Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

3d Modeling For The Architectural Engineering and

Caricato da

icTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

3d Modeling For The Architectural Engineering and

Caricato da

icCopyright:

Formati disponibili

3D Modeling for the Architectural Engineering and Construction Industry

Clark A. Cory, Assistant Professor

Dave Bozell, Assistant Professor

Purdue University, West Lafayette, Indiana, USA

ABSTRACT

Architects and residential designers are extremely slow to

reorganize and accept technology and, therefore, change their

Residential design and construction relies heavily on working environment (Christin [2]). This fact has caused most

construction documentation to convey not only form and to miss the opportunity that exists in computer design. This

function, but also to aid in the estimation and marketing of the intelligent model would be an interlining of data, materials, and

structure. If done with traditional methods, residential design documents through the use of parametric technology. From

and construction requires many people and hours to gather the this intelligent model, a single designer would be able to

data in useful forms. The traditional documents that are generate the plans, sections, details, specifications, estimate and

necessary for the construction processes are the estimate, bill of bill of materials to create a realistic simulation for marketing.

material and construction documents or working drawings. Within this new paradigm, the renaissance person would be

Furthermore, technology is providing marketing alternatives eliminating unnecessary steps, errors and overhead previously

such as three-dimensional models for visualization, simulation expensed to create marketing and construction documents.

and spatial analysis.

3D concepts aren’t something to put off until a later day; they

In today’s extremely competitive construction market, it is are used in every aspect of modern computer-aided design

logical to identify ways to combine tasks in order to save time work, states Mathews. [3] It is from this statement that we will

and money. The advent of Computer Aided Design in the look at and define the modeling abilities and procedures within

construction process has saved an abundance of time and several software packages, and look at the different packages

energy, but these tools are not being utilized to their full with a focus on the AEC industry.

potential. Some designers and architects are simply trading in

their board and T-square for a mouse and a monitor, but the

idea of a computer is to advance current practices, not just be 2.0 AUTOCAD 2000 IN AEC

an alternative method. The computer, if utilized correctly, can

create not only the traditional two-dimensional data, but also AutoCAD has been identified as one of the leading software

three-dimensional information that can provide construction packages currently used by industry and educational facilities.

documentation and marketing requirements. Standards from the software package have been undeniably

adopted by other software packages, such as the .dwg or .dxf

The availability of multiple AEC products can make it very formats. It is for these reasons and more that most educational

hard for the user to select the correct application for their institutions have introduced it to their students. The AEC

company. This leads us to research in the comparison of the industry has followed suite in the utilization of AutoCAD for

products available. In this paper, we have chosen to compare the generation of working drawings.

and contrast “geometric modelers” versus “parametric

modelers” to show the benefits and drawbacks of each. The initial start-up of the package is like most: set your

drawing limits, identify the units, set the accuracy of the units,

Keywords: Object-Oriented Modeling, Parametric Modeling, and identify a size for the grid and snap. These elements which

Imaging, AEC, AEC software, and Visualization where crucial in the start-up of 2D drawings are not as

necessary in 3D modeling. Items that are of importance are

location of the object in relationship to the world UCS, location

1.0 INTRODUCTION of the origin for blocks, spatial visualization, and manipulation

of the UCS for cognitive visualization. The user must be aware

Modeling has proven to be extremely beneficial to the that this package has the ability to create more than one type of

Manufacturing industry as displayed by the automotive a 3D model.

industry modeling entire cars, or plastic companies solid

modeling parts; then generating a rapid prototype to verify AutoCAD allows the user three geometric forms of modeling:

interaction and tolerances with other parts on the proposed wireframe, surface, and solid modeling. Matthews [3] identifies

item. According to Ethier and Ethier [1], modeling can provide the wireframe model is a skeletal description of a 3D object,

us with a wide range of benefits, and deciding on which and due to the skeletal simplicity, it’s fast and economical

modeling package to use for the AEC industry can be within the CAD database. Wireframing have no surfaces

challenging. Also, deciding on which AEC modeling package associated them; just lines and arcs which represent edges or

to teach students can be even more challenging. The benefits to limits and vertices of the object. This form of modeling is a

the students must be researched and evaluated to give students nice transition from the 2D drawing mode into an introduction

the best opportunity for future employment.

International Conference Graphicon 2001, Nizhny Novgorod, Russia, http://www.graphicon.ru/

of 3D visualization. Wireframe models unfortunately do not relentlessly pursued 3D Modeling for the AEC industry.

allow additional information, such as area or volume, to be Currently, AutoDesk has developed a couple of products

associated or attached to them and are therefore primarily geared directly toward the AEC industry. Softdesk and

utilized for visualization. Wireframe allows the user to Architectural Desktop is just a couple of the products available.

visualize the object in its entirety, front, sides, top, bottom and Other products from other software companies include Ketiv,

back all at once; but does not allow the user to see the object as Arch T and Eaglepoint to name a few.

in real life.

3.0 MODELING WITH

The surface model is the next area which has wireframe

aspects, but with a coat or skin over the frame. Surfacing uses ARCHITECTURAL DESKTOP

the wireframe geometry and complex algebraic equations to

define an area between lines or edges of the model which then Architectural Desktop is one software specifically designed for

produces a surface covering the object. The area defined is a the AEC industry. The integration of the AutoCAD 2000 tools

general polygon mesh that is planer. and architectural objects-oriented features allows improved

productivity for the AEC user. Having object-oriented features

The last type is the solid model. The space that forms the object allows the user to utilize features from the conceptual phase

is enclosed by surfaces, which forms a closed volume. Users into the design phase and finishing up with the final

can create solid models from standard primitives, composites, construction documentation. Identifying the object-oriented

extruded, and/ or revolved solids. Users usually find solid features allow for comprehensive and accurate documentation.

modeling easiest to use and understand.

The first of the features is surface modeled walls. The walls are

What information constitutes a complete model? an extrusion of the multi-line command. Depending on how the

1. Form wall is shown is dependent on how it is viewed. In the 2D plan

a. Shape & Size view, walls are viewed as parallel lines or would be seen as a

2. Attributes traditional set of floor plans that a carpenter uses. The view of

a. Materials & Physical Properties the walls in the 3D orientation is shown as parallel surfaces or

3. Relationship/Assembly as walls in a real world scenario. The z-height is predefined

a. How parts are related before insertion of the wall component. After the height has

b. What moves with what been determined, the insertion of the wall is similar to the

4. Behavior insertion of the multi-line or individual line commands in

a. Doors opening and closing AutoCAD 2000. The comparison of commands between the

b. Structural Members under load two packages makes the transition relatively easy. Walls can

All of these items are components of a 3D model according to also be customized with properties that can identify specific

Fallon [4]. Some aspects of the 3D model are easier to achieve wall types by sight or verbal description. Association of wall

than others- given the software used. How does one achieve a types with verbal identification and visual reassurance can only

true model or something close to a 3D model with simple benefit those individuals utilizing the documents during and

software packages like AutoCAD? after the construction documentation process. Walls are not the

only benefit to this software package.

Object Linking and Embedding (OLE) is one way that

AutoCAD users can experience more of the components of a Doors, windows, and openings have a parent/ child relationship

parametric modeling software package. The idea of copying with the wall object. The software does a Boolean operation on

and pasting data between different files in the same software the surfaced wall object and inserts a door or window object

package is fairly common knowledge, but copying and pasting into the opening. The relationship is identified when users

from a word processor or spreadsheet into a CAD program is select a door to insert into a wall; the door is constrained within

something CAD users will have to get used to. Given a drawing the wall object. Sizes of doors and windows are easily adjusted

with a bill of materials that is created in Microsoft Excel, the in the menu by creating a door and window database with the

user can copy the data from excel and paste it into AutoCAD to most common sizes used within the model. This database of

print out. The pasting of the excel spreadsheet into the CAD objects may be used individually within the specific project or

file forms a link between the two software packages. If the data imported into other documents to be utilized within that

in the spreadsheet is modified, the information in the CAD project. The ability to make use of one database over and over

drawing can be update manually or automatically depending on will only enhance productivity. The initial costs are sometimes

how the users specified the linking process. The unfortunate overlooked when companies make the switch from traditional

part is the user must create the bill of materials manually before 2D drawing to 3D modeling. Those initial costs include an

he/she can insert it into the CAD drawing. The ability of OLE individual taking the time to create all the windows, doors and

linking allows the user to experience what a true 3D modeling openings within a database to make us of within upcoming

or parametric software does automatically. projects. In some cases, this process can take days or even

weeks depending upon how many sizes, styles and brands of

The AEC Institute, an American Institute for AutoCAD windows or doors the firm uses in projects.

drawing standards, does not lend itself to the use of these

modeling types and OLE linking efficiently without help of Roof systems, stairs and handrails are more features included in

supplemental plug-ins or software modifications. It is for this the software package. The generation of a roof system (in the

reason that AutoDesk and other software companies have 2D form) can be challenging at times to visualize. The more

International Conference Graphicon 2001, Nizhny Novgorod, Russia, http://www.graphicon.ru/

complex roof systems can even take multiple individuals input

to figure out. Roofs are not the only troublesome component 4.0 MODELING WITH PARAMETRIC

within construction documentation. Stairs can be just as

bothersome when the project has a specified opening size and SOFTWARE

the set of stairs will not work with the given specifications.

Visually, students and even professions have a difficult time The next generation of software technology for the AEC

understanding how the stairs are inserted into an opening. industry is based upon databases and intelligent geometry,

Architectural Desktop has greatly improved the process of roof commonly referred to as parametrics. The basis behind a

systems and stair insertion. For the roof system, it is a mater of parametric modeler is the use the entire structure as a 3D

defining the original slope of the roof, then identifying the database to build digital information. Some of the AEC

corner points of the building that the roof system will rest upon. parametric packages include, but are not limited to Argos BDS,

This is an over simplification of the process, but it does provide Vertex BD, CadSoft, and Softplan.

individuals an easy way to insert a roof system to get a quick

visual reference for the structure. It will take the user some “Parametric Modelers have been around for quite a while. The

drive time on the system to understand the intricacies of roof majority of these types of modelers are specifically designed

systems in Architectural Desktop. for the engineering industry. These programs include, but are

not limited to Pro-Engineer, Iron CAD, Catiev, and Solid Edge

Stairs might seem just as easy, but the user must understand the [Bozell [5].”

process behind what the software is doing. Total rise; tread

width, riser height, and minimum headroom height are “While these programs are very productive in the engineering

concepts that must be understood before the individual industry, they are not at all suited to the migration to the AEC

proceeds into stair insertion. Otherwise, the individual is just industry [Risch [6].” Because of this, a few companies have

placing several lines that represent steps into the project just as developed parametric software specifically to fit the needs of

it might have been done in the 2D traditional sense. the AEC industry.

Architectural Desktop has greatly improved productivity and

efficiency during the construction documentation process for In these programs, information is organized into a traditional

the AEC industry; but without understanding of the concepts construction sequence, so that the migration from a

and procedures of the construction process, individuals might “geometric” modeler to a parametric modeler can be as painless

as well be drawing in a traditional 2D method. as possible.

The benefits for companies and students to utilize 3D modeling Through the use of forms, macros, databases, and architectural

in the AEC industry can be greatly beneficial. Fallon [4] states data created in a parametric intelligent model, you can

that the benefits of intelligent modeling approach to the AEC extrapolate the data that is needed to put the model into

industry are increased productivity, reduced cycle time, better production (Risch [5]). This changes the old CAD paradigm of

work flow amongst group members, and life cycle applications. drawing lines as representations of material. To create an

These are important concepts and valuable concepts to people accurate model, the correct material needs to be selected and

that are concerned with project management; but unless the used in the virtual construction process.

user has a firm grasp on the entire construction process, only a

few of these concepts will be utilized to there full potential. 4.1 Argos BDS

Other modeling software packages make it crucial for the user

to understand the entire construction, 3D visualization, and Argos BDS is a residential specific AEC parametric software

database management processes before they begin to draw line package. Like the other parametric software packages, it stores

one. It is these packages that we will look at next. all the project data into a database. Building design and project

information is organized into a project specific database that

There are problems associated with Architectural Desktop, not includes all the files relating to that project and stores it in a

just benefits. The integration of the software package with single project directory on the hard disk. This allows for easy

other products is not as efficient or easy as lead to believe. The access to all information such as materials, customers, and

biggest problem is lack of experience accomplishing task. The project parameters. This also allows for universal project

user has a good understanding how to get things done changes. Since all the information is tied together, one change

traditionally or with 2D programs, but when the software is will universally change the project. For example, if you would

supposed to generate items automatically and the user does not change the wall height from 8 feet to 9 feet, all information and

know how to accomplish the generation, it causes extreme graphics that are tied to that height are updated to reflect the

techno-stress. Due to high expectations of existing AutoCAD change both in the 2D and in the 3D.

users, the first two versions of Architectural Desktop did not

function as promised and disappointed all users. The June 2001 When a new building is designed, the user first creates a project

issue of Cadence has an article that claims Architectural file by filling out a project information form. The data within

Desktop (ADT) 3.0 corrects deficiencies from earlier versions. the form are all users defined and can be customized to suit

The authors’ will be reviewing and determining ADT 3.0 each individual company. The project form can also include

benefits and deficiencies. pre-defined aspects of the project such as building type,

framing materials and methods and finishes.

4.1.1 Wall Design

International Conference Graphicon 2001, Nizhny Novgorod, Russia, http://www.graphicon.ru/

toilets, closet shelving, stair cases, HVAC, plumbing, and

The first step in designing a home is the layout of the building. lighting to name a few.

Typically in a “geometric” program, the user would draw a line

or a 3d rectangle to represent the wall. This is fine if all you In keeping in line with the parametric modeler, the user will

want is graphics, but the ultimate goal is to have everything select from a database what they would like to add into their

integrated so that everything is stored in one place, and there is AEC model. By selecting from a database, they are able to

no duplicate data in the project. “It’s our position that not attach a 2D and 3D model of the object as well as have specific

having to duplicate information and having software that can information attached to that macro such as price, labor,

draw on the resources of other software is really critical, good manufacture, product number, or any other information that

management.” (Smith [7]) they want. Once this information is placed into the model, the

information can be extracted into a materials list that can be

This leads to the concept of drawing specific types of walls in passed on for estimation, purchasing, or project management.

the 3D model or database of information. A user will first go “What we’re tying to do is bring all parties in a construction

into the walls database and select the appropriate type of wall project together.” (Unger [7])

that they are going to use to build the wall. This wall database

will contain all of the information and material needed to build 4.1.5 Materials Management

that wall. For example, if you choose an “Exterior 2x4 wall

with brick” from the database, the wall that you place down, Much of the power and flexibility of a parametric modeler is a

will not only have the 2D and 3D lines necessary to represent direct result of the integration of the graphical data with the

the walls, but will also contain the material needed to build the materials database. This enables the user to attach any number

wall such as studs, square foot of drywall, square foot of brick, of material items, components, or characteristics directly to its

and how much insulation is necessary for that wall. By graphical symbol. Therefore, once a plan has been completed

associated these materials with the wall, you are essentially with all the elements, the system then automatically creates a

building the entire structure from start to finish in the computer. model of the design. The parametric modeler then has all the

This is what will give the user an accurate material list that can criteria defined to automatically generate a complete bill of

be utilized in the entire building process. materials and cost estimate for the project. The system also

allows the user to include labor and waste factors to further

4.1.2 Doors and Windows refine the cost estimate.

Every builder will use a different type of window or door 4.1.6 Integration with other Application

manufacture. For this same reason, every manufacture will

have a slightly different rough opening size for their doors and Why would anyone spend the extra time needed to build a

windows. parametric model? Well, the answer lies in data management.

With the capability of extracting a materials list from the 3D

Just like with the walls, a parametric modeler will ask the user parametric models, you have the ability to eliminate the need

to select the type of door or window that they want to place in for estimation on a project created into a parametric system.

their wall. Depending on the selection, the materials and rough

opening will be adjusted. When the user has selected the The information extracted has the ability to integrate into other

appropriate door or window, they simply have to place it in the software programs used in the AEC industry today. These

wall they want. The parametric software will then cut out software programs include Timberline, Primavera, Sure Sell,

materials and graphical information from the model and and many other AEC packages.

substitute in the material and graphics for the door or window.

By combining tasks, companies will have the ability to same

Again, by having a database behind the graphics, users are able time and money on projects. They will also have the

to have an accurate 2D plan, 3D model and material count for information stored in one place. The graphical information

the estimation of the building. from the model has the ability to integrate into the

aforementioned packages such as AutoCAD and 3D Studio

4.1.3 Floors and Ceilings MAX / VIZ.

Floors and ceilings contain the information such as floor 4.1.7 3-Dimensional Models

sheathing, ceiling drywall, floor joists, rim joists, ceiling joists

and blocking. The user will select what material that they wish Because all components within a parametric modeler are

to use in their construction as well as how they wish the created as 3D elements, it allows the user to quickly view and

software to build the building. The parametric software will compare various design choices interactively. The building

then take the information selected from the database and build model can also be rotated to generate additional views and

a 2D plan and 3D model that will reflect how the building will perspectives.

be built.

As discussed earlier, all elements will have the information

4.1.4 Macros already attached. The designer, therefore, can view alternatives

and instantly evaluate their impacts on both the final design and

AEC documents have a lot of information in them of what is budget. The result is a more cost efficient design and better

contained in the building. For example, kitchen cabinets, sinks, materials utilization.

International Conference Graphicon 2001, Nizhny Novgorod, Russia, http://www.graphicon.ru/

The advantage of having the 3D information available allows

the creator to check for errors that might occur in the drawing

process.

4.1.8 Automatic Options System

Increasingly today, builders must respond to the growing

requests for customization from prospective buyers. The

ability to incorporate pre-defined options and design changes

into a particular building plan can have a tremendous impact on

project completion time, construction costs, and profitability.

Argos BDS has developed an Automatic Options System into

their product. To data, it is the only one of its kind. This

system allows companies to define a base design model and

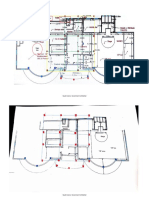

attach pre-defined options selections to it. These options are Figure 1.1

completely user defined and can be in any form the user

chooses. When an order comes in, the user merely selects the Revit is based upon family groups and databases just like

desired options from the options list. Argos then combines Argos is based upon Macros and databases. Family groups are

those specific options together, revises all the appropriate all of the intelligent elements that you put into your drawings

drawings and updates the pricing and bill of materials. that will be collected in the Bill of Materials (BOMs). The

standard family group that is installed out of the box is very

With the Automatic Options System's flexibility, the user can extensive, but you also have the ability to download extension

easily setup the building options to meet whatever needs may family groups from the Revit web site or from the user groups

develop. The system can also be used as an effective sales and for free. In addition to downloading family groups, the

marketing tool. Sales representatives or dealers can select experienced user can create their own custom family groups.

various design options with a customer and instantly show

them the final design and the costs associated with their Revit used the very popular RS Means standards for collecting

selections. the BOM or estimate of the structure. The software, with a

click of a button, will read the drawing files and all of the

4.2 Revit family groups and create an estimate based upon these RS

Means standards. There are still quite a few shortcomings with

The latest development in AEC software is Revit from Revit this type of estimate, but Revit is only in its third version and

Technologies, Inc. Revit is a “true” parametric program unlike Revit has stated that they are addressing this problem and will

a lot of the other AEC software on the market. The data have a more accurate estimation package in their future

entered into the system is completely bi-associative, which products.

means that all the drawing files are linked together. You have

the ability to go to the window schedule, adjust the sizes of the Revit Technology, Inc. has one of the best academic programs

windows, and it will update the 2D floor plans, 3D model, to date. Any academic institution can utilize their software at

elevations, sections, details and any other drawing that has the no cost. All that is needed is a short proposal of where the

changed window in it. This can save the user a tremendous software will be used and an update at the end of the semester

amount of time especially if the change comes after the on the use of the software as well as some example student

documentation has been completed. Typically in AEC work. Furthermore, Revit will allow students enrolled in the

parametric software such as Argos, you only have the ability to classes to have the software on their personal home computers

change items in the 2D plan and have it change the 3D. All at no cost. From an academic standpoint, it is very encouraging

other drawing files must be changed by hand. to see a company that has the vision to work with academic

institutions to help in the development and distribution of their

Revit is based upon the popular mechanical engineering product and knowledge.

parametric software package Pro-Engineer from Parametric

Technologies, Inc (PTC). The original creators of Pro- Revit, while still in its beginning stages, has extreme potential.

Engineer sold their company and began Revit Technologies to The program is organized in a very functional form. Instead of

address the needs of the AEC industry. Revit’s first priority slowing down or hindering the design and documenting process

was to make the user interface user friendly and easy to use. it will actually enhance and make the designing process easier

Their concept was to make the interface as familiar as possible and productive.

by designing the menus to look like Microsoft Outlook. This

will immediately give the user the sense of familiarity and help

them work through the functionality of the program. (Figure

1.1)

International Conference Graphicon 2001, Nizhny Novgorod, Russia, http://www.graphicon.ru/

5.0 PRACTICAL ISSUES trains on the software purchased. It will save you time,

headaches and stress later on if you understand the software

Today’s AEC professional worries about several items during before you engage in production.

the course of a day or the life cycle of a given project, but when

it comes right down to it- they worry about production and

money. Some items that should concern professionals when 7.0 REFERENCES

deciding whether or not to plunge into 3D modeling are:

1. Design costs and time [1] Ethier, S. J., & Ethier, C. A., (1997). AutoCAD in 3

2. Software learning curve Dimensions. (2nd ed.). New Jersey: Prentice Hall.

3. Software costs

4. Ability of the software to handle complex geometry [2] Christin, R. (1998, April). New Dimensions in CAD. 3D

5. Performance of the software- bugs Design, 4, 31-37.

6. Level of detail needed and what the software will

deliver [3] Matthews, M. (1999). AutoCAD 2000 3D. ( 1st ed.).

7. Partition the model among multiple users Arizona: The Coriolis Group, LLC.

8. Integrate model from multiple sources

9. Tools for model review and web publishing [4] Fallon, K. K., (1999, November). The Shift to Intelligent

10. Speed and working drawing extraction Modeling. Symposium conducted at the Computers for

11. Maintenance Construction ’99 Conference. Chicago, IL.

The overall goal is to keep production levels the same while the

transition of the new software takes place. This is where most [5] Bozell, D. R. (1999) Instructional System Development for

of the problems occur because the designers are concerned with Residential Design using Parametric Computer Models.

production and, most of the time he/she reverts to the software Unpublished master’s thesis, Purdue University, West

they are most comfortable utilizing to accomplish task quickly Lafayette, IN

and efficiently.

[6] Risch, J., Argos Systems, Inc. (1998). Application

6.0 CONCLUSIONS information.[On-Line]. Available: http://www.argos.com

In today’s extremely competitive AEC market and industry, it [7] Smith, D. (1999). Trends in Construction. ConstrucTECH,

is logical for industry professionals to identify ways to combine Winter,15-23

tasks, save time and furthermore, save money. The advent of

Computer Aided Design (CAD) in the construction process has [8] Unger, S. (1999). Trends in Construction. ConstrucTECH,

saved an abundance of time and energy, but these tools are not Winter,15-23

being utilized to their full potential. It is unfortunate that most

AEC professionals are from the old school and are unwilling to

utilize the benefits of 3D modeling. It may be due to their lack

of exposure with the software and the benefits using a 3D About the Authors

modeling software package. There has been a noticeable

increase in utilization of 3D modeling in the Architectural and

Clark Cory is an Assistant Professor in the Department of

Construction areas, but it is a drop in the bucket compared to

Computer Graphics Technology at Purdue University in West

Engineering and Manufacturing professions.

Lafayette, Indiana. He received his Associate of Applied

Science in Building Construction Management, a Bachelor of

In this paper, we have reviewed a portion of the AEC software

Science in Technical Graphics and a Master of Science in

packages available. Each of these software packages possess’

Education Computing from Purdue University. Clark’s primary

their own benefits and limitations. By evaluating your

professional responsibility is undergraduate instruction in

company’s specific needs, you will be able to better determine

architectural and construction graphic communication and

the software package that will make your company efficiently

visualization. He is currently helping develop a Construction

productive.

Graphics Communication specialty area within the Computer

Graphics Department at Purdue. Professor Cory’s areas of

The fact that there is multiple 3D modeling software products

interest include topics on the improvement of cognitive

for every type of industry identifies several very important facts

visualization in construction using 3D models, the impact of

before, during and after purchase of the package. First, it

new technology on the jobsite of construction, and smart house

should be the foundation knowledge emphasized in the

technology. His presentations include national and international

education. The type of software package being utilized should

conferences. He currently teaches courses on 3d modeling in

not be a factor, but just a benefit. Second, research is the key to

construction, Architectural documentation, digital lighting and

a successful and productive purchase of the software. You

rendering, raster graphics, and animation. Clark has had over

really cannot put a time limit on the initial research to identify

20 years experience in the AEC industry with positions ranging

the best possible product for your company. The last factor is

from general laborer to project manager of 25 residential

training. Strongly emphasis that your employee’s and/ or

structures per year.

students take the time to run through the tutorials, or encourage

enrolling in a short course dealing that specifically deals and

Email: cacory@tech.purdue.edu

International Conference Graphicon 2001, Nizhny Novgorod, Russia, http://www.graphicon.ru/

David Bozell is an Assistant Professor in the Department of

Computer Graphics Technology at Purdue University in West

Lafayette, Indiana. His area of specialization is Construction

Graphic Communication with an emphasis on new media and

web technology integration into the industry. David's

educational experience included receiving his Associate of

Applied Science in Building Construction Management, a

Bachelor or Science in Computer Graphics and a Master of

Science in Industrial Technology. In addition to his educational

research agendas, David is also an active consultant for

companies on how they can utilize new technologies to

increase their productivity and bottom line. His current

involvement includes: Builder Solutions in Cordova,

Tennessee, an e-commerce company serving the needs of

residential home builders; Panel Master Corporation in

Merrillville, Indiana, a residential and light commercial

panelizing company; Southern Truss and Steel in Atlanta,

Georgia, a light commercial steel panelizing company; and

Weiss Homes in South Bend, Indiana, a residential home

builder. These consulting opportunities have led to

development of industrial projects in the Department of

Computer Graphics at the Junior and Senior levels. By

incorporating real activities into the classroom, students are

able to gain practical experience in the industry, as well as

develop their customer relation skills. These techniques in the

classroom has led to a growing number companies brining

projects into the University to pre-train students that they

would like to hire after graduation. David's publications include

topics on e-commerce technologies in the classroom, the use of

3D models in the construction industry to improve visualization

and communication, parametric technologies in the A.E.C.

industry, and Data management using Graphical databases.

David has also written a book entitled "Integrated Parametric

Building Construction." David's presentations include national

and international conferences. He currently teaches courses on

3D modeling, database management, and A.E.C. marketing

technique.

Email: drbozell@tech.purdue.edu

International Conference Graphicon 2001, Nizhny Novgorod, Russia, http://www.graphicon.ru/

Potrebbero piacerti anche

- Architects Guide To 3D ModelingDocumento25 pagineArchitects Guide To 3D ModelingOzgur OzkanNessuna valutazione finora

- Information TechnologyDocumento10 pagineInformation TechnologynoahNessuna valutazione finora

- Teaching Solid Modeling With AutocadDocumento17 pagineTeaching Solid Modeling With AutocadCaurelou PitocNessuna valutazione finora

- Structural Drafting ModelDocumento10 pagineStructural Drafting ModelBeny AbdouNessuna valutazione finora

- A.V.C. College of Engineering: Title of The PaperDocumento17 pagineA.V.C. College of Engineering: Title of The PapervenkkateshNessuna valutazione finora

- Innovative Approach To The Substation Design Using Building Information Modeling (BIM) TechnologyDocumento5 pagineInnovative Approach To The Substation Design Using Building Information Modeling (BIM) TechnologyPAREEKSHIT POUDELNessuna valutazione finora

- Caliva, Joshua A.Documento10 pagineCaliva, Joshua A.chanahlouNessuna valutazione finora

- Overview of CAD SoftwareDocumento4 pagineOverview of CAD SoftwareLakshika SubodhaniNessuna valutazione finora

- Irjet V9i7575Documento7 pagineIrjet V9i7575shubs2226Nessuna valutazione finora

- SCIA Engineer Interoperability BIM PDFDocumento12 pagineSCIA Engineer Interoperability BIM PDFTomasz WiatrNessuna valutazione finora

- BIM Enables Significant Process Improvements in Building Design and ConstructionDocumento5 pagineBIM Enables Significant Process Improvements in Building Design and ConstructionSussy LópezNessuna valutazione finora

- Design and Analysis of A Gated CommunityDocumento13 pagineDesign and Analysis of A Gated CommunityInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Cad Cam Lab ManualDocumento75 pagineCad Cam Lab ManualHariprasad100% (1)

- Adapting AutoCAD Electrical for Substation DesignDocumento13 pagineAdapting AutoCAD Electrical for Substation DesignslugzNessuna valutazione finora

- Building Information Model-Based Finite Element Analysis of High-Rise Building Community Subjected To Extreme EarthquakesDocumento11 pagineBuilding Information Model-Based Finite Element Analysis of High-Rise Building Community Subjected To Extreme EarthquakesAiman Seven IINessuna valutazione finora

- EdmDocumento9 pagineEdmMax LuxNessuna valutazione finora

- CAD Modeling in Construction PlanningDocumento13 pagineCAD Modeling in Construction PlanningHaseebNessuna valutazione finora

- Paper-Building Information Modeling (BIM) - A New Paradigm For Visual Interactive Modeling and Simulation For Construction ProjectsDocumento12 paginePaper-Building Information Modeling (BIM) - A New Paradigm For Visual Interactive Modeling and Simulation For Construction ProjectsegglestonaNessuna valutazione finora

- Research Paper On CadDocumento4 pagineResearch Paper On Cadecluembkf100% (1)

- Khalid Paper 2020 No.4Documento11 pagineKhalid Paper 2020 No.4Khalid ElBazNessuna valutazione finora

- Computer Aided DesignDocumento7 pagineComputer Aided DesignRicardo AqpNessuna valutazione finora

- Intelligent Building System Automatically Constructs Complex 3D Brick ModelsDocumento11 pagineIntelligent Building System Automatically Constructs Complex 3D Brick ModelsKhalid ElBazNessuna valutazione finora

- Adoption of Building Information Modeling and Nigeria'S Quest For Project Cost Management Agele J. Alufohai, MPM, Mrics, FniqsDocumento7 pagineAdoption of Building Information Modeling and Nigeria'S Quest For Project Cost Management Agele J. Alufohai, MPM, Mrics, FniqsMehala GnanarednamNessuna valutazione finora

- Revit vs AutoCAD: A Comparison of BIM and CAD SoftwareDocumento65 pagineRevit vs AutoCAD: A Comparison of BIM and CAD SoftwareAin roseNessuna valutazione finora

- 6 Week Training ReportDocumento32 pagine6 Week Training ReportRavi KumarNessuna valutazione finora

- Simulation Lab Manual-2Documento48 pagineSimulation Lab Manual-2Satti NagendrareddyNessuna valutazione finora

- Computer Aided Drawing and Design NotesrDocumento16 pagineComputer Aided Drawing and Design NotesrMue ngineerNessuna valutazione finora

- Parametric Accuracy: Building Information Modeling Process Applied To The Cultural Heritage PreservationDocumento6 pagineParametric Accuracy: Building Information Modeling Process Applied To The Cultural Heritage PreservationGülce Tunçbilek KarakayaNessuna valutazione finora

- Revit Mep Vs Autocad MepDocumento4 pagineRevit Mep Vs Autocad MepAbdelhameed Tarig AlemairyNessuna valutazione finora

- A Cade Study in Structural Drafting Analysis and DDocumento11 pagineA Cade Study in Structural Drafting Analysis and DSATINDER KHATTRANessuna valutazione finora

- Mf7111 Cam Lab Manual Edited - 2014Documento34 pagineMf7111 Cam Lab Manual Edited - 2014Nabeel neduvalliNessuna valutazione finora

- G10-Construction Before and After Bim2Documento22 pagineG10-Construction Before and After Bim2Shady DokhanNessuna valutazione finora

- Ijtra1605295 1Documento4 pagineIjtra1605295 1Pravin PatilNessuna valutazione finora

- (MFG Engg HDBK, CHP 9) : 9.1.1 What Is CAD?Documento2 pagine(MFG Engg HDBK, CHP 9) : 9.1.1 What Is CAD?Sufian HijazNessuna valutazione finora

- Billie. A Prototypical Framework For Building Information Model VisualizationDocumento9 pagineBillie. A Prototypical Framework For Building Information Model VisualizationaMOR BENGOURICHNessuna valutazione finora

- Tutorial REVIT para PrincipiantesDocumento17 pagineTutorial REVIT para PrincipiantesBRENDA FERNANDEZNessuna valutazione finora

- AutoCAD vs SketchUp for Construction: A Comparative StudyDocumento60 pagineAutoCAD vs SketchUp for Construction: A Comparative StudyJhotuan KoNessuna valutazione finora

- Revit Structure and BimDocumento9 pagineRevit Structure and Bimcarm3nNessuna valutazione finora

- Bim and Cost EstimatingDocumento9 pagineBim and Cost Estimatingle_canh65Nessuna valutazione finora

- Building Information Modelling (BIM) User Guide For Development and Construction Division of Hong Kong Housing AuthorityDocumento53 pagineBuilding Information Modelling (BIM) User Guide For Development and Construction Division of Hong Kong Housing AuthoritySyl Vain RissNessuna valutazione finora

- Connected Augmented AssemblyDocumento8 pagineConnected Augmented Assembly董思辰Nessuna valutazione finora

- Phidl PaperDocumento10 paginePhidl PaperNomioAnneNessuna valutazione finora

- Next Generation Parametric Design_s12Documento14 pagineNext Generation Parametric Design_s12zlazarevicNessuna valutazione finora

- Bar Lish 2012Documento14 pagineBar Lish 2012ilovevinaNessuna valutazione finora

- 045 With Cover Page v2Documento13 pagine045 With Cover Page v2Agung RamadhanNessuna valutazione finora

- Introduction To ICT Specialization: Estrella B. Famini Bbtled Ict 2-2Documento18 pagineIntroduction To ICT Specialization: Estrella B. Famini Bbtled Ict 2-2Aizel AlindoyNessuna valutazione finora

- AutocadDocumento4 pagineAutocadAngela MaquilingNessuna valutazione finora

- Digital Space: Prof. Dr. Mohamed Ibrahim Abdelall, Lamiaa Adel ShaheenDocumento4 pagineDigital Space: Prof. Dr. Mohamed Ibrahim Abdelall, Lamiaa Adel ShaheenerpublicationNessuna valutazione finora

- Facilitating Mechanical Design With Augmented Reality: Poh, Y. L., Nee, A. Y. C., Youcef-Toumi, K., Ong, S. KDocumento5 pagineFacilitating Mechanical Design With Augmented Reality: Poh, Y. L., Nee, A. Y. C., Youcef-Toumi, K., Ong, S. KThe DesiNessuna valutazione finora

- BIM Execution Plan: Phase II - ConstructionDocumento26 pagineBIM Execution Plan: Phase II - ConstructionFayyazAhmadNessuna valutazione finora

- Aecosin BentleyDocumento2 pagineAecosin BentleyLuiz Amilton SalesNessuna valutazione finora

- Bim Contract IssuesDocumento9 pagineBim Contract IssuesEl ZharNessuna valutazione finora

- HE Next Generation of Rebar Detailing.: Use Your Current CAD PlatformDocumento4 pagineHE Next Generation of Rebar Detailing.: Use Your Current CAD PlatformPrinceeben1Nessuna valutazione finora

- Basic Research On BIM-Based Quantity Take-Off Guidelines: Seokheon Yun and Sangchul KimDocumento7 pagineBasic Research On BIM-Based Quantity Take-Off Guidelines: Seokheon Yun and Sangchul KimMagno RegisNessuna valutazione finora

- Technology and Communication AssignmentDocumento4 pagineTechnology and Communication AssignmentadamNessuna valutazione finora

- Towards An Earthquake-Resistant Architectural Design With The Image Classification Method-2Documento15 pagineTowards An Earthquake-Resistant Architectural Design With The Image Classification Method-2htugbaNessuna valutazione finora

- Solid Modeling WebsterDocumento19 pagineSolid Modeling WebsterPartha_2610Nessuna valutazione finora

- Exploring Autodesk Revit 2018 for MEP, 5th EditionDa EverandExploring Autodesk Revit 2018 for MEP, 5th EditionValutazione: 1 su 5 stelle1/5 (1)

- Technical Data Sheet For The HSA Stud Anchor Technical Information ASSET DOC 2027424Documento22 pagineTechnical Data Sheet For The HSA Stud Anchor Technical Information ASSET DOC 2027424icNessuna valutazione finora

- Splice Length of Reinforcing Bars Calcul PDFDocumento172 pagineSplice Length of Reinforcing Bars Calcul PDFicNessuna valutazione finora

- Technical Data Sheet For The HSA Stud Anchor Technical Information ASSET DOC 2027424Documento22 pagineTechnical Data Sheet For The HSA Stud Anchor Technical Information ASSET DOC 2027424icNessuna valutazione finora

- Strip FootingDocumento16 pagineStrip FootingConciselyNessuna valutazione finora

- Mgs 4Documento89 pagineMgs 4icNessuna valutazione finora

- MyAnalytics overview for productivity insightsDocumento107 pagineMyAnalytics overview for productivity insightsic100% (1)

- Splice Length of Reinforcing Bars Calcul PDFDocumento172 pagineSplice Length of Reinforcing Bars Calcul PDFicNessuna valutazione finora

- mgs4 CODESDocumento5 paginemgs4 CODESicNessuna valutazione finora

- Presentation1.pptx TileDocumento2 paginePresentation1.pptx TileicNessuna valutazione finora

- S.No. Drawing No. Revision: Summary of DrawingsDocumento2 pagineS.No. Drawing No. Revision: Summary of DrawingsicNessuna valutazione finora

- ARC (AU) - Reinforcement Handbook, Your Guide To Steel ReinformecentDocumento78 pagineARC (AU) - Reinforcement Handbook, Your Guide To Steel Reinformecentmica100% (1)

- Reinforced Concrete Design FILEDocumento42 pagineReinforced Concrete Design FILEJude Maala Onanad100% (1)

- Foundation Analysis and DesignDocumento32 pagineFoundation Analysis and DesignvbisketiNessuna valutazione finora

- Try To Use HTTPS Instead of HTTP Which IsDocumento1 paginaTry To Use HTTPS Instead of HTTP Which IsicNessuna valutazione finora

- Reinforced Concrete Design FILEDocumento42 pagineReinforced Concrete Design FILEJude Maala Onanad100% (1)

- Hindi ReferenceDocumento1 paginaHindi ReferenceicNessuna valutazione finora

- Structural Steel Quantity Take-Off WorksheetDocumento2 pagineStructural Steel Quantity Take-Off WorksheeticNessuna valutazione finora

- Eng MechDocumento1 paginaEng MechicNessuna valutazione finora

- Control of Shrinkage and Curling in Slabs On Grade - tcm45-342502Documento5 pagineControl of Shrinkage and Curling in Slabs On Grade - tcm45-342502icNessuna valutazione finora

- Reading and Writing ArabicDocumento22 pagineReading and Writing Arabicunxnownlogic100% (1)

- 10x12 (9x9.1) (STAIR) - ModelDocumento1 pagina10x12 (9x9.1) (STAIR) - ModelicNessuna valutazione finora

- External Reference Files (Xrefs)Documento5 pagineExternal Reference Files (Xrefs)icNessuna valutazione finora

- Reading and Writing ArabicDocumento22 pagineReading and Writing Arabicunxnownlogic100% (1)

- Aci 117 R90Documento11 pagineAci 117 R90Rafael Elgueta Aravena100% (1)

- 0 6416 1 PDFDocumento234 pagine0 6416 1 PDFicNessuna valutazione finora

- TF 700-R-07 - Slab - On - Ground PDFDocumento44 pagineTF 700-R-07 - Slab - On - Ground PDFPeteris Skels100% (1)

- FDL ModelDocumento1 paginaFDL ModelicNessuna valutazione finora

- 10x12 (9x9.1) - ModelDocumento1 pagina10x12 (9x9.1) - ModelicNessuna valutazione finora

- MID01Documento1 paginaMID01Marcel SalesNessuna valutazione finora

- Homework (Chapter 2) Math 101 - Fall 1997Documento3 pagineHomework (Chapter 2) Math 101 - Fall 1997icNessuna valutazione finora

- NV3 - GFRC or UHPC (Concealed Fixing) : Thermally Broken Cladding Support SystemDocumento16 pagineNV3 - GFRC or UHPC (Concealed Fixing) : Thermally Broken Cladding Support Systemart cafeNessuna valutazione finora

- Sound and AcousticsDocumento3 pagineSound and AcousticsmadanNessuna valutazione finora

- Highway Business District Design StandardsDocumento7 pagineHighway Business District Design StandardsAdam Rabb CohenNessuna valutazione finora

- RC III Ch-3 - Reinforced Concrete WallsDocumento11 pagineRC III Ch-3 - Reinforced Concrete WallsJo YohannesNessuna valutazione finora

- Typical Drawing of Compound WallDocumento1 paginaTypical Drawing of Compound WallAkshay KumarNessuna valutazione finora

- Emaar Square - First FloorDocumento2 pagineEmaar Square - First FloorhemaccnaNessuna valutazione finora

- My TutorialDocumento5 pagineMy TutorialSuaidah ShimaNessuna valutazione finora

- Guide To Standards and Tolerances 2017Documento72 pagineGuide To Standards and Tolerances 2017Jill Jim Livestock100% (1)

- Modular Construction BrochureDocumento12 pagineModular Construction BrochureNguyễn Xuân NamNessuna valutazione finora

- Construction ScheduleDocumento10 pagineConstruction Schedulejunlab0807100% (3)

- LysaghtArchitecturalDetailingManualRoofWallFlashingApril14 PDFDocumento40 pagineLysaghtArchitecturalDetailingManualRoofWallFlashingApril14 PDFthailanNessuna valutazione finora

- Report and DesignDocumento53 pagineReport and Designkiran raghukiranNessuna valutazione finora

- The Work Breakdown Structure Is As FollowsDocumento4 pagineThe Work Breakdown Structure Is As FollowsBobor Emmanuel OfovweNessuna valutazione finora

- Facade Notes - ACIDocumento7 pagineFacade Notes - ACIKhalid Dafer100% (1)

- Blower Door Tests (En 13829) For Quality Assurance - Getting Air-Tight Buildings in Retrofitting, TooDocumento6 pagineBlower Door Tests (En 13829) For Quality Assurance - Getting Air-Tight Buildings in Retrofitting, TooSam WeberNessuna valutazione finora

- Method Statement - DEMOLITION BUILDING - FENCINGDocumento7 pagineMethod Statement - DEMOLITION BUILDING - FENCINGprisma integratedNessuna valutazione finora

- CPCI MI Manual Low ResDocumento39 pagineCPCI MI Manual Low ResMass19Nessuna valutazione finora

- Design CriteriaDocumento21 pagineDesign CriteriaDick Anthony MabaoNessuna valutazione finora

- Structural Framing SystemDocumento6 pagineStructural Framing SystemMelchor Jaramilla Oronos100% (3)

- Guwahati Building Byelaws GMDADocumento92 pagineGuwahati Building Byelaws GMDAkolappanNessuna valutazione finora

- Roxul Safe Applications Guide: Fire Blocks, Firestops, and Rated AssembliesDocumento18 pagineRoxul Safe Applications Guide: Fire Blocks, Firestops, and Rated AssembliesHaris SienaNessuna valutazione finora

- IBS Score ManualDocumento32 pagineIBS Score Manualwanjailani83% (6)

- Singapore Fire Code 2013Documento447 pagineSingapore Fire Code 2013chenkenkent100% (2)

- Free Standing Walls and Cladding Design GuideDocumento33 pagineFree Standing Walls and Cladding Design GuideNatalia SnegurNessuna valutazione finora

- NBC 205 - 2071-02-05Documento52 pagineNBC 205 - 2071-02-05Sudish Amatya90% (20)

- Nepal National Building Code: DRAFT FINAL NBC 205:2012Documento46 pagineNepal National Building Code: DRAFT FINAL NBC 205:2012ranjan08838Nessuna valutazione finora

- NBC 2005 Vs NBC 2016 (Fire and Safety) PDFDocumento11 pagineNBC 2005 Vs NBC 2016 (Fire and Safety) PDFpratik jadhavNessuna valutazione finora

- Fire ResistantDocumento74 pagineFire ResistantMiguell DasentaNessuna valutazione finora

- Productivity Rate Labor EqptDocumento31 pagineProductivity Rate Labor Eqptnemat1233Nessuna valutazione finora

- Proposed Office Building Project PreliminariesDocumento72 pagineProposed Office Building Project Preliminariesrajayu20002724Nessuna valutazione finora