Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Types of Layouts PDF

Caricato da

Gangadhar Mamadapur0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

21 visualizzazioni3 pagineTitolo originale

Types of layouts.pdf

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

21 visualizzazioni3 pagineTypes of Layouts PDF

Caricato da

Gangadhar MamadapurCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 3

Types of Plant Layout

• Layouts can be classified into the following

Types of Layout: Product Layout categories:

v/s Process Layout – Process Layout

– Product Layout

Presented By: – Combination Layout

Anupam Kumar – Fixed Position Layout

Reader

SMS Varanasi – Group Layout

E mail: anupamkr@gmail.com

© Copyright 2013 Anupam Kumar 1 © Copyright 2013 Anupam Kumar 2

Process Layout Process Layout

• In process layout: • Advantages: • Disadvantages:

– All machines performing similar type of operations – Machines are better – Material handling cannot

utilized and fewer be mechanized

are grouped together at one location. machines are required – Process time is

– Production volume remains limited. – Flexibility of equipment prolonged

– The production happens in batches or lots. & personnel is possible – Lower productivity due

– A large variety of products can be produced from – Lower initial investments to number of set-ups

the same plant. – Higher utilization of – Throughput time is

production facility longer

– Backtracking and long movements reduces the – Diversity of tasks makes – Space & capital is tied up

material handling efficiency. the work challenging & by work in progress/

– Space and capital are tied up in WIP inventory. interesting. process.

© Copyright 2013 Anupam Kumar 3 © Copyright 2013 Anupam Kumar 4

Product Layout Product Layout

• The product layout is selected when the • Advantages: • Disadvantages:

– Reduced material – No flexibility in the

volume of production is high enough to justify handling activities. production process.

a separate production line. – Work In Process almost – Low flexibility in the

eliminated. manufacturing times.

• In this type of layout, the machines and – Minimum manufacturing – High capital investment.

auxiliary services are located according to the time. – Every workstation is

processing sequence of the product. – Simplification of the critical to the process.-

production planning and The lack of personnel or

• The facilities are arranged to ensure efficient control systems. shut down of a machine

flow of material and lower cost per unit. – Tasks simplification. stops the whole process.

– Monotonous work.

© Copyright 2013 Anupam Kumar 5 © Copyright 2013 Anupam Kumar 6

© Copyright 2013 Anupam Kumar 1

Combination or Matrix Layout Combination or Matrix Layout

• A combination layout combines the advantages of

both the process and product layouts.

• It is used when the same item is being manufactured

in different types or sizes.

• In this, the machines are arranged in the process

layout format but process grouping is arranged in a

sequence.

• The sequence of operation with each of the product

variety however remains the same.

© Copyright 2013 Anupam Kumar 7 © Copyright 2013 Anupam Kumar 8

Fixed Position Layout Group Layout or Cellular Layout

• This type of layout is suitable when one or a few • Group Layout is also a combination of Product and

identical heavy items are to be manufactured. Process Layout.

• The materials are kept fixed because the cost of • It identifies the families of components that require

transportation of material is very high. similar types of requirements and machines which

• In this type of layout, are clubbed together as cells.

– the material or the major component remain fixed and • The cellular layout is also called a multi-objective

– the tools, machinery, men and other materials move layout because this layout tries to minimize

around it. – The sum of the cost of transportation

• This type of layout is also called project type layout. – The cost of equipment

© Copyright 2013 Anupam Kumar 9 © Copyright 2013 Anupam Kumar 10

Group Layout or Cellular Layout Layout Design

Process (Functional) Layout Group (Cellular) Layout • ABC Electronics has a facility with six production areas.

A cluster • It proposes to locate 6 departments (A,B,C,D,E,F), which have the

or cell number of moves per day between departments as shown in the

T T T CG CG T T T

table below.

M • What type of layout would be suitable for the facility?

M M T

T T T SG SG • Develop a layout for the facility.

D D M D

M M D D D

SG CG CG D

A B C D E F

M M D D D SG

A 5 10 3 2

1 2 3

B 12

Resources to produce similar products 4 5 6

Similar resources placed together

placed together C 10 4 8

D 16

E 7

© Copyright 2013 Anupam Kumar 11 F 8 © Copyright 2013 Anupam Kumar 12

© Copyright 2013 Anupam Kumar 2

Bibliography

• Buffa, E.S. and Sarin, R.K., “Modern Production/Operations Management,” Eighth Edition.

Singapore: John Wiley & Sons (Asia). 1994.

• Martinich, J.S., “Production and Operations Management: An Applied Approach”, Singapore: John

Wiley & Sons (Asia), 2003.

• Badi, R.V. and Badi, N.V., “Production and Operations Management”, Second Edition, New Delhi:

Vrinda Publication, 2008.

For further details… • Chary, S.N., “Productions and Operations Management,” Third Edition, New Delhi: Tata McGraw

Hill, 2004

• Goel, B.S., “Production Operations Management”, Twenty Second Edition, Meerut, U.P.: Pragati

Prakashan, 2010.

• Kachru, U. “Production and Operations Management: Text and Cases,” New Delhi: Excel Books,

2007.

Contact • Rama Murthy, P., “Production and Operations Management,” New Delhi: New Age International,

Anupam Kumar 2012.

• Chunawalla, S.A., and Patel, D.R., “Production and Operations Management,” Mumbai: Himalaya

Reader Publishing House, 2006.

• Jauhari, V. and Dutta, K., “Services: Marketing Operations and Management,” New Delhi: Oxford

SMS Varanasi University Press, 2010.

• Verma, H.V., “Services Marketing: Text and Cases,” New Delhi: Dorling Kindersley, Pearson

E mail: anupamkr@gmail.com Education, 2009.

© Copyright 2013 Anupam Kumar 13 © Copyright 2013 Anupam Kumar 15

© Copyright 2013 Anupam Kumar 3

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- LNAT EssayDocumento2 pagineLNAT EssayFaisal . BathawabNessuna valutazione finora

- Disconnected ManDocumento4 pagineDisconnected ManBecky100% (1)

- Dimensional Engineering SeminarDocumento71 pagineDimensional Engineering Seminardramilt100% (4)

- Why There Has Been No Brandies Brief in India? Challenges To Socio-Legal Research in IndiaDocumento2 pagineWhy There Has Been No Brandies Brief in India? Challenges To Socio-Legal Research in IndiaSubhaprad MohantyNessuna valutazione finora

- Semantics Course BookDocumento67 pagineSemantics Course BookJosipa Blažević50% (2)

- Philip Kotler: Distribution Channel-DefinitionDocumento64 paginePhilip Kotler: Distribution Channel-DefinitionGangadhar MamadapurNessuna valutazione finora

- (Intelligent Systems, Control and Automation_ Science and Engineering 72) B. S. Goh, W. J. Leong, K. L. Teo (Auth.), Honglei Xu, Xiangyu Wang (Eds.)-Optimization and Control Methods in Industrial EngiDocumento300 pagine(Intelligent Systems, Control and Automation_ Science and Engineering 72) B. S. Goh, W. J. Leong, K. L. Teo (Auth.), Honglei Xu, Xiangyu Wang (Eds.)-Optimization and Control Methods in Industrial EngiVu Duc TruongNessuna valutazione finora

- Waste Segregator ReportDocumento33 pagineWaste Segregator ReportVinodNKumar25% (4)

- Understanding Change: Mba Iv SemDocumento12 pagineUnderstanding Change: Mba Iv SemGangadhar MamadapurNessuna valutazione finora

- Strategic Human Resource ManagementDocumento20 pagineStrategic Human Resource ManagementGangadhar MamadapurNessuna valutazione finora

- Data AnalysisDocumento16 pagineData AnalysisGangadhar MamadapurNessuna valutazione finora

- Strategic Human Resource ManagementDocumento25 pagineStrategic Human Resource ManagementGangadhar MamadapurNessuna valutazione finora

- Module 3 - Impact of Corporate Restructuring On HRDocumento23 pagineModule 3 - Impact of Corporate Restructuring On HRGangadhar MamadapurNessuna valutazione finora

- Fakultas Ekonomi Universitas Negeri Yogyakarta 2012Documento20 pagineFakultas Ekonomi Universitas Negeri Yogyakarta 2012Gangadhar MamadapurNessuna valutazione finora

- Uni T: Strategic Human Resource Management (SHRM)Documento19 pagineUni T: Strategic Human Resource Management (SHRM)Gangadhar MamadapurNessuna valutazione finora

- Strategic Human Resource ManagementDocumento17 pagineStrategic Human Resource ManagementGangadhar Mamadapur100% (1)

- Strategic Human Resource Management Chapter-1Documento13 pagineStrategic Human Resource Management Chapter-1Gangadhar MamadapurNessuna valutazione finora

- Strategic HR Management & PlanningDocumento33 pagineStrategic HR Management & PlanningGangadhar MamadapurNessuna valutazione finora

- Strategic HR Vs Traditional HR: Role of HR Is Evolving in Recent YearsDocumento18 pagineStrategic HR Vs Traditional HR: Role of HR Is Evolving in Recent YearsGangadhar MamadapurNessuna valutazione finora

- Strategic Human Resource ManagementDocumento17 pagineStrategic Human Resource ManagementGangadhar MamadapurNessuna valutazione finora

- Decision Making, Systems, Modeling, and SupportDocumento15 pagineDecision Making, Systems, Modeling, and SupportGangadhar MamadapurNessuna valutazione finora

- Concept and Issues: Strategic Human Resources ManagementDocumento22 pagineConcept and Issues: Strategic Human Resources ManagementGangadhar MamadapurNessuna valutazione finora

- LMS (Learning Management System)Documento9 pagineLMS (Learning Management System)Gangadhar MamadapurNessuna valutazione finora

- What Is Strategic HRM?: Has Largely Been Seen As An Administrative Function and As A Cost CenterDocumento14 pagineWhat Is Strategic HRM?: Has Largely Been Seen As An Administrative Function and As A Cost CenterGangadhar MamadapurNessuna valutazione finora

- Learning Management: SystemDocumento51 pagineLearning Management: SystemGangadhar MamadapurNessuna valutazione finora

- 9859068Documento37 pagine9859068Gangadhar MamadapurNessuna valutazione finora

- Strategic Human Resource Management: Chapter No. 8Documento31 pagineStrategic Human Resource Management: Chapter No. 8Gangadhar MamadapurNessuna valutazione finora

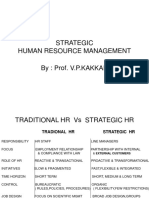

- Strategic Human Resource Management By: Prof. V.P.KAKKARDocumento8 pagineStrategic Human Resource Management By: Prof. V.P.KAKKARGangadhar MamadapurNessuna valutazione finora

- Presentation On: Human Resource PlanningDocumento51 paginePresentation On: Human Resource PlanningGangadhar MamadapurNessuna valutazione finora

- Organization and Information SystemsDocumento46 pagineOrganization and Information SystemsGangadhar MamadapurNessuna valutazione finora

- Total Quality Management: Introduction To TQM by Abdulla Jassim AbdullaDocumento10 pagineTotal Quality Management: Introduction To TQM by Abdulla Jassim AbdullaGangadhar MamadapurNessuna valutazione finora

- Decision Support System: Rev: Feb, 2012Documento25 pagineDecision Support System: Rev: Feb, 2012Gangadhar MamadapurNessuna valutazione finora

- Decision Support Systems Concepts, Methodologies, and TechnologiesDocumento26 pagineDecision Support Systems Concepts, Methodologies, and TechnologiesGangadhar MamadapurNessuna valutazione finora

- 9 Ed., Prentice HallDocumento51 pagine9 Ed., Prentice HallGangadhar MamadapurNessuna valutazione finora

- A New Four-Scroll Chaotic System With A Self-Excited Attractor and Circuit ImplementationDocumento5 pagineA New Four-Scroll Chaotic System With A Self-Excited Attractor and Circuit ImplementationMada Sanjaya WsNessuna valutazione finora

- Mabini Colleges, Inc: College of Education Daet, Camarines NorteDocumento8 pagineMabini Colleges, Inc: College of Education Daet, Camarines NorteFrancia BalaneNessuna valutazione finora

- Updating Cd2 School Heads: TradeanDocumento2 pagineUpdating Cd2 School Heads: TradeanCarlos GarciaNessuna valutazione finora

- CDP MCQs - Child Development & Pedagogy (CDP) MCQ Questions With AnswerDocumento4 pagineCDP MCQs - Child Development & Pedagogy (CDP) MCQ Questions With AnswerPallav JainNessuna valutazione finora

- Q1. Read The Passage Below and Answer The Questions That FollowDocumento3 pagineQ1. Read The Passage Below and Answer The Questions That FollowAryan KananiNessuna valutazione finora

- How To Verify SSL Certificate From A Shell PromptDocumento4 pagineHow To Verify SSL Certificate From A Shell Promptchinku85Nessuna valutazione finora

- SSRN Id3126098Documento3 pagineSSRN Id3126098Aditya kompalliNessuna valutazione finora

- Jurutera August 2014Documento28 pagineJurutera August 2014Edison LimNessuna valutazione finora

- National AnthemsDocumento6 pagineNational AnthemszhannurazimbaiNessuna valutazione finora

- GulfSea HT Oil 32 PDFDocumento1 paginaGulfSea HT Oil 32 PDFObydur RahmanNessuna valutazione finora

- Quiz Unit 2 B3Documento9 pagineQuiz Unit 2 B3Nicolás Felipe Moreno PáezNessuna valutazione finora

- ONLINE20042111 MoDocumento16 pagineONLINE20042111 MoPhương HoàngNessuna valutazione finora

- UGET 2010 Engineering Cutoff RankDocumento5 pagineUGET 2010 Engineering Cutoff RankLokesh KumarNessuna valutazione finora

- Exadata Technical Whitepaper 134575Documento31 pagineExadata Technical Whitepaper 134575Jyothi JohnNessuna valutazione finora

- Family Day by Day - The Guide To A Successful Family LifeDocumento212 pagineFamily Day by Day - The Guide To A Successful Family Lifeprajya100% (3)

- TR 4015Documento62 pagineTR 4015Matias AndréNessuna valutazione finora

- Notes PCDocumento35 pagineNotes PCSwapnil NanawareNessuna valutazione finora

- Đề 5Documento4 pagineĐề 5Nga NguyenNessuna valutazione finora

- Sans Nom 2Documento320 pagineSans Nom 2khalidNessuna valutazione finora

- Interpersonel Need of Management Student-Acilitor in The Choice of ElectivesDocumento180 pagineInterpersonel Need of Management Student-Acilitor in The Choice of ElectivesnerdjumboNessuna valutazione finora

- Mechanics of Deformable Bodies Module 6Documento65 pagineMechanics of Deformable Bodies Module 6stephaniejeancortez522Nessuna valutazione finora

- Ôn HSG - P5-HandoutDocumento4 pagineÔn HSG - P5-HandoutMinh ChâuNessuna valutazione finora

- Primate City & Rank Size Rule: O P A DDocumento7 paginePrimate City & Rank Size Rule: O P A DOmkar G. ParishwadNessuna valutazione finora