg.

Net Area Required = 4000 / 1410

= 2.8368794

RZ = 20.21 CMS

RY = 3.52 CMS

Net Area of the Member = 110.74 > 2.836879

OK

Effective Length of Member = 0.85x400

= 340 CMS

L / RMIN = 340 / 3.52

= 96.6

L / Rz = 340 / 20.21

= 16.8

Distance between tacking rivets = 163.2 mm

Check as a Bending Member

86.93 Kg/m Run

400 cms

173.86 + 40000 KG-M

Self Weight as Uniformly Distributed Load (Kg/m)

= 0.01107 x 7850

= 86.93 Kg/m Run

Maximum Bending Moment at Mid Span

= 86.9309 x 4 x 4 / 8+ 40000

= 40173.862 KG-M HOGGING MOMENT

Bending Stress at Top

= 4017386 / 1809

= 2221.15 Kg/cm2

Actual / Permissible

Bending Stress = 2221.15 / 1500.00

= 1.4807638

Sum of Ratios = 0.03 + 1.480764

= 1.51 > 1

NOT OK

Calculation for Permissible Stresses as Specified in IRC : 24

l/r 16.5 24.8 22.6 20.2

0 14 21 19.15 17.12

20 13.6 20.4 18.6 16.7

40 13 19 17.4 15.7

60 11.8 16.2 15.16 13.9

80 10.1 12.55 12.03 11.35

100 8.05 9.27 9.02 8.7

120 6.3 6.9 6.8 6.62

140 4.94 5.26 5.2 5.12

160 3.9 4.11 4.07 4.01

L/R MIN = 96.59

80 = 10.1

100 = 8.05

Pac = 8.40 Kg / mm2 Permissible Direct Compressive Stress

Potrebbero piacerti anche

- Right Gravity Wall - With Hydrodynamic - 30.09.2019Documento106 pagineRight Gravity Wall - With Hydrodynamic - 30.09.2019Nishant SarrafNessuna valutazione finora

- Determine The Bearing Plate DimensionsDocumento9 pagineDetermine The Bearing Plate DimensionsNiranjan ShresthaNessuna valutazione finora

- Code of Practice For The Design of Sub-Structures and Foundations of BridgesDocumento64 pagineCode of Practice For The Design of Sub-Structures and Foundations of BridgesNeha Singh100% (1)

- Comparative Study of RCC T-Beam Bridge byDocumento32 pagineComparative Study of RCC T-Beam Bridge byPranay Reddy100% (2)

- Load Calculation: Static Water PressureDocumento18 pagineLoad Calculation: Static Water PressureSheikh Mizanur RahmanNessuna valutazione finora

- Cross Section Properties (All Dimensions Are in CMS)Documento2 pagineCross Section Properties (All Dimensions Are in CMS)Hanamantrao KhasnisNessuna valutazione finora

- Design of Cantilever Slab As Per IS 456 2000Documento2 pagineDesign of Cantilever Slab As Per IS 456 2000Ram LangheNessuna valutazione finora

- PIER30PSC - 14.10m RCCDocumento5 paginePIER30PSC - 14.10m RCCBasava SowmyaNessuna valutazione finora

- AmitDocumento46 pagineAmitsairam saiNessuna valutazione finora

- Steel TableDocumento41 pagineSteel Tablechirag0102Nessuna valutazione finora

- PR AQ 08 Aqueduct PierDocumento30 paginePR AQ 08 Aqueduct PiernasaritaNessuna valutazione finora

- Palwal Tappal Aligarh Road SH-22A: Calculation Report - Abutment A1 Substructure Foundation For MNBR AT CH.-76+390Documento52 paginePalwal Tappal Aligarh Road SH-22A: Calculation Report - Abutment A1 Substructure Foundation For MNBR AT CH.-76+390CHANDAN VATSNessuna valutazione finora

- BEAMDocumento7 pagineBEAMAnonymous sfkedkym100% (1)

- 1.design ConditionDocumento22 pagine1.design Conditionakshay magarNessuna valutazione finora

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Documento4 pagineF To G: 1 To 2: Spreadsheets To BS 8110 & EC2JigarNessuna valutazione finora

- Intze Water TankDocumento13 pagineIntze Water TankPratikNessuna valutazione finora

- DSR 2007Documento41 pagineDSR 2007lalitNessuna valutazione finora

- SdaaDocumento78 pagineSdaaAnonymous wosn1lyNessuna valutazione finora

- Portal Frame6 Trial - SBCDocumento322 paginePortal Frame6 Trial - SBCVenkat PalliNessuna valutazione finora

- Abutment WallDocumento14 pagineAbutment WallKhan EngrNessuna valutazione finora

- Technical Checks of Structural Members in Bridges Piles: Sl. No. DescriptionDocumento6 pagineTechnical Checks of Structural Members in Bridges Piles: Sl. No. DescriptionAshutosh RawatNessuna valutazione finora

- Lne BemDocumento3 pagineLne BemANKUR MAURYANessuna valutazione finora

- Pipe Culvert Quantity Estimation and Schedule - Mozambique by PassDocumento100 paginePipe Culvert Quantity Estimation and Schedule - Mozambique by PassEskinderNessuna valutazione finora

- 00 - PSC 35m Span Design Document PDFDocumento57 pagine00 - PSC 35m Span Design Document PDFjuliyet strucNessuna valutazione finora

- Class A LoadingDocumento120 pagineClass A LoadingAakash RastogiNessuna valutazione finora

- Box Girder Reinf QtyDocumento19 pagineBox Girder Reinf Qtyarif_rubinNessuna valutazione finora

- Input: Design of Precast Prestressed Composite Beams Check of Critical SectionDocumento3 pagineInput: Design of Precast Prestressed Composite Beams Check of Critical SectionLuis Francisco Coste AriasNessuna valutazione finora

- IrcDocumento9 pagineIrcAshwani KesharwaniNessuna valutazione finora

- 14 C - BridgesDocumento4 pagine14 C - Bridgesgurumurthy38Nessuna valutazione finora

- Design of Solid SlabDocumento819 pagineDesign of Solid SlabMahendra Suryavanshi0% (1)

- VUP DesignDocumento3 pagineVUP DesignAnonymous 4emDZITjoNessuna valutazione finora

- Post-Tensioning Format For Pc-Girder General InformationDocumento1 paginaPost-Tensioning Format For Pc-Girder General InformationTirthajit RoyNessuna valutazione finora

- Appendix 5 RC Pier DesignDocumento11 pagineAppendix 5 RC Pier DesignebsiNessuna valutazione finora

- Dog Legged Staircase 463Documento2 pagineDog Legged Staircase 463errinchenw100% (1)

- 05.06 Duct Supports DS-06 Base PlateDocumento2 pagine05.06 Duct Supports DS-06 Base Platehighway20049922Nessuna valutazione finora

- Two Way Slabs PDFDocumento5 pagineTwo Way Slabs PDFmathuNessuna valutazione finora

- Design of Substructure Abutment Pile ch.44+801km, 2x30mDocumento77 pagineDesign of Substructure Abutment Pile ch.44+801km, 2x30mLalit ChoudharyNessuna valutazione finora

- 09 Diagrama ND X MDDocumento8 pagine09 Diagrama ND X MDPedro CesarNessuna valutazione finora

- Design FoundationDocumento29 pagineDesign FoundationVenkat PalliNessuna valutazione finora

- Optimization PSC Bridge An ExampleDocumento13 pagineOptimization PSC Bridge An Exampleani4576Nessuna valutazione finora

- Shear Hinge For Coupling BeamDocumento7 pagineShear Hinge For Coupling BeamLavender HoneyNessuna valutazione finora

- Study On Building Structures With Sloping Ground Under Seismic and Wind Load ConditionsDocumento4 pagineStudy On Building Structures With Sloping Ground Under Seismic and Wind Load ConditionsEditor IJTSRDNessuna valutazione finora

- Basic Data: Scour DepthDocumento6 pagineBasic Data: Scour Depthvishal guptaNessuna valutazione finora

- ULS ChecksDocumento3 pagineULS ChecksVenkata MayurNessuna valutazione finora

- The World Bank: Uttarakhand Disaster Recovery ProjectDocumento14 pagineThe World Bank: Uttarakhand Disaster Recovery Projectvicky rawatNessuna valutazione finora

- LL On Box Calculation - H&HDocumento12 pagineLL On Box Calculation - H&HSreedhar BhuduruNessuna valutazione finora

- Anchorage N Lap LengthDocumento123 pagineAnchorage N Lap LengthPrabhakaran KarunanithiNessuna valutazione finora

- Design of End DiaphragmDocumento16 pagineDesign of End DiaphragmPraveen CyssanNessuna valutazione finora

- Design of Pier Wall: ParametersDocumento5 pagineDesign of Pier Wall: ParametersChris Angelo G CaadlawonNessuna valutazione finora

- Cable Coordinates PSC CompositeDocumento4 pagineCable Coordinates PSC CompositekesharinareshNessuna valutazione finora

- L&T Construction Transportation Infrastructure: Design of Shear ConnectorDocumento4 pagineL&T Construction Transportation Infrastructure: Design of Shear ConnectorMohak NagraniNessuna valutazione finora

- Collapse analysis of externally prestressed structuresDa EverandCollapse analysis of externally prestressed structuresNessuna valutazione finora

- Standard Section Properties TabulatedDocumento23 pagineStandard Section Properties TabulatedILYAS HUSSAINNessuna valutazione finora

- TPL-KIPL JVKARNALSTP-20CDD017 SLUDGE THICKNER 27-12-18 PART 1 - ClientDocumento314 pagineTPL-KIPL JVKARNALSTP-20CDD017 SLUDGE THICKNER 27-12-18 PART 1 - Clientnavneet3bawaNessuna valutazione finora

- Structural Surface Area CalculationDocumento12 pagineStructural Surface Area CalculationJoseph DarwinNessuna valutazione finora

- Weight Calculations Specific Weight (G/CM)Documento15 pagineWeight Calculations Specific Weight (G/CM)Ranjeet Kumar ThakurNessuna valutazione finora

- 10 Design of Gantry GirderDocumento10 pagine10 Design of Gantry GirderutsavNessuna valutazione finora

- Combine Section PropertiesDocumento14 pagineCombine Section Propertiesvineetkothari1Nessuna valutazione finora

- Beam Cantiliever CalculationDocumento16 pagineBeam Cantiliever CalculationAnonymous sfkedkymNessuna valutazione finora

- Bolted Splice DesignDocumento8 pagineBolted Splice DesignAnonymous sfkedkymNessuna valutazione finora

- 40t Rope Drum Hoist220512Documento37 pagine40t Rope Drum Hoist220512Anonymous sfkedkymNessuna valutazione finora

- Connection 1Documento22 pagineConnection 1Anonymous sfkedkymNessuna valutazione finora

- Design v. PasteDocumento4 pagineDesign v. PasteAnonymous sfkedkymNessuna valutazione finora

- Calories Protine Break Fast 4 Eggs 68 14.4 Milk 150 9.75 Rusk 135Documento1 paginaCalories Protine Break Fast 4 Eggs 68 14.4 Milk 150 9.75 Rusk 135Anonymous sfkedkymNessuna valutazione finora

- Calculations of Moment of Inertia Comp. Width Depth X-Datum Y-DatumDocumento7 pagineCalculations of Moment of Inertia Comp. Width Depth X-Datum Y-DatumAnonymous sfkedkymNessuna valutazione finora

- Compression Design Section1Documento10 pagineCompression Design Section1Anonymous sfkedkymNessuna valutazione finora

- Tension Design Section5Documento8 pagineTension Design Section5Anonymous sfkedkymNessuna valutazione finora

- Compression Design Section2Documento10 pagineCompression Design Section2Anonymous sfkedkymNessuna valutazione finora

- Design Calculation For Solar PanelDocumento7 pagineDesign Calculation For Solar PanelAnonymous sfkedkymNessuna valutazione finora

- BEAMDocumento7 pagineBEAMAnonymous sfkedkym100% (1)

- Roof Truss DesignDocumento7 pagineRoof Truss DesignAnonymous sfkedkymNessuna valutazione finora

- Bolted Splice DesignDocumento8 pagineBolted Splice DesignAnonymous sfkedkymNessuna valutazione finora

- Bolted Splice DesignDocumento8 pagineBolted Splice DesignAnonymous sfkedkymNessuna valutazione finora

- 36 MTR SpanDocumento13 pagine36 MTR SpanAnonymous sfkedkymNessuna valutazione finora

- Design Calculations For Solar Panel: Purlin Design Bracing Design Column Design Rafter Design QuantityDocumento19 pagineDesign Calculations For Solar Panel: Purlin Design Bracing Design Column Design Rafter Design QuantityAnonymous sfkedkym100% (2)

- Bill of Material For Rob of 18 MTR Span (Godhra-Mp/Gujrat Border Section) (CH 171+300) (For One Set)Documento6 pagineBill of Material For Rob of 18 MTR Span (Godhra-Mp/Gujrat Border Section) (CH 171+300) (For One Set)Anonymous sfkedkymNessuna valutazione finora

- Project RealDocumento4 pagineProject RealKenneth Jay BagandoNessuna valutazione finora

- RUBEEEEDocumento44 pagineRUBEEEEAhlyssa de JorgeNessuna valutazione finora

- SDS SheetDocumento8 pagineSDS SheetΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣNessuna valutazione finora

- EikonTouch 710 ReaderDocumento2 pagineEikonTouch 710 ReaderShayan ButtNessuna valutazione finora

- General Mathematics - Module #3Documento7 pagineGeneral Mathematics - Module #3Archie Artemis NoblezaNessuna valutazione finora

- Case KohortDocumento37 pagineCase KohortNasir AhmadNessuna valutazione finora

- MAT 120 NSU SyllabusDocumento5 pagineMAT 120 NSU SyllabusChowdhury_Irad_2937100% (1)

- Ucharistic Doration: Eucharistic Adoration During MassDocumento2 pagineUcharistic Doration: Eucharistic Adoration During Masstojo116732Nessuna valutazione finora

- Thompson VarelaDocumento18 pagineThompson VarelaGiannis NinosNessuna valutazione finora

- DataSheet CertificationPaths InsuranceSuite AnalystsDocumento7 pagineDataSheet CertificationPaths InsuranceSuite Analystsshanmuga89Nessuna valutazione finora

- Republic Act No. 1125Documento8 pagineRepublic Act No. 1125Jazlynn WongNessuna valutazione finora

- Autoregressive-Moving Average (ARMA) ModelsDocumento34 pagineAutoregressive-Moving Average (ARMA) Modelsflaviorochaavila100% (1)

- Midterm Examination: General MathematicsDocumento5 pagineMidterm Examination: General MathematicsJenalyn CardanoNessuna valutazione finora

- NIA Foundation PLI Proposal Template (Repaired)Documento23 pagineNIA Foundation PLI Proposal Template (Repaired)lama dasuNessuna valutazione finora

- Constitution & By-LawsDocumento15 pagineConstitution & By-LawsMichael C. AndradeNessuna valutazione finora

- Filters SlideDocumento17 pagineFilters SlideEmmanuel OkoroNessuna valutazione finora

- (OCM) Chapter 1 Principles of ManagementDocumento23 pagine(OCM) Chapter 1 Principles of ManagementMehfooz PathanNessuna valutazione finora

- BK Hodd 000401Documento25 pagineBK Hodd 000401KhinChoWin100% (1)

- SATB All Glory Laud and HonorDocumento1 paginaSATB All Glory Laud and HonorGeorge Orillo BaclayNessuna valutazione finora

- Birth and Growth of Semiotics: November 2020Documento9 pagineBirth and Growth of Semiotics: November 2020Maria del Carmen Alvarado AcevedoNessuna valutazione finora

- Precision Nutrition. Nutrient TimingDocumento21 paginePrecision Nutrition. Nutrient TimingPaolo AltoéNessuna valutazione finora

- Chapter 4 - Transfer FunctionsDocumento36 pagineChapter 4 - Transfer FunctionsFakhrulShahrilEzanie100% (1)

- Scottish Gaelic 2nd EditionDocumento117 pagineScottish Gaelic 2nd EditionMila Akimova-LeeNessuna valutazione finora

- Module 1 Lesson 1 Activity and Analysis: Special Needs EducationDocumento2 pagineModule 1 Lesson 1 Activity and Analysis: Special Needs EducationShalyn ArimaoNessuna valutazione finora

- Adeyinka Wulemat Olarinmoye - The Images of Women in Yoruban Folktales PDFDocumento12 pagineAdeyinka Wulemat Olarinmoye - The Images of Women in Yoruban Folktales PDFAngel SánchezNessuna valutazione finora

- Tapan Pathak Case StudiesDocumento33 pagineTapan Pathak Case StudiesNeelee SoniNessuna valutazione finora

- Unit 2Documento4 pagineUnit 2api-296199660Nessuna valutazione finora

- I. Revised Penal Code (RPC) and Related Special Laws: Riminal AWDocumento11 pagineI. Revised Penal Code (RPC) and Related Special Laws: Riminal AWMc Vharn CatreNessuna valutazione finora

- Internship ProposalDocumento6 pagineInternship ProposalatisaniaNessuna valutazione finora

- Evolution of Corporate Social Responsibility in IndiaDocumento12 pagineEvolution of Corporate Social Responsibility in IndiaVinay VinuNessuna valutazione finora