Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Lec 22

Caricato da

Simanchal KarTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Lec 22

Caricato da

Simanchal KarCopyright:

Formati disponibili

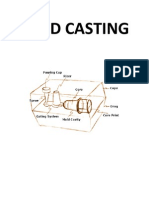

Greensand System

1. Introduction

Green moulding sand process has a long history. A large production of castings, including the vast majority of

those made by machine moulding, is cast in greensand moulds. The process uses natural sand as the main

ingredient for moulding for which any sand treatment equipment is not necessary. It is a popular moulding

process for those foundries producing small and medium size castings and may not be able to lose its position

due to economic considerations.

In some cases, there are compelling technical reasons for drying or hardening the mould, or use of some other

moulding methods. However, the greensand moulding systems has certain benefits:

1. The sand is readily reconditioned since there is little dehydration of the clay bond.

2. Greensand, having low compression strength, offers little resistance to contraction, so that the risk of hot

tearing is reduced.

3. Moulds join closely, leaving little „flash‟ for removal by fettling.

4. The rapid turnaround of moulding boxes and the smooth moulding and casting cycle make it suitable for

mechanised systems.

Recently, several new sand moulding processes have been developed which consequently reduced the use of

greensand process. However, various technological developments are made and green moulding system is still

the principal moulding system used by the foundrymen. Some of the developments include:

1. Inexpensive molten metal with modernisation of melting technique and equipment.

2. Development of sand treatment, its equipment and sand control system.

3. Mechanisation of moulding, shake-out and sand transport.

Moulds for making a ton of castings may require 4 to 5 tons of moulding sand aggregate. The sand-metal ratio

may vary from 10:1 to 0.25:1 depending on the type and size of castings and moulding methods employed. In

any case, the tonnage of sand which must be handled in a sand casting foundry is large, and its quality must be

controlled to make good castings.

2. Greensand Moulding System

A typical green moulding sand mixture/aggregate should consist of the following:

1. Sand

2. Clay

3. Moisture

4. Additives

The sands are granular materials normally obtainable or artificially produced by the disintegration or crushing of

rocks. Sand is an aggregate material essentially consisting of tiny, loose grains, minerals, or rocks which are no

larger than 2 mm or smaller than 0.05 mm in diameter. Sand also denotes a class or several minerals – rather

than just one mineral – such as silica or quartz. Zircon, olivine, chromite, and ground ceramic minerals, as well

as silica are classified as sand when they are in this size range.

In addition to sand, moulding sands may contain from 2 to 50 % clay as a binder. The word clay is applied to a

particular group of minerals which vary from fireclay (kaolinite) to Western or Southern bentonite

(montmorillonite) and a few special clays (halloysite and illite). They are residual or weathered products of

various kinds of silicate rocks. Clays have the general structure form of plate or flake in the approximate particle

size range 20 to 0.1 micron in dimension.

Moisture in moulding sand aggregate is as essential as the clay substance itself. The bonding strength of the

mould to retain the shape of the casting is developed by the sand-clay-water system. Thus, the purpose of clay

MME345/ Greensand system/page-1

will not be served until the required amount of water/moisture is added to it. Water which is present in amounts

about 1.5 to 8 % activates the clay in the sand, causing the aggregate to develop plasticity and strength.

In addition to these three basic ingredients (sand, clay and water), different types of organic or inorganic

materials are added to the moulding sand aggregate as additives in small quantities to impart certain properties

such as collapsibility, surface finish etc. Some of the organic binders include cereal, proteins, pitch, and oil while

some inorganic binders are cement, silicates and ester.

3. Characteristics of Moulding Sand Aggregate

A foundry moulding mixture passes through four main production stages, namely preparation and distribution,

mould and core production, casting, and cleaning and reclamation. The property requirements of the materials

are generally determined by moulding and casting conditions, although the preparation and reclamation stages

are also considered in some degree, particularly to the integrated sand systems.

From a general viewpoint, the moulding sand aggregate must be readily mouldable and the mould cavity should

retain its shape till the molten metal solidifies to produce a defect-free casting. Certain specific properties have

been identified, and testing procedures adapted for their quantitative description. The properties of most obvious

importance are as follows.

1. At the moulding stage:

(a) Flowability - ability of the material to be compacted to a uniform density. The degree of flowability

required largely depends upon the method of compaction which may vary from hand ramming with

tools to ramming on moulding machines.

(b) Green strength – ability to retain the shape of the mould independently without distortion or collapse

when the pattern is withdrawn. The green strength and the plasticity of moulding materials should be

sufficient at avoid distortion of mould at the green stage.

2. During casting:

(a) Thermal stability – ability to retain shape at high temperature. Heat from the casting causes rapid

expansion of the sand surface at the metal-mould interface. The mould surface may then crack, buckle,

or flake off (scab) unless the moulding sand is relatively stable dimensionally under rapid heating.

(b) Refractoriness - ability to withstand high temperatures without fusion or other major physical change.

High pouring temperatures, such as those for ferrous alloys at 1350 to 1700 °C, requires greater

refractoriness of the sand. Low-pouring-temperature metals, for example, aluminium, poured at 700 °C,

do not require a high degree of refractoriness from the sand.

(c) Dry strength - to withstand erosive forces and pressure of liquid metal. As the casting is poured, sand

adjacent to the hot metal quickly loses its water as steam. The dry sand must have strength to resist

erosion by the molten metal, and also the metallostatic pressure of the molten metal, or else the mould

may enlarge.

(d) Hot strength - to withstand distortion and deformation during heating at high temperature. In the

production of heavy castings, a considerable layer of moulding materials rises to a temperature where

the normal or green mechanical properties are no longer the main criterion governing dimensional

stability and resistance to contraction. Depending upon the mass of the casting, the sand must have

adequate combination of high temperature properties, including hot strength to withstand mould

enlargement due to heating and deformation, crack or breakage due to contraction of the casting.

(e) Collapsibility - the readiness with which the moulding material with break down in knockout and

cleaning operations. Heated sand becomes hard and rocklike after casting and is difficult to remove

from the casting and may cause the contracting metal to tear or crack.

(f) Permeability - a path for the escape of gases. The heat from casting produces a great deal of moisture

and other mould gases from the mould. Much of this can be exhausted through open feeder heads and

vents, but a large volume must also be dissipated through the pore spaces of the sand. This problem is

the greatest for greensand and coresands. The evaporation of each 1 % of moisture from green

moulding sand can be shown to generate over 30 times of its own volume of steam; this is paralleled in

coresands by gases from volatilisation and decomposition of organic compounds such as core oil and

cereal. To provide a path for the escape of gas, permeability of the mould is an essential property,

giving protection against surface blows and similar defects.

MME345/ Greensand system/page-2

(g) Fineness - required for the prevention of metal penetration and the production of smooth casting

surfaces. The liquid metal is sufficiently fluid at high temperature and has the capacity to flow between

the pores of the sand at the metal-mould interface, causing a rough surface. For wetted moulds, the

liquid metal penetration will be even higher. Since both permeability and fineness are function of grain

size and distribution, the two properties are in conflict and a compromise is usually necessary. Fineness

may be achieved by using fine grained sands, by continuous grading or by incorporation of filler

materials, but all these measures also reduce permeability. An alternative approach is to use a highly

permeable moulding material and to obtain surface fineness by the use of mould coatings.

3. At storage:

(i) Bench life - the ability to retain moulding properties on standing or storage.

(ii) Durability - the capacity to withstand repeated cycles of heating and cooling in integrated sand system.

This will decide the extent of reusability of moulding sand.

Thus it is evident that the qualities required in a moulding material cannot readily be defined in terms of simple

physical properties. For complex aggregate bulk properties are of greater significance and some of these can be

measured directly by simple tests upon sand compacts. Other qualities are represented in specially developed

empirical tests designed to reproduce conditions encountered in the foundry. These tests, in conjunction with the

direct measurement of more fundamental characteristics such as mechanical grading and chemical composition,

provide the basis for the control and development of moulding material properties.

4. Base Sand – Characteristics and Type

Granular particles of sand comprise 50 to 95 percent of the total material in a moulding sand. Most sand moulds

and cores are based on silica sand since it is the most readily available and lowest cost moulding material. The

base sand may either be clay-free, washed, white silica sand or less pure, tan-coloured sand containing some

small percentage of clay and other materials. Besides silica sand, other sands are often used where special

properties are needed. The sand particles used as moulding materials require special characteristics to satisfy the

properties and the quality required for moulding sand aggregate.

4.1 Characteristics of Moulding Sand

Aside from considerations of purity and clay content, the average fineness number and particle size distribution

are properties of base sand of major importance. Some of the important properties of base sands are discussed

bellow.

1. Size and Shape Characteristics

(a) Average grain size

The granular materials are usually classified according to the average size of the grain as follows:

2.00 - 1.00 mm Very coarse sand

1.00 - 0.50 Coarse sand

0.50 - 0.25 Medium sand

0.25 - 0.10 Fine sand

0.10 - 0.01 Silt

< 0.01 Clay

Grain sizes of foundry sands generally fall within the range of 0.1 to 1.0 mm. Foundrymen use a parameter

known as the AFS fineness number to express the average grain size of sand which is determine by mechanical

sieving.

The average grain size is an important parameter to control many properties of moulding sand aggregate, the

most important being the permeability and surface fineness. Coarser sands with greater void space produce

moulds with greater permeability and poor surface fineness. On the other hand, finer sand grains produce moulds

having higher fineness but poor permeability. Typical variation in permeability of base sand with its grain size is

shown in Fig. 1.

MME345/ Greensand system/page-3

Fig. 1. Base permeability of silica sand.

The grain size of base sand also influences the strength of moulding sand aggregate, an inverse relationship

existing between compressive strength and grain size of clay-bonded sands, Fig. 2. Finer grains also appeared to

be more easily fused (i.e. low refractoriness) than coarser ones. Where maximum refractoriness is required, as in

steel moulding sands, the coarser high-purity sands are used.

Fig. 2. Effect of grain size on strength of clay bonded sand.

MME345/ Greensand system/page-4

(b) Size distribution

Besides average grain size, the size distribution of sand is also important. A well-distributed sand grain will have

high strength but low permeability. Usually sieving is done, like for determining the average grain size, to

determine size distribution of a particular sand mixture. From this test, the sand may be categorised by the

number of screens over which the bulk fraction is spread as a 2-, 3-, 4-, 5-, etc. screen sand. A screen fraction is

arbitrarily defined as one with more than 10 per cent retained on that screen. Thus a 4-screen sand is one where

the bulk of the sand is retained on four adjacent screens, each having more than 10% retained on it. The sieve

analysis of sand A in Table 1 is an example of 5-screen sand while sand B is a 3-screen sand. Although 3-, 5- or

6-screen bulk fraction sands can be used, the 4-screen type seems to be the most versatile over a wider range of

conditions.

Table 1. Similarity in AFS grain fineness number of two sand samples with

different grain size distributions.

Percentage retained

USA sieve No.

Sand A Sand B

6 0.0 0.0

12 0.0 0.0

20 0.0 0.0

30 1.0 0.0

40 24.0 1.0

50 22.0 24.0

70 16.0 41.0

100 17.0 24.0

140 14.0 7.0

200 4.0 2.0

270 1.7 0.0

Pan 0.3 1.0

Total 100.0 100.0

AFS grain fineness No 60.0 60.0

(c) Grain shape

The shape of sand grain is important with respect to flowability and strength. The shape of individual sand grains

may be rounded, angular, sub-angular or compounded (Fig. 3) depending on the geological origin and

transportation history. Rounded sands have the lowest surface area and higher flowability, and need lower binder

and moisture produce moulds with low strength and high permeability. On the other hand, angular sand grains

have high surface area and low flowability, and need higher binder and moisture to produce moulds with high

strength and low permeability. Compounded sand grains are agglomerated particles of angular or sub-angular

grains. They disintegrate at high temperatures and, therefore, are not desirable. Although the relationship

between grain shape and mechanical strength is partly governed by the ramming density attained, a mixture of

rounded, angular and sub-angular grains is generally desirable to produces optimum properties.

Average grain shape may be readily observed under microscope or be measured by surface area measurement.

The average shape of sand grains is quantified by a parameter known as the coefficient of angularity where

Actual specific surface area (cm 2 / g )

Coefficien t of Angularity,

Theoretical specific specific surface area (cm 2 / g )

Here the actual specific surface area is defined as a surface area of all sand grains in a square centimetre area,

containing 1g of sand. The theoretical specific surface area, on the other hand, assumes that all the sand grains

are spherical.

MME345/ Greensand system/page-5

Fig. 3. Shape of sand grains: (a) Rounded, (b) Sub-angular, (c) Angular, and (d) Compounded.

2. Refractoriness and Thermal Stability

It depends on chemical composition and impurity contents of sand. Most moulding sands are based upon the

mineral quartz, which is both geologically abundant and refractory to temperatures approaching 1700 °C. As

SiO2 content in sand increases, the refractoriness increases. The purest silica sand containing >99.8 % SiO 2 has

the highest refractoriness and thermal stability. The presence of excessive amount of impurities such as iron

oxide, feldspar, and limestone lowers the fusion point of sand. So the ideal mixture would be silica sand of high

purity with a minimum of binder. For the most severe conditions, as in the case of heavy steel castings, some

other sand with high refractoriness, such as zircon sand or olivine sand, may be used. For lower melting point

alloys, refractoriness can be low and naturally bonded sands, with their much lower content of free silica, can be

selected. Typical chemical analyses of high silica sand and natural moulding sand are shown in Table 2.

Table 2. Chemical analyses of typical foundry sands.

Silica Sand Natural Sand

% %

SiO2 97.91 78.2

Al2O3 1.13

10.1

Fe2O3 0.50

TiO2 0.04 -

CaO 0.11 2.4

MgO 0.02 1.8

K2O 0.65 3.1

Na2O 0.07 0.2

Loss on ignition 0.21 4.1

3. Thermal Expansion

Low thermal expansion is mandatory for moulding sands. However, a major expansion of silica sand occurs in

the temperature ranges of 550 to 650 °C because of the allotropic transformation of silica. Silica sand is

commonly encountered four different phase transformations and the equilibrium temperature ranges for these

modifications are:

MME345/ Greensand system/page-6

Quartz up to 870 °C

Tridymite 870 – 1470 °C

Cristobalite 1470 – 1710 °C

Vitreous silica above 1710 °C

The room temperature silica (-quartz) transforms into -quartz at 573 °C during heating and this has a higher

coefficient of thermal expansion than that of -quartz (Fig. 4). At higher temperatures, still other transformations

occur with corresponding volume changes. But transformation at 573 °C probably accounts for most sand

expansion defects, especially in non-ferrous metals.

Fig. 4. Volume changes with temperature in silica structures.

4. Hardness

Adequate hardness of sand is essential so that they do not break during mould preparation, mould handling and

pouring of liquid metal.

5. pH Value

Neutral sands having the pH value in the range of 6 to 8 are ideal as moulding sand. Otherwise, they will be

susceptible to attack by the chemical binders.

4.2 Classification of Base Sand

Most sand moulds and cores are based on silica sand since it is the most readily available and lowest cost

moulding material. Other sands are used for special applications where higher refractoriness, higher thermal

conductivity or lower thermal expansion is needed. Sands used in foundry are classified as follows:

1. Natural bonded sand

2. Synthetic sand

(a) Silica sand

(b) Zircon sand

(c) Olivine sand

(d) Chromite sand

In the following sections, these sands are discussed briefly.

MME345/ Greensand system/page-7

(a) Natural Bonded Sands

They contain sufficient clay as-mined from sand pit so that they can be used directly, needing only to be

tempered and conditioned. The simplicity in preparation, handling and use make them ideal for mould making.

Natural bonded sand usually contains 70-85 % silica sand and 10-16 % clay. Natural bonded sand usually

requires 5-8 % moisture to prepare mould. These sands have low refractoriness than that of synthetic sands. If

bentonite clay added, then these are called as semi-synthetic sands.

It was found that by adding coal dust, the strip of iron castings from the mould and the surface finish of the

castings could be great1y improved. The heating of the coal dust by the liquid iron causes the formation of a type

of carbon called lustrous carbon which is not wetted by the liquid iron, so the cast surface is improved.

Clay-bonded moulding sand can be used over and over again by adding water to replace that which is lost during

casting, and re-milling the sand. However, clay which is heated to a high temperature becomes „dead,‟ that is it

loses its bonding power. The coal dust is partly turned to ash by heat, so new clay, coal dust and water must be

added and the sand re-milled to restore its bonding properties. As the sand is re-used, dead clay and coal ash

build up in the sand, reducing its permeability to gases so that eventually water vapour and other mould gases are

unable to escape from the mould and defective castings are produced.

The moulds could be used in the „green‟ or un-dried state (hence the term greensand moulding) or they could be

baked in a low temperature oven to dry and strengthen them to allow heavy castings to be made. Nowadays,

dried, clay-bonded sand is little used, having been replaced by chemically bonded pure silica sand, but greensand

is still the most widely used moulding medium, particularly for iron castings.

(b) Silica Sand

Most abundantly found either as natural (in river beds) or artificial (crushed quartz). The general chemical nature

of silica sand for foundry use is described below.

SiO2 content 95 – 96 % min. The higher the silica the more refractory the sand

Loss on ignition 0.5% max. Represents organic impurities

Fe2O3 0.3% max. Iron oxide reduces the refractoriness

CaO 0.2% max. Raise the acid demand value

K2O, Na2O 0.5% max. Reduces refractoriness

Acid demand value to pH4 6 ml max. High acid demand adversely affects acid catalysed binders

The principal division in practice, that between natural and synthetic sands, exists in all sections of the industry,

but the general trend is towards greater use of synthetic sands, particularly in mechanised foundries. Their chief

advantages lies in superior refractoriness and permeability, consistency, and the readiness in which their

properties can be controlled, particularly in reclamation systems. They are not, however, so readily hand worked

by the moulder as the naturally bonded sands with their greater latitude of moisture content and somewhat higher

green strength. Table 3 shows a comparison between the usefulness of natural sand and synthetic sand as

foundry sand, while a comparison in properties of different synthetic sands is shown in Table 4. Synthetic sands

have been most widely adopted for steel founding, where relatively coarse grained sands are bonded with

bentonites and cereals to provide properties such as those shown in Table.5.

(c) Zircon Sand

Zircon (ZrSiO4) is theoretically composed of 67.2% Zirconia (ZrO 2) and 32.8% Silica (SiO2). However practical

zircon sand usually contains a higher proportion of silica (Table 6). Zircon sand has a high specific gravity (4.6)

and high thermal conductivity which together cause castings to cool twice faster than silica sand. The chilling

effect of zircon sand can be used to produce favourable thermal gradients that promote directional solidification

giving sounder castings. The thermal expansion coefficient of zircon is very low (only 1/3 of SiO 2) (Fig. 5) so

that expansion defects can be eliminated. Zircon has higher refractoriness than silica, and moreover it does not

react with iron oxide, so sand burn-on defects can be avoided. This produces a better surface finish which

reduces cleaning cost and gives a good reproducibility. Zircon sand generally has a fine grading, with AFS

number between 140 and 65 (average grain size 115-230 microns); the most frequently used grade is around

AFS 100.

MME345/ Greensand system/page-8

Table 3 Comparison of natural and synthetic sand.

Natural sand Synthetic sand

Natural sand.

Moulding material (sand, clay, organic materials from Sand, bentonite, starch, coal.

weeds, trees, bacterium etc.).

Sand treatment (use of Usually not necessary (if poor sand Necessary (sand treatment equipment;

machine) quality, a simple sand treatment will do). mixer etc.).

Easy (especially when sand treatment is

Moulding Easy.

sufficient)

Repair of mould Easy. Relatively difficult.

Shake out Easy. Easy.

Reclamation Easy (only needs water adjustment). Easy (although mixing is necessary).

Life of sand Limited Not limited.

Similar to natural sand but to a lesser

Mould swelling. Sand adherence. Gas

Effects on casting degrees (good for rather large size

defects (depending on size of materials).

castings).

Table 4 Comparison of properties of different sands

Properties Silica Zircon Olivine Chromite

Colour White Brown Green -

Specific gravity 2.28-2.65 4.4-4.8 3.2-3.4 4.4-4.5

Melting point, C 1720 2660 1880 1550

Hardness, Moh‟s scale 6.0-6.5 7.5 6.5-7.0 -

Thermal expansion at 900 C, % 1.56 0.25 1.0 0.4-0.7

High temperature reaction Acidic Slightly acidic Basic Neutral to basic

Table 5 Synthetic sand mixtures used in steel founding.

Properties Green moulding aggregate Dry moulding aggregate

50 % Coarse silica sand

Medium grade silica sand 50 % Medium silica sand

Composition 5 % Bentonite 6 % Ball clay

0.75 % Starch 3 % Bentonite

0.5 % Dextrin

Moisture content, % 3.0 6.0

Permeability 170 100

Green compressive strength, kN/m2 7 8

Dry compressive strength, kN/m2 0.7 1.7

Table 6. Chemical composition of zircon sand.

ZrO2 TiO2 SiO2 Fe2O3 Al2O3 P2O5 Cr2O3

65.80 0.26 33.60 0.05 0.25 0.01 0.001

MME345/ Greensand system/page-9

Fig. 5. Thermal expansion of mould refractories.

Zircon is probably the most widely used of the non-silica sands. It is used with chemical binders for high quality

steel castings and for critical iron castings such as hydraulic spool valves which contain complex cores, almost

totally enclosed by metal, making core removal after casting difficult. Zircon has low acid demand value and can

be used with all chemical binder systems. The Cosworth casting process uses the low thermal expansion of

zircon sand cores and moulds to cast dimensionally accurate castings. The high cost of zircon sand makes

reclamation necessary and thermal reclamation of resin bonded moulds and cores are frequently practised.

Because of high cost, instead of making the whole mould, mould wash onto a greensand or silica mould is often

used. Some zircon sands contain radioactive minerals which may cause a health hazard. The supplier should be

contacted to confirm that the level of radioactivity is safe.

(c) Olivine Sand

Olivine sand is basic sand composed of forsterite (Mg2SiO4) and fayallite (Fe2SiO4) minerals. The typical

composition of olivine sand is shown in Table 7. Olivin sand is used mainly for the production of austenitic

manganese steel castings (which react with silica and other sands to give serious burn-on defects). It has also

been used to avoid the health hazards possible with silica sand. Being a basic sand, olivine has a very high acid

demand and is not suitable for use with organic binders (such as furan resins) since all organic binders are acidic

in nature. Common binders used with olivine sands are: bentonite, fireclay and sodium silicate. Being a crushed

rock, it is highly angular and consequently requires high binder additions. Thermal expansion is regular and

quite low.

Table 7. Chemical composition of olivine sand.

MgO SiO2 Fe2O3 Al2O3

46.0 43.08 8.98 1.02

(d) Chromite Sand

This is crushed chrome ore having a mixture of chromite (Fe2O3.Cr2O3), piere chromite (MgO.Cr2O3), spinel

(MgO.Al2O3) and gangue materials (e.g. hydrated minerals like serpantine). The sand is theoretically composed

of 68% Cr2O3. A typical composition of chromite sand is shown in Table 8.

Table 8. Chemical composition of chromite sand.

Cr2O3 Fe2O3 Al2O3 SiO2 MgO CaO MnO TiO2 V 2O 5

45.3 25.1 14.7 1.6 10.1 0.13 0.26 0.61 0.37

MME345/ Greensand system/page-10

Chromite is basic sand and has high specific gravity (4.5) and high thermal conductivity which provide a

pronounced chilling effect. Thermal expansion is low so expansion defects are unlikely to occur. Chromite sand

has a glossy black appearance, and has greater resistance to metal penetration than zircon in spite of its generally

coarser grading (typically AFS 70). It has somewhat higher acid demand than other sands, which entails greater

additions of acid catalyst when furan resin is used. Apart from this the sand is compatible with all the usual

binder systems. The common binder is bentonite clay (usually ½ to 2/3 that of SiO2). Chromite is generally used

for steel casting to provide chilling. It is difficult to reclaim chromite sand since, if it becomes contaminated with

silica, its refractoriness is seriously reduced.

(e) Chamotte Sand

Chamotte sands are calcined high grade fire clays which are formed by burning approximately at 1450 °C and

then crushing to required grain size. Typical chemical composition of chamotte sand is shown in Table 9.

Table 9. Chemical composition of chamotte sand.

SiO2 Al2O3 Fe2O3 MgO Na2O

67.7 29.7 2.1 0.25 Trace

This sand has low thermal expansion property which effects to prevent defects as scab. But care should be taken

when using this sand as it absorbs moisture. The sand is much cheaper than zircon and olivine. Specific

characteristics of chamotte sand and negligible affinity to liquid steel make it suitable for steel castings.

5. Clays, Water and Additives

Moulding sands for green and dry sand practice are most commonly bonded with clay, the second most

important constituent of the aggregate. In the natural moulding sands the clay occurs in association with the sand

grains, whilst the synthetic sands are bonded with selected clays from separate deposits.

Clays are hydrous aluminium silicates obtained as weathered products of silicate rocks and when tempered with

water, produce a plastic or semi-plastic mass. Clays have the general structural form of plate or flakes in the

approximate particle size range 0.01 – 1.0 micron in breadth, and plasticity and bond are developed by the

addition of water. Net attractive forces are generated between charged hydrated clay particles and between these

and the surfaces of sand grains. The strength of the ionic bond depends on the total surface area of the particles

and is strongly influenced by adsorption of exchangeable cations at the free surfaces that modify the balance of

local forces between the particles.

On drying, loss of adsorbed water produces shrinkage of the lattice and further strengthening of the bond, so that

clay binders are effective in both green and dried condition. Hydration is reversible to temperatures well above

the drying range: thus moulds may be dried or cast and the bond can be regenerated by addition of water after

each cycle. Heating to progressively higher temperatures, however, removes chemically combined water and

causes permanent loss of bonding capacity. The temperature at which this occurs varies with the particular clay

but the loss begins at approximately 400 °C and is in all cases complete at 700 °C. At still higher temperatures

the clays undergo drastic mineralogical changes involving crystallisation of alumina and cristobalite and the

formation of mullite.

Although the basic ingredients of a sand mix are only sand, clay and water, other materials are often added in

small amounts to moulding and core sands for special purposes. Some of the most important additives include

cereal, coal dust, iron oxide, molasses, dextrin etc.

5.1 Clays – Types and Characteristics

According to the American Foundry Society (AFS), clay is defined as those particles of sand having a diameter

of 20 micron or less and, when suspended in water, fails to settle at a rate of 25 mm per minute. Clay consists of

two ingredients: fine silt and true clay. Fine silt is foreign matter of mineral deposit having no bonding power.

True clay supplied the necessary bond.

MME345/ Greensand system/page-11

Effective clay is defined as the fraction of the clay present in total clay of the sand-clay mixture with has

effective bonding ability similar to the new clay. It is necessary to maintain a close control on the effective clay

present in a sand mix during moulding and particularly in case of closed cycle machine moulding operations.

Based on the composition and structure, the clays used in the foundry as binder can be classified into three

groups, i.e. kaolinite, montmorillonite, and illite.

1. Kaolinite. It corresponds to the general formula Al2O3.2SiO2.2H2O and is formed by weathering of feldspar

or other aluminous minerals. Kaolinite is the principal constituent of china clay, ball clays and fire clay.

Relatively high alumina content of these clays makes them reasonably refractory (softening point 1600 -

1700 °C), but irreversible dehydration occurs in the temperature range 400 – 650 °C. The bonding

properties of these clays are not high as compared to other clays and hence higher binder content is

required, often in the range of 10 – 20 %. Therefore, the use of kaolinite in foundry is very limited.

2. Montmorillonite. These types of clays can be represented by the basic formula Al2O3.4SiO2.2H2O, but a

proportion of Al+3 ions are replaced by Mg+2 ions in isomorphic substitution. Whenever Mg+2 replaces Al+3,

there is capacity for adsorption of exchangeable cations such as Na + and Ca+2 to which the properties of

clay are particularly sensitive.

Montmorillonite is the principal mineral constituent of bentonite clays. These clays have a high capacity for

water absorption and exceptionally favourable bonding characteristics: strength properties can therefore be

derived from additions as low as 3 – 5 %. Use of bentonites offers the following advantages:

(a) Bentonite can be circulated in closed systems and the bond is regenerated by the addition of water.

(b) Patterns can be stripped easily and thus mould can be made quickly.

(c) Bentonite resists erosion of moulds.

(d) Volumetric contraction of bentonites helps in compensating the expansion of silica grains.

(e) Bentonites retain their capacity for water absorption up to 500 – 700 °C and can thus be regarded as

thermally more stable than other clays, with a potentially longer lift in closed systems.

Depending on the kind of substitution metal present, bentonites are of two types i.e. sodium bentonite

known as Western bentonite and calcium bentonite known as Southern bentonite. The notable

characteristics of sodium bentonites are high swelling capacity, high liquid limit, low plasticity, low green

strength, and high level of dry and hot strength. The characteristics of calcium bentonites include low

swelling, low dry and hot strength, low liquid limit, high plasticity, and high green strength.

3. Illite. These clays are produced by the weathering of micas and form the principal source of bond in the

natural moulding sands. They do not swell in the same manner as the bentonites but give reasonable

strength properties. Irreversible dehydration occurs in the temperature range 500 – 550 °C. Other

characteristics of illite clays are fusion point 1380 °C, moderate base exchange, and moderate shrinkage to

loss of water.

5.2 Properties of Foundry Clays

The basic function of clay as binder is to produce cohesion between the refractory grains in the green or dried

state by forming a thin film of coating around each grain. As the bonding layers become continuous and then

progressively thick, proportionately less advantage is to be gained from further additions. The general form of

relationship between the strength and the binder is shown in Fig. 6, while typical effect of clay content on

relation between mould hardness and green compressive is shown in Fig. 7.

Generally, Western bentonites are used in sands requiring a higher level of dry compressive strength, in excess

of 80 psi, for example. Southern bentonites are used in sands where a lower level of dry compressive strength is

acceptable, 40 – 80 psi, for example. Fire clays produce moderate dry strength in the sand. Maximum dry

compressive strength over 200 psi can be obtained with mixtures of fire clay and western bentonite.

Depending on the percentage of clay present, greensand may be classified as clay-saturated or clay-unsaturated

mixtures. A clay-saturated greensand is defined as one containing a high enough percentage of clay so that any

further increase in clay content will not cause an increase in maximum green compressive strength of the

aggregate. This means that, the sand mixture is fully bonded. This definition is depicted graphically in the

schematic diagram of Fig. 8. The shaded area in the figure represents a variation in maximum strength due to

clay purity and source, sieve analysis of base sand, moulding aggregate mixing efficiency and other factors.

MME345/ Greensand system/page-12

Fig. 6. Influence of binder content on strength of moulding sand

(silica sand bonded with bentonite clay).

Fig. 7. Typical effect of clay content on relationship between mould hardness and green compressive

strength. The curve marked „maximum‟ applies equally well to clay-saturated southern and western

bentonite and fire clay-bonded sands.

Fig. 8. Schematic diagram showing the approximate effect of bentonite clays on the

maximum green compressive strength of clay-sand-water mixtures.

MME345/ Greensand system/page-13

The specific percentage of clay required for saturation depends upon purity and type of clay, base sand, and

additives. In most cases, however, about 8 – 12 % bentonites or about 20 – 25 % fire clay is sufficient to produce

a clay-saturated mixture with the sand of fineness AFS 60 – 100. Clay-saturated sands are probably the most

versatile greensand mixtures for a wide range of casting weights and alloy types. Casting defects due to sand

expansion, erosion etc. are reduced or even eliminated. Since such sands are normally of high strength (14 – 20

psi green compressive strength), they require adequate ramming (probably over 85 mould hardness) to develop

their properties. Clay-unsaturated sand systems, on the other hand, use 4 – 9 % bentonites and 10 – 15 % fire

clays. Such sands are used for making lighter castings where expansion defects, erosion etc. are lesser problems.

5.3 Clay and Water

Since the development of bond strength depends upon hydration of the clay, the green strength of a moulding

mixture increases with the temper water content up to an optimum value determined by the proportion of clay.

Above this value, additional free water causes the green strength to diminish again as illustrated in Fig. 9. Dry

strength, however, continues to increase to much higher original moisture contents, probably due to improved

distribution of the binder and the higher bulk densities attainable. Thus by determination of the optimum water

content the required strength properties can be obtained with minimum use of clay. Typical combined

relationship between clay and water contents and bond strength is illustrated in Figs. 10 and 11 respectively.

From these figures it is clear that, for a given clay type and content, there is an optimum water content which

form the greatest number of clay-water-quartz bonds. Too much water causes excessive plasticity and dry

strength. Too little water fails to develop adequate strength and plasticity. Control of moisture in the moulding

sand so that the best properties are developed is a necessary basis of sand control.

Fig. 9. Influence of moisture content of green and dry strengths of moulding sands

(bentonite-bonded silica sand).

5.4 Clay-Water Bonding

The science of clays and silica sands, particularly as applied to aggregates used for moulding purposes, has not

progressed to the point where we can state clearly what forces are involved in holding particles of clay together.

Accordingly, the bonding forces involved may be accounted for by several theories: electrostatic bonding,

surface tension forces, and interparticle friction bond.

1. Electrostatic Bonding of Clays

The mechanism of electrostatic bonding of clays may be described as a network of dipolar forces operating at the

sand-clay and clay-clay interfaces. This network of forces is initiated by the preferential adsorption of positive

ions and negative ions on combined water and clay (hydrated) surfaces.

MME345/ Greensand system/page-14

Fig. 10. Effect of variations in clay and water content on the strength of sand mixture. (a) Maximum

strength of different clay-sand mixture. (b) Effect of clay on green strength of Southern benmtonite-sand

mixture. (c) Effect of clay on green strength of Western benmtonite-sand mixture. (d) Effect of clay on

green strength of kaolinite-sand mixture

Dry clay does not provide the necessary bond to hold sand grains firmly together; bond is developed only when

clay particles are hydrated. When water is added to dry clay, the negative hydroxyl (OH –) ions are adsorbed on

the nuclei of the clay atoms, owing to unsatisfied valence bonds at the surface of the clay crystal, and form an

integral part of the crystal. So the clay-water particle becomes negatively charged.

The positive (H+) ions in the surrounding water media are attracted by the negative clay ions, but repelled by the

nuclei of the clay atoms, with the result that the positive ions take up equilibrium positions. The hydrogen ions

and the adsorbed hydroxyl ions about the clay particle comprise a so-called double diffuse layer. A hydrated clay

particle or micelle is illustrated schematically in Fig. 12.

Particles of sand (quartz) also form micelles by the adsorption of hydroxyl and hydrogen ions. When quartz and

clay micelles are formed in each other‟s presence, the hydroxyl ions of the clay micelle exhibit an attraction for

the hydrogen ions contained in the quartz micelles. Thus a clay dipole is formed and the result is an electrostatic

bond between sand and clay particles and between clay particles as sketched in Fig. 13. The maximum attractive

force is found to be at an optimum distance of separation x. There are many such dipoles in a clay-water

medium. Depending on the type of clay, a maximum degree of hydration is necessary to develop a dipole

completely. This is why the strengths of clay-bonded sands increase with increasing amounts of water, up to a

maximum value. As the amount of water is increased further, water enters the spaces between the dipoles to a

distance greater than x, resulting in a decrease in the net intermicellular force, Fig. 14.

MME345/ Greensand system/page-15

Fig. 11. Effect of initial water content on dry strength. (a) Southern bentonite clay.

(b) Western bentonite clay. (c) Kaolinite clay.

Fig. 12. Schematic representation of a clay micelle. Surrounding the clay particle are negatively charged

hydroxyl ions positioned at varying distances from the particle. Outside this layer, positively charged hydrogen

ions also are located at various distances from the clay centre; hence the term double diffuse layer applies. This

layer is rigidly attached to the surface of the clay particle and is considered to behave as a solid.

MME345/ Greensand system/page-16

(a)

(b)

Fig. 13. (a) Micellular dipoles, indicating the localized concentration of adsorbed negatively charged hydroxyl

ions and positively charged ions; x denotes critical intermicelluar spacings, the result of a compromise between

the forces of attraction and repulsion. (b) Schematic sketch showing disposition of clay and quartz dipoles. In

green sand the intermicellular voids are filled with water.

2. Bonding by Surface Tension Forces

Forces developed by electrostatic interaction between sand-clay particles do not seem strong enough to account

for all the strength properties of green sand mixtures – nor in particular for the high resistance to deformation of

dry sand aggregates. Another possible source of bond strength is the surface tension of the water surrounding the

clay and clay-sand particles, and filling the capillary interstices, particularly the interstices of the clay particles.

The bond strength values as high as 880 psi have been obtained, attributable to the surface layers of water acting

on a stretched membrane of hydrated clay, forcing the particles together. As the water layer becomes thinner by

drying, the forces holding the particles together increase.

3. Bonding Due to Interparticle Friction

The geometry of the aggregate can provide another force adding to the strength of the bond between particles.

The so called “block and wedge” theory involves essentially the interparticle friction developed in non-plastic

particulate materials under pressure. When moulding sand is rammed inside a flask, most particles are jammed

against their neighbours. The resultant interparticle friction opposes further deformation, and causes a bridging

action between long rows of favourably oriented particles and the sides of the flask. The changes in strength

properties of sand mixtures due to the use of various sized and shaped sand grains indicate the existence of an

interlocking or frictional force.

MME345/ Greensand system/page-17

Fig. 14. Dipole alignment of hydrated clay particles (condition of minimum free energy)

in a water medium (green state).

5.3 Additives

In order to obtain specific characteristics in moulding and core making sands according to the requirement of

molten metal and base sand, suitable additives are mixed during sand preparation. The additives may be of

reducing or fibrous nature, or may act as binding agents. These may also help in improving high-temperature

plasticity and hot strength, produce anti metal penetration properties and impart good surface finish to the

castings. It is necessary to select the right type and determine the correct proportion of the additive for any given

moulding and casting conditions so as to enable the production of flawless castings. The commonly used

additives are discussed below. A summary of functions of additives are also given in Table 10.

Coal Dust or Sea coal. It is a finely ground soft coal commonly used in greensand and dry-sand moulding for

protecting mould surfaces against the action of molten metal and improving surface finish of cast iron castings.

When the molten metal comes in contact with mould surfaces containing coal dust, a gaseous envelope is formed

which resists the fusion of sand to metal. Use of coal dust increases both green and dry strength, reduces

expansion, tendency to scabbing and metal penetration. It, however, tends to reduce the permeability of sand.

The sea coal is usually ground to fineness similar to that of the moulding sand in which it is used. Percentages

employed in sands are about 2 to 8 per cent. A good quality coal dust suitable for foundry use should have

minimum 30% volatile matter, maximum 20% ash, 3% moisture, 1 % sulphur and 0.2% phosphorus content.

Pitch and fuel oil are also used as reducing agents and have similar effect as coal dust.

Iron Oxide. Iron oxide powder is used as an additive for both moulding and core making sands to achieve high-

temperature plasticity, hot strength and anti-metal penetration characteristics. In core sands, it prevents veining

or high-temperature cracking of cores. The use of iron oxide is common in steel foundries both for moulds and

cores. In iron foundries, its use is restricted to cores only. Good quality iron oxide should have iron oxide

(Fe2O3) content not less than 93% and iron content not less than 6%. Its pH value in 10% distilled water solution

should not be more than 9%. Its fineness should be 150 mesh BS sieve (106 micron IS sieve).

Cereals. Cereal are used as binder to influence the bonding properties of sand. They are mainly starch and

dextrine made from corn. Starch is made by separating the starchy portion from corn by dry or wet milling

followed by cooking to gelatinate the starch and finally grinding to required size. Dextrines are produced from

corn starch by acidifying with hydrochloric acid and heating in large steam jacketed roasters. This treatment

makes the starch soluble in cold water. Sometime dextrose (crystalline corn sugar) is also used. The cereal

binders develop a gelationus bond with water and are normally employed along with other binders, e.g. in clay

bonded moulding sands and in oil and resin bonded core sands. In moulding sands the cereals increase air setting

strength, toughness and collapsibility and prevent sand from drying quickly. During pouring they gasify

producing voids between sand grains and allowing their expansion without distortion. An additional advantage is

MME345/ Greensand system/page-18

increased resistance of greensand moulds to friability on air drying. Addition of cereals results in strong moisture

retention which delays air drying of sand mixtures and improves bench life. Use of cereal also eliminates

scabbing and other expansion defects.

In core sands, cereal binder gives improved green strength and collapsibility with ease of knockout. However,

they increase gas evolution and decrease the resistance of dried cores to the absorption of moisture. Dextrin is

more effective than starch and it gives the same strength with less moisture. Generally two types of dextrin are

available, yellow and white. Both should have fineness of 100 mesh, BS sieve and moisture not more than 10%.

The yellow variety should have a minimum dextrin content of 85% and maximum ash content 1 % whereas the

white variety should have minimum dextrin content 65% and ash content maximum 0.5%.

Resins. Resins are high melting point gums produced by chemical alterations of rosins (low melting point gums

obtainable from pine trees) or produced synthetically. Synthetic resins are of two types, i.e. (a) furans that are

urea formaldehyde resins modified with furfuryl alcohol in varying proportions, and (b) phenolics that are

phenol formaldehyde modified with urea in varying proportions. In general, furans are more stable even in warm

weather, where as phenolics are cheaper and are resistant to heat and moisture. A large number of resins made in

different ways are available suited for particular jobs. Resins are not soluble in water and also do not swell in

water. When resins are mixed in the moulding sands, following improvements are obtained:

(a) good surface finish of casting.

(b) improved appreciably the dry strength properties.

(c) improved frictional properties.

(d) decreased toughness and brittleness of green moulding sand.

(e) increase flowability of sand and improved dispersion of fines throughout the sand mix and thus moulds are

produced with finer details.

(f) With the addition of 1.5% neutralised resins, green moulding sand can be stored for longer time.

Molasses. It is a commonly used additive both in moulding and core making for iron castings. It is a dark brown

viscous liquid containing 60-70% solid sugar obtained as a by-product during sugar refining. It may be used as

substitute of dextrine. It enhances the bench life of sands and imparts high dry strength and collapsibility. Due to

high viscosity and wettability, it also increases green strength. Its decomposition at high temperature generates

CO2, which set up a hardening action of the mould and increases hot compressive strength. On further heating

the strength gets decreased, thus making the mould collapsible. However, due to the high hygroscopicity of the

mix prepared with molasses, its use is not much favoured for good quality castings.

Linseed Oil (Core Oils). It is the most popular binder for core sand mixes. Linseed oil or other proprietary oils

known as core oils, which are made by blending various ingredients such as vegetable oil, mineral oil, animal

oils, natural resins and by-product residues from vegetable oil based industries, are used either with cereal

binders like dextrin or with dextrin and bentonite. The sand mix develops strength only when the cores prepared

from the mix are heated to a temperature of 200-240°C for a specified time that may vary from 1 to 3 hours. The

hardening is developed by polymerisation or cross-linking. Overall rate of hardening is controlled by the rate of

oxygen supply through sand and thus it emphasises the need of permeability, core venting, core stove ventilation.

Reduced dry strength and friability result due to excess baking temperature. A specific characteristic of linseed

oil is the resistance of its hardened film to moisture, due to which cores can be stored for prolonged periods

without affecting the properties. The cores so prepared have very good baked strength, scratch hardness,

permeability and collapsibility and can be stored for a long time. The specific gravity of core oils at 30°C should

be about 0.90 and their acid value not more than 10. Standard core oils are of two grades, fast baking and slow

baking depending upon-the baking time required at 220°C to attain peak tensile strength. Further depending on

the maximum strength developed after baking, core oils are of two types, low strength and high strength.

Sodium Silicate (Water Glass). This is the most common binder used in air-setting or self-hardening processes

for moulding and core making. The CO2 process, ferrosilicon process, cement process, dicalcium silicate

process, and others make use of sodium silicate as a binder, along with a solid or gaseous hardener. The variety

suitable for the CO2, process should contain total soluble silica (as SiO 2 26 to 32%; total alkalinity (as Na2O) 11

to 13%; relative sp.gr. at 20°C, 1.50 to 1.60; and total invert sugar content, 5 to 10%.

Fibrous Materials. These materials are used to improve collapsibility and prevent scabbing and expansion

defects. The commonly used materials are wood flour, chaff (dried grass), horsehair or cowhair, sawdust,

manure and asbestos. Ground wood flour or other cellulose materials such as cob-flour, cereal hulls, and

carbonised cellulose may be added in amounts of 0.5 to 2.0 per cent to moulding sands. They may function to

control the expansion of the sand by burning out at elevated temperature. They also can improve collapsibility

MME345/ Greensand system/page-19

and flowability of the sand.

Silica Flour. Pulverized silica, finer than 200 mesh, is called silica flour. It may be used in amounts up to 35 per

cent for the purpose of increasing hot strength of the sand. It also increases the density of the sand for resisting

metal penetration.

Table 10. Summary of functions of additives in greensand moulding aggregate

Purposes Additives

As binder Cereal, molasses, resin, linseed oil, water glass

Increase collapsibility Cereals, molasses, fibrous materials

Reduce expansion problems Cereals, coal dust, fibrous materials

Increase green strength Coal dust, molasses

Increase dry strength Cereals, resin, molasses, coal dust

Increase hot strength Iron oxide, silica flour

Reduce metal penetration Coal dust, iron oxide, silica flour

Improve surface finish Coal dust, resin

Increase flowability Resin, fibrous materials

Increase bench life Cereals, resin, molasses

MME345/ Greensand system/page-20

Potrebbero piacerti anche

- Green Sand For HPMLDocumento2 pagineGreen Sand For HPMLvivek1312Nessuna valutazione finora

- Porosity or PermeabilityDocumento30 paginePorosity or PermeabilitytabibkarimNessuna valutazione finora

- Publication 11 21839 1710Documento4 paginePublication 11 21839 1710Dimi BelNessuna valutazione finora

- Sand CastingDocumento19 pagineSand CastingAtul KaushikNessuna valutazione finora

- The Moulding Material DECDocumento59 pagineThe Moulding Material DECtilahun yeshiyeNessuna valutazione finora

- Casting and Casting Processes: Prof. (DR.) Dalgobind Mahto 3/10/2015Documento28 pagineCasting and Casting Processes: Prof. (DR.) Dalgobind Mahto 3/10/2015keethanNessuna valutazione finora

- Foundry Sand ProjectDocumento32 pagineFoundry Sand ProjectVed Deep100% (3)

- ME317 Manufacturing Technology Lab ManualDocumento22 pagineME317 Manufacturing Technology Lab ManualLakshmi PrasadNessuna valutazione finora

- CH 3-Moulding and Core MakingDocumento49 pagineCH 3-Moulding and Core Makinggosaye desalegn100% (3)

- Sand MouldingDocumento17 pagineSand MouldingbvbprasadNessuna valutazione finora

- Moulding & Moulding Materials: Casting ProcessesDocumento97 pagineMoulding & Moulding Materials: Casting ProcessesTrung Quoc LeNessuna valutazione finora

- Casting: Forming Sheet Metal Processing Powder-And Ceramics Processing Plastics ProcessingDocumento109 pagineCasting: Forming Sheet Metal Processing Powder-And Ceramics Processing Plastics ProcessingasitacharyaNessuna valutazione finora

- Mouldingsand 170509114249 PDFDocumento49 pagineMouldingsand 170509114249 PDFAnything You Could ImagineNessuna valutazione finora

- Various Types of CastingDocumento146 pagineVarious Types of CastingKaushik SreenivasNessuna valutazione finora

- Reduction in Sand Related ScrapDocumento6 pagineReduction in Sand Related Scraprumabiswas853Nessuna valutazione finora

- Moulding Sund Mixtare: Prtperties, Preparatiot and OesningDocumento17 pagineMoulding Sund Mixtare: Prtperties, Preparatiot and OesningMohamed MahdiNessuna valutazione finora

- Moulding ProcessesDocumento10 pagineMoulding ProcessesChinmay Das67% (3)

- Casting & Forging Notes - 2022Documento13 pagineCasting & Forging Notes - 2022MuktaNessuna valutazione finora

- Service 1Documento1 paginaService 1Pankaj ShettiNessuna valutazione finora

- tn9 PDFDocumento7 paginetn9 PDFlukas0% (1)

- Analysis of Drying Process in Ceramic Tiles Industries Ijariie2063Documento10 pagineAnalysis of Drying Process in Ceramic Tiles Industries Ijariie2063map vitcoNessuna valutazione finora

- Career Episode LatestDocumento32 pagineCareer Episode LatestHarmeet100% (1)

- LAB SESSION No 2 ManufacturingDocumento4 pagineLAB SESSION No 2 Manufacturingm.sheraz malikNessuna valutazione finora

- Properties of Moulding SandDocumento2 pagineProperties of Moulding Sandvijayanandan thekkethodikayilNessuna valutazione finora

- Unit 2casting Process PPT BMP Unit 2Documento61 pagineUnit 2casting Process PPT BMP Unit 2Bhaskar KandpalNessuna valutazione finora

- Construction Materials and Testing Manual NewDocumento89 pagineConstruction Materials and Testing Manual NewJosiah AntoninoNessuna valutazione finora

- 16 Foundry Resins: 16.1 Mold-And Core-Making ProcessesDocumento13 pagine16 Foundry Resins: 16.1 Mold-And Core-Making ProcessesJoão Victor VieiraNessuna valutazione finora

- MPI Unit IDocumento54 pagineMPI Unit IArun PatilNessuna valutazione finora

- 1.what Is Masonry ?Documento9 pagine1.what Is Masonry ?Nguyễn Đăng MinhNessuna valutazione finora

- Dr. Chaitanya Sharma Phd. Iit RoorkeeDocumento68 pagineDr. Chaitanya Sharma Phd. Iit RoorkeeTrung Quoc LeNessuna valutazione finora

- Foundry Sand Project PDFDocumento32 pagineFoundry Sand Project PDFShaheen GudunavarNessuna valutazione finora

- Clay BricksDocumento21 pagineClay BricksArul Gnanapragasam100% (1)

- 4801 Ramrattan EvaluatingACeramicResin-CoatedDocumento9 pagine4801 Ramrattan EvaluatingACeramicResin-CoatedXantos YulianNessuna valutazione finora

- Sand Moulding Sand Types, Cores, Machines: Hareesha N G Lecturer, Dept. of Aeronautical Engg, DSCE, Bangalore-78Documento50 pagineSand Moulding Sand Types, Cores, Machines: Hareesha N G Lecturer, Dept. of Aeronautical Engg, DSCE, Bangalore-78upender100% (1)

- Module 2-ConcreteDocumento17 pagineModule 2-ConcreteLiz Gaviola PescoNessuna valutazione finora

- Al Sand Casting ReportDocumento5 pagineAl Sand Casting ReportRajib karmakarNessuna valutazione finora

- Vol-1 Issue-3Documento5 pagineVol-1 Issue-3RakeshNessuna valutazione finora

- ECV 205 Tutorial AnswersDocumento8 pagineECV 205 Tutorial AnswersRobertNessuna valutazione finora

- Cement Manufacturing ProcessDocumento42 pagineCement Manufacturing Processkanishkkrishna7Nessuna valutazione finora

- Foundry Hand ToolsDocumento83 pagineFoundry Hand ToolsKiran MunavalliNessuna valutazione finora

- Lecture 4 (Read-Only)Documento10 pagineLecture 4 (Read-Only)Md RahmanNessuna valutazione finora

- Sand CastingDocumento42 pagineSand Castingshar8awy 506Nessuna valutazione finora

- Sand CastingDocumento9 pagineSand CastingMohamed OmarNessuna valutazione finora

- Foundry Shop ManualDocumento14 pagineFoundry Shop ManualAprajitaNessuna valutazione finora

- Chapter 3 MaterialDocumento9 pagineChapter 3 Materialdawana samuelNessuna valutazione finora

- Casting Series 3Documento23 pagineCasting Series 3Janmayjoy Halder SwagataNessuna valutazione finora

- Manus Factus: Manufacturing Technology Production TechnologyDocumento52 pagineManus Factus: Manufacturing Technology Production TechnologyrahulNessuna valutazione finora

- Sand CastingDocumento5 pagineSand Casting12dcc1947Nessuna valutazione finora

- Bricks: 3.1 Raw MaterialsDocumento9 pagineBricks: 3.1 Raw MaterialseyobNessuna valutazione finora

- Chapter - 1: Experimental Analysis of Concrete Incorporating Waste Foundry Sand and Waste Ceramic TilesDocumento44 pagineChapter - 1: Experimental Analysis of Concrete Incorporating Waste Foundry Sand and Waste Ceramic TilesIrfan KhanNessuna valutazione finora

- MP 2Documento8 pagineMP 2Empty DivineNessuna valutazione finora

- R - Bluding (Zaid Alaa) BDocumento22 pagineR - Bluding (Zaid Alaa) Bali ahmedNessuna valutazione finora

- How Clay Bricks Are Made: Technical Information Sheet 16Documento4 pagineHow Clay Bricks Are Made: Technical Information Sheet 16rajamd123Nessuna valutazione finora

- Recommendations (Molding and Pouring)Documento2 pagineRecommendations (Molding and Pouring)Muhamad Arif100% (1)

- CH 5. ConcreteDocumento25 pagineCH 5. ConcreteThazin LinnNessuna valutazione finora

- Self-healing Ceramic Matrix Composites: A MonographDa EverandSelf-healing Ceramic Matrix Composites: A MonographNessuna valutazione finora

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Documento3 pagineIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Simanchal KarNessuna valutazione finora

- Rolling PDFDocumento69 pagineRolling PDFSimanchal KarNessuna valutazione finora

- Panadyne International Sieve ChartDocumento1 paginaPanadyne International Sieve ChartSimanchal KarNessuna valutazione finora

- Bulletin 2017 18Documento626 pagineBulletin 2017 18Simanchal KarNessuna valutazione finora

- DSMTS 0005 3 AlODocumento4 pagineDSMTS 0005 3 AlOSimanchal KarNessuna valutazione finora

- Foundary Shop Exp 2Documento1 paginaFoundary Shop Exp 2Simanchal KarNessuna valutazione finora

- Diez 1993Documento8 pagineDiez 1993Simanchal KarNessuna valutazione finora

- S. Kar, S. Singh & S.P. Lal: Innovation-Driven Environmentally-Benign Manufacturing: A Case StudyDocumento36 pagineS. Kar, S. Singh & S.P. Lal: Innovation-Driven Environmentally-Benign Manufacturing: A Case StudySimanchal KarNessuna valutazione finora

- 44th Engineers DayDocumento2 pagine44th Engineers DaySimanchal KarNessuna valutazione finora

- Disaster Management An OverviewDocumento17 pagineDisaster Management An OverviewSimanchal KarNessuna valutazione finora

- Summary of PaperDocumento5 pagineSummary of PaperSimanchal KarNessuna valutazione finora

- Casting GuidelinesDocumento7 pagineCasting GuidelinesurwakhanNessuna valutazione finora

- Geostatistics For Soil SamplingDocumento169 pagineGeostatistics For Soil SamplingMiguel Gonzalez100% (1)

- Capozio1982-Geotechnical Problems Related To The Building of A Tailings Dam On Sensitive Varved ClayDocumento11 pagineCapozio1982-Geotechnical Problems Related To The Building of A Tailings Dam On Sensitive Varved ClayMariela Huaripata HuaripataNessuna valutazione finora

- The British Soil Classification System For Engineering Purposes-Its Development and Relation To Other Comparable SystemsDocumento29 pagineThe British Soil Classification System For Engineering Purposes-Its Development and Relation To Other Comparable SystemsWubetie Mengist50% (4)

- Unfired Clay Masonry: Information Paper IP 16/11Documento6 pagineUnfired Clay Masonry: Information Paper IP 16/11Amanpreet singhNessuna valutazione finora

- CVE - 131 - 1 - Lecture 1Documento24 pagineCVE - 131 - 1 - Lecture 1ZxeroNessuna valutazione finora

- Soil Properties GuidlineDocumento27 pagineSoil Properties GuidlineJulfikar KhanNessuna valutazione finora

- C34 PDFDocumento3 pagineC34 PDFMateriales FicNessuna valutazione finora

- Jozanikohan-Abarghooei2022 Article TheFourierTransformInfraredSpeDocumento14 pagineJozanikohan-Abarghooei2022 Article TheFourierTransformInfraredSpeMd. BadrulNessuna valutazione finora

- XRD Analysis of Clay Minerals VOL 2 Practical Identification TheoryDocumento45 pagineXRD Analysis of Clay Minerals VOL 2 Practical Identification Theoryjuan diego gomez quinteroNessuna valutazione finora

- So Your Home Is Built On Expansive SoilsDocumento102 pagineSo Your Home Is Built On Expansive Soilsedd casNessuna valutazione finora

- 4.9 Cone Penetration Tests (CPT) : Friction Ratio (RF) Inferred LithologyDocumento4 pagine4.9 Cone Penetration Tests (CPT) : Friction Ratio (RF) Inferred LithologyRaaf RifandiNessuna valutazione finora

- Reading PracticeDocumento10 pagineReading PracticeEmy kriswinartiNessuna valutazione finora

- Chapter 3: Constraints, Trade-Offs and Standards 3.1 Design ConstraintsDocumento3 pagineChapter 3: Constraints, Trade-Offs and Standards 3.1 Design ConstraintsVincent Gabrielle NepomucenoNessuna valutazione finora

- PandPofCC (8th Edition)Documento629 paginePandPofCC (8th Edition)Carlos Alberto CaicedoNessuna valutazione finora

- Geotechnical Properties of Clayey SandDocumento120 pagineGeotechnical Properties of Clayey SandJaga ChNessuna valutazione finora

- Practical Methods Manual of Soil Science.Documento239 paginePractical Methods Manual of Soil Science.chia jalelNessuna valutazione finora

- Case Study - Agr231 - Muhammad Aiman Haikal Bin Mohd AzmiDocumento4 pagineCase Study - Agr231 - Muhammad Aiman Haikal Bin Mohd AzmiAiman HaikalNessuna valutazione finora

- Tunnel LectureNotesDocumento29 pagineTunnel LectureNotesAhmed HamedNessuna valutazione finora

- Maintenance Engineer CivilDocumento39 pagineMaintenance Engineer CiviljavedNessuna valutazione finora

- Bentonite Grade Details..Documento6 pagineBentonite Grade Details..moto rola100% (1)

- Efficascy of Fly Ash & Stone Dust Stabilizing Clayey Soil 1Documento77 pagineEfficascy of Fly Ash & Stone Dust Stabilizing Clayey Soil 1KrishnaNessuna valutazione finora

- GeoVancouver 2016 - New Afton Clay PDFDocumento10 pagineGeoVancouver 2016 - New Afton Clay PDFttameigud1Nessuna valutazione finora

- Science Activity Sheet Quarter 4 - MELC 1 Week 1: Types of SoilDocumento10 pagineScience Activity Sheet Quarter 4 - MELC 1 Week 1: Types of SoilShareinne TeamkNessuna valutazione finora

- Ceramic Materials I: Asst - Prof. Dr. Ayşe KALEMTAŞDocumento32 pagineCeramic Materials I: Asst - Prof. Dr. Ayşe KALEMTAŞŞebnem Gül İlarslanNessuna valutazione finora

- Grade 8 - Integrated Science Consolidated CurriculumDocumento12 pagineGrade 8 - Integrated Science Consolidated Curriculumshonaishot hottieNessuna valutazione finora

- A B Brick Field-Amal Borah-CC - FinalDocumento35 pagineA B Brick Field-Amal Borah-CC - FinalMaddu Janak RaoNessuna valutazione finora

- Cob Project ReportDocumento8 pagineCob Project ReportrituNessuna valutazione finora

- PultrusionDocumento4 paginePultrusionHaren SinghNessuna valutazione finora

- Clay Lumps and Friable MaterialsDocumento2 pagineClay Lumps and Friable MaterialsSushant GiriNessuna valutazione finora

- Engineering Proporties of Komice (Pumice) SoilDocumento19 pagineEngineering Proporties of Komice (Pumice) SoilLiyu GudissaNessuna valutazione finora