Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ASTM Grades For Insulating Fire Brick

Caricato da

rajachemTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ASTM Grades For Insulating Fire Brick

Caricato da

rajachemCopyright:

Formati disponibili

IFB 3000 - BNZ Materials Page 1

About BNZ Contact Us Locations

Search ...

Call Us Today! 1 (800) 999-0890

HOME INSULATING FIREBRICK INSULATING AGGREGATES MARINITE TRANSITE CASTABLES CEMENT MORTARS

IFB 3000 Home / Insulating Firebrick / IFB 3000

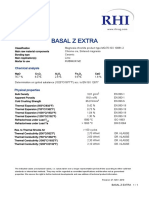

Typical Data STANDARD ASTM C 155 GRADES

Properties BNZ-20 BNZ-23 BNZ-23 HS BNZ-23A BNZ-26 BNZ-26-60 BNZ-28 BNZ-3000 BNZ-32

ASTM Classification 20/23 23 23 23 26 26 28 30 32

Temperature Use Limit °F 2300 2300 2300 2300 2600 2600 2800 3000 3200

(Normal oxidizing atmosphere) °C 1260 1260 1260 1260 1427 1427 1538 1649 1760

Density, Avg. lb/ft² 36 37 42 33 48 50 55 65 75

ASTM C 134 kg/m³ 577 593 673 529 769 801 881 1041 1201

lb/BEq 2.1 2.2 2.5 1.93 2.8 2.9 3.2 3.8 4.4

kg/str. 0.9 1.0 1.1 0.86 1.3 1.3 1.5 1.7 2.0

Modulus of Rupture lb/in² 95 105 140 115 200 190 220 250 300

ASTM C 133 MPa 0.7 0.7 1.0 0.79 1.4 1.3 1.5 1.7 2.1

kg/cm² 6.7 7.4 9.9 8 14.1 13.4 15.5 17.6 21.1

Cold Crushing of Strength lb/in² 105 125 190 145 270 290 340 440 450

ASTM C 133 MPa 0.7 0.9 1.3 1 1.9 2.0 2.3 3.0 3.1

kg/cm² 7.4 8.8 13.4 10.2 19.0 20.4 23.9 31.0 31.7

Permanent Linear Change %

ASTM C 210

24 hrs at soaking temp: °F (°C)

2250 (1232) 0.0 0.0 0.0 0.0 – – – – –

2350 (1290) – – – – – – – –

2450 (1343) – – – – – – – –

2550 (1399) – – – -0.4 -0.2 – – –

2750 (1510) – – – – – -0.7 – –

2800 (1538) – – – – – – – –

2950 (1621) – – – – – – -0.7 –

3150 (1732) – – – – – – – -0.4

Reversible Linear Thermal

%

Expansion

at 2000°F (1093°C) 0.6 0.6 0.6 0.6 0.6 0.6 0.65 0.65 0.65

Hot Load Strength %

ASTM C 16 deformation

10 psi load for 11/2 hours: °F (°C)

2000 (1093) 0 0 0 0 – – – – –

2200 (1204) – – – 0.2 0.1 0.1 – –

2400 (1316) – – – – – – 0.3 0.2

Btu-in/ft²,

Thermal Conductivity

hr, °F

ASTM C 182 (W/mk)

Mean temperature, °F (°C)

500 0.9 1.0 1.2 .92 1.6 1.8 2.3 2.8 3.9

(260) 0.13 0.14 0.17 0.13 0.23 0.26 0.33 0.40 0.56

1000 1.2 1.3 1.5 1.14 1.9 2.0 2.4 2.9 4.1

(538) 0.17 0.19 0.22 0.16 0.27 0.29 0.35 0.42 0.59

1500 1.5 1.6 1.7 1.39 2.2 2.1 2.6 3.1 4.2

(816) 0.22 0.23 0.25 0.2 0.32 0.30 0.37 0.45 0.61

2000 1.7 1.8 2.0 1.64 2.6 2.3 2.7 3.3 4.3

(1093) 0.24 0.26 0.29 0.24 0.37 0.33 0.39 0.48 0.62

To convert Btu-in/ft², hr,

°F to Kcal-m², hr, °C,

multiply by 0.124.

Chemical Analysis

Alumina – Al2O3 39.4 39.4 39.4 38 47.0 60.4 67.0 69.9 78.3

Silica – SiO2 51.7 51.7 51.7 45 49.2 36.1 30.5 28.1 20.7

Ferric Oxide – Fe2O3 0.6 0.6 0.6 0.3 0.6 0.4 0.3 0.3 0.2

Titanium Oxide – Ti2O2 1.5 1.5 1.5 1.6 1.3 1.0 0.9 1.2 0.5

http://www.bnzmaterials.co... 4/23/2018 6:01:14 PM

IFB 3000 - BNZ Materials Page 2

Calcium Oxide – CaO 6.4 6.4 6.4 15 0.3 0.1 0.3 0.2 0.1

Magnesium Oxide – MgO 0.1 0.1 0.1 0.1 0.1 0.2 0.0 0.1 0.1

Alkalies, as Na2O & K2O 0.3 0.3 0.3 0.5 1.5 1.8 1.0 0.2 0.1

INSULATING PRODUCTS RESOURCES INDUSTRY NEWS

Select Language

Powered by

Insulation Products that

will save you energy!

http://www.bnzmaterials.co... 4/23/2018 6:01:14 PM

Potrebbero piacerti anche

- NDT HandBook Volume 10 (NDT Overview)Documento600 pagineNDT HandBook Volume 10 (NDT Overview)mahesh95% (19)

- MulcoaDocumento2 pagineMulcoaRolando Cordova100% (1)

- Gouda Refractories Brochure WEbDocumento16 pagineGouda Refractories Brochure WEbjsszep jNessuna valutazione finora

- BF Cast House Product & DesignDocumento50 pagineBF Cast House Product & DesignHara Prasad MurtyNessuna valutazione finora

- Datasheet-Sandvik-11r51-En-V2020-08-27 13 - 59 Version 1Documento5 pagineDatasheet-Sandvik-11r51-En-V2020-08-27 13 - 59 Version 1Kashish100% (2)

- Body of Knowledge For API 936 ExamDocumento3 pagineBody of Knowledge For API 936 ExamMKAMRANBHATTI67% (3)

- Alsiflex®-1260 Blankets - Technical Data Sheet - English PDFDocumento2 pagineAlsiflex®-1260 Blankets - Technical Data Sheet - English PDFTanmay GorNessuna valutazione finora

- Refractory Lining Project Corrected (Chapter 1)Documento7 pagineRefractory Lining Project Corrected (Chapter 1)Don Rayburn PilanNessuna valutazione finora

- Urcast Shac Ev 0 3 CLDocumento1 paginaUrcast Shac Ev 0 3 CLmahreza189Nessuna valutazione finora

- Ladle Refractory Monitoring WebDocumento6 pagineLadle Refractory Monitoring WebsusantaNessuna valutazione finora

- Blast Furnace BF Refractory Lining PatternDocumento5 pagineBlast Furnace BF Refractory Lining PatternSarthakShangariNessuna valutazione finora

- Fused and Sintered AluminaDocumento7 pagineFused and Sintered AluminaSaragadam DilsriNessuna valutazione finora

- Basal Z Extra: Chemical AnalysisDocumento1 paginaBasal Z Extra: Chemical Analysismahreza189Nessuna valutazione finora

- Data Sheet Greencast 94: DescriptionDocumento2 pagineData Sheet Greencast 94: Descriptionmani0% (1)

- Catalog of ProductsDocumento20 pagineCatalog of ProductsDee Affanist100% (2)

- Lecture 15: Application of Refractory MaterialsDocumento7 pagineLecture 15: Application of Refractory MaterialsMiguel Kühnert FrichenbruderNessuna valutazione finora

- FHS Ladle Installation Manual Incld OPI - 10.5.2018Documento28 pagineFHS Ladle Installation Manual Incld OPI - 10.5.2018Nguyễn ChungNessuna valutazione finora

- LHF/R HF R Oof: Application R HI Quality Eafroof Ank Ofor M F S 90S 0-15 V LHF R Oof Ank Ofor M F S 90S 0-15 VDocumento2 pagineLHF/R HF R Oof: Application R HI Quality Eafroof Ank Ofor M F S 90S 0-15 V LHF R Oof Ank Ofor M F S 90S 0-15 VMashiur RahmanNessuna valutazione finora

- Float Glass RefractoryDocumento4 pagineFloat Glass RefractorySans SenNessuna valutazione finora

- Refractories For Induction Furnaces For DisplayDocumento9 pagineRefractories For Induction Furnaces For Displayabdul rochimNessuna valutazione finora

- Tap Hole Clay - VesuviusDocumento26 pagineTap Hole Clay - VesuviusSaumit Pal100% (1)

- E Sintering Process of Iron Ore FinesDocumento6 pagineE Sintering Process of Iron Ore FinesJose Marval RodriguezNessuna valutazione finora

- MonolithicRefractory PDFDocumento2 pagineMonolithicRefractory PDFmevaNessuna valutazione finora

- Specification HGRM-30 GRADEDocumento1 paginaSpecification HGRM-30 GRADESanjayNessuna valutazione finora

- Refractory Science Refractories - : 1.1 Composition and StructureDocumento14 pagineRefractory Science Refractories - : 1.1 Composition and StructureNikki AlbiosNessuna valutazione finora

- Ankerfix Rp10 Stahl Flow Control Iso enDocumento1 paginaAnkerfix Rp10 Stahl Flow Control Iso enthinhbntNessuna valutazione finora

- Materials in Industrial Furnace ConstructionDocumento28 pagineMaterials in Industrial Furnace ConstructionAlexander TabaresNessuna valutazione finora

- 228-04 KALTEK SG Iron French FoundryDocumento4 pagine228-04 KALTEK SG Iron French FoundryMar CarreonNessuna valutazione finora

- Physical Properties Classification: The Siam Refractory Industry Co., LTDDocumento23 paginePhysical Properties Classification: The Siam Refractory Industry Co., LTDManekGorisNessuna valutazione finora

- RefrateckDocumento21 pagineRefrateckMagesh KumarNessuna valutazione finora

- CALDE Iron Casthouse V2 112015-CompressedDocumento12 pagineCALDE Iron Casthouse V2 112015-CompressedChristian PurbaNessuna valutazione finora

- EAF Refractory Performance at Pacific SteelDocumento11 pagineEAF Refractory Performance at Pacific SteelSaragadam DilsriNessuna valutazione finora

- New Additive Packages For Self-Flowing High-Alumina and MgO Based Refractory CastablesDocumento6 pagineNew Additive Packages For Self-Flowing High-Alumina and MgO Based Refractory CastablespetemberNessuna valutazione finora

- Insulation Castables Application Procedure - Rev-2Documento10 pagineInsulation Castables Application Procedure - Rev-2Ezhil KumarNessuna valutazione finora

- Anatomy of A Boiler FailureDocumento14 pagineAnatomy of A Boiler FailureIlker CetinNessuna valutazione finora

- Refractory-Systems Steuler-Kch en PDFDocumento20 pagineRefractory-Systems Steuler-Kch en PDFNaeem QasimNessuna valutazione finora

- REFractories FOR GLASS-TRL PDFDocumento24 pagineREFractories FOR GLASS-TRL PDFram cNessuna valutazione finora

- Slide Gate System DevelopmentDocumento14 pagineSlide Gate System DevelopmentA.S.M. Mosayeb RafiNessuna valutazione finora

- Magnesite and Forsterite RefractoriesDocumento25 pagineMagnesite and Forsterite RefractoriesfayzaNessuna valutazione finora

- Cement PDFDocumento16 pagineCement PDFhisemNessuna valutazione finora

- Steel Ladle Calderys Brochure A4Documento22 pagineSteel Ladle Calderys Brochure A4Mitone Diaz100% (1)

- C I M P R O G E T T I: Lime TechnologiesDocumento12 pagineC I M P R O G E T T I: Lime TechnologiesRao AkbarNessuna valutazione finora

- Comprit F50G-6: General InformationDocumento2 pagineComprit F50G-6: General InformationNic RicNessuna valutazione finora

- Linings - Nf-E.pdf - Downloadasset Vesuvius PDFDocumento8 pagineLinings - Nf-E.pdf - Downloadasset Vesuvius PDFpungkiNessuna valutazione finora

- Carbon Pick-Up IF Steels PDFDocumento3 pagineCarbon Pick-Up IF Steels PDFAnonymous jYdzzw6Nessuna valutazione finora

- Ankral RNTDocumento1 paginaAnkral RNTmahreza189Nessuna valutazione finora

- Vesuvius ResearchDocumento9 pagineVesuvius ResearchRohit ThapliyalNessuna valutazione finora

- Cast House - VesuviusDocumento74 pagineCast House - VesuviusSaumit Pal100% (1)

- SUPRAL - S60 Per Blocchi (Equivalente RESISTAL S60) PDFDocumento1 paginaSUPRAL - S60 Per Blocchi (Equivalente RESISTAL S60) PDFgiuseppe.timpone1Nessuna valutazione finora

- Foundry: Monolithic Concept SolutionsDocumento20 pagineFoundry: Monolithic Concept Solutionsmuhammad abidinNessuna valutazione finora

- Refractory Bricks: Ce8391 Construction MaterialsDocumento22 pagineRefractory Bricks: Ce8391 Construction MaterialsrangaNessuna valutazione finora

- Ladle Refractories Web 2017 PDFDocumento12 pagineLadle Refractories Web 2017 PDFrivrsideNessuna valutazione finora

- Raw Materials For Manufacturing of Superior Quality Mgo-C BricksDocumento8 pagineRaw Materials For Manufacturing of Superior Quality Mgo-C Bricksjom erfNessuna valutazione finora

- AnchorDocumento5 pagineAnchorpadalakirankumarNessuna valutazione finora

- IFB 2300 - BNZ MaterialsDocumento2 pagineIFB 2300 - BNZ Materialsmiltone87Nessuna valutazione finora

- A.S.T.M. B584-09a: WWW - Okendo.mxDocumento4 pagineA.S.T.M. B584-09a: WWW - Okendo.mxShariq KhanNessuna valutazione finora

- Datasheet Sandvik Saf 2507 en PDFDocumento15 pagineDatasheet Sandvik Saf 2507 en PDFShesharam Chouhan100% (1)

- Physical and Piezoelectric Properties of APC MaterialsDocumento2 paginePhysical and Piezoelectric Properties of APC MaterialsTrương Anh DuyNessuna valutazione finora

- Tuff47-En RefractarioDocumento1 paginaTuff47-En RefractarioHECTOR POOUNessuna valutazione finora

- Ceramic Fiber Blanket CatalogDocumento7 pagineCeramic Fiber Blanket Catalogevelyn reksaNessuna valutazione finora

- CLC 18-10Nb: A NB Stabilized 18Cr-10Ni Austenitic Stainless Steel (347 Grade)Documento4 pagineCLC 18-10Nb: A NB Stabilized 18Cr-10Ni Austenitic Stainless Steel (347 Grade)PeterWayNessuna valutazione finora

- Mole Fraction Volume FractionDocumento9 pagineMole Fraction Volume FractionameyckulkarniNessuna valutazione finora

- Karthik Updated ResumeDocumento2 pagineKarthik Updated ResumerajachemNessuna valutazione finora

- Field Experience With The Blasch VectorWall Reaction Furnace Checkerwall PTQ Q1 2014Documento7 pagineField Experience With The Blasch VectorWall Reaction Furnace Checkerwall PTQ Q1 2014rajachemNessuna valutazione finora

- TF-08 Therminol 66Documento8 pagineTF-08 Therminol 66rajachemNessuna valutazione finora

- Preliminary Feasibility Study Co2 Carrier Ship Based Ccs Unmanned Offshore FacilityDocumento112 paginePreliminary Feasibility Study Co2 Carrier Ship Based Ccs Unmanned Offshore FacilityrajachemNessuna valutazione finora

- Sample Chapter Steam TurbineDocumento53 pagineSample Chapter Steam TurbineShawn WairisalNessuna valutazione finora

- Kast O Lite 97 L - DatasheetDocumento1 paginaKast O Lite 97 L - DatasheetrajachemNessuna valutazione finora

- Boiling Heat TansferDocumento33 pagineBoiling Heat TansferVineet K. MishraNessuna valutazione finora

- BPHE Process Gas Waste Heat Recovery System EDocumento20 pagineBPHE Process Gas Waste Heat Recovery System ErajachemNessuna valutazione finora

- Hysys V8.0 Tutorial - Part 1 PDFDocumento109 pagineHysys V8.0 Tutorial - Part 1 PDFrajachem100% (1)

- Hysys V8.0 Tutorial - Part 1 PDFDocumento109 pagineHysys V8.0 Tutorial - Part 1 PDFrajachem100% (1)

- Greencast 94 PlusDocumento1 paginaGreencast 94 PlusAHMAD FAHRUR ROZAQNessuna valutazione finora

- Boiling Heat TransferDocumento16 pagineBoiling Heat Transferrr1819Nessuna valutazione finora

- PV Newslette June 2015Documento20 paginePV Newslette June 2015sklatakeNessuna valutazione finora

- Dowtherm BookDocumento30 pagineDowtherm BookMeghnad M GavitNessuna valutazione finora

- Steam HXDocumento1 paginaSteam HXrajachemNessuna valutazione finora

- PetroSync - TEMA HTRI - Heat Exchanger Design Cost Saving Management 2016Documento5 paginePetroSync - TEMA HTRI - Heat Exchanger Design Cost Saving Management 2016rajachemNessuna valutazione finora

- CO2 Recovery Plant To Urea Production in Abu Dhabi: Back To Projects DatabaseDocumento2 pagineCO2 Recovery Plant To Urea Production in Abu Dhabi: Back To Projects DatabaserajachemNessuna valutazione finora

- Choosing API 650 and API 620 TanksDocumento7 pagineChoosing API 650 and API 620 TanksrajachemNessuna valutazione finora

- C - 533 - 95 Calcium Silicate Block and Pipe Thermal InsulationDocumento4 pagineC - 533 - 95 Calcium Silicate Block and Pipe Thermal Insulationhamid vahedil larijaniNessuna valutazione finora

- C - 533 - 95 Calcium Silicate Block and Pipe Thermal InsulationDocumento4 pagineC - 533 - 95 Calcium Silicate Block and Pipe Thermal Insulationhamid vahedil larijaniNessuna valutazione finora

- Fuel Oil AdditivesDocumento2 pagineFuel Oil AdditivesrajachemNessuna valutazione finora

- Choosing API 650 and API 620 TanksDocumento7 pagineChoosing API 650 and API 620 TanksrajachemNessuna valutazione finora

- Hairpin Heat ExchangersDocumento9 pagineHairpin Heat ExchangersrajachemNessuna valutazione finora

- PetroSync - TEMA HTRI - Heat Exchanger Design Cost Saving Management 2016Documento5 paginePetroSync - TEMA HTRI - Heat Exchanger Design Cost Saving Management 2016rajachemNessuna valutazione finora

- Hairpin Heat ExchangersDocumento9 pagineHairpin Heat ExchangersrajachemNessuna valutazione finora

- 110-Nb1 Anton Marco Fantolini SaipemDocumento21 pagine110-Nb1 Anton Marco Fantolini SaipemrajachemNessuna valutazione finora

- Project No. 16279S Project Name Bapco - JVTST: Calculation of Emissivity of Process GasDocumento11 pagineProject No. 16279S Project Name Bapco - JVTST: Calculation of Emissivity of Process GasrajachemNessuna valutazione finora

- 110-Nb1 Anton Marco Fantolini SaipemDocumento21 pagine110-Nb1 Anton Marco Fantolini SaipemrajachemNessuna valutazione finora

- A Vision System For Surface Roughness Characterization Using The Gray Level Co-Occurrence MatrixDocumento12 pagineA Vision System For Surface Roughness Characterization Using The Gray Level Co-Occurrence MatrixPraveen KumarNessuna valutazione finora

- CBSE Class 10 Science Sample Paper SA 2 Set 1Documento5 pagineCBSE Class 10 Science Sample Paper SA 2 Set 1Sidharth SabharwalNessuna valutazione finora

- Laporan Keuangan TRIN Per Juni 2023-FinalDocumento123 pagineLaporan Keuangan TRIN Per Juni 2023-FinalAdit RamdhaniNessuna valutazione finora

- Forensic My Cology Mcgraw HillDocumento8 pagineForensic My Cology Mcgraw HillJayanti RaufNessuna valutazione finora

- Written Report in Instructional PlanningDocumento6 pagineWritten Report in Instructional PlanningRose Aura HerialesNessuna valutazione finora

- Ajsl DecisionMakingModel4RoRoDocumento11 pagineAjsl DecisionMakingModel4RoRolesta putriNessuna valutazione finora

- Acronyms and AbbreviationsDocumento875 pagineAcronyms and AbbreviationsLacky KrishnanNessuna valutazione finora

- CSR Report On Tata SteelDocumento72 pagineCSR Report On Tata SteelJagadish Sahu100% (1)

- DS SX1280-1-2 V3.0Documento143 pagineDS SX1280-1-2 V3.0bkzzNessuna valutazione finora

- Planning Effective Advertising and Promotion Strategies For A Target AudienceDocumento16 paginePlanning Effective Advertising and Promotion Strategies For A Target Audiencebakhoo12Nessuna valutazione finora

- GT I9100g Service SchematicsDocumento8 pagineGT I9100g Service SchematicsMassolo RoyNessuna valutazione finora

- Unit 2 Operations of PolynomialsDocumento28 pagineUnit 2 Operations of Polynomialsapi-287816312Nessuna valutazione finora

- Micronet TMRDocumento316 pagineMicronet TMRHaithem BrebishNessuna valutazione finora

- Bahan Ajar Application LetterDocumento14 pagineBahan Ajar Application LetterNevada Setya BudiNessuna valutazione finora

- Exploded Views and Parts List: 6-1 Indoor UnitDocumento11 pagineExploded Views and Parts List: 6-1 Indoor UnitandreiionNessuna valutazione finora

- T10 - PointersDocumento3 pagineT10 - PointersGlory of Billy's Empire Jorton KnightNessuna valutazione finora

- Bakteri Anaerob: Morfologi, Fisiologi, Epidemiologi, Diagnosis, Pemeriksaan Sy. Miftahul El J.TDocumento46 pagineBakteri Anaerob: Morfologi, Fisiologi, Epidemiologi, Diagnosis, Pemeriksaan Sy. Miftahul El J.TAlif NakyukoNessuna valutazione finora

- Malampaya Case StudyDocumento15 pagineMalampaya Case StudyMark Kenneth ValerioNessuna valutazione finora

- Makerere University Is Inviting Applications For Undergraduate Admissions On Private Sponsorship For Academic Year 2015/2016Documento9 pagineMakerere University Is Inviting Applications For Undergraduate Admissions On Private Sponsorship For Academic Year 2015/2016The Campus TimesNessuna valutazione finora

- Microbial Diseases of The Different Organ System and Epidem.Documento36 pagineMicrobial Diseases of The Different Organ System and Epidem.Ysabelle GutierrezNessuna valutazione finora

- Geography NotesDocumento2 pagineGeography NotesMinethegroundNessuna valutazione finora

- Tugas Inggris Text - Kelas 9Documento27 pagineTugas Inggris Text - Kelas 9salviane.theandra.jNessuna valutazione finora

- Lab Report 2Documento5 pagineLab Report 2Md jubayer SiddiqueNessuna valutazione finora

- Estill Voice Training and Voice Quality Control in Contemporary Commercial Singing: An Exploratory StudyDocumento8 pagineEstill Voice Training and Voice Quality Control in Contemporary Commercial Singing: An Exploratory StudyVisal SasidharanNessuna valutazione finora

- The Global Entrepreneurship and Development Index 2014 For Web1 PDFDocumento249 pagineThe Global Entrepreneurship and Development Index 2014 For Web1 PDFAlex Yuri Rodriguez100% (1)

- Session 1: Strategic Marketing - Introduction & ScopeDocumento38 pagineSession 1: Strategic Marketing - Introduction & ScopeImrul Hasan ChowdhuryNessuna valutazione finora

- Catalogo HydronixDocumento68 pagineCatalogo HydronixNANCHO77Nessuna valutazione finora

- Daily Plankton Agrabinta CianjurDocumento141 pagineDaily Plankton Agrabinta CianjurPutra Cahya GemilangNessuna valutazione finora

- Harley Davidson U S Reportedly Uses Risk Sharing Agreements With Its Foreign SubsidiariesDocumento1 paginaHarley Davidson U S Reportedly Uses Risk Sharing Agreements With Its Foreign Subsidiariestrilocksp SinghNessuna valutazione finora