Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Elkem 10 Tundish Cover Ladle Nodularization PDF

Caricato da

Anonymous iztPUhIiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Elkem 10 Tundish Cover Ladle Nodularization PDF

Caricato da

Anonymous iztPUhIiCopyright:

Formati disponibili

Technical Information 10

Tundish Cover Ladle Nodularization

Magnesium treatment for nodularization of ductile iron can be carried out by several different

treatment processes. The tundish cover ladle process will under most conditions, be a

convenient, effective and reliable process with good economy. The process provides good

consistency and high recoveries of magnesium over a wide range of treatment sizes. A well-

operated system will give between 60 – 80 % recovery of magnesium while the operating and

maintenance costs normally fall well below most other commercial processes. Tundish ladle

treatments also offer virtually no flare, about 90 % fume reduction, no metal splashing and

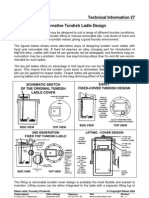

minimum carbon and temperature losses. The figure below shows an example of a tundish

cover ladle.

Figure 1: Schematic representation of a tundish cover ladle with dual alloy pockets.

Calculation of Filling Hole Dimensions

The following formula can be used to calculate the diameter of the tundish lid filling hole:

W

d = 0.07

t⋅h

Where d is the filling hole diameter in centimetres (cm), W is the liquid iron batch weight in

grams (g), t is the pouring time in seconds (s), and h is the ferrostatic height of metal in the

tundish basin in centimetres (cm). Note: h is the height of metal, not the height of the basin

itself.

Base metal sulphur contents should preferably not exceed 0.02% before treatment to ensure

maximum efficiency of the tundish ladle. If sulphur levels are higher, a desulphurizing step is

recommended prior to nodularization.

Elkem ASA, Silicon Division

Postal address: Office address: Telephone: Revision No. 2

P.O.Box 5211 Majorstua Hoffsveien 65 B 47 22 45 01 00 14.03.1997

N-0303 Oslo Oslo Telefax

Norway 47 22 45 01 52

Magnesium Alloy Selection and Addition

The tundish cover process may be used with most magnesium ferrosilicon alloys containing

between 3 to 12 % magnesium but generally alloys containing 4 – 6% Mg are used. Typically

an alloy of the following composition:

45% Si 5% Mg 1% Ca 1% RE max. 1% Al Bal. Fe

would be used to treat base iron composed of a mixture of steel scrap, pig iron and returns.

Alloy size grading of about 1 – 10 mm is most suitable for small treatments while sizes up to 4

– 35 mm are preferable for larger treatments. See Elkem Technical Information Sheet No. 20

for more details on selection of nodularizers in ductile iron.

The amount of alloy added usually lies between 1.2 and 1.8 weight % depending on the base

sulphur content, the metal temperature, the magnesium content of the alloy and the

consistency with which the process is carried out.

Cover Material Selection

It is recommended to use a cover material over the magnesium alloy in the reaction chamber

in order to obtain maximum treatment economy. The cover should retain the alloy in the

chamber for as long as possible before the reaction starts. Covers commonly consist of clean

steel plate or clippings of a grade similar to that used in the melt charges. Cast iron cover

plates can be cast from the spare metal left at the end of a cast thus avoiding the carbon

dilution due to the steel cover. However, the best results are obtained using a ferrosilicon alloy

as a cover material.

Example of Recovery Improvements

Figure 2: Schematic representation of recovery improvements as a function of sulphur content,

treatment temperature, and ladle design modifications. The initial case of 2.0 wt% addition rate

represents a situation with 0.03% S and 1520°C treatment temperature.

Potrebbero piacerti anche

- 6 Jazz Reading Exercise PDFDocumento5 pagine6 Jazz Reading Exercise PDFQuốc LiêmNessuna valutazione finora

- Common Metallurgical Defects in Grey Cast IronDocumento9 pagineCommon Metallurgical Defects in Grey Cast IronRolando Nuñez Monrroy100% (1)

- MagnesiumDocumento3 pagineMagnesiumIsidoro LópezNessuna valutazione finora

- Allison 1,000 & 2,000 Group 21Documento4 pagineAllison 1,000 & 2,000 Group 21Robert WhooleyNessuna valutazione finora

- 26-ELKEM Poster-Graphite Structures in Cast IronsDocumento1 pagina26-ELKEM Poster-Graphite Structures in Cast IronsHOSSIENNessuna valutazione finora

- Sampling of Liquid Cast IronDocumento2 pagineSampling of Liquid Cast Ironarnaldorcr8646Nessuna valutazione finora

- MCM AllDocumento7 pagineMCM AllPalanisamy RajaNessuna valutazione finora

- Creating Attachments To Work Items or To User Decisions in WorkflowsDocumento20 pagineCreating Attachments To Work Items or To User Decisions in Workflowselampe100% (1)

- Late Metal Stream InoculationDocumento2 pagineLate Metal Stream Inoculationarnaldorcr8646Nessuna valutazione finora

- Al B Ti (Aluminum Boron Titanium)Documento2 pagineAl B Ti (Aluminum Boron Titanium)Kaan BulutNessuna valutazione finora

- Cleaness Steel CastingDocumento61 pagineCleaness Steel CastingSUNDRAMNAGANessuna valutazione finora

- Alternative Tundish Ladle DesignDocumento2 pagineAlternative Tundish Ladle Designarnaldorcr8646Nessuna valutazione finora

- Chunky GraphiteDocumento16 pagineChunky GraphitesachinguptachdNessuna valutazione finora

- BS 3100 1991Documento20 pagineBS 3100 1991Anonymous iztPUhIi100% (1)

- BS 3100 1991Documento20 pagineBS 3100 1991Anonymous iztPUhIi100% (1)

- BS 3100 1991Documento20 pagineBS 3100 1991Anonymous iztPUhIi100% (1)

- Shrinkage in Iron CastingsDocumento10 pagineShrinkage in Iron CastingskarthikkandaNessuna valutazione finora

- Pneumatic Conveying of Bulk Solids PDFDocumento231 paginePneumatic Conveying of Bulk Solids PDFCarloLopez100% (2)

- ISO 1940-2-1997 Mechanical VibDocumento20 pagineISO 1940-2-1997 Mechanical VibJavad Monfared100% (3)

- ISO 1940-2-1997 Mechanical VibDocumento20 pagineISO 1940-2-1997 Mechanical VibJavad Monfared100% (3)

- Steel CastingsDocumento50 pagineSteel CastingsVijayakumar TNessuna valutazione finora

- ATAS Dynamic InoculationDocumento27 pagineATAS Dynamic InoculationRaymundodelCampoNessuna valutazione finora

- T0000598REFTRGiDX 33RevG01052017 PDFDocumento286 pagineT0000598REFTRGiDX 33RevG01052017 PDFThanhNessuna valutazione finora

- Elkem 10 Tundish Cover Ladle NodularizationDocumento2 pagineElkem 10 Tundish Cover Ladle Nodularizationmarcotulio123Nessuna valutazione finora

- Analysis of Quality and Cost of FeSiMg Treatment Master Alloy vs. Cored Wire in Production of Ductile Cast IronDocumento4 pagineAnalysis of Quality and Cost of FeSiMg Treatment Master Alloy vs. Cored Wire in Production of Ductile Cast IronAdams GodoyNessuna valutazione finora

- Elkem 13 Compacted Graphite IronDocumento2 pagineElkem 13 Compacted Graphite Ironmarcotulio123Nessuna valutazione finora

- ELMAGDocumento2 pagineELMAGthomazfabricioNessuna valutazione finora

- CarburizerDocumento28 pagineCarburizerWalton BangladeshNessuna valutazione finora

- Surface Graphite Degeneration in Ductile Iron CastDocumento8 pagineSurface Graphite Degeneration in Ductile Iron CastKhairul MuzafarNessuna valutazione finora

- Effect of Basic Chemical Element in Sgi Ductile Iron IJERTV1IS7135Documento7 pagineEffect of Basic Chemical Element in Sgi Ductile Iron IJERTV1IS7135Uma KoduriNessuna valutazione finora

- Din en 10226-1 PDFDocumento14 pagineDin en 10226-1 PDFAnonymous iztPUhIiNessuna valutazione finora

- AntiSegregation HopperDocumento5 pagineAntiSegregation Hoppermecaunidos7771Nessuna valutazione finora

- Elkem 05 Inoculation MechanismsDocumento2 pagineElkem 05 Inoculation Mechanismsmarcotulio123Nessuna valutazione finora

- Induction Furnace Vs Electric Arc FurnaceDocumento1 paginaInduction Furnace Vs Electric Arc FurnaceAnonymous iztPUhIi100% (1)

- BS 3100 1991Documento20 pagineBS 3100 1991Anonymous iztPUhIi100% (1)

- BS 3100 1991Documento20 pagineBS 3100 1991Anonymous iztPUhIi100% (1)

- MX3Documento154 pagineMX3Dung Nguyen0% (1)

- Sew 520Documento8 pagineSew 520Anonymous iztPUhIiNessuna valutazione finora

- BS en 1370-2011Documento18 pagineBS en 1370-2011Pablo Andrés Duque Ramírez80% (5)

- 23 Factors Influencing The Recovery and Addition of Magnesium in Ductile Iron Ladle Treatment Processes PDFDocumento4 pagine23 Factors Influencing The Recovery and Addition of Magnesium in Ductile Iron Ladle Treatment Processes PDFSIDDHARTH GOYALNessuna valutazione finora

- 1999 Ductile Iron Production - A Comparison of Alternative Treatment Methods PDFDocumento19 pagine1999 Ductile Iron Production - A Comparison of Alternative Treatment Methods PDFDouglas VidalNessuna valutazione finora

- O HC HCDocumento101 pagineO HC HCIndustrial Infra Jobs100% (1)

- Oxidation of Ferrosilicon Alloys During StorageDocumento1 paginaOxidation of Ferrosilicon Alloys During Storagearnaldorcr8646Nessuna valutazione finora

- Hot Rolled Steel Sheet, Plate and Strip For Forming and Flanging Purposes According To IS 5986:2017Documento9 pagineHot Rolled Steel Sheet, Plate and Strip For Forming and Flanging Purposes According To IS 5986:2017Mari MuthuNessuna valutazione finora

- Ferroalloy Storage Bin DesignDocumento2 pagineFerroalloy Storage Bin Designarnaldorcr8646Nessuna valutazione finora

- Manganese, Sulfur and Manganese-Sulfur Ratio Effects in Gray Cast IronDocumento30 pagineManganese, Sulfur and Manganese-Sulfur Ratio Effects in Gray Cast IronNetoNessuna valutazione finora

- Nitrogen Fissures Defects in Iron Castings: Back ToDocumento2 pagineNitrogen Fissures Defects in Iron Castings: Back ToJustin DixonNessuna valutazione finora

- Compression MountingDocumento12 pagineCompression MountingEden HazardNessuna valutazione finora

- Cold Mounting EnglishpdfDocumento6 pagineCold Mounting EnglishpdfJorge BonillaNessuna valutazione finora

- Factors Influencing The Recovery and Addition of MagnesiumDocumento4 pagineFactors Influencing The Recovery and Addition of Magnesiumarnaldorcr8646Nessuna valutazione finora

- Cast Iron SolidificationDocumento12 pagineCast Iron Solidificationkatchani123100% (1)

- Gray Iron Foundries PDFDocumento20 pagineGray Iron Foundries PDFbebe3838Nessuna valutazione finora

- Ductile Iron: 2000 Issue 3Documento73 pagineDuctile Iron: 2000 Issue 3karthikkandaNessuna valutazione finora

- Crystals 12 00978Documento9 pagineCrystals 12 00978irmaNessuna valutazione finora

- Versatility of Cored Wire Process For Producing Ductile IronDocumento10 pagineVersatility of Cored Wire Process For Producing Ductile IronDNessuna valutazione finora

- BLUESIL BP 9710 RepelenteDocumento3 pagineBLUESIL BP 9710 Repelentehector mauricio paez cantorNessuna valutazione finora

- Cast Iron BrochureDocumento12 pagineCast Iron BrochureFlamarion BadaroNessuna valutazione finora

- Ductile Iron ReviewDocumento36 pagineDuctile Iron ReviewDenis Yasmin AlineNessuna valutazione finora

- Heat Conservation in Liquid IronDocumento2 pagineHeat Conservation in Liquid Ironarnaldorcr8646Nessuna valutazione finora

- Niobium in Cast IronDocumento13 pagineNiobium in Cast IronTayyab HussainNessuna valutazione finora

- kalpur-FE KSP SleevesDocumento6 paginekalpur-FE KSP SleevesSachin KumbharNessuna valutazione finora

- Offsetting Macro-Shrinkage in Ductile IronDocumento13 pagineOffsetting Macro-Shrinkage in Ductile IronmetkarthikNessuna valutazione finora

- Bas CatDocumento31 pagineBas Catanwer_ahsanNessuna valutazione finora

- Gas Fron Green SandDocumento13 pagineGas Fron Green Sandjose.figueroa@foseco.comNessuna valutazione finora

- Application Manual Chapter 6 - Feeding & GatingDocumento148 pagineApplication Manual Chapter 6 - Feeding & GatingVishal MaliNessuna valutazione finora

- Cast Iron DampingDocumento5 pagineCast Iron Dampinggabs88Nessuna valutazione finora

- ATAS Metstar Kovis FoundryDocumento18 pagineATAS Metstar Kovis FoundryslagmercuryNessuna valutazione finora

- 229-01 Dross Inclusions in An Iron FoundryDocumento4 pagine229-01 Dross Inclusions in An Iron Foundryjlplazaola100% (1)

- Ductile Iron Data - Section 12Documento17 pagineDuctile Iron Data - Section 12ante_zivkovic1Nessuna valutazione finora

- Colour MetallographyDocumento12 pagineColour MetallographystefaneduardNessuna valutazione finora

- Effect of Minor and Trace Elements in Cast IronDocumento2 pagineEffect of Minor and Trace Elements in Cast IronsachinguptachdNessuna valutazione finora

- KB Alloys Foundrymans Guide To SR and TiBorDocumento7 pagineKB Alloys Foundrymans Guide To SR and TiBorfoundryjoeNessuna valutazione finora

- Molding Training PresentationDocumento30 pagineMolding Training PresentationVinesh RJNessuna valutazione finora

- Home About Us Products Quality Control Representation Useful Links Contact UsDocumento5 pagineHome About Us Products Quality Control Representation Useful Links Contact Ustushak mNessuna valutazione finora

- Continuous casting The Ultimate Step-By-Step GuideDa EverandContinuous casting The Ultimate Step-By-Step GuideNessuna valutazione finora

- Metal matrix composites: Processing and InterfacesDa EverandMetal matrix composites: Processing and InterfacesR EverettNessuna valutazione finora

- En 1564-1997Documento18 pagineEn 1564-1997Anonymous iztPUhIiNessuna valutazione finora

- PDF Design ImperialDocumento9 paginePDF Design ImperialAnonymous iztPUhIiNessuna valutazione finora

- Spheroidal Graphite (Nodular) Cast Iron:: Product Type Grade of Product Sub GradeDocumento5 pagineSpheroidal Graphite (Nodular) Cast Iron:: Product Type Grade of Product Sub GradeAnonymous iztPUhIiNessuna valutazione finora

- Screw ThreadsDocumento11 pagineScrew ThreadsAnonymous iztPUhIiNessuna valutazione finora

- Norsok Standard M-122: Rev. 1, June 2003Documento18 pagineNorsok Standard M-122: Rev. 1, June 2003BlainNessuna valutazione finora

- Astm A 297Documento3 pagineAstm A 297friasdelacruz50% (2)

- How To SellDocumento13 pagineHow To SellAnonymous iztPUhIiNessuna valutazione finora

- Process Knowledge in FoundriesDocumento23 pagineProcess Knowledge in FoundriesAnonymous iztPUhIiNessuna valutazione finora

- TemperaturesDocumento1 paginaTemperaturesAnonymous iztPUhIiNessuna valutazione finora

- Temperatures PDFDocumento1 paginaTemperatures PDFAnonymous iztPUhIiNessuna valutazione finora

- Chance in BballDocumento12 pagineChance in BballAnonymous iztPUhIiNessuna valutazione finora

- Working With The Cold Box ProcessDocumento21 pagineWorking With The Cold Box ProcessAnonymous iztPUhIiNessuna valutazione finora

- Steel Castings in Architecture and Engineering: Hans SchoberDocumento5 pagineSteel Castings in Architecture and Engineering: Hans SchoberAnonymous iztPUhIiNessuna valutazione finora

- AlphabetDocumento1 paginaAlphabetAnonymous iztPUhIiNessuna valutazione finora

- Welding Solutions: Selecting The Proper PositionerDocumento1 paginaWelding Solutions: Selecting The Proper PositionerAnonymous iztPUhIiNessuna valutazione finora

- Par 5.6Documento1 paginaPar 5.6Anonymous iztPUhIiNessuna valutazione finora

- 67261-BS EN 1593-1999 无损检验-漏泄试验-起泡技术Documento14 pagine67261-BS EN 1593-1999 无损检验-漏泄试验-起泡技术Thiago Souza da SilvaNessuna valutazione finora

- AlphabetDocumento1 paginaAlphabetAnonymous iztPUhIiNessuna valutazione finora

- SL-19536 - REV2!02!13 User Manual MC CondensersDocumento68 pagineSL-19536 - REV2!02!13 User Manual MC CondensersCristian SevillaNessuna valutazione finora

- 307-01 Automatic Transmission 10 Speed - Description and Operation - DescriptionDocumento12 pagine307-01 Automatic Transmission 10 Speed - Description and Operation - DescriptionCARLOS LIMADANessuna valutazione finora

- Sympoly Toolbox IssuesDocumento7 pagineSympoly Toolbox IssuesAli FahemNessuna valutazione finora

- Review Problems Chapter 4 Solutions PDFDocumento4 pagineReview Problems Chapter 4 Solutions PDFAntoninoNessuna valutazione finora

- 21 API Functions PDFDocumento14 pagine21 API Functions PDFjet_mediaNessuna valutazione finora

- ElutriatorDocumento9 pagineElutriatoratiyorockfan9017Nessuna valutazione finora

- Tech Specs - TC 5540 PDFDocumento2 pagineTech Specs - TC 5540 PDFziaarkiplanNessuna valutazione finora

- VT300 User ManualDocumento21 pagineVT300 User ManualLuvNessuna valutazione finora

- Fongs ProgrammerDocumento5 pagineFongs ProgrammerPankaj PolaraNessuna valutazione finora

- Flame Test ExplanationDocumento2 pagineFlame Test ExplanationMia-shae ClarkeNessuna valutazione finora

- C191HM Powermeter and Harmonic Manager CommunicationsDocumento30 pagineC191HM Powermeter and Harmonic Manager CommunicationsRoberto GarridoNessuna valutazione finora

- The Big TEGO. Products Services Data Sheets-75-150-16!76!31-61Documento31 pagineThe Big TEGO. Products Services Data Sheets-75-150-16!76!31-61DWI RAHMASARI FATMAWATINessuna valutazione finora

- SkyCiv Beam - Hand Calculations - AJW8CTBuLE8YKrkKaG8KTtPAw8k74LSYDocumento13 pagineSkyCiv Beam - Hand Calculations - AJW8CTBuLE8YKrkKaG8KTtPAw8k74LSYsaad rajawiNessuna valutazione finora

- Shaping Plastic Forming1Documento24 pagineShaping Plastic Forming1Himan JitNessuna valutazione finora

- Chem 17 Exp 3 RDR Chemical KineticsDocumento4 pagineChem 17 Exp 3 RDR Chemical KineticscrazypatrishNessuna valutazione finora

- Mathematics in The Modern World ReviewerDocumento2 pagineMathematics in The Modern World ReviewerVince Luigi ZepedaNessuna valutazione finora

- 3 1 5b Ohms Law WorksheetDocumento5 pagine3 1 5b Ohms Law Worksheetapi-291536660100% (1)

- Aluminum: DR 900 Analytical ProcedureDocumento4 pagineAluminum: DR 900 Analytical Procedurewulalan wulanNessuna valutazione finora

- Microcontroller Based Vehicle Security SystemDocumento67 pagineMicrocontroller Based Vehicle Security Systemlokesh_045Nessuna valutazione finora

- Biomechanic of Foot PDFDocumento8 pagineBiomechanic of Foot PDFMichealowen BabygoalNessuna valutazione finora

- SR-X Script Reference - EDocumento24 pagineSR-X Script Reference - EDomagoj ZagoracNessuna valutazione finora

- Ss e (Bocr) ManualDocumento2 pagineSs e (Bocr) ManualNaveen GuptaNessuna valutazione finora

- Notes For Class 11 Maths Chapter 8 Binomial Theorem Download PDFDocumento9 pagineNotes For Class 11 Maths Chapter 8 Binomial Theorem Download PDFRahul ChauhanNessuna valutazione finora

- Nihonto Part IDocumento38 pagineNihonto Part IGergő VidaNessuna valutazione finora