Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fabrication Tolerances 51G14r1

Caricato da

Selvakpm06Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Fabrication Tolerances 51G14r1

Caricato da

Selvakpm06Copyright:

Formati disponibili

Guidelines for Fabrication Tolerances / Acceptance Criteria for Page No.

: 1 of 6

Inspection & Testing Revision : 1.0 / 26.04.2008

Purpose:

To have a common understanding of fabrication tolerances / acceptance criteria amongst all Quality Control

Personnel assisting them in carrying out their day-to-day inspection and test activities.

Guideline:

This guideline provides the general fabrication tolerances and acceptance criteria for various members of the

Structural Steel Products.

Implementation of these tolerances on various projects can only be applied, when: -

• Such tolerances are not specified by the customer in their project technical specifications.

• The Design / Construction code of the project is the same as that specified in the Reference Standard of this

guideline

The tolerances / acceptance criteria specified in the LATEST edition / addendum of the APPLICABLE CODE shall be

referred for final acceptance.

Where fabrication tolerance / acceptance criteria is clearly defined in the scope of project, this guideline shall be

superseded by project requirements.

Doc. No. 5-1-G14

Guidelines for Fabrication Tolerances / Acceptance Criteria for Page No. : 2 of 6

Inspection & Testing Revision : 1.0 / 26.04.2008

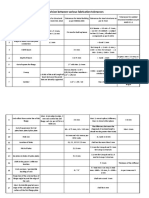

REFERANCE

Sr. DESCRIPTION TOLERANCES

STANDARDS

1. Rolled Section 1.1 ASTM A6 / A6M 1.1 ASTM A6 / A6M

1.2 BS4 OR BS4848 1.2 BS4 OR BS 4848

2. BUILT-UP MEMBERS 2.1 Depth, D = ±4mm BS 5950 : PART 2 - 1992

2.2 Width of flanges, B = ±6mm

2.3 Off centre of WEB, e(max) = ±6mm (See Attachment No.1)

2.4 At any cross section the quantity (C-D)

shall not exceed:

a) +6mm for flanges not exceeding

450mm wide

b) +9mm for flanges over 450mm wide.

where:

C = max overall measured Average

depth.

D = is the measured average depth.

2.5 Out of Squareness of flanges (max) F

= 6mm.

2.6 Out of flatness of flange (max)

= B or 3mm

150

2.7 Maximum distortion on web,

at depth, d, shall not exceed

d or 3mm

150

3. BUILT UP BOX SECTIONS Built-up box section shall not deviate BS 5950

from the specified shape at the PART 2 - 1992

diaphragm by more than

±5mm or ± D1+D2

400

4. LENGTH ±3mm BS 5950 PART 2 - 1992

Doc. No. 5-1-G14

Guidelines for Fabrication Tolerances / Acceptance Criteria for Page No. : 3 of 6

Inspection & Testing Revision : 1.0 / 26.04.2008

REFERANCE

Sr. DESCRIPTION TOLERANCES

STANDARDS

5.1 STRAIGHTNESS AWS D1.1 - 2004

For welding columns and a) For length less than 9meter,

primary truss members, straightness tolerance shall be

regardless of cross section

3mm x Total Length (meter)

3

b) For length 9 meters to 14 meters :

= 10mm

c) For lengths above 14 meters :

= 10mm + 3mm x L - 14

3

5.2 For welded Beams and AWS D1.1 - 2004

Girders, regardless of 3mm x Total Length (meter)

cross section, where there

3

no specified camber or

sweep.

6. CAMBER AWS D1.1 - 2004

a) At midspan: -0, +38 mm for spans

6.1 Camber for typical girder

≥30meters.

b) At mid span: -0, + 19mm for spans <

30 meters

c At supports = 0 for end supports =3mm

for interior supports.

6.2 The deviation from 12mm or 1mm per meter specified BS 5950 : Part 2 - 1992

specified camber ordinate camber length of the curved member.

at the mid-length of the

portion to be curved :

7. SWEEP For horizontally curved welded Beams AWS D1.1 - 2004

or Girders, the allowable variation

specified sweep at the midpoint is :

± 3mmx Total Length in meters

3

8. FLATNESS h -h ≤t ISO 13920 : 1996 (E)

Max. min.

(See attachment No. 2 Figure 7)

9. PARALLELISM h -h ≤t ISO 13920 : 1996 (E)

Max. min.

(See attachment No. 2 Figure 8)

10. ANGULAR DIMENSION Refer to Table 2 ISO 13920 : 1996 (E)

(See attachment No. 3)

11. HOLES AISC Manual

a) Enlargement of Holes +1/32” (0.794mm) 9th Edition (ASD) / 13th

b) Hole Location Edition (LRFD)

(Pitch / Gauges) ± 1/16” (1.6mm)

Doc. No. 5-1-G14

Guidelines for Fabrication Tolerances / Acceptance Criteria for Page No. : 4 of 6

Inspection & Testing Revision : 1.0 / 26.04.2008

Doc. No. 5-1-G14

Guidelines for Fabrication Tolerances / Acceptance Criteria for Page No. : 5 of 6

Inspection & Testing Revision : 1.0 / 26.04.2008

Doc. No. 5-1-G14

Guidelines for Fabrication Tolerances / Acceptance Criteria for Page No. : 6 of 6

Inspection & Testing Revision : 1.0 / 26.04.2008

Doc. No. 5-1-G14

Potrebbero piacerti anche

- Comparison of Tolerances - Is 7215 - AWS - MBMADocumento1 paginaComparison of Tolerances - Is 7215 - AWS - MBMASunil Pulikkal100% (2)

- 3.2 Standard1Documento1 pagina3.2 Standard1Thi PhamNessuna valutazione finora

- Waviness Tolerance 18.01.10Documento1 paginaWaviness Tolerance 18.01.10Thi PhamNessuna valutazione finora

- Distortion in Weld JointDocumento54 pagineDistortion in Weld JointDiVik BhargAva100% (1)

- EN 10025 S275 Steel (S275JR, S275J0 & S275J2)Documento3 pagineEN 10025 S275 Steel (S275JR, S275J0 & S275J2)MohamedNessuna valutazione finora

- Is 7307Documento22 pagineIs 7307ponmanikandan1100% (1)

- Comparision of Fabrication TolerancesDocumento4 pagineComparision of Fabrication TolerancesSatish Keskar100% (1)

- Norma ASME A-516 SADocumento7 pagineNorma ASME A-516 SASTRUCPIPE CALIDAD100% (1)

- Tes-W-109.01-R0-General Welding CriteriaDocumento23 pagineTes-W-109.01-R0-General Welding CriteriaUtkucan KILIÇNessuna valutazione finora

- Basic Erection Execution Sequence: GROUND RULE: Erection Always Starts On A Braced BayDocumento7 pagineBasic Erection Execution Sequence: GROUND RULE: Erection Always Starts On A Braced BaypvmoorthiNessuna valutazione finora

- PEB Specification and Standards With DetailsDocumento15 paginePEB Specification and Standards With DetailsMujjo SahbNessuna valutazione finora

- Fabrication Division QMDDocumento11 pagineFabrication Division QMDRakesh RanjanNessuna valutazione finora

- Weld Repair AWS D1.1Documento3 pagineWeld Repair AWS D1.1Hemant PatelNessuna valutazione finora

- Consumable Definition AWS D1.1-2020 PDFDocumento14 pagineConsumable Definition AWS D1.1-2020 PDFNguyen Duc Thien PhucNessuna valutazione finora

- MBMA Fabricate & Erection Tolerance 18.01.10Documento2 pagineMBMA Fabricate & Erection Tolerance 18.01.10Thi Pham100% (3)

- TGN-BC-01 Tack Welding of Reinforcement BarDocumento8 pagineTGN-BC-01 Tack Welding of Reinforcement BarFerhat KahveciNessuna valutazione finora

- Resume - Fabrication Engineer Heavy Engineering Steel FabricationDocumento7 pagineResume - Fabrication Engineer Heavy Engineering Steel Fabricationsivagnanam s67% (3)

- Astm A500.1978 PDFDocumento8 pagineAstm A500.1978 PDFpradellesNessuna valutazione finora

- DBMSC Steel BrochureDocumento5 pagineDBMSC Steel BrochureDaniel MartinezNessuna valutazione finora

- Steel Structure SpecsDocumento61 pagineSteel Structure SpecstOMNessuna valutazione finora

- Operation and Maintenance Manual For Structural Steel - EVS - Revision 02Documento87 pagineOperation and Maintenance Manual For Structural Steel - EVS - Revision 02wilfred50% (2)

- (First Reprint JULY 1990) : (Reaffirmed 1998)Documento9 pagine(First Reprint JULY 1990) : (Reaffirmed 1998)Nitin J PatelNessuna valutazione finora

- Aws D1.1Documento7 pagineAws D1.1jacquesmayol100% (1)

- Is 16162Documento11 pagineIs 16162Parthasarathi Paul100% (1)

- Bend Test Acceptance CriteriADocumento1 paginaBend Test Acceptance CriteriAGowrisanthosh PalikaNessuna valutazione finora

- Structural Steel - S235, S275, S355 Chemical Composition, Mechanical Properties and Common ApplicationsDocumento5 pagineStructural Steel - S235, S275, S355 Chemical Composition, Mechanical Properties and Common ApplicationsAndika PusbiantoNessuna valutazione finora

- Aws d1.1 WPQR GuidesDocumento3 pagineAws d1.1 WPQR GuidesDo XuanNessuna valutazione finora

- Welder QualificationDocumento5 pagineWelder Qualification0502raviNessuna valutazione finora

- Indian Standard For Steel Erection ToleranceDocumento5 pagineIndian Standard For Steel Erection ToleranceMartine BareauNessuna valutazione finora

- BS en 499Documento15 pagineBS en 499Hrishikesan100% (2)

- Weld RepairsDocumento40 pagineWeld Repairsவிஷ்ணு ராஜசெல்வன்Nessuna valutazione finora

- CE Marking of StructuralDocumento31 pagineCE Marking of StructuralRavi ValiyaNessuna valutazione finora

- S355 European Standard SteelDocumento7 pagineS355 European Standard SteelmaiquelernNessuna valutazione finora

- IS 4923 Chemical CompositionDocumento1 paginaIS 4923 Chemical CompositionTulasidas MalajiNessuna valutazione finora

- SUBTEXT On Weld Defect For AWS Standard.Documento2 pagineSUBTEXT On Weld Defect For AWS Standard.fammacat100% (1)

- Distortion Control MethodsDocumento36 pagineDistortion Control Methodsbmkramesh100% (4)

- Is 1852Documento28 pagineIs 1852kbasawaNessuna valutazione finora

- Welding Procedure QualificationDocumento23 pagineWelding Procedure QualificationHosam AhmedNessuna valutazione finora

- Is 12843 1989 PDFDocumento8 pagineIs 12843 1989 PDFRajaram JayaramanNessuna valutazione finora

- IS 4000 For BOLT TIGHTENINGDocumento15 pagineIS 4000 For BOLT TIGHTENINGinfiniteNessuna valutazione finora

- BS EN 10056-2 AngleDocumento1 paginaBS EN 10056-2 AngleMahfuz AlamNessuna valutazione finora

- P1 To P8Documento9 pagineP1 To P8Pat AuffretNessuna valutazione finora

- Prof. Ir. Jamasri, PH.D., IPU., AER. Department of Mechanical & Industrial Engineering Engineering Faculty UGMDocumento43 pagineProf. Ir. Jamasri, PH.D., IPU., AER. Department of Mechanical & Industrial Engineering Engineering Faculty UGMKeristiyantoNessuna valutazione finora

- Consumable by AWS D5.1Documento8 pagineConsumable by AWS D5.1Fuaz Sukarya Abu Fatih100% (1)

- Gas Metal Arc Welding (GMAW) : University of Kuala Lumpur - Malaysia France InstituteDocumento16 pagineGas Metal Arc Welding (GMAW) : University of Kuala Lumpur - Malaysia France InstituteKamarul Nizam100% (1)

- Is 1977Documento11 pagineIs 1977rahulmechdceNessuna valutazione finora

- Bs Steel CodeDocumento14 pagineBs Steel CodeA.K.A. HajiNessuna valutazione finora

- HIRAI LTCC Design GuidelineDocumento19 pagineHIRAI LTCC Design GuidelineAkanksha BhutaniNessuna valutazione finora

- Stress Classification ASME DIV2 Sec5 V1Documento13 pagineStress Classification ASME DIV2 Sec5 V1pajadhavNessuna valutazione finora

- 1.7 - Is 12779Documento6 pagine1.7 - Is 12779vrgohilNessuna valutazione finora

- 1989 Reff2019Documento6 pagine1989 Reff2019Raju Singh ShekhawatNessuna valutazione finora

- DTW 1213 Protective Fabric Sleeve For Single Hydraulic HosesDocumento6 pagineDTW 1213 Protective Fabric Sleeve For Single Hydraulic HosesRaymundo68Nessuna valutazione finora

- Apar Industries Limited: Marketing & Registered OfficeDocumento1 paginaApar Industries Limited: Marketing & Registered OfficeQM F ZeusNessuna valutazione finora

- TDS - Galmac PVC Coated Gabions June 10Documento2 pagineTDS - Galmac PVC Coated Gabions June 10Chana PalominoNessuna valutazione finora

- SRM-51-47-00 Fastener Pitch and Edge Distance DataDocumento13 pagineSRM-51-47-00 Fastener Pitch and Edge Distance DataJelpi Duvan LariosNessuna valutazione finora

- RC Cantilever DeflectionDocumento1 paginaRC Cantilever Deflectionklára LudínováNessuna valutazione finora

- N-2409 - Flexible Pipes PDFDocumento88 pagineN-2409 - Flexible Pipes PDFIgor BastosNessuna valutazione finora

- Fastener Spacing and Margin DataDocumento13 pagineFastener Spacing and Margin DataLONG VUNessuna valutazione finora

- Serviceability Limit StateDocumento12 pagineServiceability Limit StateMohamad Salleh YassinNessuna valutazione finora

- Branch RF CalcDocumento6 pagineBranch RF CalcHarish Harish0% (1)

- Visual Inspection - AWS & BS PDFDocumento22 pagineVisual Inspection - AWS & BS PDFSelvakpm06Nessuna valutazione finora

- Iso 8502 3 PDFDocumento15 pagineIso 8502 3 PDFFernandoi83% (6)

- Pip Stf05530 GratingDocumento6 paginePip Stf05530 GratingSelvakpm06Nessuna valutazione finora

- Is 9890 (Specification For General Purpose Ball Valves)Documento3 pagineIs 9890 (Specification For General Purpose Ball Valves)Selvakpm06Nessuna valutazione finora

- TriMarkCatalog PDFDocumento50 pagineTriMarkCatalog PDFSelvakpm06Nessuna valutazione finora

- 09 Samss 069 PDFDocumento10 pagine09 Samss 069 PDFSelvakpm06100% (1)

- Code Ref.Documento155 pagineCode Ref.Selvakpm06Nessuna valutazione finora

- IMOA Shop Sheet 1087 PDFDocumento2 pagineIMOA Shop Sheet 1087 PDFSelvakpm06Nessuna valutazione finora

- Military Standard Mil-Std-130m PDFDocumento45 pagineMilitary Standard Mil-Std-130m PDFSelvakpm06Nessuna valutazione finora

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocumento2 pagineInspection & Testing Requirements Scope:: Test and Inspection PerSelvakpm06Nessuna valutazione finora

- NeboshDocumento117 pagineNeboshmuruganNessuna valutazione finora

- CARRIER - Phschrometric ChartDocumento2 pagineCARRIER - Phschrometric ChartSelvakpm06Nessuna valutazione finora

- Tempilstick UseDocumento1 paginaTempilstick UseSelvakpm06Nessuna valutazione finora

- VT For NDT - 2017Documento29 pagineVT For NDT - 2017Selvakpm06Nessuna valutazione finora

- SSPC Ab3Documento5 pagineSSPC Ab3Claudia Henríquez100% (2)

- Sspc-Ab1 - 2017Documento5 pagineSspc-Ab1 - 2017Selvakpm06100% (1)

- Caterpillar 785c 789c Off Highway Trucks Service TrainingDocumento20 pagineCaterpillar 785c 789c Off Highway Trucks Service Trainingjames100% (45)

- EnglishDocumento10 pagineEnglishAnonymous KYw5yyNessuna valutazione finora

- 19BCG1077 - Swarup DebDocumento1 pagina19BCG1077 - Swarup DebUX ༒CONQUERERNessuna valutazione finora

- Resistron: Operating InstructionsDocumento51 pagineResistron: Operating Instructions16_45_2013_gabri0% (1)

- File Upload XSS - Hack 2 LearnDocumento12 pagineFile Upload XSS - Hack 2 LearnTech HelpNessuna valutazione finora

- Appointment Confirmation: Important Instructions To Nonimmigrant Visa ApplicantsDocumento3 pagineAppointment Confirmation: Important Instructions To Nonimmigrant Visa ApplicantsDimitri D'Lost SandtoesNessuna valutazione finora

- Grades of Reinforcing SteelDocumento15 pagineGrades of Reinforcing Steelshuckss taloNessuna valutazione finora

- F A N T - Filtering and Noise Adding Tool: Author DateDocumento4 pagineF A N T - Filtering and Noise Adding Tool: Author DateAhmed Khalid KadhimNessuna valutazione finora

- LM341/LM78MXX Series 3-Terminal Positive Voltage Regulators: Features DescriptionDocumento18 pagineLM341/LM78MXX Series 3-Terminal Positive Voltage Regulators: Features Descriptiondasch7788Nessuna valutazione finora

- Gambia ICT - Final - WebDocumento77 pagineGambia ICT - Final - Webabey.mulugetaNessuna valutazione finora

- Licenseid TDD/FDD License DescriptionDocumento34 pagineLicenseid TDD/FDD License DescriptionfazadoNessuna valutazione finora

- Clause by Clause Explanation of ISO 27001 enDocumento26 pagineClause by Clause Explanation of ISO 27001 ennacho1963Nessuna valutazione finora

- SSL Bochure enDocumento17 pagineSSL Bochure enlineylosadagNessuna valutazione finora

- Project Report - PWEE 781 - TitleDocumento7 pagineProject Report - PWEE 781 - TitleRishav GhoshNessuna valutazione finora

- ECSS Q ST 60 12C (31july2008)Documento52 pagineECSS Q ST 60 12C (31july2008)jsadachiNessuna valutazione finora

- Airport Qualification and Familiarization ChartsDocumento3 pagineAirport Qualification and Familiarization Chartsjackygdp645Nessuna valutazione finora

- Honeywell Uop Callidus Combustion Technology BrochureDocumento5 pagineHoneywell Uop Callidus Combustion Technology BrochurePawel MielnikNessuna valutazione finora

- Saudi Arabian Oil Company: Equipment Noise Data SheetDocumento1 paginaSaudi Arabian Oil Company: Equipment Noise Data SheetAnonymous X3PnFL6Nessuna valutazione finora

- Panasonic Kx-ft982ls-984ls-988ls (Service Manual Repair)Documento194 paginePanasonic Kx-ft982ls-984ls-988ls (Service Manual Repair)servitecdj100% (2)

- Ekta Prajapati Resume PDFDocumento2 pagineEkta Prajapati Resume PDFghanapathy ramNessuna valutazione finora

- Hanyoung Control SwitchDocumento3 pagineHanyoung Control SwitchBeruang Kodding LagiNessuna valutazione finora

- Chopper-Stabilized Operational AmplifiersDocumento6 pagineChopper-Stabilized Operational Amplifiersluis albertoNessuna valutazione finora

- Chapter 1Documento6 pagineChapter 1Bhuvaneswari TSNessuna valutazione finora

- 2023-6-23-Minutes of Monthly Coordination Meeting - 06 (PIU, PIC & KRJV) DraftDocumento7 pagine2023-6-23-Minutes of Monthly Coordination Meeting - 06 (PIU, PIC & KRJV) DraftSivamurugan SivanayagamNessuna valutazione finora

- LED Lights Coding On Non LED Equipped Vehicles - OBDelevenDocumento18 pagineLED Lights Coding On Non LED Equipped Vehicles - OBDelevenMarko ŠtambukNessuna valutazione finora

- Privacy Policy NykaaDocumento3 paginePrivacy Policy Nykaatushar nandwaniNessuna valutazione finora

- Assignment No. 7Documento5 pagineAssignment No. 7John Ericsson RobariosNessuna valutazione finora

- Advanced Product Quality Planning (APQP)Documento15 pagineAdvanced Product Quality Planning (APQP)José AlcocerNessuna valutazione finora

- Indicative ProfileDocumento5 pagineIndicative ProfileYashveer TakooryNessuna valutazione finora

- 20 Digital Twins Solution ProvidersDocumento9 pagine20 Digital Twins Solution Providersferdi66Nessuna valutazione finora