Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

A 12 UNIfloc Leaflet 2936-V11 86370 Original English 86370

Caricato da

Yogeshkumar j joshiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

A 12 UNIfloc Leaflet 2936-V11 86370 Original English 86370

Caricato da

Yogeshkumar j joshiCopyright:

Formati disponibili

Fibre Preparation

A 12 UNIfloc

A 12 UNIfloc

A 12 UNIfloc Automatic Bale Opener

Innovative bale take-off technology guarantees

high efficiency in the blowroom

A 12 UNIfloc Automatic Bale Opener

Innovative bale take-off technology guarantees high efficiency in the blowroom

With a line production up to 2 000 kg/h, the A 12 UNIfloc is extremely economical. The machine concept is based on a robust

monocoque design, torque controlled direct drive and a unique scanning force measurement of the take-off unit. The fibre tufts are

taken off uniformly by a patented take-off roller system, opened into so-called microtufts and thus optimally prepared for the fur-

ther blowroom process. Energy costs can be reduced by feeding back the brake power into the network.

ECONOMY QUALITY FLEXIBILITY

High production after bale group change thanks Uniform and gentle material take-off to microtufts Intuitive and safe operation by means of the

to patented bale scanning colour touchscreen

• With 2 000 kg/h line production, • Bale opening into microtufts provides • The intuitive and safe operation is

the A 12 UNIfloc supplies the cards the basis for the effective cleaning effected by a colour touchscreen

reliably. and dust extraction by the subsequent monitor with direct menu navigation

blowroom process. and visual display of the inputs and

• The patented force measuring for

operating conditions.

scanning the bale laydown allows the • The unique scanning force measure-

required high productivity rate to be ment on the take-off unit results in a • The connection to the blowroom con-

obtained from the very beginning, uniform take-off of the feed bale. trol UNIcontrol permits a convenient

even with a new bale group. overview of the whole blowroom.

• Thanks to the patented wobble disc

• Energy saving by means of the future- take-off roller, gentle and continuous • The A 12 UNIfloc processes up to 3

orientated direct drive concept and extraction of the tufts is ensured. assortments.

the feedback of brake power into the

• The microtufts allow an extremely

electricity network.

homogeneous blend already at the

start of the process.

Rieter Machine Works Ltd. Rieter India Private Ltd. Rieter (China) The data and illustrations in this brochure and on the cor-

Klosterstrasse 20 Gat No. 768/2, Village Wing Textile Instruments Co., Ltd. responding data carrier refer to the date of printing. Rieter

reserves the right to make any necessary changes at any time

CH-8406 Winterthur Shindewadi-Bhor Road Shanghai Branch and without special notice. Rieter systems and Rieter innova-

T +41 52 208 7171 Taluka Khandala, District Satara Unit B-1, 6F, Building A, tions are protected by patents.

F +41 52 208 8320 IN-Maharashtra 412 801 Synnex International Park

machines@rieter.com T +91 2169 304 141 1068 West Tianshan Road 2936-v11 en 1705

aftersales@rieter.com F +91 2169 304 226 CN-Shanghai 200335

T +86 21 6037 3333

F +86 21 6037 3399 www.rieter.com

Potrebbero piacerti anche

- Carr and Latham's Technology of Clothing ManufactureDa EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerValutazione: 4 su 5 stelle4/5 (1)

- A 11 UNIfloc Brochure 2135-v1 en 24747Documento8 pagineA 11 UNIfloc Brochure 2135-v1 en 24747Vincent TeodoReNessuna valutazione finora

- Rieter-A 11 UNIfloc Automatic Bale OpenerDocumento3 pagineRieter-A 11 UNIfloc Automatic Bale Openerashik1111007Nessuna valutazione finora

- High-Performance Pre-Cleaner Uniclean B 15Documento4 pagineHigh-Performance Pre-Cleaner Uniclean B 15Lemi Desalegn100% (1)

- Fan TV425Documento87 pagineFan TV425Khaled RabeaNessuna valutazione finora

- Tuchler Vs ReiterDocumento17 pagineTuchler Vs ReiterUmer IrshadNessuna valutazione finora

- Rieter Rotor Semi r36 Brochure 3101 v1 87068 enDocumento28 pagineRieter Rotor Semi r36 Brochure 3101 v1 87068 enHai PhamNessuna valutazione finora

- New Rieter Center P+® Ring Centering Device: Info No. G 14 Ring Spinning Machines: All ModelsDocumento2 pagineNew Rieter Center P+® Ring Centering Device: Info No. G 14 Ring Spinning Machines: All ModelsVenkatesh BabuNessuna valutazione finora

- Product Guide: Teraspin Spindle Bearing Units and Complete SpindlesDocumento6 pagineProduct Guide: Teraspin Spindle Bearing Units and Complete SpindlesNeelakandan DNessuna valutazione finora

- Rieter c70 Parts DescriptionDocumento1 paginaRieter c70 Parts DescriptionAbdul RafayNessuna valutazione finora

- Cardingmachine 140324082245 Phpapp01Documento33 pagineCardingmachine 140324082245 Phpapp01SantoshNessuna valutazione finora

- Blowroom: Basic Operations in The BlowroomDocumento3 pagineBlowroom: Basic Operations in The BlowroomIndu VikasiniNessuna valutazione finora

- Trutzschler Drawing Fram 03 - GBDocumento32 pagineTrutzschler Drawing Fram 03 - GBzulqarnain-rana-2024Nessuna valutazione finora

- Learning Outcomes of This Week: The Students Will Be Able ToDocumento24 pagineLearning Outcomes of This Week: The Students Will Be Able ToTalha saeedNessuna valutazione finora

- Fibula Drawframe RSB-D 40 and SB-D 40: Milestones in Drawframe EngineeringDocumento36 pagineFibula Drawframe RSB-D 40 and SB-D 40: Milestones in Drawframe EngineeringamirthaksharaNessuna valutazione finora

- Autocard Poduct Brochure ENDocumento16 pagineAutocard Poduct Brochure ENRj ShajahanNessuna valutazione finora

- Blow Room Lab 1Documento9 pagineBlow Room Lab 1Partho Kumar Roy100% (1)

- Textile Technology Internship ReportDocumento24 pagineTextile Technology Internship Reportgunashekarkalluri100% (1)

- OM Rieter Unifloc A11Documento330 pagineOM Rieter Unifloc A11Thích HátNessuna valutazione finora

- Rieter - G 35 Ring Spinning MachineDocumento8 pagineRieter - G 35 Ring Spinning MachineAbo AnasNessuna valutazione finora

- The Card: "The Heart of Spinning"Documento101 pagineThe Card: "The Heart of Spinning"Umår F ÃfriDiNessuna valutazione finora

- Uster Quantum ClearerDocumento27 pagineUster Quantum ClearerMd. Humayun KabirNessuna valutazione finora

- Effect of Cleaning Point of Uniclean Machine in Blow Room On Cleaning Efficiency and Yarn QualityDocumento21 pagineEffect of Cleaning Point of Uniclean Machine in Blow Room On Cleaning Efficiency and Yarn QualitySantoshNessuna valutazione finora

- Double-Head Draw Frame SB-D 22: AdvantagesDocumento24 pagineDouble-Head Draw Frame SB-D 22: AdvantagesMuhammad Farooq KokabNessuna valutazione finora

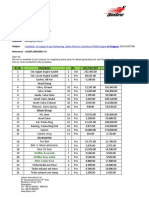

- United Towels: Production CapacityDocumento10 pagineUnited Towels: Production CapacityAli HaiderNessuna valutazione finora

- Inspection of Waste Extracted by Different Machines of Spinning Department.Documento3 pagineInspection of Waste Extracted by Different Machines of Spinning Department.Ammar Naeem BhattiNessuna valutazione finora

- Control Systemte of BlowroomDocumento18 pagineControl Systemte of BlowroomNiveditaKumariNessuna valutazione finora

- Machine Load CalculationDocumento3 pagineMachine Load Calculationস্মৃতিরছেড়াপাতাNessuna valutazione finora

- Modern Developments in WeavingDocumento13 pagineModern Developments in WeavingRakeahkumarDabkeyaNessuna valutazione finora

- Ring Spinning Vs All Technologies Part 2Documento29 pagineRing Spinning Vs All Technologies Part 2SOhaib KazmeNessuna valutazione finora

- Brushing Sueding MachineDocumento4 pagineBrushing Sueding MachineZheejae Lao-atenNessuna valutazione finora

- Spinning Section Trutzschler: ITMA 2019 New Machinery / New Innovations DisplayedDocumento8 pagineSpinning Section Trutzschler: ITMA 2019 New Machinery / New Innovations DisplayedPadmanaban PasuvalingamNessuna valutazione finora

- Course: Yarn Manufacturing 2Documento24 pagineCourse: Yarn Manufacturing 2fekadeNessuna valutazione finora

- 5-6 Winding Part 2Documento28 pagine5-6 Winding Part 2Md. Towfiq ImrozNessuna valutazione finora

- Elements of Circular KnittingDocumento5 pagineElements of Circular KnittingSanika JoshiNessuna valutazione finora

- 3rd Revise Introduction To YM (TE-2111 Fall 2019)Documento17 pagine3rd Revise Introduction To YM (TE-2111 Fall 2019)Aftab Amin0% (1)

- Sussen CompactDocumento8 pagineSussen CompactArumugham RMNessuna valutazione finora

- Friction SpinningDocumento39 pagineFriction SpinningPåñdît ẞhyãmãñtãk MãñîNessuna valutazione finora

- Weaving Loom Parts Catalogue Van de Wiele SpareDocumento23 pagineWeaving Loom Parts Catalogue Van de Wiele SpareRamesh HspNessuna valutazione finora

- Smart Ringframe LRJ9SXDocumento16 pagineSmart Ringframe LRJ9SXSudheer Singh chauhanNessuna valutazione finora

- J 20 Air-Jet Spinning Machine Brochure 2386-V1 en 34515Documento16 pagineJ 20 Air-Jet Spinning Machine Brochure 2386-V1 en 34515Ishwar DudagiNessuna valutazione finora

- Qpro 9 en Auto Doffer.Documento24 pagineQpro 9 en Auto Doffer.Md Hanif SonketNessuna valutazione finora

- Reiter F40Documento8 pagineReiter F40ASIF AZAM ANSARI100% (1)

- 05 - Weaving Chapter2b 3 ProductionDocumento31 pagine05 - Weaving Chapter2b 3 ProductionOsama Shaaraf100% (1)

- Draw FrameDocumento50 pagineDraw FrameDev Narayan KushwahaNessuna valutazione finora

- Rieter - Card C 60Documento8 pagineRieter - Card C 60Marathi VideoNessuna valutazione finora

- Ring-Spinning Machine G 33 Programming PDFDocumento34 pagineRing-Spinning Machine G 33 Programming PDFTuan Nguyen Minh75% (4)

- Unimix LB7 4Documento2 pagineUnimix LB7 4MY Lê Thị Trà100% (2)

- Circular Knitting ModuleDocumento27 pagineCircular Knitting ModuleRajivNessuna valutazione finora

- Practical Observation of Material Flow On Ring-Fame, Auto Cone Rotor SpinningDocumento5 paginePractical Observation of Material Flow On Ring-Fame, Auto Cone Rotor SpinningTalha saeedNessuna valutazione finora

- Fabric IV PPT MahasinDocumento12 pagineFabric IV PPT MahasinS.m. MahasinNessuna valutazione finora

- Blowroom: Manish Bhargava TDD - IiiDocumento5 pagineBlowroom: Manish Bhargava TDD - IiiShantnu MittalNessuna valutazione finora

- Rotor Spinning ReportDocumento6 pagineRotor Spinning Reportdsethi23Nessuna valutazione finora

- Lap Former Machine - Features of Lap Former Machine - Textile LearnerDocumento1 paginaLap Former Machine - Features of Lap Former Machine - Textile LearnerTanmay JagetiaNessuna valutazione finora

- Ring Frame - Technological AspectsDocumento43 pagineRing Frame - Technological AspectsAliAhmad67% (3)

- Optimax-I Brochure 2019 enDocumento22 pagineOptimax-I Brochure 2019 enACE CONSULTANTS100% (1)

- Weaving Loom Parts Catalogue Somet Rapier SpareDocumento106 pagineWeaving Loom Parts Catalogue Somet Rapier Sparealper güzel100% (1)

- SE-640 Description of The Features 1Documento24 pagineSE-640 Description of The Features 1SantoshNessuna valutazione finora

- ProjectGenerator V1 4Documento80 pagineProjectGenerator V1 4Hasan SAYINNessuna valutazione finora

- NASA - Management.a.continuing - Bibliography.with - Indexes.19800014705 1980014705Documento175 pagineNASA - Management.a.continuing - Bibliography.with - Indexes.19800014705 1980014705mac9papNessuna valutazione finora

- Weighing The Move To An OpenStack Cloud in GovernmentDocumento21 pagineWeighing The Move To An OpenStack Cloud in GovernmentScoop News GroupNessuna valutazione finora

- ERP Stands For Enterprise Resource and PlanningDocumento6 pagineERP Stands For Enterprise Resource and PlanningBhupendra MishNessuna valutazione finora

- Shilpi Agarwal ResumeDocumento3 pagineShilpi Agarwal ResumeShilpi AgarwalNessuna valutazione finora

- Head Group: ACI Godrej Agrovet Private LimitedDocumento2 pagineHead Group: ACI Godrej Agrovet Private LimitedsaifulNessuna valutazione finora

- A SIEM Solution Implementation: TEK-UP UniversityDocumento39 pagineA SIEM Solution Implementation: TEK-UP UniversityKaisSlimeniNessuna valutazione finora

- 1st Place & Galloway Street NE - Appendix ADocumento111 pagine1st Place & Galloway Street NE - Appendix ADistrict Department of TransportationNessuna valutazione finora

- Construction Today MagazineDocumento1 paginaConstruction Today MagazineSchofield MediaNessuna valutazione finora

- Types of ComputerDocumento41 pagineTypes of ComputerAngelita CapagalanNessuna valutazione finora

- Ms 101Documento244 pagineMs 101HandeNessuna valutazione finora

- Are Social Networks An Advantage To Share Information or A Problem That Affects The Privacy of Each One?Documento1 paginaAre Social Networks An Advantage To Share Information or A Problem That Affects The Privacy of Each One?Rocio Peña ArdilaNessuna valutazione finora

- PLM Case StudyDocumento4 paginePLM Case StudyMANOJNessuna valutazione finora

- Diffentian Transformer ProtectionDocumento227 pagineDiffentian Transformer ProtectionHuget St100% (3)

- IR ISO - Intercompany Pricing PDFDocumento6 pagineIR ISO - Intercompany Pricing PDFShiva ChaitanyaNessuna valutazione finora

- Packaging and LabellingDocumento32 paginePackaging and LabellingVishal100% (1)

- SC 37 Operating Instructions 0928Documento148 pagineSC 37 Operating Instructions 0928Pranav PatilNessuna valutazione finora

- Form 1aDocumento3 pagineForm 1aSafety Bharatpur OCPNessuna valutazione finora

- Esq. Elétrico Carro Inferior LTM 1400Documento67 pagineEsq. Elétrico Carro Inferior LTM 1400Leonardo BorbaNessuna valutazione finora

- RCV STV 2Documento1 paginaRCV STV 2goss8877Nessuna valutazione finora

- HWS Series: Single Output Industrial Power SuppliesDocumento2 pagineHWS Series: Single Output Industrial Power SuppliesSteveNessuna valutazione finora

- Aci sp-215-2003Documento446 pagineAci sp-215-2003Abigael Valles RamirezNessuna valutazione finora

- Chapter 2 Campus Area Network Server Configurations 2.5Documento32 pagineChapter 2 Campus Area Network Server Configurations 2.5PREEVITHANessuna valutazione finora

- VP-540i Intialize The LimitDocumento2 pagineVP-540i Intialize The LimitEzawaliNessuna valutazione finora

- Application of Hidden Markov Model On Car Sensors For Detecting Drunk DriversDocumento6 pagineApplication of Hidden Markov Model On Car Sensors For Detecting Drunk DriversselbalNessuna valutazione finora

- BFD2 ManualDocumento180 pagineBFD2 Manuallarrygates100% (6)

- Sonifier SFX250 and SFX550 Cell Disruptors and HomogenizersDocumento6 pagineSonifier SFX250 and SFX550 Cell Disruptors and HomogenizersAlison AlcarazNessuna valutazione finora

- Senior Six Exam of C++Documento10 pagineSenior Six Exam of C++Christian AMANINessuna valutazione finora

- Portable Smart Phone Charger Using HumanDocumento6 paginePortable Smart Phone Charger Using HumanKipkoech FrankNessuna valutazione finora

- PC5108FLR v2.0 Installation Instructions: General EnclosuresDocumento2 paginePC5108FLR v2.0 Installation Instructions: General EnclosuresMario Gabriel MoralliNessuna valutazione finora