Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

TABLE 2 Dimensions of Circular Washers: 8. Workmanship, Finish, and Appearance

Caricato da

GHULAM NABITitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

TABLE 2 Dimensions of Circular Washers: 8. Workmanship, Finish, and Appearance

Caricato da

GHULAM NABICopyright:

Formati disponibili

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 436M – 93 (2000)

TABLE 2 Dimensions of Circular Washers

Nominal Washer Inside Diameter (A), mm Outside Diameter (B), mm Thickness (C), mm Clipped Width

Size, mm A (E), mm, min B

max min max min max min

12 14.4 14.0 27.0 25.7 4.6 3.1 10.5

14 16.4 16.0 30.0 28.7 4.6 3.1 12.2

16 18.4 18.0 34.0 32.4 4.6 3.1 14.0

20 22.5 22.0 42.0 40.4 4.6 3.1 17.5

22 24.5 24.0 44.0 42.4 4.6 3.4 19.2

24 26.5 26.0 50.0 48.4 4.6 3.4 21.0

27 30.5 30.0 56.0 54.1 4.6 3.4 23.6

30 33.6 33.0 60.0 58.1 4.6 3.4 26.2

36 39.6 39.0 72.0 70.1 4.6 3.4 31.5

42 45.6 45.0 84.0 81.8 7.2 4.6 36.7

48 52.7 52.0 95.0 92.8 7.2 4.6 42.0

56 62.7 62.0 107.0 104.8 8.7 6.1 49.0

64 70.7 70.0 118.0 115.8 8.7 6.1 56.0

72 78.7 78.0 130.0 127.5 8.7 6.1 63.0

80 86.9 86.0 142.0 139.5 8.7 6.1 70.0

90 96.9 96.0 159.0 156.5 8.7 6.1 78.7

100 107.9 107.0 176.0 173.5 8.7 6.1 87.5

A

Nominal washer sizes are intended for use with fasteners of the same nominal thread diameter.

B

Washers may be clipped on one side not closer to the center of the washer than width E.

9.2 When specified in the purchase order, the manufacturer

shall furnish a test report certified to be the last complete set of

mechanical tests for each stock size in each shipment.

9.3 When the purchaser requires that additional tests be

performed by the manufacturer to determine that the properties

FIG. 1 Washer Inside Profile of products in an individual shipment are within specified

limits, the purchaser shall specify the testing requirements,

limits specified in Table 2, however, the specified maximum including the sampling plan and basis of acceptance, in the

inside diameter may be exceeded at the washer face on the inquiry and purchase order.

breakout side by a maximum taper allowance of 25 % of the 9.3.1 When the purchaser does not specify the sampling

specified maximum washer thickness for each size. plan and basis of acceptance the conditions in 9.3.1.1 through

7.2 Beveled washers shall conform to dimensions in accor- 9.3.1.3 shall apply:

dance with ANSI B18.23.2M.

7.3 Clipped beveled washers shall conform to dimensions 9.3.1.1 The lot, for purposes of selecting samples, shall

for beveled washers in accordance with ANSI B18.23.2, except consist of all washers offered for inspection and testing, at one

that one edge may be clipped off not closer than 0.0875 times time, that are the same type, style, nominal size, and surface

the washer nominal size from the center of the hole. finish.

9.3.1.2 From each lot, samples shall be selected at random

8. Workmanship, Finish, and Appearance and tested for each requirement, except as specified in 9.3.1.3,

8.1 Washers shall be free of excess mill scale, excess in accordance with Table 3.

coatings, and foreign material on bearing surfaces. Arc and gas 9.3.1.3 When determining the weight of coating of plated

cut washers shall be free of metal spatter. and coated washers, the sampling plan defined in 9.3.1.2 shall

9. Sampling and Number of Tests and Retests apply, except that in no case shall the sample consist of less

than three washers.

9.1 The requirements of this specification shall be met in

continuous mass production for stock, and the manufacturer

10. Test Methods

shall make sample inspections to ensure that the product

conforms to the specified requirements. Additional tests of 10.1 Hardness tests shall be performed in accordance with

individual shipments of material are not ordinarily necessary. Test Methods F 606M.

Potrebbero piacerti anche

- 0145E16598760151 - 1 - Def - Selecton Internal Floating Roofs v1.1 May 2014Documento42 pagine0145E16598760151 - 1 - Def - Selecton Internal Floating Roofs v1.1 May 2014Manuel Alejandro González MarcanoNessuna valutazione finora

- JIS G3452 PipeDocumento0 pagineJIS G3452 PipefaridyeniNessuna valutazione finora

- Case Study - 7: Numerical in API 510 CodeDocumento4 pagineCase Study - 7: Numerical in API 510 CodeVishal BailurNessuna valutazione finora

- Submerged Arc Welding (Saw)Documento5 pagineSubmerged Arc Welding (Saw)Nnaji Chukwuma SlamNessuna valutazione finora

- Quiz 1Documento1 paginaQuiz 1shabbir626Nessuna valutazione finora

- Multiple Choice Question Answering by Meshael SultanDocumento89 pagineMultiple Choice Question Answering by Meshael SultanMeshs100% (1)

- ASME P-NumbersDocumento9 pagineASME P-NumbersAamer MohammedNessuna valutazione finora

- 2-Questions API 650 Question N°02 2022Documento3 pagine2-Questions API 650 Question N°02 2022korichiNessuna valutazione finora

- CBT QuestionsDocumento17 pagineCBT QuestionsNaseer Ahmed SokhalNessuna valutazione finora

- Indt QCP RT HJ 05NDocumento14 pagineIndt QCP RT HJ 05NAsad Bin Ala QatariNessuna valutazione finora

- QW-451 Welding THK - June5Documento17 pagineQW-451 Welding THK - June5Raj SNessuna valutazione finora

- Aws Form E-9 Stud Welding Procedure Specification (WPS) or Procedure Qualification Record (PQR) or Welder Qualification Record (WQR) 000 PDFDocumento1 paginaAws Form E-9 Stud Welding Procedure Specification (WPS) or Procedure Qualification Record (PQR) or Welder Qualification Record (WQR) 000 PDFrajNessuna valutazione finora

- NDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023Documento16 pagineNDT-SA-ARAMCO-MCCL-PMI-57 Rev 00 Date 26-June-2023SANJEEV YADAVNessuna valutazione finora

- API 650 12th - 2013Documento4 pagineAPI 650 12th - 2013mohamed100% (1)

- Preheat RequirementsDocumento3 paginePreheat RequirementsVJG369Nessuna valutazione finora

- API 653 Above Ground Storage Tank InspectorDocumento2 pagineAPI 653 Above Ground Storage Tank InspectorMohamed Hichem Guesmi0% (1)

- MTC Er70s 2Documento1 paginaMTC Er70s 2Mirza BaigNessuna valutazione finora

- Asme V Ob JKDocumento16 pagineAsme V Ob JKBoon India TrichyNessuna valutazione finora

- Answer Key For The Inspector's Calc's ExercisesDocumento4 pagineAnswer Key For The Inspector's Calc's ExercisesHeartyscorpionNessuna valutazione finora

- Api 653Documento1 paginaApi 653BashMohandesssNessuna valutazione finora

- API 510 Case Study - 7Documento2 pagineAPI 510 Case Study - 7Khaled FatnassiNessuna valutazione finora

- Pressure Vessel Inspection ReportDocumento34 paginePressure Vessel Inspection ReportJinlong SuNessuna valutazione finora

- EGWDocumento2 pagineEGWpratishgnairNessuna valutazione finora

- 9 Multiple Choice Questions: No Answer GivenDocumento3 pagine9 Multiple Choice Questions: No Answer GivenAnonymous Q4YUvRNessuna valutazione finora

- C Closed B Losed B Ook Ook P Practice Que Ractice Questio Stio Ns NsDocumento10 pagineC Closed B Losed B Ook Ook P Practice Que Ractice Questio Stio Ns NsElankumaran Periakaruppan100% (1)

- Api 570, 2015 PDFDocumento3 pagineApi 570, 2015 PDFrajeev raviNessuna valutazione finora

- Norma CWB Cambios en W47.1-2009Documento6 pagineNorma CWB Cambios en W47.1-2009Jose ManuelNessuna valutazione finora

- Open Book Testing - API 653Documento9 pagineOpen Book Testing - API 653EdisonCorderoNessuna valutazione finora

- ButtWelding Is 11790 1986Documento11 pagineButtWelding Is 11790 1986kathir1965Nessuna valutazione finora

- ST 37Documento7 pagineST 37rendra.farisrNessuna valutazione finora

- API 510 - Day 1: G T Technical & Management Institute PVT - LTD.Documento109 pagineAPI 510 - Day 1: G T Technical & Management Institute PVT - LTD.fathiNessuna valutazione finora

- BS en 287Documento7 pagineBS en 287Chris Thomas0% (1)

- Welder Qualification Record: CODE: AS/NZS 1554.5-2014 WMS-WPS-30Documento2 pagineWelder Qualification Record: CODE: AS/NZS 1554.5-2014 WMS-WPS-30Ali TalebiNessuna valutazione finora

- Asme VDocumento1 paginaAsme VMohd AnsariNessuna valutazione finora

- API 570 Authorized Piping Inspector Preparatory Program: Open Book Mockup ExaminationDocumento8 pagineAPI 570 Authorized Piping Inspector Preparatory Program: Open Book Mockup ExaminationmelvinNessuna valutazione finora

- ST 35.8 (Germany / DIN) : Material PropertiesDocumento3 pagineST 35.8 (Germany / DIN) : Material Propertiesmohammad zareiNessuna valutazione finora

- UT AssessmentDocumento1 paginaUT AssessmentSantanu SahaNessuna valutazione finora

- SB410 (JIS) - Worldwide Equivalent Grades 11Documento1 paginaSB410 (JIS) - Worldwide Equivalent Grades 11valli raju100% (1)

- CSWIP-WI-6-92 12th Edition May 2012Documento17 pagineCSWIP-WI-6-92 12th Edition May 2012Shaju ShamsudheenNessuna valutazione finora

- API 510 Section 8 QuizDocumento17 pagineAPI 510 Section 8 Quizamalhaj2013Nessuna valutazione finora

- CVN Aws D1.1Documento1 paginaCVN Aws D1.1neilNessuna valutazione finora

- Inspection of CastingDocumento23 pagineInspection of CastingRaghu SanthNessuna valutazione finora

- Sample Forms WPS PQRDocumento22 pagineSample Forms WPS PQRGMNessuna valutazione finora

- 0301e - Guidebook For Inspectors - 2018-3Documento6 pagine0301e - Guidebook For Inspectors - 2018-3FranciscoNessuna valutazione finora

- Welding Procedure Specification: Material / Joints QualifiedDocumento2 pagineWelding Procedure Specification: Material / Joints Qualifiedmurshid badshahNessuna valutazione finora

- Soft Magnetic Iron Parts Fabricated by Powder Metallurgy (P/M) TechniquesDocumento4 pagineSoft Magnetic Iron Parts Fabricated by Powder Metallurgy (P/M) TechniquesEduardoNessuna valutazione finora

- Steel Pipes Tubes Eng PDFDocumento21 pagineSteel Pipes Tubes Eng PDFsintaprisilliaNessuna valutazione finora

- API-570-Exam-100-Q (계산문제 정리할수 있는 문제) PDFDocumento23 pagineAPI-570-Exam-100-Q (계산문제 정리할수 있는 문제) PDFasNessuna valutazione finora

- IRTS Studying For The HARECDocumento40 pagineIRTS Studying For The HARECserepezNessuna valutazione finora

- API 6A RadiographyDocumento4 pagineAPI 6A RadiographyminakshissawantNessuna valutazione finora

- Fixing API 653 Tank Bottom Corrosion R230218Documento21 pagineFixing API 653 Tank Bottom Corrosion R230218David RodriguesNessuna valutazione finora

- Cswip Div 9 03 General Inspector 4th Edition Jan 2008Documento12 pagineCswip Div 9 03 General Inspector 4th Edition Jan 2008obinnaNessuna valutazione finora

- Grade Point Average CalculatorDocumento1 paginaGrade Point Average CalculatorRaquelNessuna valutazione finora

- Safety Valve Api 576 Edition 4Documento117 pagineSafety Valve Api 576 Edition 4dende martinaNessuna valutazione finora

- Soil Classification1Documento1 paginaSoil Classification1Mohammed SalhinNessuna valutazione finora

- Metering Pumps: Models A and BDocumento5 pagineMetering Pumps: Models A and Bbmanojkumar16Nessuna valutazione finora

- Tubos de Acero Inoxidable Soldables EFW ASTM A312 SCH 10S / 40S / 80SDocumento3 pagineTubos de Acero Inoxidable Soldables EFW ASTM A312 SCH 10S / 40S / 80SSmithSaitAlarconPintoNessuna valutazione finora

- Appendix B Pipe Piles: EI 02C097 01 Jul 97Documento5 pagineAppendix B Pipe Piles: EI 02C097 01 Jul 97Waho HadakNessuna valutazione finora

- FR Codo de 90 Ac Ced80 Astm A234 Gr. WPBDocumento1 paginaFR Codo de 90 Ac Ced80 Astm A234 Gr. WPBSERVICIOS INTEGRALES OSDANessuna valutazione finora

- PL10X173 X 219: 2 1605087-W117 No Item MKD'Documento1 paginaPL10X173 X 219: 2 1605087-W117 No Item MKD'GHULAM NABINessuna valutazione finora

- Erection DrawingDocumento1 paginaErection DrawingGHULAM NABINessuna valutazione finora

- Material Approval RequestDocumento1 paginaMaterial Approval RequestGHULAM NABINessuna valutazione finora

- 3368 2Documento2 pagine3368 2GHULAM NABINessuna valutazione finora

- PL10X173 X 219: 2 1605087-W117 No Item MKD'Documento1 paginaPL10X173 X 219: 2 1605087-W117 No Item MKD'GHULAM NABINessuna valutazione finora

- PL10X173 X 219: 2 1605087-W117 No Item MKD'Documento1 paginaPL10X173 X 219: 2 1605087-W117 No Item MKD'GHULAM NABINessuna valutazione finora

- 5 1605087-W121 No Item MKD': For ConstructionDocumento1 pagina5 1605087-W121 No Item MKD': For ConstructionGHULAM NABINessuna valutazione finora

- Pipe Schedule PDFDocumento1 paginaPipe Schedule PDFSrinivasan SeenuNessuna valutazione finora

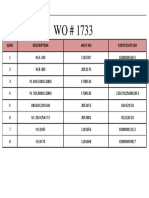

- Wo # 1733 Summary List PDFDocumento1 paginaWo # 1733 Summary List PDFGHULAM NABINessuna valutazione finora

- Wo # 1733 Summary List PDFDocumento1 paginaWo # 1733 Summary List PDFGHULAM NABINessuna valutazione finora

- PL8X350 X 11821: 1 1736027BU-BUS1 No Item MKD'Documento1 paginaPL8X350 X 11821: 1 1736027BU-BUS1 No Item MKD'GHULAM NABINessuna valutazione finora

- PL8X350 X 11821: 1 1736027BU-BUS1 No Item MKD'Documento1 paginaPL8X350 X 11821: 1 1736027BU-BUS1 No Item MKD'GHULAM NABINessuna valutazione finora

- 1805 StatusDocumento36 pagine1805 StatusGHULAM NABINessuna valutazione finora

- AWS - Welding SymbolsDocumento1 paginaAWS - Welding SymbolsAli Saifullizan IsmailNessuna valutazione finora

- 3 - Module 3-FinalDocumento102 pagine3 - Module 3-FinalGHULAM NABINessuna valutazione finora

- Astm A578 - 07 PDFDocumento5 pagineAstm A578 - 07 PDFMuhammad Maulana100% (1)

- E376-96 EC Measuring Coarting Thickness PDFDocumento4 pagineE376-96 EC Measuring Coarting Thickness PDFGanesh R NairNessuna valutazione finora

- MDocumento20 pagineMGHULAM NABINessuna valutazione finora

- ROD12 X 1171 ROD12: 35 1642002-9037 No Item MKD'Documento1 paginaROD12 X 1171 ROD12: 35 1642002-9037 No Item MKD'GHULAM NABINessuna valutazione finora

- MM Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi WiDocumento1 paginaMM Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi Wi WiGHULAM NABINessuna valutazione finora

- MDocumento20 pagineMGHULAM NABINessuna valutazione finora

- Tensile Test ReportDocumento1 paginaTensile Test ReportGHULAM NABINessuna valutazione finora

- MDocumento24 pagineMGHULAM NABINessuna valutazione finora

- 224 1639005-2006 No Item MKD': For ConstructionDocumento1 pagina224 1639005-2006 No Item MKD': For ConstructionGHULAM NABINessuna valutazione finora

- Girder 3 MKD' NO. 1613503-2027: Riyadh Metro Project Package 2 Line 3Documento1 paginaGirder 3 MKD' NO. 1613503-2027: Riyadh Metro Project Package 2 Line 3GHULAM NABINessuna valutazione finora

- 18 1639005-2015 No Item MKD': For ConstructionDocumento1 pagina18 1639005-2015 No Item MKD': For ConstructionGHULAM NABINessuna valutazione finora

- 60 (PL3X114 X 180) : 6 1642001-9026 No Item MKD'Documento1 pagina60 (PL3X114 X 180) : 6 1642001-9026 No Item MKD'GHULAM NABINessuna valutazione finora

- 18 1639005-2012 No Item MKD': For ConstructionDocumento1 pagina18 1639005-2012 No Item MKD': For ConstructionGHULAM NABINessuna valutazione finora

- 224 1639005-2010 No Item MKD': For ConstructionDocumento1 pagina224 1639005-2010 No Item MKD': For ConstructionGHULAM NABINessuna valutazione finora

- Welding Endoresement 17Documento1 paginaWelding Endoresement 17GHULAM NABINessuna valutazione finora

- Terrorizer July 2015 UK PDFDocumento84 pagineTerrorizer July 2015 UK PDFGeraldo Saldanha FilhoNessuna valutazione finora

- Tourism Awareness and Tour GuidingDocumento25 pagineTourism Awareness and Tour GuidingAnnalyn PeñaNessuna valutazione finora

- XciteDocumento10 pagineXciteabdul0786Nessuna valutazione finora

- 3 Bup 2 EvDocumento11 pagine3 Bup 2 EvcladelolNessuna valutazione finora

- Jazz Prepaid Packages (Jazz Easy, Jazz Budget, Jazz One, Jazz Champion) - Cells - PKDocumento10 pagineJazz Prepaid Packages (Jazz Easy, Jazz Budget, Jazz One, Jazz Champion) - Cells - PKSajid IqbalNessuna valutazione finora

- Ntse JharkhandDocumento9 pagineNtse JharkhandAshish KumarNessuna valutazione finora

- Cable Tray Inspection ListDocumento1 paginaCable Tray Inspection ListTreesa Archnana100% (1)

- Lesson 4Documento8 pagineLesson 4Sheena Mae Po100% (1)

- Cookery - 10 - Summative - 1 - Quarter 4Documento4 pagineCookery - 10 - Summative - 1 - Quarter 4Marie-Cris QuintoNessuna valutazione finora

- Rural Marketing Rural Marketing: - A Paradigm Shift in Indian MarketingDocumento19 pagineRural Marketing Rural Marketing: - A Paradigm Shift in Indian MarketingGowtham Reloaded DNessuna valutazione finora

- Thesis Joseph SchmittDocumento141 pagineThesis Joseph SchmittdaigoryuuNessuna valutazione finora

- Anchoring Script-Haryana DayDocumento5 pagineAnchoring Script-Haryana Dayrashmi pahelNessuna valutazione finora

- GSC Members Birthday Voucher Aug 2017Documento2 pagineGSC Members Birthday Voucher Aug 2017altern8tubeNessuna valutazione finora

- Menu PlanningDocumento10 pagineMenu PlanningGeline Suzane Combalicer TobiasNessuna valutazione finora

- 101 Onomatopoeic SoundsDocumento4 pagine101 Onomatopoeic SoundsErick EspirituNessuna valutazione finora

- Sdre14-5 Ral 1-2-Rev17Documento3 pagineSdre14-5 Ral 1-2-Rev17lwin_oo2435Nessuna valutazione finora

- D&D 5 0 Draco Studios Itza's Guide To Dragonbonding v1 1, CompleteDocumento348 pagineD&D 5 0 Draco Studios Itza's Guide To Dragonbonding v1 1, CompleteAlexsandro CuencaNessuna valutazione finora

- LoveSick ObssessiveImpulsive CoupleDocumento21 pagineLoveSick ObssessiveImpulsive CoupleCatarina KimNessuna valutazione finora

- Locatii Pet Friendly RomaniaDocumento4 pagineLocatii Pet Friendly RomaniaIoana RotaruNessuna valutazione finora

- INSCRIPCIÓN DE ACTIVIDADES A SEMANA HSEQ-RSE 2019 (Respuestas)Documento33 pagineINSCRIPCIÓN DE ACTIVIDADES A SEMANA HSEQ-RSE 2019 (Respuestas)Cristina AgudeloNessuna valutazione finora

- The Time-Traveling PenDocumento1 paginaThe Time-Traveling PenkvvswaminaiduNessuna valutazione finora

- Mechanics of Interpretative DanceDocumento2 pagineMechanics of Interpretative DanceJurryNessuna valutazione finora

- Present Simple (Affirmative)Documento2 paginePresent Simple (Affirmative)A3rch001Nessuna valutazione finora

- Spilt MilkDocumento9 pagineSpilt Milkbhawna ranaNessuna valutazione finora

- Hydroponics Lettuce Production (Schedule)Documento2 pagineHydroponics Lettuce Production (Schedule)Rowena Babagonio SarsuaNessuna valutazione finora

- I O and The South BridgeDocumento5 pagineI O and The South BridgeMarceloNessuna valutazione finora

- WinPE 10 Sergei Strelec (x64) 2016.04.28 English VersionDocumento6 pagineWinPE 10 Sergei Strelec (x64) 2016.04.28 English VersionSalvatore Bonaffino100% (1)

- Wayfaring Stranger-Joe DaltonDocumento7 pagineWayfaring Stranger-Joe DaltonPoss HumNessuna valutazione finora

- Wing Chun Training ScheduleDocumento10 pagineWing Chun Training SchedulesrbjkdNessuna valutazione finora

- Rockfm 500Documento22 pagineRockfm 500Mauri PalauNessuna valutazione finora