Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

WJ 1987 08 s241 PDF

Caricato da

vitor_silva_56Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

WJ 1987 08 s241 PDF

Caricato da

vitor_silva_56Copyright:

Formati disponibili

An Investigation of Weld Hot Cracking in

Duplex Stainless Steels

Cracking susceptibility in commercial grades is linked to a

Cu- and P-enriched, low-melting liquid film

BY D. E. NELSON, VV. A. BAESLACK III AND J. C. LIPPOLD

ABSTRACT. The weld fusion zone hot of these complex synergistic alloying ele- tance to pitting, crevice corrosion, and

cracking behavior of four duplex stainless ment effects. stress-corrosion cracking (Refs. 1-4). The

steel alloys was investigated using the Fractographic study of the hot crack increase in ferrite-stabilizing elements (Cr,

Varestraint test. The duplex stainless surfaces in the duplex alloys showed Mo) relative to austenite-stabilizing ele-

steels evaluated included: Ferralium Alloy both dendritic and flat columnar topo- ments (Ni, N) in these alloys results in a

255 (UNS-S32550), Uddeholm NU744LN graphies. The flat regions, which were microstructure which is "duplex" in

(UNS-S31803), and two experimental Fe- found at locations on the fracture surface nature, containing both ferrite and aus-

Cr-Ni alloys. Two commercial Type 304L farthest from the crack front at the time tenite. Duplex stainless steel base

alloys were included in the study for of straining, have been attributed to grain materials are normally solution heat

comparison. boundary formation and migration during treated at a temperature which produces

Varestraint test results indicated that and immediately subsequent to the final nearly equal proportions of ferrite and

the commercial duplex stainless steels stages of fusion zone solidification. It is austenite.

were more susceptible to fusion zone hot postulated that the incidence of flat frac- The unique properties of the duplex

cracking than the experimental alloys and ture is related to the greater susceptibility stainless steels have resulted in their use

a Type 304L alloy which exhibited Ferrite of the duplex alloys to weld solidification in a variety of industrial applications,

Number (FN) 4.5 in the weld fusion zone. cracking versus the FN 4.5 Type 304L including chemical process plant piping,

All of the duplex alloys were less suscep- alloy, which exhibited an exclusively den- oil and gas transmission lines, and struc-

tible to hot cracking than the Type 304L dritic surface. tures for use in marine environments

alloy, which solidified as austenite and (Refs. 5, 6). Since welding is widely used

exhibited a ferrite-free fusion zone micro- in the fabrication of many components

structure. Introduction and Background used in these applications, understanding

Metallographic inspection of Vare- the factors which affect the weldability of

The duplex stainless steels have been

straint specimens revealed that fusion duplex stainless steels is critical to the

developed to provide a higher strength,

zone hot cracking in the duplex alloys successful implementation of these engi-

corrosion-resistant alternative to the 300-

was associated with grain boundaries neering materials.

series austenitic stainless steels. Relative

which had been fully ferritic during the

to the conventional Type 304L and 316L

final stages of solidification. Microprobe Weld Hot Cracking

alloys, the duplex stainless steels typically

analysis of the remnants of liquid films

contain increased chromium (22-26 wt- Weld hot cracking, or solidification

along the crack paths in the commercial

%), decreased nickel (4-8 wt-%), cracking, generally occurs slightly above

alloys revealed increased levels of cop-

increased molybdenum (2-5 wt-%), the melting temperature of the lowest

per, molybdenum, nickel and phospho-

increased nitrogen (0.1-0.2 wt-%), and melting constituent, sometimes referred

rus. It is suggested that the partitioning of

occasional additions of copper. These to as the effective solidus temperature

copper and phosphorus to the ferritic

alloy modifications impart excellent resis- (Refs. 7, 8). At this point in the weld

solidification boundaries promoted the

formation of complex low-melting liquid solidification process, adjacent dendrites

films which readily wet the single-phase have impinged upon each other to form

boundaries. The lower hot cracking sus- solidified bridges, which are surrounded

ceptibility of the experimental duplex KEY W O R D S by regions containing lower-melting inter-

alloys appears to be due to the absence dendritic liquid. These solid bridges are

Duplex Stainless Stl subject to the greatest proportion of

Weld Hot Cracking shrinkage-induced strain as the surround-

D. E NELSON is with Hughes Aircraft Co., El Crack Susceptibility ing material cools. A threshold amount of

Segundo, Calif. W. A. BAESLACK III is with the Zone Solidification either low-melting liquid or strain may

Department of Welding Engineering, Ohio Element Segregation cause fracture of these solid bridges and

State University, Columbus, Ohio. J. C. LIP- Varestraint Testing the subsequent formation of a weld hot

POLD is with the Edison Welding Institute, Alloy UNS-S32550 crack (Refs. 9-12). By definition, weld hot

Columbus, Ohio. Alloy UNS-S31803 cracks are interdendritic in nature, occur-

Fe-Cr-Ni Alloys ring either between individual dendrites

Based on a paper presented at the 66th Annual

A WS Meeting, held April 28 to May 3, 1985, in Microprobe Analysis or, more commonly, along a weld "grain

Las Vegas, Nev. boundary," where dendrites of different

WELDING RESEARCH SUPPLEMENT 1241-s

decreased. A further increase in this ratio,

S which resulted in welds containing more

than 30 vol-% ferrite, again resulted in an

increase in cracking. Suutala, et al. (Refs.

20, 26, 27), suggested that this increase in

A< cracking results from a shift in solidifica-

tion behavior during the final stages of

freezing. Below approximately 30 vol-%

'Ei ferrite, some austenite forms at the inter-

stices of the primary ferrite dendrites as a

secondary solidification product. The

presence of austenite during the final

stages of solidification inhibits interden-

dritic wetting and reduces crack suscepti-

bility, as proposed by Hull (Ref. 15). In

welds which exhibit more than 30 vol-%

ferrite, solidification is entirely ferritic, and

interdendritic liquid films are more likely

to wet the ferrite-ferrite boundaries.

Despite the metallurgical rationale

which suggests increased hot cracking

susceptibility of the duplex stainless steels

relative to austenitic stainless steels, only

a few instances of weld hot cracking in

5 0 ;,.m these materials have been reported (Refs.

Fig 1-Base metal microstructures of the duplex stainless steels. A-Ferralium Alloy 255; 28-30). Gooch (Ref. 29) observed crack-

B - Uddeholm NU744LN; C - Alloy 21-9; D- Alloy 23-7. The ferrite (F) and austenite (A) phases areing only when welding plate thicknesses

indicated were above 10 mm (0.4 in.). Blumfield, et

al. (Ref. 28), and Flasche (Ref. 30) have

growth orientation impinge. The thresh- Duplex Stainless Steels reported only minor difficulties with hot

old level of both strain and interdendritic

Weld hot cracking in the duplex stain- cracking in Ferralium Alloy 255. The

liquid necessary to cause cracking is apparent discrepancy in hot cracking

less steels has received considerably less

material specific and depends to a large behavior predicted by laboratory results

attention. These alloys solidify as ferrite

extent on both the composition of the and that actually encountered during field

and may exhibit from 20 to 80 vol-%

material and the welding conditions. fabrication is puzzling in light of the good

ferrite in the as-welded microstructure.

Based on the correlation between crack- correlation obtained with the austenitic

Austenitic Stainless Steels stainless steels.

ing susceptibility and solidification behav-

Weld hot cracking of the austenitic ior developed for the austenitic stainless This investigation was designed to

stainless steels has been the subject of steels, the susceptibility of the duplex evaluate the relative hot cracking suscep-

considerable research interest over the alloys to hot cracking would be expected tibility of four duplex and t w o austenitic

past 30 years. The beneficial effect of to be low. stainless steel alloys and relate the

delta ferrite was first recognized in the In fact, Hull (Ref. 15) reported that hot observed hot cracking behavior to the

1940's and has since been substantiated cracking in small cast ingots of austenitic solidification behavior of the individual

by many investigators (Refs. 13-24). Early stainless steels increased as the ferrite alloys.

studies by Borland (Ref. 14) and Hull (Ref. content of the as-solidified ingot

15) demonstrated that austenitic stainless increased above 10 vol-%. He proposed

steel welds and castings which contained that the optimum cracking resistance of Material and

between 5 and 10 vol-% delta ferrite the castings containing 5 to 10% ferrite Experimental Procedure

provided optimum resistance to hot resulted from the presence of significant

cracking in a variety of alloy systems. austenite-ferrite interfacial area during Materials

Since these initial observations, additional the final stages of solidification. The low The duplex stainless steels which were

studies have investigated the metallurgi- interfacial energy of these two-phase studied included: Ferralium Alloy 255

cal basis accounting for the beneficial boundaries inhibits boundary wetting by (UNS-S32550), a nitrogen-bearing steel

effect of weld metal ferrite. Masumoto, low-melting liquid films, thus reducing the with approximately 26Cr-5Ni-2Cu-

etal. (Ref. 17), first reported the influence propensity for separation (cracking) along 3.3Mo; Uddeholm NU744LN (UNS-

of solidification behavior on cracking sus- these boundaries. He further postulated S31803), a nitrogen-bearing steel contain-

ceptibility. They found that alloys whose that like-phase boundaries, such as aus- ing approximately 22Cr-6Ni-3Mo; and

primary solidification product was ferrite tenite-austenite or ferrite-ferrite grain or t w o experimental alloys, designated as

were much more resistant to hot cracking subgrain boundaries, would be more sus- 21-9 and 23-7, which were simple alloys

than alloys whose primary solidification ceptible to cracking due to more exten- of the Fe-Cr-Ni system, containing

product was austenite. The presence of sive wetting by liquid films. approximately 21Cr-9Ni-2Mn and 23Cr-

at least 5 vol-% ferrite in the as-welded Suutala, et al. (Refs. 20, 26, 27), 7Ni-2Mn, respectively. All material was in

microstructure was merely an indication observed that the cracking susceptibility the form of plate which had been solu-

that weld solidification occurred as pri- in a wide range of stainless steels could tion-annealed at 1020°-1100°C (1870°-

mary ferrite. Austenitic stainless steel be correlated with a Cr e q/Ni e q ratio. At 2010°F), followed by rapid cooling in air

welds which were either fully austenitic low ratio values, primary solidification or water.

or contained only a small amount of occurred as austenite and cracking sus- The as-received base metal microstruc-

ferrite ( < 2 vol-%) generally solidified as ceptibility was high. Above a threshold tures for the four duplex stainless steel

primary austenite and were susceptible value of Cr e q /Ni e q , primary solidification alloys studied are illustrated in Fig. 1.

to hot cracking (Refs. 18, 20, 22-26). shifted to ferrite and cracking propensity Ferralium Alloy 255, Uddeholm NU744LN

242-s | AUGUST 1987

with an energy dispersive spectrometer

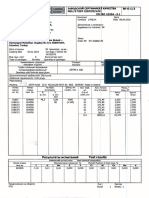

Table 1—Compositions for the Alloys Investigated (wt-%)

(EDS) in order to characterize the fracture

morphology and identify particles or

Materials Cr Ni Si Mn Mo Cu C N S

phases which were associated with the

Ferralium Alloy 24.9 5.4 0.54 1.1 3.1 1.7 0.027 0.17 0.001 0.023 hot crack surface.

255

Uddeholm 21.6 4.9 0.44 1.7 2.4 0.2 0.067 0.10 0.001 0.024 Analytical Evaluation

NU744LN

Alloy 21-9 20.8 9.0 0.62 1.7 0.07 0.024 0.007 0.008 0.025 An electron microprobe was used to

Alloy 23-7 22.8 7.1 0.54 1.8 0.06 0.033 0.006 0.009 0.027 determine the degree of solute segrega-

304E (FN 0) 18.3 11.4 0.41 1.7 0.04 0.023 0.037 0.002 0.007 tion associated with solidification and hot

304t (FN 4.5) 18.6 10.7 0.54 1.9 0.21 0.017 0.040 0.001 0.024 cracking in the commercial duplex alloys.

The analyses were performed at an

accelerating voltage of 25 kV and a beam

the following equation: current of 10 nA, producing an effective

Table 2—Mini-Varestraint Test Parameters

probe size of approximately 1 ^ m

£ « t/2R

(0.00004 in.).

Current 180 ± 10 A where t is the specimen thickness and R is Hot crack surface analysis was also

Voltage 17 ± 1 V the radius of the die block over which the performed on the commercial alloys,

Travel speed 152 m m / m i n (6 ipm) specimen is deformed. using a scanning Auger microprobe

Electrode-to-work 2.38 mm (3/32 in.) Following testing, the specimens were (SAM). An accelerating voltage of 5 kV

distance chemically cleaned using an alkaline per- and a beam current of 1.85 ^A were used

Electrode W . T h 0 2 , 60-deg manganate-citrate acid method (Ref. 32) to examine the surface. Composition

included angle to remove high-temperature oxides depth profiles were obtained to a depth

Electrode diameter 2.38 mm (3/32 in.)

which made observation of hot cracks of 100 nm by sputtering the surface with

Ram velocity 300 m m / s (11.7 in./s)

difficult. The samples were first immersed a beam of argon ions.

Shielding gas Argon

Flow rate (Torch) 0.29 L/s (40 cfh)

for 1 h in a boiling solution containing

Flow rate (Trail) 0.53 L/s (70 cfh) 10% NaOH and 3% KMnCX, in 1 L of

water. After rinsing in water, the samples Results

were immersed for 1 h in a boiling Predicted Solidification and

and the 23-9 alloy all exhibited approxi- solution containing 12 g ammonium Transformation Behavior

mately equal proportions of austenite citrate, 100 mg EDTA, and 1 L of water, in

and ferrite, while the 21-9 alloy contained which the pH was adjusted to 4-4.5 with The solidification and solid-state phase

a greater proportion of austenite. Also citric acid. This cleaning method effec- transformation behavior of austenitic and

evident from Fig. 1 is the elongated tively removed the oxide without attack- duplex stainless steels is a strong function

morphology of the ferrite. The austenite ing the underlying metal. A quantitative of the composition of the particular steel.

phase, which formed at ferrite-ferrite measure of the extent of hot cracking in Since the duplex stainless steels are basi-

grain boundaries, was also elongated, each sample was determined using a cally high-Cr, low-Ni versions of the aus-

with the exception of the 21-9 alloy, in binocular microscope equipped with a tenitic stainless steels, the Fe-Cr-Ni terna-

which an equiaxed austenite grain struc- filar eyepiece. The number and length of ry system is useful for predicting the

ture was observed. all cracks produced along the trailing solidification and solid-state transforma-

A conventional Type 304L stainless edge of the weld pool during the mini- tion characteristics of these materials. The

steel which contained approximately 5 Varestraint test were determined at 70X pseudo-binary section of the Fe-Cr-Ni

vol-% (FN 4.5) delta ferrite in the weld magnification. ternary system at 60 wt-% iron (Ref. 33),

fusion zone at room temperature and a shown in Fig. 2, can be used to describe

Type 304L stainless steel which remained the behavior of a typical duplex stainless

fully austenitic in the weld fusion zone Metallography steel upon cooling from the solidification

were also tested in order to provide a range. A nominal composition, C 0 , at

Selected mini-Varestraint test speci-

baseline for comparison of the hot crack- 30Cr-10Ni, has been selected as repre-

mens were sectioned, mounted, and pol-

ing susceptibilities of the duplex stainless sentative, since the majority of commer-

ished with 0.05 micron alumina for metal-

steels. Complete compositional analyses cial alloys contain molybdenum and nitro-

lographic analysis. Sections were made

for all the alloys tested are shown in gen additions which increase their "effec-

through the cracked regions of the test

Table 1. tive" chromium and nickel contents (Cr-

specimens to reveal the hot crack mor-

and Ni-equivalents), respectively.

phology and in unstrained areas for a

Varestraint Testing more detailed examination of the weld Alloys which lie to the right of the

fusion and heat-affected zone structures. triangular, three-phase region at approxi-

The mini-Varestraint test (Ref. 31) was Samples were etched using either a mately 25Cr-15Ni in Fig. 2 solidify as

utilized to assess the relative weld hot mixed acid reagent containing equal primary ferrite. Alloys which solidify as

cracking susceptibility of the duplex and amounts of nitric, hydrochloric, and ace- ferrite in close proximity to this three-

austenitic alloys. As-received 12.8-mm tic acid or a 10% oxalic acid electrolytic phase region may form some austenite

(0.5-in.) thick plates were machined into etch at 6 V for 10-20 s. during the final stages of solidification, as

test specimens with dimensions of a consequence of a peritectic/eutectic

0 . 6 4 X 2 . 5 4 X 1 5 . 2 4 cm (0.25 X 1.0 X reaction (Refs. 21, 23). As the composi-

Fractography

6.0 in.). The specimens were thoroughly tion is enriched in chromium and de-

degreased with acetone and wiped dry Selected Ferralium Alloy 255 and pleted in nickel at a constant iron content,

immediately prior to testing. The GTA Uddeholm NU744LN test samples con- this reaction becomes less favorable and

welding parameters used in mini-Vares- taining hot cracks were carefully sec- solidification is completely ferritic. Thus,

traint testing are listed in Table 2. tioned and broken in order to reveal hot Fig. 2 predicts that duplex stainless steels

The specimens were tested over a crack fracture surfaces. The fracture sur- will solidify as primary ferrite with little or

range of augmented strains from 0.5 to faces were examined using a scanning no austenite forming as a secondary

5%. The augmented strain, £, is given by electron microscope (SEM) equipped solidification product.

WELDING RESEARCH SUPPLEMENT 1243-s

1600 Following solidification, a duplex stain-

less steel of composition C 0 enters the

LIQUID single-phase ferrite region of the phase

diagram. Within this region, diffusion is

2600 rapid, and much of the elemental parti-

1400 tioning resulting from solidification may

Y+L be reduced, depending primarily on the

rate of cooling through this region. Upon

further cooling, the alloy enters the aus-

2200 tenite plus ferrite phase field and a grad-

1200

ual transformation of ferrite to austenite

occurs. The austenite will form preferen-

3 tially at defect structures in the ferrite,

e e.g., grain and solidification substructure

ui

3 1000 boundaries, which may be enriched in

1800

elements which stabilize austenite (Ni,

Mn, Cu, N, C). Note that, unlike the

hi UJ austenitic stainless steels, a typical duplex

a. o. stainless steel remains within the bounds

•00 of the austenite plus ferrite region to

1400 room temperature. As a result, the fusion

zone of these alloys would be expected

to contain a large fraction of ferrite in the

room-temperature microstructure.

600

IOOO The pseudo-binary diagram in Fig. 2

can also be used to explain the effect of

the solution-annealing temperature on

6 0 % IRON the microstructure and phase composi-

400 • tion of the duplex stainless steel base

materials. Solution annealing an alloy of

15 20 25 30 35 40 WT % Cr composition C 0 in the temperature range

from 1020° to 1100°C results in an equi-

25 20 15 10 5 0 W T % Ni librium mixture containing nearly equal

Fig. 2 — Vertical section of the Fe-Cr-Ni phase diagram at 60% iron. The CD composition line proportions of ferrite and austenite. The

represents a typical duplex stainless steel (Ref. 32) composition of these phases would be

roughly approximated by the austenite

and ferrite solvus lines at the solution-

annealing temperature. Since the width

of the two-phase region is large, a signif-

icant difference in composition should

exist between the ferrite and the austen-

ite. (This assumes that the alloy is held at

;/- -'.'' f

i'r,Ay" ,. y.-

:7S •y-yy;;- %

the solution-annealing temperature long

enough to achieve equilibrium and that

i.-y the isothermal tie line lies in the plane of

- y i "-vc* s"A

W' J /

-' the 60% iron section.)

;/yy

;

,• '.»$£

y.<C&U / yV,'^ j J~A' / ' %

'}. , / - • • fy W e l d Microstructures

"i

/ ^ - 7 ^ -y # -'-'- * >J J'J ' ) *- •"'• I 7.

-A - 1~

- <~ \ '' ii%

' f 7i~y' • A-. :The weld fusion zone and fusion

:rs 'A': -t

/rA

*X# boundary region microstructures of the

-A'.

duplex stainless steels evaluated during

50um i

~A-

"• *y.~

, •} ••

2y

this investigation are shown in Fig. 3.

These microstructures are representative

of welds made using the parameters

listed in Table 2. The fusion zone micro-

D structure of Ferralium Alloy 255 (Fig. 3A)

/ !i consists of large, epitaxial ferrite grains

f-

y/y> y I / with continuous austenite networks at

/

j /

prior ferrite grain boundaries and intra-

granular austenite precipitates. The weld

ferrite content of the Ferralium Alloy 255,

determined using the Extended Ferrite a--*

Number (EFN) scale of the Magne-Gage

-rp' — : - — " *~ - ' - '

(Ref. 34), was on the order of EFN 60. The

adjacent heat-affected zone (HAZ) also

5Oum _ f -Sgjofcv? -rfZr^iJr '•»?. '-j^'-y.:'vrr. y-*>?i

50,um ^ - ^ ^ - ~. t- -* ^$£—*-tT. ;-^ exhibited a continuous grain boundary

austenite network but showed little intra-

Fig. 3—The weld fusion boundary regions of the duplex stainless steels evaluated. A —Ferralium

Alloy 255; B- Uddeholm NU744LN; C-Alloy 21-9; D-Alloy 23-7. Arrows indicate the approxi- granular austenite precipitation. Instead, a

mate location of the weld fusion interface fine precipitate was observed to be local-

244-s | AUGUST 1987

ized in the ferrite phase. These particles

could not be precisely identified, but Table 3- -Summary of Mini-Varestraint Test

were found to be enriched in chromium Results

(Ref. 35). A precipitate-free zone corre-

/o No. TCL

sponds to regions surrounding the aus-

Material Strain Cracks (mm)

tenite, suggesting that austenite may act

as a sink for fast-diffusing, interstitial ele- Ferralium 1.0 2 0.41

ments, such as carbon and nitrogen, Alloy 255 1.5 4 0.76

which may be integral in the formation of 2.1 13 3.00

the precipitate. 3.1 24 6.24

5.0 40 10.44

The weld microstructure and fusion

boundary region of the Uddeholm Uddeholm 1.0 4 0.34

NU744LN steel are shown in Fig. 3B. The NU744LN 1.5 4 0.41

25-m. 2.1 16 2.42

ferrite content of the fusion zone was

approximately EFN 70. Similar to the Fer- 3.1 24 5.57

Fig. 4 — Ferralium Alloy 255 fusion zone micro- 5.0 31 6.31

ralium Alloy 255, continuous austenite structure. Note the alignment of intragranular

networks existed at the ferrite grain austenite along the solidification growth direc- Alloy 0.5 0 0

boundaries. A fine distribution of intra- tion 21-9 1.0 0 0

granular precipitates was observed with- 2.1 5 0.72

in the fusion zone, reminiscent of the cracking susceptibility was provided by 3.1 21 3.58

HAZ microstructure in the Ferralium Alloy plotting the total crack length (TCL) on 5.0 43 7.10

255 (Fig. 3A). the specimen surface versus the aug- Alloy 0.5 0 0

The weld structure of Alloy 21-9, mented strain over the range from Vs to 23-7 1.0 0 0

shown in Fig. 3C, consisted of large 5%, as illustrated in Fig. 5. Using this index, 2.1 15 1.18

ferrite grains with Widmanstatten-type the Ferralium Alloy 255 proved to be the 3.1 12 2.23

austenite precipitating from the grain most susceptible to hot cracking of the 5.0 35 5.98

boundary austenite. The ferrite content duplex alloys over the entire range of

Type 304L 0.5 0 0

of the Alloy 21-9 fusion zone was on the augmented strain. At intermediate strain (FN 5) I 0 0 0

order of EFN 40, the lowest of the four levels (2 and 3%), the hot cracking sus- 2 I 5 0.47

duplex alloys evaluated. Alloy 23-7 exhib- ceptibility of Ferralium Alloy 255 and 3.1 33 2.65

ited a highly ferritic fusion zone micro- Uddeholm NU744LN were essentially 5.0 46 5.55

structure with a ferrite content of identical, but both exceeded that of the

Type 304L 0.5 6 1.73

approximately EFN 80 (Fig. 3D). Austenite experimental alloys (21-9 and 23-7) and

(FN 0) 1.0 16 6.23

in the Alloy 23-7 fusion zone was restrict- the Type 304L alloy with 4.5 FN. At the

2.1 21 8.92

ed almost exclusively to the grain bound- lowest levels of augmented strain (below 3.1 24 11.86

aries. The fine intragranular precipitation 1.5%), all the alloys tested, with the

observed in the Uddeholm NU744LN exception of the fully austenitic Type

fusion zone was not apparent in Alloy 304L material, exhibited equivalent crack

23-9.

Weld solidification substructure

boundaries were not readily apparent in

any of the weld microstructures. Closer 12-

examination of the Ferralium Alloy 255

11-

microstructure (Fig. 4) did indicate that

the intragranular austenite may precipi-

tate along prior substructure (cellular or

E 10-

dendritic) boundaries. As mentioned pre- E 9-

viously, during solidification as primary

ferrite, nickel partitions to the solidifica- 8-

tion boundaries (Refs. 20, 22, 23). Assum- O

ing diffusion is insufficient to eliminate the Z 7

local nickel enrichment, this boundary will LU

become a preferential site for austenite

precipitation during cooling through the

austenite plus ferrite phase field (Fig. 2). a

<

5-

As the Cr e q /Ni e q increases, diffusion is

more pronounced, since the weld cools 4-

through a larger temperature range in the CJ

3-

ferrite phase field before the austenite _J L«g*nd

transformation begins. As a result, any

evidence of prior solidification structure i< 2- rCMAUUM .VU.0T

UPPCHOIM HU744LX

Hi

or tendency for intragranular austenite

precipitation is severely reduced.

o 1 TYP[ ) 0 4 L - r H - 0

JtPl 3041.- ^4_5_

0 «n-°T»-»

* » • " " » - » <

Varestraint Test Results

The results of mini-Varestraint tests for 2 3 4

the four duplex alloys and t w o Type 304L

alloys are summarized in Table 3. The

AUGMENTED STRAIN (%)

best index of the relative fusion zone hot Fig. 5 —Results of the mini-Varestraint test in terms of total crack length vs. augmented strain

WELDING RESEARCH SUPPLEMENT | 245-s

cantly greater than when austenite is a

secondary solidification product, i.e.,

Type 304L, FN 4.5.

Metallographic Analysis of

Varestraint Samples

Metallographic examination of the

duplex stainless steel Varestraint samples

revealed that hot cracking in all four

materials was associated with fusion zone

grain boundaries. Partitioning of alloy and

impurity elements is generally greater

along these grain boundaries than at the

subgrain boundaries (Refs. 7, 8, 22), and

thus weld hot cracking is more prevalent

—- at these sites1.

lOOMml

The top surface of a Ferralium Alloy

• - 255 Varestraint sample tested at 5% strain

is shown in Fig. 6. The hot cracks were

distributed around the periphery of the

solid-liquid interface at the instant of

applied strain. As noted, the cracks

shown in Fig. 6 were located at grain

boundaries in the Ferralium Alloy 255

microstructure. These boundaries were

delineated by the continuous austenite

networks.

I SO M"1 I At higher magnification (inset, Fig. 6),

note that austenite side plates emanated

from the crack boundaries. Since it is

Fig. 6 — Fusion zone hot cracking in a Ferralium Alloy 255 Varestraint sample tested at 5% strain (top likely that solidification of Ferralium Alloy

surface section). Arrows indicate the approximate location of the solid-liquid interface at the instant 255 occurred entirely as ferrite (no eutec-

of testing tic/peritectic reaction), this austenite

formed during cooling from the solidifica-

susceptibilities. None of the duplex alloys embrittlement temperature range (Ref. tion range. Thus, the hot crack shown in

approached the high degree of crack 36). The average crack length (ACL) at Fig. 6 initiated and propagated along

susceptibility found in the fully austenitic 3.1% strain for the four duplex materials ferrite-ferrite grain boundaries.

Type 304L alloy. and the t w o 304L alloys is presented in A transverse metallographic section

The average length of hot cracks at a Table 4. The ACL for the duplex materials from a Ferralium Alloy 255 Varestraint

particular strain level may also be used as is two to three times greater than that of sample is shown in Fig. 7. This section was

a measure of the degree of susceptibility the Type 304L alloy with FN 4.5, but is located such that the subsurface hot

to cracking and often provides an indica- only one-third to one-half that of the fully cracks which formed during the Vare-

tion as to the relative magnitude of the austenitic Type 304L alloy. Assuming that straint test were revealed. The solidifica-

the temperature gradient into the solid is tion growth direction was nearly vertical

nearly linear at temperatures just below in Fig. 7. This growth orientation resulted

the liquidus and relatively uniform for all in relatively straight grain boundaries,

the materials (welding parameters were which facilitated crack propagation.

identical), the embrittlement temperature A metallographic section representa-

range for fully ferritic or fully austenitic tive of the top surface of a Uddeholm

solidification would appear to be signifi- NU744LN Varestraint sample is shown in

Fig. 8. Again, note that hot cracking was

restricted to the prior-ferrite grain bound-

:

y 2r'&: aries, as delineated by the continuous

~ >?. *£& y -V: austenite networks. Similar metallograph-

yW^- r-.-i sS&i *(?%

'Af% yt -. ic sections are presented for Alloy 21-9

and Alloy 23-7 in Fig. 9.

1. Two types of grain boundaries may exist in

the weld fusion zone. One type results from

the impingement of solidification subgrains of

different growth orientation and is delineated

by both the growth orientation mismatch and

elemental segregation. The other type results

J€, - from migration of this boundary on cooling

fe%.,MfifelO 0 ,„ir lOOum from the solidification temperature range. The

Fig. 7— Transverse section of a Ferralium AlloyFig. 8 —Fusion zone hot cracking in a Udde- former is the usual site for weld hot cracking

255 Varestraint specimen tested at 3% strain. holm NU744LN Varestraint specimen tested at and, unless otherwise specified, will be the

Note the straight grain boundaries along which 5% strain type implied in this paper when discussing the

cracks propagate weld fusion zone microstructure.

246-s | AUGUST 1987

phology of the Type 304L alloys was also

examined and is shown in Fig. 10. Hot B

cracks in the fully austenitic (FN 0) Type

304L Varestraint specimens were associ- .iS^~rv-

ated with relatively straight fusion zone

grain boundaries (Fig. 10A), similar to the

morphology exhibited by the duplex

alloys (Figs. 6-9). In contrast, hot cracks in

the Type 304L alloy which exhibited FN \

4.5 were extremely short and could not

be associated with a distinct fusion zone

grain boundary (Fig. 10B).

Heat-affected zone cracking was not

observed in either the duplex alloys or 100M"I 100jim

the Type 304L alloy with FN 4.5, even at

Fig. 9 - Fusion zone hot cracking in experimental duplex stainless steel Varestraint specimens tested

the highest level of restraint. In contrast, at 5% strain. A -Alloy 21-9; B-Alloy 23-7

heat-affected zone cracking was routine-

ly observed in the fully austenitic Type

304L alloy. These HAZ cracks were usual- rj ••',y-'~

A 'Ji / - v y \y^.y,

ly continuous across the fusion line, sug- ''B.yr.,--

gesting that the cracks initiated in the a' a V . .'' / / V71f /

fusion zone and propagated into the

heat-affected zone. -•A • y

y, *,.* y.\,-•:•*/.-; -

'. *• V , *

• ', J * 6 y.y yL> / t .-; i

A

* s '•' ' ~s ^* - " J

Fractography

Figure 11 A, which illustrates a hot

, **v^ y?-yfy': Ay--y; t

crack fracture surface in Ferralium Alloy

^A, y.y:\\.'-\,y'. A /•'-'. "-T ••' H

. ' • \ <& • yy . , ,-.--'/

• > ' ' k ' \.' \ •> r i * \ z £y* -

J •.7- •

255, clearly reveals the fine protrusions

>~*-A\:, ':'"•"'> t ~:'-',''?~y, ' A'r /, te.

which correspond to cellular-dendrite pri- i i • ' ~ *_ "a- y • ,' i ' r. * -^ - /' '-;.

mary and secondary arms and which are 100nm 50nm - • •• J <' . . ' : : ' 1 -A '•

commonly associated with a solidifica- Fig. 10 — Fusion zone hot cracking in Type 304L Varestraint specimens tested at 5% strain. A—FN 0;

tion-related fracture surface. An examina- B — FN 4.5. Note difference in magnification

tion of this fracture surface at increased

magnification also revealed a transition in observed in the Ferralium 255. As indi- range of the weld metal. The analysis of

this fracture surface morphology from a cated in Figs. 12A and 12B, there was the remnants of these liquid films is often

relatively smooth, intergranular appear- strong evidence of the fracture of den- useful in determining the nature of the

ance on the surface of the crack most drites which may have acted as bridges cracking. Since these films tend to be

distant from the solid-liquid interface to separating the areas of low-melting liquid. extremely thin, electron optics tech-

an increasingly dendritic structure nearer However, the characterization of match- niques are usually employed to deter-

this interface (Figs. 11B and 11C). The ing opposite sides in order to confirm this mine their nature. The electron micro-

generally " w a v y " appearance of this sur- possibility was not conducted. probe is particularly well suited for ana-

face at high magnification confirmed that lyzing bulk samples.

the crack was completely solidification- A region along the tip of a hot crack in

related, and that crack extension by a Microprobe and Auger Analysis

a Ferralium Alloy 255 sample is shown in

solid-state "ductility dip" process was Weld hot cracking is usually associated Fig. 13. Analysis at several points along

unlikely. Fracture in the Uddeholm with liquid films which persist along fusion the crack path, as indicated in Fig. 13,

NU744LN and experimental duplex stain- zone grain boundaries, thus extending revealed an increase in molybdenum,

less steels appeared very similar to that the effective solidification temperature copper, nickel, and phosphorus relative

Fig. 11- Scanning electron fractographs of hot crack surface in Ferralium Alloy 255. A - Entire crack surface; arrow indicates end of crack farthest from

solid-liquid interface at the time of straining; B — higher magnification of A showing relatively flat fracture surface in regions farthest from solid-liquid

interface; C — higher magnification of A showing more dendritic-appearing fracture surface nearer the solid-liquid interface

WELDING RESEARCH SUPPLEMENT 1247-s

commercial duplex stainless steels were

more resistant to cracking than a Type

304L alloy which solidified as austenite

and was fully austenitic (FN 0) at room

temperature. The cracking susceptibility

of the experimental duplex alloys (23-7

and 21-9) approached that of the Type

304L alloy with FN 4.5.

.•.MX

Field experience with commercial

duplex stainless steels (Refs. 28-30) sug-

gests that these materials are relatively

immune to weld hot cracking and com-

pare favorably with 300-series stainless

steels which produce a weld microstruc-

Fig. 12 — Scanning electron fractographs of hot crack surface in Uddeholm NU744LN. A — ture with FN 3-10. The apparent discrep-

Dendritic-appearing fracture surface; B - higher magnification of A showing apparent "fractured" ancy between field experience and the

dendrite Varestraint results (Fig. 5) may be

explained by considering the level of

to the bulk composition. The analysis was cal of solidification cracks. Note that solidification-induced strain to which the

confounded somewhat by the austenite molybdenum, nickel, copper, silicon, field welds are subjected. In Fig. 5, note

transformation which occurred along the nitrogen, and sulfur are present in appre- that at augmented strain levels below

boundary subsequent to the formation of ciable concentrations in the near-surface approximately 2%, the duplex stainless

the hot crack. Partitioning of austenite- layer. These results corroborate the elec- steels exhibit the same resistance to

forming elements (primarily Ni) to the tron microprobe results and indicate that cracking as the Type 304L alloy with FN

fusion zone grain boundaries during pri- higher levels of molybdenum and sulfur 4.5. Varestraint tests at restraint levels

mary ferrite solidification promoted the may be associated with the grain bound- below 2% are probably more representa-

formation of austenite at these sites, but ary film than were apparent from the tive of the actual welding practice using

it was unclear to what degree diffusion microprobe analysis. In contrast to the conventional processes (SMAW, GTAW,

following solidification modified the microprobe results, phosphorus was not GMAW). As a result, the satisfactory

boundary composition. For instance, detected on the fracture surface by the weld cracking resistance of the duplex

under equilibrium conditions, both nickel SAM. This discrepancy may be due to stainless steels which has been reported

and copper would tend to diffuse to the either insufficient data or to the precipita- is, in fact, predicted by the Varestraint

austenite during the ferrite-austenite tion of discrete phosphides along the test.

transformation. During rapid cooling fol- solidification boundary, which may have

lowing solidification, however, diffusion escaped detection by the highly localized The fully austenitic Type 304L alloy

of these elements would be more Auger technique. exhibited a significant increase in cracking

restricted. susceptibility relative to the duplex stain-

less steels at all levels of augmented

Auger surface analysis is also useful in Discussion strain. This large difference in cracking

determining the composition of thin films susceptibility is in general agreement with

on hot crack fracture surfaces. Since Evaluation of Varestraint Test Results

service experience using fully austenitic

cracks propagate along a liquid grain Weld hot cracking is the product of a stainless steel weld metals.

boundary film, the surface of these crack-susceptible microstructure and At higher levels of weld restraint

cracks will reflect the composition of the weld restraint during solidification. In the- (> 2%), the susceptibility of the duplex

liquid. Again, the analysis was confound- ory, fusion zone microstructures in all but stainless steels to weld hot cracking was

ed both by the solid-state transformation pure materials (or alloys which solidify at found to increase relative to Type 304L

that occurred along the boundary during an invariant point, such as a eutectic) may with FN 4.5. Specifically, at 3.1% strain

cooling and by high-temperature diffu- be susceptible to cracking during the final (Fig. 5) the cracking susceptibility of the

sion. An Auger compositional profile to stages of solidification. In practice, the duplex alloys was approximately midway

an approximate 100-nm depth on the relative susceptibility of welds to hot between that exhibited by the t w o Type

surface of a hot crack in a Ferralium Vare- cracking is measured by the amount of 304L variants. This relative increase in

straint specimen is shown in Fig. 14. strain that the microstructure can accom- susceptibility at higher strain levels sug-

The depth profile was performed in a modate during solidification. Weld micro- gests that the duplex stainless steels may

region of the fracture surface which structures which can accommodate large experience weld cracking problems in

exhibited the dendritic morphology typi- imposed strains during solidification are applications where the weld restraint is

resistant to hot cracking, while those high (for example, high depth-to-width

which fail at low levels of restraint are restrained joints).

judged susceptible. The Varestraint test is The difference in cracking susceptibility

a useful tool for both determining the at higher strain levels may result from

degree of strain accommodation in a several factors, including the possibility

particular microstructure and comparing that at lower strains the solidification

that behavior with alternate microstruc- boundary strength may be sufficient to

tures. resist separation, despite the presence of

In this investigation, the Varestraint test low-melting liquid at these boundaries.

v. i

results have shown that the commercial Above some critical strain level (1.5-2%),

duplex stainless steels (Ferralium Alloy the boundary strength may be insuffi-

255 and Uddeholm NU744LN) are more cient to prevent separation, resulting in

20 nil susceptible to weld solidification cracking the formation of a hot crack.

Fig. 13 — Electron microprobe analysis results than a Type 304L alloy which solidified as Despite the similarity in solidification

near the crack tip in a Ferralium Alloy 255 ferrite and exhibited a fusion zone micro- behavior, the experimental duplex alloys

Varestraint specimen structure with FN 4.5. Conversely, these are, in general, less susceptible to weld

248-s | AUGUST 1987

hot cracking than the commercial alloys.

Differences in solidification crack suscep-

tibility among similar alloys are often the

result of slight variations in chemical com-

position, particularly with respect to

impurity content. Table 1 shows that the

level of sulfur and phosphorus in the

experimental alloys was higher than that

in the commercial alloys. Thus, the

increase in cracking susceptibility due to

higher impurity levels is not possible.

Note that both copper and molybde-

num are present in the Ferralium (1.7Cu, Fig. 14 —Auger

3.1Mo) and Uddeholm (0.2Cu, 2.4Mo) depth profile

alloys but absent in the experimental showing the

alloys. Electron microprobe and Auger concentration of

analysis of solidification grain boundaries elements on a

(Fig. 13) and hot crack fracture surfaces Ferralium Alloy 255

hot crack surface.

(Fig. 14) of these alloys revealed an in-

Carbon and oxygen

crease in both of these elements at these were present as a

locations. Other elemental segregation 20-nm-thick

(Ni, Mn, Si, P, S) to the solidification grain contamination layer

boundaries was similar among the duplex but have been

alloys and thus does not explain the omitted for clarity

20

difference in cracking susceptibility. DEPTH (nm)

Copper and molybdenum both de-

press the melting point of Fe-base alloys

(Refs. 37, 38). As a result, significant attributed to a decrease in the quantity of ular corrosion or mechanical fracture in

localized segregation of these elements residual liquids at interdendritic regions the weld fusion zone, suggesting that this

to solidification grain and subgrain with decreasing temperature. Little ten- region is associated with crack propaga-

boundaries would likely reduce the solid- dency for the flat columnar fracture sur- tion along a migrated grain boundary.

ification temperature relative to the sur- face has been reported for hot cracks in This possibility is supported by Matsuda

rounding weld microstructure and welds which exhibit coupled ferrite/aus- and Nakagawa (Ref. 39), who suggest

expand the effective solidification range tenite solidification along fusion zone that the flat fracture originates from grain

of the weld. Unfortunately, it is difficult to grain and subgrain boundaries and which boundary migration among residual liq-

predict the effect of individual alloying or contain a small amount of ferrite (FN uids in the low-temperature crack region,

impurity elements on hot cracking sus- 3-10) in the room temperature micro- and by Dixon and Phillips (Ref. 41), who

ceptibility in multicomponent systems structure (Ref. 39). These results are con- relate flat fracture to the formation of

from simple equilibrium binary systems. sistent with the fractographic analysis of grain boundaries during the final stages of

Synergistic interactions with other alloy- the FN 4.5 Type 304L alloy evaluated in solidification. Unfortunately, details of

ing (Ni, Mn, Cr, Si, C, N) or impurity the present investigation. these grain boundary phenomena during

elements (S and P) may promote the In order to understand the origin of the the final stages of solidification have not

formation of liquid films along fusion flat fracture on the surface of the weld been reported. Although the present

zone boundaries, which would not be hot cracks in the duplex alloys, and deter- investigation did not identify the specific

predicted by consideration of simple mine how this morphology relates to origin of the flat fracture region, several

binary reactions. These same synergisms cracking susceptibility, it is necessary to potential explanations can be offered.

may enhance the wetting characteristics define the boundary along which the These include:

of the liquid along ferrite grain bound- fracture occurs. The fusion zone grain 1. Grain boundary migration and

aries and further increase the cracking boundaries along which hot cracking is straightening while liquid is still present in

susceptibility. most prevalent originate by the impinge- a continuous or semi-continuous distribu-

ment of cellular dendrites of different tion.

growth orientation during the final stages 2. Liquid penetration under a state of

Hot Crack Morphology of solidification. Microscopically, this stress of a solidified and migrated grain

Hot crack surfaces generally exhibit boundary would be expected to be very boundary (analogous to liquid metal

fine protuberances associated with pri- irregular during the final stages of solidifi- embrittlement).

mary and secondary cellular-dendrite cation, and thus would tend to migrate 3. The occurrence of solid-state "duc-

arms. In the present study, the careful following solidification in an effort to tility-dip" cracking.

examination of hot crack surfaces for the minimize the total grain boundary area. As noted above, Type 304L stainless

duplex stainless steels also revealed a Evidence of such grain boundary migra- steels exhibiting FN 3-15 display an exclu-

columnar, microscopically flat region, and tion is often visible in the room tempera- sively dendritic crack surface (Ref. 39).

a gradual transition from this flat fracture ture microstructure as a difference Matsuda and Nakagawa (Ref. 39) suggest

near the rear portion of the hot crack between the actual grain boundary and that this absence of flat fracture is related

(that farthest from the solid-liquid inter- the original solidification boundary, as to the peritectic/eutectic reaction experi-

face at the time of straining) to increasing- delineated by the presence of residual, enced during solidification of most Type

ly dendritic fracture near the front of the segregated alloying elements. 304 stainless steels, which prevents the

crack. Similar transitions in hot crack sur- The examination of flat fracture sur- grain boundary from migrating and

face topography have been reported faces in the duplex alloys studied in this straightening at near-solidus tempera-

previously in stainless steels which solidify investigation showed columnar-shaped, tures. The concept of such grain bound-

to either fully ferritic or fully austenitic smooth fracture surfaces comparable to ary irregularity or tortuosity reducing hot

structures (Refs. 39-41), and have been those commonly observed for intergran- cracking in austenitic stainless steels was

WELDING RESEARCH SUPPLEMENT 1249-s

originally p r o p o s e d b y M a t s u d a (Ref. 36) References 22. Lippold, J. C , and Savage, W . F. 1982.

a n d later b y Brooks (Ref. 23) t o explain Solidification of austenitic stainless steel weld-

t h e cracking resistance o f t h e l o w FN 1. Solomon, H. D., and Devine, T. M. 1983. ments: part 3 - t h e effect of solidification

A tale of t w o phases. Conf. Proc. Duplex behavior on hot cracking susceptibility. Weld-

stainless steel w e l d s . In w e l d m e n t s w h i c h

Stainless Steels, ASM, pp. 693-756. ing Journal 61(12):388-s to 396-s.

solidify c o m p l e t e l y t o austenite or ferrite,

2. DeBold, T. A., Martin, ). W , and Tver- 23. Brooks, J. A., Thompson, A. W., and

this grain b o u n d a r y m o t i o n is n o t restrict-

berg, ). C. 1983. Duplex stainless offers Williams, J. C. 1984. A fundamental study of

e d , w h i c h results in a less t o r t u o u s strength and corrosion resistance. Ibid., pp. the beneficial effect of delta ferrite in reducing

b o u n d a r y a n d a greater cracking sensitiv- 169-189. weld cracking. Welding Journal 63(3):71-s to

ity. Correlations of quantitative cracking 3. Poznansky, A., Nalbone, C. S., and Craw- 83-s.

results w i t h f r a c t o g r a p h y results dis- ford, J. D. 1983. The corrosion resistance of 24. Ogawa, T., and Tsunetomi, E. 1982. Hot

cussed a b o v e f o r the present investiga- 25Cr-3.5Mo-6Ni and 25Cr-4.5Mo-6Ni cast cracking susceptibility of austenitic stainless

t i o n s u p p o r t this p r o p o s e d grain b o u n d - duplex stainless steels. Ibid., pp. 431-444. steels. Welding Journal 61(3):82-s to 93-s.

ary t o r t u o s i t y e f f e c t o n hot cracking sus- 4. Honeycombe,)., and Gooch, T. G. 1977. 25. Arata, Y., Matsuda, F., and Katayama, S.

ceptibility. Intergranular attack in welded stress-corrosion 1977. Solidification crack susceptibility in weld

resistant stainless steels. Welding Journal metals of fully austenitic stainless steels (report

56(11):339-s to 353-s. il). Trans. /l4//?/6(1):105-116.

5. Tynell, M. 1983. Applicability range for a 26. Takalo, T., Suutala, N., and Moisio, T.

Conclusions

high strength duplex stainless steel in deep 1979. Austenitic solidification mode in austenit-

sour oil and gas wells. Conf. Proc. Duplex ic stainless steel welds. Met. Trans. 10A

1. Varestraint test results s h o w the

Stainless Steels, ASM, pp. 283-292. (8):1173-1181.

c o m m e r c i a l duplex stainless steels, Ferral-

6. Miyuki, H., Kudo, T., Koso, M., Miura, 27. Suutala, N., Takalo, T., and Moisio, T.

i u m Alloy 255 a n d U d d e h o l m N U 7 4 4 L N ,

M., and Moroishi, T. 1983. 25%Cr containing 1979. Single-phase ferritic solidification in aus-

t o b e m o r e susceptible t o fusion z o n e duplex phase stainless steel for hot sea water tenitic-ferritic stainless steel welds, Met. Trans.

h o t cracking t h a n Fe-Cr-Ni e x p e r i m e n t a l applications. Ibid., pp. 95-112. 10A(8):1183-1190.

duplex alloys w h i c h exhibit similar solidifi- 7. Savage, VV. F., tundin, C. D., and Aron- 28. Blumfield, D., Clark, G. A., and Guha, P.

cation b e h a v i o r . son, A. H. 1965. Weld metal solidification 1981. Welding duplex austenitic-ferritic stain-

2. Varestraint test results s h o w that mechanics. Welding Journal 44(4): 175-s to less steel weldments. Metal Construction

t h e c o m m e r c i a l duplex stainless steels are 181-s. 13(5):269-273.

m o r e susceptible t o cracking at high lev- 8. Savage, W . F., Nippes, E. F., and Miller, T. 29. Gooch, T. G. 1983. Weldability of

VV. 1976. Microsegregation in 70Cu-30Ni duplex ferritic-austenitic stainless steels. Conf.

els of a u g m e n t e d strain than a FN 4.5

weld metal. Welding Journal 55(6): 165-s to Proc. Duplex Stainless Steels, ASM, pp. 573-

T y p e 304L stainless steel, but less suscep- 173-s. 602.

tible t h a n a FN 0 T y p e 304L stainless steel 9. Borland, ). C. 1960. Generalized theory 30. Flasche, L. H. 1983. Weldability of Fer-

o v e r the entire range o f strain. of super-solidus cracking in welds and castings. ralium Alloy 255. Ibid., pp. 553-572.

3. Fusion zone hot cracking in t h e Brit. Weld. Jour. 7(8):508-512. 31. Lundin, C. D., Lingenfelter, A. C ,

duplex stainless steels o c c u r r e d exclusive- 10. Apblett, W . R„ and Pellini, W . S. 1954. Grotke, G. E., Lessmann, G. O , and Matthews,

ly along ferrite grain b o u n d a r i e s . H A Z Factors which influence weld hot cracking. S. ]. 1982. The Varestraint test. Weld. Res.

cracking in the duplex alloys was n o t Welding Journal 33(2):83-s to 90-s. Council Bulletin, No. 280.

o b s e r v e d in t h e d u p l e x o r FN 4.5 T y p e 11. Medovar, B. I. 1954. O n the nature of 32. Berry, W . E. 1967. Procedures for quan-

weld cracking. Avtom. Svarka 7(4):12-18. titative removal of oxide scales formed in high

304L stainless steels, a l t h o u g h it w a s

12. Borland, ). C. 1960. Hot cracking in temperature water and steam. Materials Pro-

present in t h e FN 0 T y p e 304L stainless tection 6(7):69.

welds. Brit. Weld. Jour. 7(9):558-559.

steel. 13. Scherer, R., Riedrich, G., and Hougardy, 33. Lippold, ). C , and Savage, W . F. 1979.

4. O p t i c a l m e t a l l o g r a p h y in c o n c e r t H. 1941. Welding Rod, U.S. Patent Solidification of austenitic stainless steel weld-

w i t h electron m i c r o p r o b e and Auger 2,240,672. ments, part 1 — a proposed mechanism. Weld-

analysis suggest that t h e greater cracking 14. Borland, ). C , and Younger, R. N. 1960. ing Journal 58(12):361-s to 374-s.

susceptibility of the c o m m e r c i a l duplex Some aspects of cracking in welded Cr-Ni 34. Kotecki, D. J. 1982. Extension of the

stainless steels resulted f r o m the likely austenitic steels. Brit. Weld. Jour. (1):22-59. WRC ferrite number system. Welding Journal

f o r m a t i o n o f a c o m p l e x , l o w - m e l t i n g liq- 15. Hull, F. C. 1967. Effect of delta ferrite on 61(11):352-s to 361-s.

the hot cracking of stainless steel. Welding 35. Greulich, F. A. 1985. Unpublished

uid film e n r i c h e d in c o p p e r and p h o s p h o -

Journal 46(9):399-s to 409-s. research performed at Sandia National Labora-

rus.

16. Fredriks, H., and Vander Toorn, L. ]. tories, Livermore, Calif.

5. Fractographic e x a m i n a t i o n of the 1968. Hot cracking in austenitic stainless steel 36. Matsuda, F., Nakagawa, H., Uehara, T.,

f r a c t u r e surfaces s h o w e d a transition weld deposits. Brit. Weld. Jour. (4):178-182. Katayama, S., and Arata, Y. 1979. A new

f r o m dendritic t o flat f r a c t u r e exclusively 17. Masumoto, I., Tamaki, K., and Kutsuna, explanation for the role of delta ferrite in

in the single-phase-solidifying duplex M. 1972. Hot cracking of austenitic weld improving the weld solidification crack suscep-

stainless steels. T h e existence of this flat metal. Trans. /I4/S41(11):1306-1341. tibility in austenitic stainless steel. Trans. JWRl

fracture has b e e n related t o t h e greater 18. Arata, Y., Matsuda, F., and Saruwatari, 8(1).

cracking susceptibility o f these alloys v e r - S. 1974. Varestraint test for solidification crack 37. Hellawell, A., and Hume-Rothery, W .

susceptibility in weld metal of austenitic stain- 1957. Phil. Trans. Royal Society of London, Ser.

sus the FN 4.5 T y p e 304L stainless steel,

less steels. Trans. JWRl 3(1):79-88. A, 249:417-459.

w h i c h exhibited only dendritic fracture.

19. Lundin, C. D., DeLong, W . T., and 38. Sinha, A. K „ Buckley, R. A., and Hume-

Spond, D. F. 1975. Ferrite-fissuring relationship Rothery, W . 1967. /. Iron and Steel Inst.

in austenitic stainless steel weld metals. Weld- 205:191-195

Acknowledgments

ing Journal 54(8):241-s to 246-s. 39. Matsuda, F., and Nakagawa, H. 1979.

The authors are grateful t o A n d y Gar- 20. Suutala, N., Takalo, T., and Moisio, T. Fractographic features and classification of

d e a , Clarence Karfs, Miles Clift a n d D a v e 1980. Ferritic-austenitic solidification mode in weld solidification cracks. Trans. JWRl 8(1).

Ruddle, all f r o m Sandia National L a b o r a t o - austenitic stainless steel welds. Met. Trans. 40. Dixon, B. F„ and Phillips, R. H. Cracking

11A(5):717-725. in the trans-Varestraint test, part 3 —fractogra-

ries, L i v e r m o r e , Calif., w h o s e willing assis-

21. Matsuda, F., Nakagawa, H., Uehara, T., phy. Metal Construction (4):232-237.

tance a n d technical skills w e r e invaluable

Katayama, S., and Arata, Y. 1979. A new 41. Katayama, S., Fujimoto, T., and Matsu-

d u r i n g t h e c o u r s e of this investigation. This explanation for the role of delta-ferrite in nawa, A. 1985. Correlation among solidifica-

w o r k w a s s u p p o r t e d in part b y the U.S. improving weld solidification crack susceptibili- tion process, microstructure, microsegregation

D e p a r t m e n t o f Energy (DOE) u n d e r C o n - ty in austenitic stainless steel. Trans. JWRl and solidification cracking susceptibility in

tract N o . D E - A C 0 4 - 7 5 D P 0 0 7 8 9 . 8(1):105-112. stainless steel weld metals. Trans. JWRl 14(1).

250-s | AUGUST 1987

Potrebbero piacerti anche

- HAZ Liquation Cracking in Austenitic and Duplex S.S. - J.C. Lippold PDFDocumento14 pagineHAZ Liquation Cracking in Austenitic and Duplex S.S. - J.C. Lippold PDFHagen_of_TronjeNessuna valutazione finora

- Fissures in Austenitic Stainless Steel Weld MetalsDocumento12 pagineFissures in Austenitic Stainless Steel Weld MetalsthanhNessuna valutazione finora

- Hot Cracking in Austenitic Stainless SteelsDocumento4 pagineHot Cracking in Austenitic Stainless SteelsHarish KrishnaNessuna valutazione finora

- Task Ii Technology & Weld Metallurgy: Welding of Ferritic Stainless SteelDocumento8 pagineTask Ii Technology & Weld Metallurgy: Welding of Ferritic Stainless SteelMuhammad Irman Budi PermanaNessuna valutazione finora

- Stabilization Improves Weldability of Ferritic Stainless SteelsDocumento8 pagineStabilization Improves Weldability of Ferritic Stainless SteelsAshish Kumar AgrawalNessuna valutazione finora

- Environmental Degradation of Dissimilar Austenitic 316L and Duplex 2205 Stainless Steels Welded JointsDocumento6 pagineEnvironmental Degradation of Dissimilar Austenitic 316L and Duplex 2205 Stainless Steels Welded Jointsk.touilebNessuna valutazione finora

- Journal of Manufacturing Processes: Full Length ArticleDocumento14 pagineJournal of Manufacturing Processes: Full Length ArticleSudish Jay MishraNessuna valutazione finora

- 1 s2.0 S1526612517302542 MainDocumento14 pagine1 s2.0 S1526612517302542 Mainsudish mishraNessuna valutazione finora

- Weldability Al IronDocumento8 pagineWeldability Al IronomarNessuna valutazione finora

- Heat-Affected Zone Infiltration in Dissimilar Metal WeldsDocumento9 pagineHeat-Affected Zone Infiltration in Dissimilar Metal WeldsshivabejugamaNessuna valutazione finora

- Power PlantDocumento17 paginePower PlantVasu RajaNessuna valutazione finora

- Prevention of Solidification Cracking PDFDocumento8 paginePrevention of Solidification Cracking PDFMohamedNessuna valutazione finora

- WWW Aws Org WJ Supplement Barnhouse Barnhouse PDFDocumento17 pagineWWW Aws Org WJ Supplement Barnhouse Barnhouse PDFamitNessuna valutazione finora

- Passive Films On Stainless Steels - Chemistry, Structure and GrowthDocumento12 paginePassive Films On Stainless Steels - Chemistry, Structure and GrowthaauriscNessuna valutazione finora

- WJ - 1986 - 08 - s213 - TVT Reaquecido - Gráficos LegaisDocumento14 pagineWJ - 1986 - 08 - s213 - TVT Reaquecido - Gráficos LegaisRafaella SilvaNessuna valutazione finora

- BF 02814824Documento17 pagineBF 02814824Saiful ShokriNessuna valutazione finora

- SSC DWDocumento4 pagineSSC DWsanketpavi21Nessuna valutazione finora

- Weld Properties of AISI 303 Free-Machining Stainless SteelDocumento9 pagineWeld Properties of AISI 303 Free-Machining Stainless SteeltazzorroNessuna valutazione finora

- Ferrite Morphology and Variations inDocumento9 pagineFerrite Morphology and Variations inAndrea CalderaNessuna valutazione finora

- Corrosion Science 50 (2008) 2620–2634Documento15 pagineCorrosion Science 50 (2008) 2620–2634pepe martinezNessuna valutazione finora

- Fiber Laser WeldingDocumento10 pagineFiber Laser WeldingAnonymous GhPzn1xNessuna valutazione finora

- Hot Cracking Duplex Stainless Steel2Documento18 pagineHot Cracking Duplex Stainless Steel2Sergio Antonio Muñoz PinzónNessuna valutazione finora

- Weld Solidification and Cracking Behavior of Free-Machining Stainless SteelDocumento14 pagineWeld Solidification and Cracking Behavior of Free-Machining Stainless SteeltazzorroNessuna valutazione finora

- 2205 FFDocumento9 pagine2205 FFcsshin1Nessuna valutazione finora

- Weldability of Duplex Stainless Steels TDocumento10 pagineWeldability of Duplex Stainless Steels Tel_sharkawy2011Nessuna valutazione finora

- A Simple Test For Solidification Cracking Susceptibility and Filler Metal EffectDocumento13 pagineA Simple Test For Solidification Cracking Susceptibility and Filler Metal Effectdavid perezNessuna valutazione finora

- Mseij 02 00071Documento5 pagineMseij 02 00071Dr. Rachid djoudjouNessuna valutazione finora

- The Influence of Molybdenum On Stainless Steel Weld MicrostructuresDocumento12 pagineThe Influence of Molybdenum On Stainless Steel Weld Microstructureskamal touilebNessuna valutazione finora

- Abrasion Resistance of Iron-Based Hardfacing AlloysDocumento10 pagineAbrasion Resistance of Iron-Based Hardfacing AlloysRolando Mario Nuñez MonrroyNessuna valutazione finora

- Nelson Part 2Documento11 pagineNelson Part 2Nipun AhujaNessuna valutazione finora

- Ductility Troughs in Microalloyed SteelDocumento12 pagineDuctility Troughs in Microalloyed SteelAtanu MukherjeeNessuna valutazione finora

- 2021 Influence of Immersion Corrosion AISI 430 AISI 316L - IJE - Volume 34 - Issue 5 - 2021Documento11 pagine2021 Influence of Immersion Corrosion AISI 430 AISI 316L - IJE - Volume 34 - Issue 5 - 2021cesold delcaribeNessuna valutazione finora

- Optics & Laser Technology: M.M.A. Khan, L. Romoli, R. Ishak, M. Fiaschi, G. Dini, M. de SanctisDocumento9 pagineOptics & Laser Technology: M.M.A. Khan, L. Romoli, R. Ishak, M. Fiaschi, G. Dini, M. de SanctisLuan CaetanoNessuna valutazione finora

- Hot Cracking Susceptibility of Austenitic Stainless Steels: by T. Ogawa and E. TsunetomiDocumento12 pagineHot Cracking Susceptibility of Austenitic Stainless Steels: by T. Ogawa and E. Tsunetomipradip meneNessuna valutazione finora

- Materials Science & Engineering A: V.D. Vijayanand, K. Laha, P. Parameswaran, V. Ganesan, M.D. MathewDocumento7 pagineMaterials Science & Engineering A: V.D. Vijayanand, K. Laha, P. Parameswaran, V. Ganesan, M.D. Mathewqtie87Nessuna valutazione finora

- Deep Cryogenic Treatment Improves Mechanical Properties of Friction Stir Welded Aluminum Alloy JointsDocumento7 pagineDeep Cryogenic Treatment Improves Mechanical Properties of Friction Stir Welded Aluminum Alloy JointsGeoffreyNessuna valutazione finora

- Laser Welding of Grey Cast Iron With Spheroidal GRDocumento14 pagineLaser Welding of Grey Cast Iron With Spheroidal GRYasser SobhyNessuna valutazione finora

- ActaMat 51 ToroDocumento12 pagineActaMat 51 Toroaltoro44Nessuna valutazione finora

- Dissimilar Welding of Stainless Steel To Other MetailsDocumento15 pagineDissimilar Welding of Stainless Steel To Other Metailssandeep_kale83Nessuna valutazione finora

- Materials Science & Engineering A: Jun Hu, Lin-Xiu Du, Jian-Jun Wang, Cai-Ru GaoDocumento8 pagineMaterials Science & Engineering A: Jun Hu, Lin-Xiu Du, Jian-Jun Wang, Cai-Ru GaoAlfiansyah DarmawanNessuna valutazione finora

- Duplex SS HistoryDocumento7 pagineDuplex SS HistoryPedro CarneiroNessuna valutazione finora

- Effects of Weldin G Parameters On Hard Zone Dissimilar Metal WeldsDocumento8 pagineEffects of Weldin G Parameters On Hard Zone Dissimilar Metal WeldsRami GhorbelNessuna valutazione finora

- Annealing of Cold-Worked Austenitic Stainless SteeDocumento10 pagineAnnealing of Cold-Worked Austenitic Stainless SteeHassaan RidwanNessuna valutazione finora

- Etc.) - The Number of Grades Is Therefore Seemingly Infinite, With A Large NumberDocumento16 pagineEtc.) - The Number of Grades Is Therefore Seemingly Infinite, With A Large Numberandres16012008Nessuna valutazione finora

- Temper-Brittleness: Part I - Unalloyed Steels: B. R. Nijhawan National Metallurgical Laboratory, JamshedpurDocumento13 pagineTemper-Brittleness: Part I - Unalloyed Steels: B. R. Nijhawan National Metallurgical Laboratory, JamshedpurShital ManeNessuna valutazione finora

- Materials and Design: Peng Li, Jinglong Li, Muhammad Salman, Li Liang, Jiangtao Xiong, Fusheng ZhangDocumento8 pagineMaterials and Design: Peng Li, Jinglong Li, Muhammad Salman, Li Liang, Jiangtao Xiong, Fusheng ZhangVishwajeet GuptaNessuna valutazione finora

- WSRC Ms 2001 00544Documento25 pagineWSRC Ms 2001 00544arjun prajapatiNessuna valutazione finora

- Study of PlasmaDocumento12 pagineStudy of PlasmaFerdinando Marco Rodrigues BorgesNessuna valutazione finora

- 1 s2.0 S0921509301016562 MainDocumento7 pagine1 s2.0 S0921509301016562 Mainsatyanarayana chvvNessuna valutazione finora

- Corrosion Resistance of Cast Duplex SteelsDocumento6 pagineCorrosion Resistance of Cast Duplex SteelsGeorge DobreNessuna valutazione finora

- Effect of Tempering Pass on HSLA-80 Steel HAZ MicrostructuresDocumento8 pagineEffect of Tempering Pass on HSLA-80 Steel HAZ Microstructuresdavid perezNessuna valutazione finora

- Corrosion Behavior of Welded Stainless Steel PDFDocumento20 pagineCorrosion Behavior of Welded Stainless Steel PDFLanang Dian NugrohoNessuna valutazione finora

- Influence of Welding Process On Type IV PDFDocumento11 pagineInfluence of Welding Process On Type IV PDFDiego AlonsoNessuna valutazione finora

- Influence of The Microstructure of Duplex Stainless Steels On Their Failure Characteristics During Hot DeformationDocumento5 pagineInfluence of The Microstructure of Duplex Stainless Steels On Their Failure Characteristics During Hot DeformationAbraham MallisaNessuna valutazione finora

- The Salt Spray Environments For Mechanical Degradation of Welded SS304 Stainless SteelsDocumento5 pagineThe Salt Spray Environments For Mechanical Degradation of Welded SS304 Stainless SteelserpublicationNessuna valutazione finora

- 409 M and Kaltenhausen FormulaDocumento9 pagine409 M and Kaltenhausen Formulakr_ananthNessuna valutazione finora

- Metal Transfer and Build-up in Friction and CuttingDa EverandMetal Transfer and Build-up in Friction and CuttingNessuna valutazione finora

- Hydrogen in Steel: Effect of Hydrogen on Iron and Steel During Production, Fabrication, and UseDa EverandHydrogen in Steel: Effect of Hydrogen on Iron and Steel During Production, Fabrication, and UseNessuna valutazione finora

- Solidification Cracking in Austenitic Stainless Steel WeldsDocumento24 pagineSolidification Cracking in Austenitic Stainless Steel WeldsTalha MahmoodNessuna valutazione finora

- ASME PCC-1-2013 Guidelines For Pressure Boundary Bolted Flange Joint Assembly - Part2Documento26 pagineASME PCC-1-2013 Guidelines For Pressure Boundary Bolted Flange Joint Assembly - Part2mistervacunaNessuna valutazione finora

- ASME PCC-1-2013 Guidelines For Pressure Boundary Bolted Flange Joint Assembly - Part2Documento26 pagineASME PCC-1-2013 Guidelines For Pressure Boundary Bolted Flange Joint Assembly - Part2mistervacunaNessuna valutazione finora

- ASME PCC-1-2013 Guidelines For Pressure Boundary Bolted Flange Joint Assembly - Part2Documento26 pagineASME PCC-1-2013 Guidelines For Pressure Boundary Bolted Flange Joint Assembly - Part2mistervacunaNessuna valutazione finora

- DataDocumento52 pagineDataAtanu BiswasNessuna valutazione finora

- STD 1104 Welding of Pipelines and Related FacilitiesDocumento1 paginaSTD 1104 Welding of Pipelines and Related FacilitiesJuan CarlosNessuna valutazione finora

- Structural Steel DesignDocumento108 pagineStructural Steel DesignMilomir Gavrilovic77% (13)

- All AlloysDocumento74 pagineAll AlloyswmkaneNessuna valutazione finora

- Abrasive ProcessesDocumento63 pagineAbrasive ProcessesmohdhmNessuna valutazione finora

- Research Paper On D and F Block PDFDocumento9 pagineResearch Paper On D and F Block PDFVishwa RahulNessuna valutazione finora

- 48,3x5,08 824000Documento2 pagine48,3x5,08 824000Mehmet ŞaHanNessuna valutazione finora

- Machinability Study of Duplex Stainless Steel 2205 Using Cryogenic CoolantDocumento6 pagineMachinability Study of Duplex Stainless Steel 2205 Using Cryogenic CoolantirinaNessuna valutazione finora

- En GJS 600 3Documento2 pagineEn GJS 600 3abhiNessuna valutazione finora

- Fastners MTCDocumento18 pagineFastners MTCmaheshmalaichamy007Nessuna valutazione finora

- Surbhi Steel Catalouge NewDocumento4 pagineSurbhi Steel Catalouge NewVenkatesh KumarNessuna valutazione finora

- KnurlingDocumento2 pagineKnurlingSounak BanerjeeNessuna valutazione finora

- PT. ZUG INDUSTRY WELDING QUALIFICATIONSDocumento4 paginePT. ZUG INDUSTRY WELDING QUALIFICATIONSMuhammad Fitransyah Syamsuar PutraNessuna valutazione finora

- Compositions, Properties and Uses of AlloysDocumento4 pagineCompositions, Properties and Uses of Alloysoasis_dessert100% (8)

- Tube Catalogue AnitaDocumento64 pagineTube Catalogue AnitaChinnaraja GandhiNessuna valutazione finora

- Astm A514Documento5 pagineAstm A514FYNessuna valutazione finora

- AISI 4130 alloy steel guideDocumento2 pagineAISI 4130 alloy steel guideALEX MURPHYNessuna valutazione finora

- Centennial College: Milestone - 1 Project: - Hand Power SawDocumento14 pagineCentennial College: Milestone - 1 Project: - Hand Power Sawanmol singhNessuna valutazione finora

- Cast Iron - A Predictable Material 25 Years of ModDocumento14 pagineCast Iron - A Predictable Material 25 Years of ModScribdtsNessuna valutazione finora

- Laser Rust Removal - PowerlaseDocumento17 pagineLaser Rust Removal - PowerlaseIoannis MetsiosNessuna valutazione finora

- Piping For PDFDocumento1 paginaPiping For PDFSumañ DašNessuna valutazione finora

- Bohler Ars 5 - e 71 T-1 C (M) H8Documento1 paginaBohler Ars 5 - e 71 T-1 C (M) H8Mario MolinaNessuna valutazione finora

- Important Questions For CBSE Class 8 Science Chapter 4Documento5 pagineImportant Questions For CBSE Class 8 Science Chapter 4SashankNessuna valutazione finora

- Ni-Fe-Cr-Mo-Cu-N Low-Carbon Alloys (UNS N08925, UNS N08031, UNS N08354, and UNS N08926), and Cr-Ni-Fe-N Low-Carbon Alloy (UNS R20033) Bar and Wire, and Ni-Cr-Fe-Mo-N Alloy (UNS N08936) WireDocumento7 pagineNi-Fe-Cr-Mo-Cu-N Low-Carbon Alloys (UNS N08925, UNS N08031, UNS N08354, and UNS N08926), and Cr-Ni-Fe-N Low-Carbon Alloy (UNS R20033) Bar and Wire, and Ni-Cr-Fe-Mo-N Alloy (UNS N08936) WireSrinivasan KrishnamoorthyNessuna valutazione finora

- 201172711456351Documento9 pagine201172711456351Ferlie IndrapatiNessuna valutazione finora

- Forming and Shaping Processes and Equipment: Manufacturing Engineering Technology in SI Units, 6 EditionDocumento35 pagineForming and Shaping Processes and Equipment: Manufacturing Engineering Technology in SI Units, 6 EditionRodger OlynNessuna valutazione finora

- Vimp Theory of Metal Cutting 2Documento100 pagineVimp Theory of Metal Cutting 2Harsh PawarNessuna valutazione finora

- Materials For Aggresive EnvironmentsDocumento26 pagineMaterials For Aggresive EnvironmentsfabianoNessuna valutazione finora

- BS en 10163-2-2004Documento14 pagineBS en 10163-2-2004Dave CheungNessuna valutazione finora

- Carta Maestra de Soldadura y CortDocumento7 pagineCarta Maestra de Soldadura y CortAlejandro Del Valle TovarNessuna valutazione finora