Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

T2700 Tower Specifications PDF

Caricato da

mdalt9180Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

T2700 Tower Specifications PDF

Caricato da

mdalt9180Copyright:

Formati disponibili

“Manufacturing is Our Game

Satisfaction is Our Fame!”

Over 40 Years of Experience…

Fiberglass Cooling Tower Manufacturer

Tower Specifications:

Model TT--2700

Cooling

Tower

Systems

The best just got better.

MEMBER

196 Lower Cherry Street

Macon, GA 31201

800-752-1905

478-755-1905

800-203-4925 FAX

478-755-8304 FAX

www.coolingtowersystems.com

info@coolingtowersystems.com

Tower Specifications: Model T-

T-2700

MATERIALS KEY

NOTE:

FRP Fiberglass Reinforced Plastic These are STANDARD specifications

for this cooling tower. For

HDGS Hot Dip Galvanized Steel

custom/non-standard specifications,

AC Aluminum Alloy Cast please contact our National Sales

STS

Office.

Stainless Steel

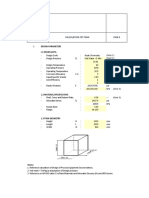

Design and Operating Conditions Water Distribution System Construction Materials

Tower type: CounterFlow Induces Draft Stand pipe: PVC

Water flow rates: 2101 gpm Sprinkler head: AC

Hot water temperature: 95° f Sprinkler pipe: PVC

Cold water temperature: 85° f Mechanical Equipment

Ambient wet bulb temperature: 75° f Fan unit: one unit per tower

Total fan BHP: 20 hp Type: Axial Flow

Total pump head: 97 5/8 ft Manufacturer: CTS

Drift loss of water flow rates: 0.002% Diameter: 133 1/8 in

Evaporation loss of water flow rates: 0.93% Blade material: AC

Design wind load: 30.7 lb/sq ft Hub material: AC

Structural Details Nominal air volume: 125,000 cfm

Overall diameter: 259 7/8 in Fan Motor

Overall height: 181.31 in Number of motors: one unit per tower

Dry weight: 7848 lbs Type: Induction

Operating weight: 24127 lbs Manufacturer: CTS

Basic Tower Construction Materials Insulation: E Class

Tower support frame assembly: HDGS Rated HP: 20 hp

Casing: FRP Voltage and phase: 220/440-3

Casing supporter: HDGS Piping Connections

Cold water basin: FRP Primary water inlet diameter: 10 in

Filling: PVC Primary water outlet diameter: 10 in

Filling support: HDGS Auto fill inlet diameter: 2 in

Fan guard: HDGS Quick fill inlet diameter: 2 in

Mechanical equipment support HDGS Overflow outlet diameter: 4 in

Air inlet louver: PVC Drain diameter: 2 in

Bolts, nuts and washers: STS Nominal water flow: 2101 gpm

Specifications subject to change without notice.

www.coolingtowersystems.com -2- 40 Years of Manufacturing Experience

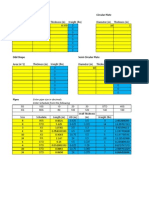

Parts List: Model T-

T-2700

FOR TECHNICAL DIAGRAMS FOR ASSEMBLY DIAGRAM

Item No. Description Material QTY Ref. No. Description QTY

1 Fan Motor - 1 pcs 01-01 Base Plate - A 8

2 V-Belt Reducer - 1 set 01-02 Ring Frame 8

3 Motor Frame Assembly HDGS 1 set 01-03 Truss Pipe - A1 8

4 Fan AC 1 set 01-04 Truss Pipe - A2 8

5 Fan Guard HDGS 1 set 01-06 Tie Rod 8

6 Casing FRP 16 pcs 02-01 Water Sump 1

7 Hand Hole EVA 1 pcs 02-02 Outlet Nozzle 1

8 Sprinkler Head AC 1 set 02-03 Inlet Nozzle 1

9 Sprinkler Pipe PVC 8 pcs 02-04 Over Flow Nozzle 1

10 Eliminator FRP 8 pcs 02-05 Drain Nozzle 1

11 Tension Device HDGS 1 set 02-06 Automatic Filler Nozzle 1

12 Stand Pipe PVC 1 set 02-07 Quick Filler Nozzle 1

13 Filling PVC 1 set 02-08 Float Valve Assembly 2

14 Stopper or Column HDGS 1 set 02-09 Over Flow 1

15 Filling Supporter HDGS 1 set 02-10 Suction Strainer 1

16 Casing Supporter HDGS 6 pcs 02-12A Connector 1

17 Inlet Louver PVC 1 set 02-13 Elbow 3

18 Frame Assembly HDGS 1 set 03-01 Water Basin 16

19 Water Basin FRP 12 pcs 04-01 Base Plate - B 8

20 Water Sump FRP 1 pcs 04-02 Stiffener Ring - 1 8

21 Ladder HDGS 1 set 04-03 Truss Pipe - B1 8

22 Strainer STS 1 pcs 04-04 Truss Pipe - B2 8

23 Flange HDGS 2 pcs 05-01 Casing (Diffuser) 16

24 Basin Supporter HDGS 16 pcs 05-02 Casing (Cylinder) 16

05-03 Stiffener Ring - 2 8

MATERIALS KEY

05-04 Casing Stand 16

05-05 Inserted Bar 16

FRP Fiberglass Reinforced Plastic 05-06 Hand Hole Cover 1

06-01 Stand Pipe 1

HDGS Hot Dip Galvanized Steel 06-02 Stand Pipe Base 1

06-03 Packing 1

AC Aluminum Alloy Cast 07-02 Column 1

08-01 Filling Supporter - A 8

STS Stainless Steel 08-02 Filling Supporter - B 8

08-03 Filling Supporter - C 24

08-04 Fill Supt. Clamping Band 16

WaterBasin Sealing Material 08-06 Filling Supporter - E 16

10-01-1 Ladder (A Section - 1) 1

A Fiberglass 1 Set 10-01-2 Ladder (A Section - 2) 1

10-02 Ladder (B Section) 1

B Polyester Resin 1 Keg 10-03 Ladder Bracket - A 2

10-04 Ladder Bracket - B 2

C Catalyst 1 Bottle 11-01 Filling (Inner Section) -

11-03 Filling (1/3 Section) 6

11-06 Filling (1/6 Section) -

11-08 Filling (1/8 Section) 16

12-01 Sprinkler Head 1

12-02 Center Post 1

12-03 Turnbuckle 8

12-04 Tension Wire 8

13-01 Sprinkler Pipe 8

13-02 End Cap 8

www.coolingtowersystems.com -3- 40 Years of Manufacturing Experience

Parts List: Model T-

T-2700

FOR TECHNICAL DIAGRAMS FOR ASSEMBLY DIAGRAM

Item No. Description Material QTY Ref. No. Description QTY

13-03 Eliminator 8

14-01 Frame Ass'y Main Pipe 2

14-02 Frame Ass'y Stay Pipe 2

15-01 Motor Base 1

15-02 U-Bolt 4

16-01 Motor 1

16-02 Speed Reducer 1

16-03 Fan Key 1

16-04 Fasten Nut 1

16-05 Lock Nut 1

17-01 Fan Hub 1

17-02 Fan Blade 4

17-04 U-Bolt 8

18-01 Fan Guard 8

19-00 Basin Supporter Ass'y 16

20-01 Louver Supporter 48

20-01B Louver Supporter - B 48

20-02 Inlet Louver 16

20-08 Wing Bolt 144

20-09 Plastic Washer 144

OTHERS Bolts & Nuts 1 SET

www.coolingtowersystems.com -4- 40 Years of Manufacturing Experience

Technical Image A: Model T-

T-2700

www.coolingtowersystems.com -5- 40 Years of Manufacturing Experience

Technical Image B: Model T-

T-2700

www.coolingtowersystems.com -6- 40 Years of Manufacturing Experience

Technical Image C: Model T-

T-2700

Technical Image D: Model T-

T-2700

www.coolingtowersystems.com -7- 40 Years of Manufacturing Experience

Assembly Diagram: Model T-

T-2700

www.coolingtowersystems.com -8- 40 Years of Manufacturing Experience

Potrebbero piacerti anche

- FE Brosur PDFDocumento2 pagineFE Brosur PDFsudiNessuna valutazione finora

- Inline Centrifugal Duct Fan Installation & Technical SpecsDocumento3 pagineInline Centrifugal Duct Fan Installation & Technical SpecsTedi A MaulanaNessuna valutazione finora

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocumento7 pagineHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNessuna valutazione finora

- American Wide F Beam 6Documento1 paginaAmerican Wide F Beam 6bhaskarNessuna valutazione finora

- Extract Pages From Tower Triangle 20 M - Revisi 1Documento2 pagineExtract Pages From Tower Triangle 20 M - Revisi 1Sholahuddin DiinNessuna valutazione finora

- Domae MCB Data Sheet OverviewDocumento12 pagineDomae MCB Data Sheet OverviewViverSharinganUchihaNessuna valutazione finora

- Easy Maintenance Air Conditioning System FeaturesDocumento1 paginaEasy Maintenance Air Conditioning System FeaturesKevin Lau100% (1)

- Katalog FCU DDB050BWDocumento35 pagineKatalog FCU DDB050BWMICAH JEDAH0% (1)

- AB Wool Glasswool PDFDocumento2 pagineAB Wool Glasswool PDFAmin Danar NoviyantoNessuna valutazione finora

- Penawaran Jasa InstallationDocumento1 paginaPenawaran Jasa InstallationadihartokoNessuna valutazione finora

- PT - Economie MandiriDocumento8 paginePT - Economie MandiriHariadi Budi SantosoNessuna valutazione finora

- Hvac Boq For Kwara Stadium Indoor Sport HallDocumento6 pagineHvac Boq For Kwara Stadium Indoor Sport HallAbdulyekini AhmaduNessuna valutazione finora

- Pricelist 2020 Sluruh Harga Diskon 30%Documento128 paginePricelist 2020 Sluruh Harga Diskon 30%EdwinAulawiNessuna valutazione finora

- CM YSM Air Handling Unit CatalogueDocumento20 pagineCM YSM Air Handling Unit CatalogueKhalid ImamNessuna valutazione finora

- Fresh & Healthy Home VentilationDocumento2 pagineFresh & Healthy Home VentilationdetailsNessuna valutazione finora

- Tabel Baja: Diameter Berat KG/M: 1 Balok (Wide-Flange)Documento11 pagineTabel Baja: Diameter Berat KG/M: 1 Balok (Wide-Flange)reys_mar12Nessuna valutazione finora

- Catalogue Clamp & Gasket Ferrule SPVDocumento1 paginaCatalogue Clamp & Gasket Ferrule SPVadittyasusantounjNessuna valutazione finora

- AC Cassette DAIKIN Non InverterDocumento1 paginaAC Cassette DAIKIN Non InverterYusup Supri YadieNessuna valutazione finora

- Calculation Cpi Tank: I. Design Parameters I.1 Design DataDocumento5 pagineCalculation Cpi Tank: I. Design Parameters I.1 Design DataikramNessuna valutazione finora

- VRV Single Outdoor Part 1Documento226 pagineVRV Single Outdoor Part 1Faizal AchmadNessuna valutazione finora

- Proposal Teknis Project GITC Duri Pulo - Fire PumpDocumento25 pagineProposal Teknis Project GITC Duri Pulo - Fire PumpSyncroFlo IndonesiaNessuna valutazione finora

- Spare Part Turbin PLTA Bengkok PDFDocumento1 paginaSpare Part Turbin PLTA Bengkok PDFAditya PrajasNessuna valutazione finora

- WeightsDocumento11 pagineWeightsGanesh AdityaNessuna valutazione finora

- EPPM Quote RQE880-00 Cooling Tower SpecDocumento1 paginaEPPM Quote RQE880-00 Cooling Tower SpecBilel Mahjoub100% (1)

- Spesifikasi Trafo DistribusiDocumento1 paginaSpesifikasi Trafo DistribusiJustin PerryNessuna valutazione finora

- Brosur U 1040 BDocumento6 pagineBrosur U 1040 BTania EngineeringNessuna valutazione finora

- Kebutuhan Wrapping PipaDocumento4 pagineKebutuhan Wrapping Pipapanji uteNessuna valutazione finora

- ADT Series Centrifugal Fans for Ventilation, Drying & Air ExtractionDocumento2 pagineADT Series Centrifugal Fans for Ventilation, Drying & Air ExtractionEddy LinNessuna valutazione finora

- 1014 Graha Paramita II Bintaro, Tangerang (r.12) Jaga - Citra - Inti Fans Mar21 250321Documento3 pagine1014 Graha Paramita II Bintaro, Tangerang (r.12) Jaga - Citra - Inti Fans Mar21 250321imam wardhanaNessuna valutazione finora

- Daikin Aircond Inverter - FTKQ-0419-B-L (Leaflet) PDFDocumento2 pagineDaikin Aircond Inverter - FTKQ-0419-B-L (Leaflet) PDFMohd Nazrin Mohd NordinNessuna valutazione finora

- Floor Standing Indoor and Outdoor Air Conditioner UnitsDocumento2 pagineFloor Standing Indoor and Outdoor Air Conditioner UnitsCombox Black100% (1)

- Penawaran Harga Pipa Refrigrant, Isolasi, Support MaterialDocumento2 paginePenawaran Harga Pipa Refrigrant, Isolasi, Support MaterialAgus Sofiansyah100% (1)

- Analisa Harga SatuanDocumento4 pagineAnalisa Harga Satuanqwkerbk090909Nessuna valutazione finora

- Fire Pump Test Meter (6.8)Documento2 pagineFire Pump Test Meter (6.8)Luigi CasamassimaNessuna valutazione finora

- Price List Kabel SupremeDocumento6 paginePrice List Kabel SupremeEvi JayanthiNessuna valutazione finora

- Tower Drawing 100 FeetDocumento3 pagineTower Drawing 100 FeetMian M Khurram100% (3)

- Rencana Anggaran Biaya: Pt. PLN (Persero) Area Penyaluran Dan Pengatur Beban Kalimantan BaratDocumento1 paginaRencana Anggaran Biaya: Pt. PLN (Persero) Area Penyaluran Dan Pengatur Beban Kalimantan Baratandri kustiawanNessuna valutazione finora

- ASME manual coil heating procedureDocumento8 pagineASME manual coil heating procedurehgagNessuna valutazione finora

- Dike WallDocumento18 pagineDike WallManan MansoorNessuna valutazione finora

- Brosur Bed Elevator HyundaiDocumento8 pagineBrosur Bed Elevator HyundaiSeptian Adi SNessuna valutazione finora

- KDK 2018 Fan CatalogeDocumento32 pagineKDK 2018 Fan CatalogeOnn LajerNessuna valutazione finora

- Refurbishing Silo Structure Painting ReportDocumento2 pagineRefurbishing Silo Structure Painting Reportmarifa tullahNessuna valutazione finora

- Wall Thickness CalcDocumento2 pagineWall Thickness Calcpbao_12Nessuna valutazione finora

- TM Midea V8 High Static Pressure Duct VRF Engineering Data Book 20230721 V3Documento29 pagineTM Midea V8 High Static Pressure Duct VRF Engineering Data Book 20230721 V3mohamed.irfan.mepNessuna valutazione finora

- Drawing Sppbe Pt. SdeDocumento9 pagineDrawing Sppbe Pt. SdeHeri AriawansyahNessuna valutazione finora

- Timeline RABDocumento1 paginaTimeline RABAnonymous y6NmP9NHkYNessuna valutazione finora

- Engineering Catalog: HL160M Dri-Prime Pump Engineering DataDocumento6 pagineEngineering Catalog: HL160M Dri-Prime Pump Engineering DatamuahdibNessuna valutazione finora

- Price List Wasser Pump (2016.07.01)Documento1 paginaPrice List Wasser Pump (2016.07.01)kosasih aji somantri100% (1)

- Calculation For Steam and Hot Water Consumption For: Sun Rise CharmingDocumento4 pagineCalculation For Steam and Hot Water Consumption For: Sun Rise CharmingYasser FathiNessuna valutazione finora

- Cara Hitung Kebutuhan Wrapping PipaDocumento4 pagineCara Hitung Kebutuhan Wrapping PipahadiNessuna valutazione finora

- E No.04-01Documento14 pagineE No.04-01Erdinc Senman0% (1)

- Katalog Onaji 2021Documento6 pagineKatalog Onaji 2021adityhot100% (1)

- Hitachi Packaged Air Conditioners Technical CatalogDocumento44 pagineHitachi Packaged Air Conditioners Technical CatalogHa CongNessuna valutazione finora

- RAB Penambahan Instalasi Pipa Loading CPODocumento1 paginaRAB Penambahan Instalasi Pipa Loading CPOMuslim MunawarNessuna valutazione finora

- Galvanized and Black Malleable Iron Pipe Fittings SpecificationsDocumento24 pagineGalvanized and Black Malleable Iron Pipe Fittings SpecificationsdeniNessuna valutazione finora

- Drawing of Chimney Frame PDFDocumento1 paginaDrawing of Chimney Frame PDFsridharNessuna valutazione finora

- 1.ChillerTechnicalData 1 1Documento2 pagine1.ChillerTechnicalData 1 1Nguyên Trịnh CaoNessuna valutazione finora

- Pricelist Bahan Bangunan NewDocumento1 paginaPricelist Bahan Bangunan NewzainulNessuna valutazione finora

- Model T-220 Tower Specifications PDFDocumento8 pagineModel T-220 Tower Specifications PDFcarlosgomes164Nessuna valutazione finora

- Offer No 763 DTD 10.03.23Documento6 pagineOffer No 763 DTD 10.03.23Shahab Z AhmedNessuna valutazione finora

- Type Min Max ActuatorsDocumento6 pagineType Min Max Actuatorsmdalt9180Nessuna valutazione finora

- Easylab: Controller TCU3Documento20 pagineEasylab: Controller TCU3mdalt9180Nessuna valutazione finora

- Briefspec Picture Humidifiers 1 080808Documento7 pagineBriefspec Picture Humidifiers 1 080808mdalt9180Nessuna valutazione finora

- MAYDAY CDX Drift Eliminator Rev ADocumento1 paginaMAYDAY CDX Drift Eliminator Rev Amdalt9180Nessuna valutazione finora

- Hot Water Adsorption Chillers Guide SpecificationsDocumento6 pagineHot Water Adsorption Chillers Guide Specificationsmdalt9180Nessuna valutazione finora

- DHG Ro 20Documento3 pagineDHG Ro 20mdalt9180Nessuna valutazione finora

- DHRC Catalog - F164LR.Documento28 pagineDHRC Catalog - F164LR.mdalt9180Nessuna valutazione finora

- TL k5 2 2 1 Min Max de enDocumento16 pagineTL k5 2 2 1 Min Max de enmdalt9180Nessuna valutazione finora

- Food Industry Air Handling Guidance PDFDocumento6 pagineFood Industry Air Handling Guidance PDFDavidNessuna valutazione finora

- AT4 HumidifierDocumento64 pagineAT4 Humidifiermdalt9180Nessuna valutazione finora

- Cooling TowerDocumento22 pagineCooling TowerAnonymous xcFcOgMiNessuna valutazione finora

- CLA-100-data Sheet PDFDocumento5 pagineCLA-100-data Sheet PDFmdalt9180Nessuna valutazione finora

- ASHRAE Journal - Optimizing Design Control of Chilled Water Plants Part 5 Optimized Control SequencesDocumento20 pagineASHRAE Journal - Optimizing Design Control of Chilled Water Plants Part 5 Optimized Control Sequencesmdalt9180Nessuna valutazione finora

- Spcification - VolzDocumento2 pagineSpcification - Volzmdalt9180Nessuna valutazione finora

- Danfoss DrivesDocumento2 pagineDanfoss Drivesmdalt9180Nessuna valutazione finora

- Kutty ModelDocumento1 paginaKutty Modelmdalt9180Nessuna valutazione finora

- Refrigerant Heat Pipes for DehumidificationDocumento1 paginaRefrigerant Heat Pipes for Dehumidificationmdalt9180Nessuna valutazione finora

- ASHRAE Journal - Optimizing Design Control of Chilled Water Plants Part 2 Condenser Water Distribution System DesignDocumento12 pagineASHRAE Journal - Optimizing Design Control of Chilled Water Plants Part 2 Condenser Water Distribution System Designmdalt9180Nessuna valutazione finora

- 2012 Comprehensive StudyDocumento13 pagine2012 Comprehensive Studymdalt9180Nessuna valutazione finora

- Load Calculation Spreadsheets: Quick Answers Without Relying On Rules of ThumbDocumento8 pagineLoad Calculation Spreadsheets: Quick Answers Without Relying On Rules of ThumbGithu OommenNessuna valutazione finora

- Warehouse Duct PlanDocumento1 paginaWarehouse Duct Planmdalt9180Nessuna valutazione finora

- Tang Layout With Existing MCDocumento1 paginaTang Layout With Existing MCmdalt9180Nessuna valutazione finora

- PIBCVDocumento8 paginePIBCVmdalt9180Nessuna valutazione finora

- 30KW - 150601 - Arpitha Associates India MartDocumento4 pagine30KW - 150601 - Arpitha Associates India Martmdalt9180Nessuna valutazione finora

- Sopt TisDocumento2 pagineSopt Tismdalt9180Nessuna valutazione finora

- M GaugeDocumento1 paginaM Gaugemdalt9180Nessuna valutazione finora

- Stairwell & Lift Pressurization CalculationsDocumento31 pagineStairwell & Lift Pressurization CalculationsAneng2890% (10)

- Marie Barakat Visualcv ResumeDocumento3 pagineMarie Barakat Visualcv ResumebalakrishnaNessuna valutazione finora

- Section (Wall)Documento1 paginaSection (Wall)mdalt9180Nessuna valutazione finora

- Todo Matic PDFDocumento12 pagineTodo Matic PDFSharrife JNessuna valutazione finora

- Bula Defense M14 Operator's ManualDocumento32 pagineBula Defense M14 Operator's ManualmeNessuna valutazione finora

- NABARD road inspection report formatDocumento24 pagineNABARD road inspection report formatSrinivas PNessuna valutazione finora

- PeopleSoft Security TablesDocumento8 paginePeopleSoft Security TablesChhavibhasinNessuna valutazione finora

- 202112fuji ViDocumento2 pagine202112fuji ViAnh CaoNessuna valutazione finora

- What's Wrong With American Taiwan Policy: Andrew J. NathanDocumento14 pagineWhat's Wrong With American Taiwan Policy: Andrew J. NathanWu GuifengNessuna valutazione finora

- LegoDocumento30 pagineLegomzai2003Nessuna valutazione finora

- Jesd8 15aDocumento22 pagineJesd8 15aSridhar PonnurangamNessuna valutazione finora

- LEARNING ACTIVITY Sheet Math 7 q3 M 1Documento4 pagineLEARNING ACTIVITY Sheet Math 7 q3 M 1Mariel PastoleroNessuna valutazione finora

- SDS OU1060 IPeptideDocumento6 pagineSDS OU1060 IPeptideSaowalak PhonseeNessuna valutazione finora

- IELTS Speaking Q&ADocumento17 pagineIELTS Speaking Q&ABDApp Star100% (1)

- Philippine Population 2009Documento6 paginePhilippine Population 2009mahyoolNessuna valutazione finora

- WWW - Commonsensemedia - OrgDocumento3 pagineWWW - Commonsensemedia - Orgkbeik001Nessuna valutazione finora

- Public Private HEM Status AsOn2May2019 4 09pmDocumento24 paginePublic Private HEM Status AsOn2May2019 4 09pmVaibhav MahobiyaNessuna valutazione finora

- 100 Training Games - Kroehnert, GaryDocumento180 pagine100 Training Games - Kroehnert, GarywindsorccNessuna valutazione finora

- DBMS Architecture FeaturesDocumento30 pagineDBMS Architecture FeaturesFred BloggsNessuna valutazione finora

- CBT For BDDDocumento13 pagineCBT For BDDGregg Williams100% (5)

- Philippine Army BDU BidDocumento2 paginePhilippine Army BDU BidMaria TeresaNessuna valutazione finora

- Factors of Active Citizenship EducationDocumento2 pagineFactors of Active Citizenship EducationmauïNessuna valutazione finora

- Listening Exercise 1Documento1 paginaListening Exercise 1Ma. Luiggie Teresita PerezNessuna valutazione finora

- Hi-Line Sportsmen Banquet Is February 23rd: A Chip Off The Ol' Puck!Documento8 pagineHi-Line Sportsmen Banquet Is February 23rd: A Chip Off The Ol' Puck!BS Central, Inc. "The Buzz"Nessuna valutazione finora

- Ielts Practice Tests: ListeningDocumento19 pagineIelts Practice Tests: ListeningKadek Santiari DewiNessuna valutazione finora

- I Will Be Here TABSDocumento7 pagineI Will Be Here TABSEric JaoNessuna valutazione finora

- OS LabDocumento130 pagineOS LabSourav BadhanNessuna valutazione finora

- Ovr IbDocumento27 pagineOvr IbAriel CaresNessuna valutazione finora

- Technical Manual - C&C08 Digital Switching System Chapter 2 OverviewDocumento19 pagineTechnical Manual - C&C08 Digital Switching System Chapter 2 OverviewSamuel100% (2)

- LIST OF ENROLLED MEMBERS OF SAHIWAL CHAMBER OF COMMERCEDocumento126 pagineLIST OF ENROLLED MEMBERS OF SAHIWAL CHAMBER OF COMMERCEBASIT Ali KhanNessuna valutazione finora

- LSMW With Rfbibl00Documento14 pagineLSMW With Rfbibl00abbasx0% (1)

- CTR Ball JointDocumento19 pagineCTR Ball JointTan JaiNessuna valutazione finora

- Employee Confidentiality and Non-Disclosure AgreementDocumento5 pagineEmployee Confidentiality and Non-Disclosure AgreementshamoojeeNessuna valutazione finora