Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

MAYDAY CDX Drift Eliminator Rev A

Caricato da

mdalt9180Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MAYDAY CDX Drift Eliminator Rev A

Caricato da

mdalt9180Copyright:

Formati disponibili

INDUSTRIAL COOLING Unit 31, Sandy Way

MAYDAY ENGINEERS Amington Industrial Estate

DESIGN, INSTALLATION Tamworth

INDUSTRIAL & MAINTENANCE Staffs, B77 4DS

Tel: 01827 53633

Fax: 01827 53686

www.maydayindustrial.co.uk

TECHNICAL DATA SHEET

CDX-80 DRIFT ELIMINATOR FOR CROSS & COUNTER FLOW COOLING TOWERS

CROSS FLOW COUNTER FLOW

AccuPac® CELLULAR DRIFT ELIMINATORS

DESIGN: CDX-80 Drift eliminators utilize a series of sinusoidal-shaped corrugations bonded to mating sinusoidal

structural waves to form closed cells that force the leaving airstream to make three distinct changes in direction. The drift

droplets carried in the airstream, when forced to make the changes in direction in each cell, create centrifugal forces on

the drift droplets, forcing them to be captured by inertial impaction and direct interception. The high surface area of

cellular eliminators and these unique design features, ensures state-of-the-art drift removal efficiency.

STRENGTH: Because this design utilizes structural waves between the corrugated cells, these drift eliminators can be

manufactured to meet span requirements up to 2.4m. This improvement in strength and span capabilities reduces the net

blockage of air due to additional support beams. Additionally, these drift eliminators can be field cut for a tight fit around

columns and other structure without sacrificing any structural integrity.

PERFORMANCE: The CDX-80 is designed to meet the most stringent specifications where very low drift levels are

required. The drift removal efficiency of this product is unequaled in the industry. CDX-80 in designed for applications in

either cross flow or counter flow cooling towers.

DRAINAGE CHANNELS: Our unique design for cross flow applications allows captured drift droplets to be removed as a

film of water through drainage channels. Once drift droplets are captured on the side walls of the eliminator, they form a

film of water that flows down the wall via gravity to the drainage channels and then out the bottom of the eliminator,

reducing the opportunity for rein-trainment. Other manufacturers' designs force the captured water to the face of the

eliminator where it trickles down the edge, allowing more opportunities for reintrainment as drift droplets. Drainage

channels are a unique AccuPac design that can greatly improve the drift removal efficiency of your cooling tower.

SPECIAL FEATURES NESTING: Our CDX-80 is designed so they nest or

interlock with the module next to them, eliminating interfaces between modules.

This important feature eliminates a possible bypass of the air that can occur when

modules are not tightly sealed at the module to module interface In a flat sheet

design any small gaps between the flat sheets will cause air to bypass the

eliminator, taking the path of less resistance and carrying drift droplets with it.

SPECIFACATION STANDARD CDX-80:

Materials: PVC, HPVC Mass: 8.9 kg/m²

Depth: 140mm Drift loss % recirculation: 0.001 (CTI-HBIK Std.140 test)

Width: 305 mm Maxim air velocity 3.7 m/s

Length: 610 - 3050 mm Pressure drop at 3.5 m/s 16 Pa

Corrugation pitch: 21 mm

Sheet thickness: 0.25 mm

The company’s policy of continued improvement may necessitate design being changed without notice.

Potrebbero piacerti anche

- Accu PacDocumento2 pagineAccu PacGanesh.MahendraNessuna valutazione finora

- Bus Bar Insulating ShroudsDocumento3 pagineBus Bar Insulating ShroudsRohit SharmaNessuna valutazione finora

- Ubbink Air Excellent BrochureDocumento24 pagineUbbink Air Excellent BrochureRazvan AlexandrescuNessuna valutazione finora

- Mobil Dte 20Documento3 pagineMobil Dte 20alexander900616Nessuna valutazione finora

- Agiecharmilles Cut 20p 30p - enDocumento20 pagineAgiecharmilles Cut 20p 30p - enMark Hahn0% (1)

- CNC Pure Water Jet Cutting MachinesDocumento5 pagineCNC Pure Water Jet Cutting MachinesDarren MadlansacayNessuna valutazione finora

- 00643Documento9 pagine00643Sunilkumar ReddyNessuna valutazione finora

- Precast Concrete Headwalls - NydotDocumento6 paginePrecast Concrete Headwalls - NydotgemotorresNessuna valutazione finora

- Free Water Knock Out Separator: System DescriptionDocumento4 pagineFree Water Knock Out Separator: System DescriptionMurat KalfaNessuna valutazione finora

- VR3 Cnctubenotching3 WebsiteDocumento2 pagineVR3 Cnctubenotching3 WebsiteSachaNessuna valutazione finora

- Corning Consideracion para Soplado de Cables en Microducto - AEN096-BENDocumento3 pagineCorning Consideracion para Soplado de Cables en Microducto - AEN096-BENPaul MarquinaNessuna valutazione finora

- ProfilDocumento18 pagineProfilAnonymous 6EW2MsFbkNessuna valutazione finora

- Busbar Trunking SystemDocumento21 pagineBusbar Trunking SystemJordan Ansh50% (2)

- IEICOS Wind Tunnel Catalog 2012Documento8 pagineIEICOS Wind Tunnel Catalog 2012cparamesNessuna valutazione finora

- MAPAL Anwendungsorientierte Werkzeugspannfutter EN V1.0.0Documento28 pagineMAPAL Anwendungsorientierte Werkzeugspannfutter EN V1.0.0xmen norNessuna valutazione finora

- 12.1 Đầu Cáp Ngầm Ngoài Trời 24kV- (1x300) Mm2 - GIẢMDocumento124 pagine12.1 Đầu Cáp Ngầm Ngoài Trời 24kV- (1x300) Mm2 - GIẢMhoangtinbkNessuna valutazione finora

- Radiscreen-C Coarse Screen BR-ENDocumento4 pagineRadiscreen-C Coarse Screen BR-ENmriosqNessuna valutazione finora

- Disc Brake Units Be 100, Be 125, and Be 200: Technical InformationDocumento6 pagineDisc Brake Units Be 100, Be 125, and Be 200: Technical InformationJose Maria Castro PazosNessuna valutazione finora

- MCD Slb801 enDocumento4 pagineMCD Slb801 endino_pNessuna valutazione finora

- Counter Flow Induced Draft: SeriesDocumento8 pagineCounter Flow Induced Draft: SeriesAmro Metwally El HendawyNessuna valutazione finora

- Design Calculations From Engineering Assessment: 165 219 8.10 10.35 Owner Contact Diamondwrap® ContactDocumento2 pagineDesign Calculations From Engineering Assessment: 165 219 8.10 10.35 Owner Contact Diamondwrap® ContactManikandan MNessuna valutazione finora

- Tunneling Excavator: Cat C7 Diesel Engine With ACERT™ TechnologyDocumento16 pagineTunneling Excavator: Cat C7 Diesel Engine With ACERT™ TechnologyImran HasicNessuna valutazione finora

- Structural Design Calculation - PMCC Building in PT PlantDocumento28 pagineStructural Design Calculation - PMCC Building in PT PlantSatya NarayanaNessuna valutazione finora

- Calculation Note: Armadillo 500RDocumento27 pagineCalculation Note: Armadillo 500RMacNessuna valutazione finora

- Barclay SilencersDocumento12 pagineBarclay SilencerspostboxsgNessuna valutazione finora

- Pre StressingDocumento48 paginePre StressingRameshNessuna valutazione finora

- Filtro Especial PME AirtekDocumento2 pagineFiltro Especial PME AirtekEduardo CervantesNessuna valutazione finora

- DTS 400 PDM VesDocumento5 pagineDTS 400 PDM Vesalvaro.gimenez.colegioNessuna valutazione finora

- Compact ColdMillsDocumento32 pagineCompact ColdMillsdownloadNessuna valutazione finora

- Hydro-Mechanical Anderreamer Tech SummaryDocumento2 pagineHydro-Mechanical Anderreamer Tech SummaryYaqoob Ibrahim100% (1)

- W4 305E Hot Strip Mills - Mechanical Equipment PDFDocumento32 pagineW4 305E Hot Strip Mills - Mechanical Equipment PDFjojoNessuna valutazione finora

- Filtro de Aire Metálico DL - EblackDocumento8 pagineFiltro de Aire Metálico DL - EblackJavierNessuna valutazione finora

- Hose Catalogue: Customer Service: +44 (0) 1772 323529Documento52 pagineHose Catalogue: Customer Service: +44 (0) 1772 323529po truongNessuna valutazione finora

- MultiCam 3000-Series CNC WaterjetDocumento12 pagineMultiCam 3000-Series CNC WaterjetDaniel AustinNessuna valutazione finora

- SUBSEA ConnectorsDocumento32 pagineSUBSEA Connectorslijojose1Nessuna valutazione finora

- MasterSeal 940 TDSDocumento4 pagineMasterSeal 940 TDSbayuargad100% (1)

- ECPEN11-800 D-AHU-Professional Catalogues EnglishDocumento8 pagineECPEN11-800 D-AHU-Professional Catalogues EnglishRan NNessuna valutazione finora

- Miller Spectrum 875 XtremeDocumento4 pagineMiller Spectrum 875 XtremeomaralihasNessuna valutazione finora

- Geodesic Dome Brochure REV 4 1508Documento2 pagineGeodesic Dome Brochure REV 4 1508Bilal ZahidNessuna valutazione finora

- JS4BD-KB Series: Technical SpecificationsDocumento12 pagineJS4BD-KB Series: Technical SpecificationsKokoNessuna valutazione finora

- DYWIDAG Prestressing Systems Using BarsDocumento18 pagineDYWIDAG Prestressing Systems Using Barsbignose93gmail.comNessuna valutazione finora

- Busbar Design GuideDocumento22 pagineBusbar Design Guidejohnwu_2009100% (6)

- Structural Analysis and Design Report-M009 Upper CrustDocumento27 pagineStructural Analysis and Design Report-M009 Upper CrustdasmindpcqboNessuna valutazione finora

- Reservoir Vent FiltersDocumento8 pagineReservoir Vent FiltersHesham MahdyNessuna valutazione finora

- Simotec Langstab EngDocumento8 pagineSimotec Langstab EngHillary Mcgowan0% (1)

- Sur Club Quote PDFDocumento18 pagineSur Club Quote PDFsamanthaNessuna valutazione finora

- Tkis-Polytrack-Factsheet-210 X 297-WebpdfDocumento2 pagineTkis-Polytrack-Factsheet-210 X 297-WebpdfHa Kim BJNessuna valutazione finora

- Vibrations-Kontrollsiebmaschine kts-vs2 GB ScreenDocumento2 pagineVibrations-Kontrollsiebmaschine kts-vs2 GB ScreenzolikaNessuna valutazione finora

- Quotation of DKM-RV300F - 5000CCDocumento8 pagineQuotation of DKM-RV300F - 5000CCabd elmohsen saedNessuna valutazione finora

- Gates MachineryDocumento27 pagineGates MachineryAlex PeñaNessuna valutazione finora

- Blade Drift EliminatorsDocumento2 pagineBlade Drift EliminatorsAvicena AlbiruniNessuna valutazione finora

- Cti UxDocumento8 pagineCti UxYogesh SainNessuna valutazione finora

- Waterjet Brochure X3 and X4 PDFDocumento12 pagineWaterjet Brochure X3 and X4 PDFRamon Martz100% (1)

- NIT Vol4GTSDocumento112 pagineNIT Vol4GTShgfdgdhNessuna valutazione finora

- VV Important 4 Krofta ADTDocumento2 pagineVV Important 4 Krofta ADTBhaskar BethiNessuna valutazione finora

- Sewage Disposal Works: Their Design and ConstructionDa EverandSewage Disposal Works: Their Design and ConstructionNessuna valutazione finora

- Design Guidelines for Surface Mount TechnologyDa EverandDesign Guidelines for Surface Mount TechnologyValutazione: 5 su 5 stelle5/5 (1)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDa Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsValutazione: 4 su 5 stelle4/5 (1)

- TL k5 2 2 1 Min Max de enDocumento16 pagineTL k5 2 2 1 Min Max de enmdalt9180Nessuna valutazione finora

- Type Min Max ActuatorsDocumento6 pagineType Min Max Actuatorsmdalt9180Nessuna valutazione finora

- Easylab: Controller TCU3Documento20 pagineEasylab: Controller TCU3mdalt9180Nessuna valutazione finora

- Food Industry Air Handling Guidance PDFDocumento6 pagineFood Industry Air Handling Guidance PDFDavidNessuna valutazione finora

- DHRC Catalog - F164LR.Documento28 pagineDHRC Catalog - F164LR.mdalt9180Nessuna valutazione finora

- Adsorption Chiller Guide SpecificationsDocumento6 pagineAdsorption Chiller Guide Specificationsmdalt9180Nessuna valutazione finora

- AT4 HumidifierDocumento64 pagineAT4 Humidifiermdalt9180Nessuna valutazione finora

- ASHRAE Journal - Optimizing Design Control of Chilled Water Plants Part 5 Optimized Control SequencesDocumento20 pagineASHRAE Journal - Optimizing Design Control of Chilled Water Plants Part 5 Optimized Control Sequencesmdalt9180Nessuna valutazione finora

- Tang Layout With Existing MCDocumento1 paginaTang Layout With Existing MCmdalt9180Nessuna valutazione finora

- Briefspec Picture Humidifiers 1 080808Documento7 pagineBriefspec Picture Humidifiers 1 080808mdalt9180Nessuna valutazione finora

- T2700 Tower Specifications PDFDocumento8 pagineT2700 Tower Specifications PDFmdalt9180Nessuna valutazione finora

- DHG Ro 20Documento3 pagineDHG Ro 20mdalt9180Nessuna valutazione finora

- Cooling TowerDocumento22 pagineCooling TowerAnonymous xcFcOgMiNessuna valutazione finora

- CLA-100-data Sheet PDFDocumento5 pagineCLA-100-data Sheet PDFmdalt9180Nessuna valutazione finora

- Spcification - VolzDocumento2 pagineSpcification - Volzmdalt9180Nessuna valutazione finora

- Kutty ModelDocumento1 paginaKutty Modelmdalt9180Nessuna valutazione finora

- ASHRAE Journal - Optimizing Design Control of Chilled Water Plants Part 2 Condenser Water Distribution System DesignDocumento12 pagineASHRAE Journal - Optimizing Design Control of Chilled Water Plants Part 2 Condenser Water Distribution System Designmdalt9180Nessuna valutazione finora

- 2012 Comprehensive StudyDocumento13 pagine2012 Comprehensive Studymdalt9180Nessuna valutazione finora

- Danfoss DrivesDocumento2 pagineDanfoss Drivesmdalt9180Nessuna valutazione finora

- Stairwell & Lift Pressurization CalculationsDocumento31 pagineStairwell & Lift Pressurization CalculationsAneng2890% (10)

- Load Calculation Spreadsheets: Quick Answers Without Relying On Rules of ThumbDocumento8 pagineLoad Calculation Spreadsheets: Quick Answers Without Relying On Rules of ThumbGithu OommenNessuna valutazione finora

- Refrigerant Wrap Around Heat Pipe-Enhanced Dehumidification SpecficationDocumento1 paginaRefrigerant Wrap Around Heat Pipe-Enhanced Dehumidification Specficationmdalt9180Nessuna valutazione finora

- 30KW - 150601 - Arpitha Associates India MartDocumento4 pagine30KW - 150601 - Arpitha Associates India Martmdalt9180Nessuna valutazione finora

- Marie Barakat Visualcv ResumeDocumento3 pagineMarie Barakat Visualcv ResumebalakrishnaNessuna valutazione finora

- M GaugeDocumento1 paginaM Gaugemdalt9180Nessuna valutazione finora

- Warehouse Duct PlanDocumento1 paginaWarehouse Duct Planmdalt9180Nessuna valutazione finora

- Sopt TisDocumento2 pagineSopt Tismdalt9180Nessuna valutazione finora

- PIBCVDocumento8 paginePIBCVmdalt9180Nessuna valutazione finora

- Section (Wall)Documento1 paginaSection (Wall)mdalt9180Nessuna valutazione finora

- PNGRB T4SDocumento52 paginePNGRB T4SC D JOSHINessuna valutazione finora

- Em534mvi3 InstallationandoperatinginstructionsDocumento36 pagineEm534mvi3 InstallationandoperatinginstructionscipyyyyNessuna valutazione finora

- Agilent Tech., 6060B DMM Serive Manual PDFDocumento95 pagineAgilent Tech., 6060B DMM Serive Manual PDFLulu Sweet ThingNessuna valutazione finora

- Sample ReportDocumento75 pagineSample ReportNirav Patel100% (1)

- Contract No. Bapex/Admin/1528: Shipping MarkDocumento7 pagineContract No. Bapex/Admin/1528: Shipping MarkhaosfNessuna valutazione finora

- Wheel Chair (Spec) (R)Documento1 paginaWheel Chair (Spec) (R)Andri StyaNessuna valutazione finora

- Lesson Guide in Earth Science I. ObjectivesDocumento4 pagineLesson Guide in Earth Science I. ObjectivesallanrnmanalotoNessuna valutazione finora

- Astm F 435-03Documento6 pagineAstm F 435-03JORGE ARTURO TORIBIO HUERTANessuna valutazione finora

- BHEL Reference Manuals S.No Manual DescriptionDocumento4 pagineBHEL Reference Manuals S.No Manual DescriptionShubhamPrinceNessuna valutazione finora

- Liebherr L514-790 Wheel Loader Service Repair Manual SN 14000 PDFDocumento40 pagineLiebherr L514-790 Wheel Loader Service Repair Manual SN 14000 PDFjfjksekdmeikNessuna valutazione finora

- Knauf F12 PDFDocumento34 pagineKnauf F12 PDFIvana ŽivkovićNessuna valutazione finora

- Emt 1250Documento7 pagineEmt 1250TayiefNessuna valutazione finora

- Case Study - Lucas TVSDocumento19 pagineCase Study - Lucas TVSMangesh GhandatNessuna valutazione finora

- Comparative StudyDocumento20 pagineComparative Studyapi-351236050Nessuna valutazione finora

- Lauire Baker and Other Architects PDFDocumento8 pagineLauire Baker and Other Architects PDFmoni_john_1Nessuna valutazione finora

- Catalogo APOLLO - Valvulas EsferaDocumento38 pagineCatalogo APOLLO - Valvulas EsferaAntonio Jimenez DCNessuna valutazione finora

- Drop Raising in Underground MinesDocumento20 pagineDrop Raising in Underground Minespartha das sharmaNessuna valutazione finora

- Set Point and Alarm List (Threshold) Fgs SystemDocumento1 paginaSet Point and Alarm List (Threshold) Fgs SystemjajakaNessuna valutazione finora

- Free ScaleDocumento39 pagineFree ScaleRavi VarmaNessuna valutazione finora

- 100KW GeneratorDocumento3 pagine100KW GeneratorNicole PalomaresNessuna valutazione finora

- Kim Lighting 120 Volt Landscape Lighting Catalog 1971Documento20 pagineKim Lighting 120 Volt Landscape Lighting Catalog 1971Alan MastersNessuna valutazione finora

- Reduccion de Carga Viva CubiertasDocumento2 pagineReduccion de Carga Viva CubiertasmrnicusNessuna valutazione finora

- Platinium CCDocumento1 paginaPlatinium CCGustavo Henrique133% (3)

- MSDS BriquettesDocumento4 pagineMSDS BriquettesKrishnudu NallaNessuna valutazione finora

- Injection Pump R&RDocumento17 pagineInjection Pump R&RMahdi Besbes100% (2)

- Air Conditioning SystemDocumento15 pagineAir Conditioning Systemshrikant100% (25)

- Diagrama de Guiillotina DurmaDocumento18 pagineDiagrama de Guiillotina DurmaJoel VegaNessuna valutazione finora

- M201 07262017 000091 Biddoc PDFDocumento32 pagineM201 07262017 000091 Biddoc PDFAr Hanz Gerome SuarezNessuna valutazione finora

- Biodiesel Feed Stock, Production TechnologyDocumento27 pagineBiodiesel Feed Stock, Production TechnologySaswata PradhanNessuna valutazione finora

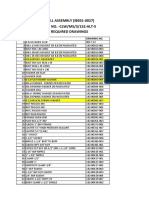

- Wap-7 Drawing DrequiredDocumento8 pagineWap-7 Drawing DrequiredM PankajNessuna valutazione finora