Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

FVT (1) Resistencia

Caricato da

DavidTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

FVT (1) Resistencia

Caricato da

DavidCopyright:

Formati disponibili

FVT

www.vishay.com

Vishay Huntington

Wirewound Resistor, Industrial Power,

Vitreous Coated, Fixed Tubular

FEATURES

• High temperature vitreous coating

• Complete welded construction

• Available in non-inductive style (special “NI”)

with Ayrton-Perry winding

• Tight tolerance of 5 % for values above 1

• Excellent stability in operation (< 3 % change

resistance)

• Material categorization:

for definitions of compliance please see

www.vishay.com/doc?99912

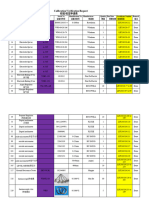

STANDARD ELECTRICAL SPECIFICATIONS

RESISTANCE RESISTANCE

POWER RATING RANGE RANGE WEIGHT

GLOBAL HISTORICAL

P25 °C (typical)

MODEL MODEL

W g

±5% ± 10 %

FVT005 FVT-5 5 1.0 to 20.5K 0.1 to 20.5K 4.60

FVT005...NI FVT-5-...-NI 5 1.0 to 750 1.0 to 750 4.60

FVT010 FVT-10 12 1.0 to 58K 0.1 to 58K 6.7

FVT010...NI FVT-10-...-NI 12 1.0 to 3.9K 1.0 to 3.9K 6.7

FVT020 FVT-20 20 1.0 to 95K 0.1 to 95K 12.57

FVT020...NI FVT-20-...-NI 20 1.0 to 6.8K 1.0 to 6.8K 12.57

FVT20A - 15 1.0 to 60K 0.10 to 60K 8.64

FVT025 FVT-25 25 1.0 to 115K 0.1 to 115K 20.7

FVT025...NI FVT-25-...-NI 25 1.0 to 8.8K 1.0 to 8.8K 20.7

FVT25A FVT-25A 30 1.0 to 56K 0.1 to 56K 20.7

FVT25A...NI FVT-25A-...-NI 30 1.0 to 7.25K 1.0 to 7.25K 20.7

FVT25B FVT-25B 30 1.0 to 49K 0.1 to 49K 14.5

FVT25B...NI FVT-25B-...-NI 30 1.0 to 6.8K 1.0 to 6.8K 14.5

FVT050 FVT-50 50 1.0 to 112K 0.1 to 112K 42.1

FVT050...NI FVT-50-...-NI 50 1.0 to 21.5K 1.0 to 21.5K 42.1

FVT50A FVT-50A 60 1.0 to 145K 0.1 to 145K 65.6

FVT50A...NI FVT-50A-...-NI 60 1.0 to 27.2K 1.0 to 27.2K 65.6

FVT50B FVT-50B 70 1.0 to 170K 0.1 to 170K 60.0

FVT50B...NI FVT-50B-...-NI 70 1.0 to 31.4K 1.0 to 31.4K 60.0

FVT075 FVT-75 75 1.0 to 276K 0.1 to 276K 98.5

FVT075...NI FVT-75-...-NI 75 1.0 to 35K 1.0 to 35K 98.5

FVT75A FVT-75A 90 1.0 to 238K 0.1 to 238K 64.8

FVT75A...NI FVT-75A-...-NI 90 1.0 to 31K 1.0 to 31K 64.8

FVT080 - 80 1.0 to 190K 0.10 to 190K 121.58

FVT100 FVT-100 100 1.0 to 260K 0.1 to 260K 91.4

FVT100...NI FVT-100-...-NI 100 1.0 to 48.5K 1.0 to 48.5K 91.4

FVT130 FVT-130 130 1.0 to 380K 0.1 to 380K 192.4

FVT130...NI FVT-130-...-NI 130 1.0 to 70.2K 1.0 to 70.2K 192.4

FVT160 FVT-160 175 1.0 to 470K 0.1 to 470K 250.8

FVT160...NI FVT-160-...-NI 175 1.0 to 105K 1.0 to 105K 250.8

FVT175 - 175 1.0 to 500K 0.10 to 500K 250.8

FVT200 FVT-200 225 1.0 to 645K 0.1 to 645K 310.0

FVT200...NI FVT-200-...-NI 225 1.0 to 121K 1.0 to 121K 310.0

FVT225 FVT-225 225 1.0 to 645K 0.1 to 645K 310.0

FVT225...NI FVT-225-...-NI 225 1.0 to 121K 1.0 to 121K 310.0

Revision: 03-Jun-16 1 Document Number: 31838

For technical questions, contact: ww2dresistors@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

FVT

www.vishay.com

Vishay Huntington

GLOBAL PART NUMBER INFORMATION

Global Part Numbering example: FVT02506E25R00JE (visit www.vishay.net SAP parts manual for all options)

F V T 0 2 5 0 6 E 2 5 R 0 0 J E

TERMINAL TERMINAL

GLOBAL MODEL VALUE TOLERANCE PACKAGING CODE SPECIAL

(6 digits) DESIGNATION FINISH (5 digits) (1 digit) (1 digit) (up to 2 digits)

(2 digits) (1 digit)

(see Standard 02, 05, E = lead R = decimal J=±5% E = lead (Pb)-free (dash number)

Electrical 06, 14, (Pb)-free K = thousand K = ± 10 % bulk pack from 1 to 99 as applicable

Specifications 15, 20 1R500 = 1.5 91 = 100 style horizontal

Global Model FC = ferrule cap 1K500 = 1.5 k high bracket

column for 92 = 200 style

options) push-in bracket

93 = 300 style

thru-bolt bracket

NI = non-inductive

NP = non-inductive +

92 style push-in bracket

NH = non-inductive +

91 style horizontal

bracket

NV = non-inductive +

style vertical bracket

Historical Part Number example: FVT-25-25-5 %

FVT-25 25 5%

HISTORICAL MODEL RESISTANCE VALUE TOLERANCE SPECIAL

Revision: 03-Jun-16 2 Document Number: 31838

For technical questions, contact: ww2dresistors@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

FVT

www.vishay.com

Vishay Huntington

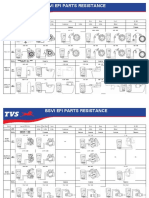

DIMENSIONS in inches (millimeters)

TERMINAL SETBACK

DISTANCE CENTER TO CENTER

A O.D. I.D.

LENGTH

CORE DIMENSIONS TERMINAL DISTANCE TERMINAL DESIGNATION

A O.D. I.D. SETBACK CENTER TO OPTIONAL

MODEL

MAX. LENGTH ± 0.031 ± 0.031 ± 0.031 CENTER STANDARD (QUICK

(0.79) (0.79) (0.79) (REF.) CONNECT)

0.406 1.000 0.313 0.188 0.094 0.625

FVT005 (10.31) (25.40) (7.95) (4.78) (2.39) 05 14

(15.88)

0.406 1.750 0.313 0.188 0.094 1.375

FVT010 05 14

(10.31) (44.45) (7.95) (4.78) (2.39) (34.93)

0.563 2.000 0.438 0.260 0.094 1.625

FVT020 02 14

(14.30) (50.8) (11.13) (6.60) (2.39) (41.28)

FVT20A 0.563 1.500 0.438 0.313 0.094 0.937 02 14

(14.30) (38.10) (11.11) (7.94) (2.38) (23.80)

0.688 2.000 0.563 0.313 0.094 1.562

FVT025 06 15

(17.48) (50.8) (14.30) (7.95) (2.39) (39.67)

0.906 2.000 0.750 0.500 0.094 1.562

FVT25A (23.01) (50.8) (19.05) (12.70) (2.39) 06 15

(39.67)

0.770 2.000 0.625 0.453 0.094 1.562

FVT25B 06 15

(19.56) (50.8) (15.88) (11.51) (2.39) (39.67)

0.688 4.000 0.563 0.313 0.094 3.562

FVT050 06 15

(17.48) (101.6) (14.30) (7.95) (2.39) (90.47)

0.906 4.000 0.750 0.500 0.062 3.626

FVT50A (23.01) (101.6) (19.05) (12.70) (1.57) 06 15

(92.10)

0.906 4.500 0.750 0.547 0.125 4.000

FVT50B 06 15

(23.01) (114.3) (19.05) (13.89) (3.18) (101.60)

0.688 6.000 0.563 0.313 0.094 5.562

FVT075 06 15

(17.48) (152.4) (14.30) (7.95) (2.39) (141.27)

0.906 6.000 0.750 0.500 0.094 5.562

FVT75A (23.01) (152.4) (19.05) (12.70) (2.39) 06 15

(141.27)

1.313 4.000 1.125 0.750 0.219 2.812

FVT080 (33.34) (101.6) (28.58) (19.05) (5.56) (71.42) 20 15

0.906 6.500 0.750 0.500 0.125 6.000

FVT100 (23.01) (165.1) (19.05) (12.70) (3.18) 06 15

(152.40)

1.313 6.500 1.125 0.750 0.282 5.374

FVT130 20 15

(33.35) (165.1) (28.58) (19.05) (7.16) (136.50)

1.313 8.500 1.125 0.750 0.267 7.404

FVT160 20 15

(33.35) (215.9) (28.58) (19.05) (6.78) (188.06)

FVT175 1.313 8.500 1.125 0.750 0.219 7.312 20 15

(33.34) (215.9) (28.58) (19.05) (5.56) (185.72)

FVT200 1.313 10.500 1.125 0.750 0.266 9.406

20 15

FVT225 (33.35) (266.7) (28.58) (19.05) (6.76) (238.91)

TERMINAL DIMENSIONS in inches (millimeters)

TERMINAL STYLE

DIMENSIONS

20 02 05 06 14 15

A D A D 0.375 0.188 0.188 0.250 0.188 0.250

WIDTH A

(9.53) (4.76) (4.76) (6.35) (4.76) (6.35)

C C 0.562 0.393 0.393 0.500 0.563 0.594

HEIGHT B

Style 02, 05, 06, (14.07) (9.98) (9.98) (12.70) (14.29) (15.08)

B 0.204 0.133 0.133 0.172 0.050 0.065

and 20 Styles 14 and 15 DIAMETER C

B (5.18) (3.38) (3.38) (4.36) (1.27) (1.65)

0.020 0.020 0.020 0.020 0.020 0.031

THICKNESS D

(0.51) (0.51) (0.51) (0.51) (0.51) (0.79)

Revision: 03-Jun-16 3 Document Number: 31838

For technical questions, contact: ww2dresistors@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

FVT

www.vishay.com

Vishay Huntington

DIMENSIONS in inches (millimeters)

MOUNTING HARDWARE

91 = 100 Style Horizontal 1 High Bracket

AVAILABLE BRACKET TYPES BY MODEL

91 = 100

GLOBAL 92 = 200 93 = 300

STYLE

MODEL STYLE STYLE B

HORIZONTAL

PUSH-IN THRU-BOLT 0.046 (1.17) H

1 HIGH

BRACKET BRACKET

BRACKET C

Core length plus “X”

FVT005 n/a 202 n/a

BRACKET MOUNTING

X Y Z H C B

TYPE SLOT

FVT010 101 202 301

1.063 0.500 0.950 1.000 0.219 x 0.438 0.750 1.375

101

(26.99) (12.70) (24.13) (25.40) (5.56 x 11.11) (19.05) (34.93)

FVT020 101 203 301 1.063 0.750 0.859 1.250 0.219 x 0.438 0.750 1.750

102

(26.99) (19.05) (21.83) (31.75) (5.56 x 11.11) (19.05) (44.45)

FVT20A 101 203 301 1.063 1.250 1.000 1.500 0.281 x 0.563 0.927 2.125

103

(26.99) (31.75) (25.40) (38.10) (7.14 x 14.29) (23.55) (53.98)

FVT025 102 204 301

92 = 200 Style Push-In Bracket

FVT25A 102 206 302

FVT25B 102 205 301 Z

H

FVT050 102 204 302 Core length

plus “X”

Y

FVT50A 102 206 302

BRACKET HOLE

X H Y Z

TYPE (DIA.)

FVT50B 102 208 302

0.478 0.250 0.125 0.375 0.170

202

(12.14) (6.35) (3.175) (9.53) (4.32)

FVT075 102 204 301 0.583 0.580 0.188 0.460 0.115

203

(14.80) (14.73) (4.78) (11.68) (2.92)

FVT75A 102 206 302 0.700 0.578 0.250 0.500 0.156

204

(17.78) (14.68) (6.35) (12.70) (3.96)

0.846 0.800 0.375 0.600 0.343 x 0.213

FVT100 102 206 302 205

(21.49) (20.32) (9.53) (15.24) (8.71 x 5.46)

0.846 0.800 0.375 0.600 0.343 x 0.213

FVT130 103 207 302 206

(21.49) (20.62) (9.53) (15.24) (8.71 x 5.46)

0.700 1.125 0.500 0.687 0.250 x 0.188

207

FVT175 103 207 303 (17.78) (28.58) (12.70) (17.45) (6.35 x 4.78)

0.846 0.800 0.375 0.600 0.343 x 0.213

208

(21.49) (20.62) (9.53) (15.24) (8.71 x 5.46)

FVT200 103 207 303

93 = 300 Style Thru-Bolt Bracket

FVT225 103 207 303

BRACKET X

THREAD

TYPE (APPROXIMATE)

0.373

301 8 to 32

(9.47)

0.271

302 8 to 32

(6.88)

0.463

303 1/4 to 20

(11.76)

Revision: 03-Jun-16 4 Document Number: 31838

For technical questions, contact: ww2dresistors@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

FVT

www.vishay.com

Vishay Huntington

TECHNICAL SPECIFICATIONS

PARAMETER UNIT RESISTOR CHARACTERISTICS

Power Rating W 5 to 225

Resistance Range 0.1 to 645K

Resistance Tolerance % 5

Temperature Coefficient ppm/°C ± 260 for 20 and above, ± 400 for 1 to 19.99

Operating Temperature °C -55 °C to 350°C

Temperature Rise °C 325 °C above an ambient of 25 °C

Maximum Altitude f.a.s.l. 10 000

Short-Term Overload - 10x rated power for 5 s

Surge Windings Available

Maximum Working Voltage - (P x R)0.5

Insultation Resistance 1M

Dielectric Voltage VRMS 1000 VAC

Creepage Varies by wattage, see “Terminal Setback” in Dimensions table

Terminal Sleeves n/a

Inductance μH Varies by wattage and resistance

Non-Inductive Winding Available

Terminal Strength lb 10 lbs

Electrical or Mechanical Customization Contact factory: ww2dresistors@vishay.com

MATERIAL SPECIFICATIONS

Element Copper-nickel alloy or nickel-chrome alloy, depending on resistance value

Core Cordierite, steatite

Coating Special high temperature vitreous enamel

Standard Terminals Tinned alloy 42

Optional Terminals Alloy 42

Terminal Bands Alloy 42

Part Marking HEI, model, wattage, value, tolerance, date code

NON-INDUCTIVE

Models of equivalent physical and electrical specifications are available with non-inductive (Ayrton-Perry) winding. They are

identified by adding the letters “NI” to the end of the part number in the special section. For non-inductive models the maximum

resistance values are lower, see Standard Electrical Specifications table.

DERATING

120

RATED POWER IN %

100

80

60

40

20

0

0 50 100 150 200 250 300 350

25

AMBIENT TEMPERATURE IN °C

Revision: 03-Jun-16 5 Document Number: 31838

For technical questions, contact: ww2dresistors@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Legal Disclaimer Notice

www.vishay.com

Vishay

Disclaimer

ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROVE

RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively,

“Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained in any datasheet or in any other

disclosure relating to any product.

Vishay makes no warranty, representation or guarantee regarding the suitability of the products for any particular purpose or

the continuing production of any product. To the maximum extent permitted by applicable law, Vishay disclaims (i) any and all

liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special,

consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular

purpose, non-infringement and merchantability.

Statements regarding the suitability of products for certain types of applications are based on Vishay’s knowledge of

typical requirements that are often placed on Vishay products in generic applications. Such statements are not binding

statements about the suitability of products for a particular application. It is the customer’s responsibility to validate that a

particular product with the properties described in the product specification is suitable for use in a particular application.

Parameters provided in datasheets and / or specifications may vary in different applications and performance may vary over

time. All operating parameters, including typical parameters, must be validated for each customer application by the customer’s

technical experts. Product specifications do not expand or otherwise modify Vishay’s terms and conditions of purchase,

including but not limited to the warranty expressed therein.

Except as expressly indicated in writing, Vishay products are not designed for use in medical, life-saving, or life-sustaining

applications or for any other application in which the failure of the Vishay product could result in personal injury or death.

Customers using or selling Vishay products not expressly indicated for use in such applications do so at their own risk.

Please contact authorized Vishay personnel to obtain written terms and conditions regarding products designed for

such applications.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this document

or by any conduct of Vishay. Product names and markings noted herein may be trademarks of their respective owners.

© 2017 VISHAY INTERTECHNOLOGY, INC. ALL RIGHTS RESERVED

Revision: 08-Feb-17 1 Document Number: 91000

Potrebbero piacerti anche

- (SPN) On J1939 Data LinkDocumento107 pagine(SPN) On J1939 Data LinkAM76Nessuna valutazione finora

- PLLV Client Consent FormDocumento4 paginePLLV Client Consent Formapi-237715517Nessuna valutazione finora

- Grammar WorksheetsDocumento161 pagineGrammar WorksheetsKhánhNessuna valutazione finora

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Too Much Time in Social Media and Its Effects On The 2nd Year BSIT Students of USTPDocumento48 pagineToo Much Time in Social Media and Its Effects On The 2nd Year BSIT Students of USTPLiam FabelaNessuna valutazione finora

- LEBV4830Documento371 pagineLEBV4830anton100% (1)

- DS - F-12-0-001 Fenwal Heat DetectorDocumento6 pagineDS - F-12-0-001 Fenwal Heat DetectorElia Nugraha AdiNessuna valutazione finora

- Fine Fragrances After Shave, Eau de Parfum, Eau de Cologne, Eau de Toilette, Parfume Products (9-08)Documento6 pagineFine Fragrances After Shave, Eau de Parfum, Eau de Cologne, Eau de Toilette, Parfume Products (9-08)Mustafa BanafaNessuna valutazione finora

- ABAP On HANA Interview QuestionsDocumento26 pagineABAP On HANA Interview QuestionsNagesh reddyNessuna valutazione finora

- OSN 8800 6800 3800 V100R011C00 Alarms and Performance Events Reference 01Documento1.544 pagineOSN 8800 6800 3800 V100R011C00 Alarms and Performance Events Reference 01Oscar Behrens ZepedaNessuna valutazione finora

- Vishay Power ResistorsDocumento6 pagineVishay Power ResistorsSami Enis ArıoğluNessuna valutazione finora

- Sidac: (95 - 330 Volts)Documento6 pagineSidac: (95 - 330 Volts)Nithish NithiNessuna valutazione finora

- C10, C11Documento52 pagineC10, C11Mae MegumiNessuna valutazione finora

- Dsa00445142 (Rur640)Documento4 pagineDsa00445142 (Rur640)DanielNessuna valutazione finora

- Metering Class Current Transformer: Features 600V Class SpecificationsDocumento1 paginaMetering Class Current Transformer: Features 600V Class SpecificationsDavid RojasNessuna valutazione finora

- Usfull Solar Pump Inverter Catalog 2021Documento12 pagineUsfull Solar Pump Inverter Catalog 2021علاء البناء100% (1)

- SV Series - Special Medium Voltage Leaded Varistors: DescriptionDocumento4 pagineSV Series - Special Medium Voltage Leaded Varistors: DescriptionIgor PNessuna valutazione finora

- 22 08 09 Nord 18556010Documento5 pagine22 08 09 Nord 18556010Sebastián Felipe Argüello LópezNessuna valutazione finora

- FORA LED Flex High Power Flood Light Spec Sheet PDFDocumento7 pagineFORA LED Flex High Power Flood Light Spec Sheet PDFRoberto AlladoNessuna valutazione finora

- Siliicon Planar Zener Diodes BZX55C 500mW DO-35 Glass Axial PackageDocumento4 pagineSiliicon Planar Zener Diodes BZX55C 500mW DO-35 Glass Axial PackageRizky AnandaNessuna valutazione finora

- MoellerDocumento2 pagineMoellera safaieNessuna valutazione finora

- TAIKAI Group-CompressedDocumento27 pagineTAIKAI Group-CompressedGV TNessuna valutazione finora

- LED Custom Square Retrofit Kit LED SRK SeriesDocumento2 pagineLED Custom Square Retrofit Kit LED SRK Serieskelly DufourNessuna valutazione finora

- Capacitores Eletroliticos Panasonic PDFDocumento212 pagineCapacitores Eletroliticos Panasonic PDFJose Paulo MarcianoNessuna valutazione finora

- Reed Switch Magnetic Sensor For Airtec Slots Al 01Documento1 paginaReed Switch Magnetic Sensor For Airtec Slots Al 01ElectricalNessuna valutazione finora

- Capacitor Switching ContactorDocumento4 pagineCapacitor Switching ContactorBch Electric ltdNessuna valutazione finora

- Linde EMotion Inverters Datasheet enDocumento5 pagineLinde EMotion Inverters Datasheet engoegres0% (1)

- SI-8201L SankenelectricDocumento6 pagineSI-8201L SankenelectricErasmo Franco SNessuna valutazione finora

- IL1206AT, IL1207AT, IL1208AT: Vishay SemiconductorsDocumento9 pagineIL1206AT, IL1207AT, IL1208AT: Vishay SemiconductorsAhmed EmiraNessuna valutazione finora

- 2 KV AL Cable Datasheet - Priority CablesDocumento1 pagina2 KV AL Cable Datasheet - Priority CablesVipin KhandelwalNessuna valutazione finora

- WS-100 To WS-235: Arun SeriesDocumento3 pagineWS-100 To WS-235: Arun Seriesajitp123Nessuna valutazione finora

- STB10NK60Z, STP10NK60Z STW10NK60ZDocumento19 pagineSTB10NK60Z, STP10NK60Z STW10NK60ZАлексей ЧумаковNessuna valutazione finora

- Binder1 20Documento1 paginaBinder1 20theserviceNessuna valutazione finora

- Before Light-Tin After Matte-TinDocumento2 pagineBefore Light-Tin After Matte-TinMateo SudyNessuna valutazione finora

- Ac Watt Transducer ModelPC5Documento5 pagineAc Watt Transducer ModelPC5anon-657923Nessuna valutazione finora

- Selector Switches Data SheetDocumento5 pagineSelector Switches Data SheetIshak MohammedNessuna valutazione finora

- SIOV Metal Oxide Varistors: Data Sheet Data SheetDocumento11 pagineSIOV Metal Oxide Varistors: Data Sheet Data Sheetmaykel valdezNessuna valutazione finora

- 计量器具校验申请表 Calibration Application request-yahuiDocumento2 pagine计量器具校验申请表 Calibration Application request-yahuiSHAHID KHAN CHANNARNessuna valutazione finora

- Westinghouse Lighting Price List Outdoor Lighting Renewal Parts 7-70Documento8 pagineWestinghouse Lighting Price List Outdoor Lighting Renewal Parts 7-70Alan MastersNessuna valutazione finora

- Standard Coverage Sprinkler Quick Reference Guide: Light, Ordinary, and Extra HazardDocumento1 paginaStandard Coverage Sprinkler Quick Reference Guide: Light, Ordinary, and Extra HazardTaufik KurniawanNessuna valutazione finora

- 1N5712Documento7 pagine1N5712Jeetu AnjanaNessuna valutazione finora

- Bzx84C2V4-Au Series: Surface Mount Silicon Zener DiodesDocumento7 pagineBzx84C2V4-Au Series: Surface Mount Silicon Zener DiodesErasmo Franco SNessuna valutazione finora

- 20 Catalog Krisbow 9 WeldingDocumento14 pagine20 Catalog Krisbow 9 WeldingEnrique da MattaNessuna valutazione finora

- EFI ResistanceDocumento3 pagineEFI ResistanceMuni Muniyappan33% (3)

- EL EL EL EL Elastimold Astimold Astimold Astimold Astimold: 15kV Loadbreak Reducing Tap Plug 650ETPDocumento2 pagineEL EL EL EL Elastimold Astimold Astimold Astimold Astimold: 15kV Loadbreak Reducing Tap Plug 650ETPJonnyRcNessuna valutazione finora

- Functional Specification For Single Phase Overhead Type Distribution Transformers 5 167 Kva Ps201001enDocumento11 pagineFunctional Specification For Single Phase Overhead Type Distribution Transformers 5 167 Kva Ps201001enJorge Alexander Román MoralesNessuna valutazione finora

- Superseded: Not The Latest RevisionDocumento10 pagineSuperseded: Not The Latest RevisionjohovitchNessuna valutazione finora

- CATALOG OF Indicating Lamp & PushbuttonDocumento16 pagineCATALOG OF Indicating Lamp & PushbuttonAVIJIT MITRANessuna valutazione finora

- Info Ooacplt350 000eDocumento12 pagineInfo Ooacplt350 000eSkjhkjhkjhNessuna valutazione finora

- Huf75344G3, Huf75344P3: N-Channel Ultrafet Power Mosfet FeaturesDocumento10 pagineHuf75344G3, Huf75344P3: N-Channel Ultrafet Power Mosfet FeaturesChristina MullinsNessuna valutazione finora

- USFULL Solar Pump Inverter 2021 01Documento4 pagineUSFULL Solar Pump Inverter 2021 01hector ayalaNessuna valutazione finora

- IXYS HV MOSFETsDocumento17 pagineIXYS HV MOSFETsshahinNessuna valutazione finora

- Ficha Contactores HGC enDocumento14 pagineFicha Contactores HGC ensundewsNessuna valutazione finora

- PowerTrsGuide معادلات ترنزستورات البور الحديثةDocumento14 paginePowerTrsGuide معادلات ترنزستورات البور الحديثةAhmed FawzyNessuna valutazione finora

- Datasheet Familia P10NK60 - B10NK60 (Z y ZFP)Documento24 pagineDatasheet Familia P10NK60 - B10NK60 (Z y ZFP)Pablo José Rodriguez HerreraNessuna valutazione finora

- K - TG-F832E Sight Flow GlassDocumento7 pagineK - TG-F832E Sight Flow GlassBrion Bara IndonesiaNessuna valutazione finora

- We en Web in Ar Sic Mosfet 1638931895460Documento29 pagineWe en Web in Ar Sic Mosfet 1638931895460Алексей ЯмаNessuna valutazione finora

- AC1240 Jan 2012Documento169 pagineAC1240 Jan 2012taoistpengNessuna valutazione finora

- Rfg50N06Le, Rfp50N06Le, Rf1S50N06Lesm: 50A, 60V, 0.022 Ohm, Logic Level N-Channel Power Mosfets FeaturesDocumento9 pagineRfg50N06Le, Rfp50N06Le, Rf1S50N06Lesm: 50A, 60V, 0.022 Ohm, Logic Level N-Channel Power Mosfets FeaturesrwylieNessuna valutazione finora

- Price List: Havells Flexible Industrial Cables - Flame Retardant - 0112KDocumento2 paginePrice List: Havells Flexible Industrial Cables - Flame Retardant - 0112Kphanendra2Nessuna valutazione finora

- Datasheet LM337 XDocumento4 pagineDatasheet LM337 Xhydraplus2Nessuna valutazione finora

- 00BC0W PDFDocumento10 pagine00BC0W PDFReaper LazareusNessuna valutazione finora

- Solar CellDocumento20 pagineSolar Cellaisya mutia syafiiNessuna valutazione finora

- Jameco Componentes 141catalogDocumento172 pagineJameco Componentes 141catalogwalterjnr100% (1)

- ToftosDocumento5 pagineToftosPalmNessuna valutazione finora

- AC FusesDocumento16 pagineAC Fusesankitkumawat622Nessuna valutazione finora

- Nature Hill Middle School Wants To Raise Money For A NewDocumento1 paginaNature Hill Middle School Wants To Raise Money For A NewAmit PandeyNessuna valutazione finora

- High Performance Computing in Power System Applications.: September 1996Documento24 pagineHigh Performance Computing in Power System Applications.: September 1996Ahmed adelNessuna valutazione finora

- TP913Documento5 pagineTP913jmpateiro1985Nessuna valutazione finora

- Nelson/Salmo Pennywise March 15, 2016Documento48 pagineNelson/Salmo Pennywise March 15, 2016Pennywise PublishingNessuna valutazione finora

- Modeling Cover Letter No ExperienceDocumento7 pagineModeling Cover Letter No Experienceimpalayhf100% (1)

- Vitus Bering, Centre For Higher Education: Jens Bertelsen & Jens Peder PedersenDocumento50 pagineVitus Bering, Centre For Higher Education: Jens Bertelsen & Jens Peder PedersenAnca IscruNessuna valutazione finora

- Sec 11Documento3 pagineSec 11Vivek JhaNessuna valutazione finora

- Muhammad Safuan Othman (CD 4862)Documento24 pagineMuhammad Safuan Othman (CD 4862)Andy100% (1)

- Magicolor2400 2430 2450FieldSvcDocumento262 pagineMagicolor2400 2430 2450FieldSvcKlema HanisNessuna valutazione finora

- Mysuru Royal Institute of Technology. Mandya: Question Bank-1Documento2 pagineMysuru Royal Institute of Technology. Mandya: Question Bank-1chaitragowda213_4732Nessuna valutazione finora

- Gamboa-Roces vs. Judge PerezDocumento1 paginaGamboa-Roces vs. Judge PerezDiane Dee YaneeNessuna valutazione finora

- 3d Mug Tutorial in 3d MaxDocumento5 pagine3d Mug Tutorial in 3d MaxCalvin TejaNessuna valutazione finora

- BPI vs. Posadas, G.R. No. L - 34583, 1931Documento8 pagineBPI vs. Posadas, G.R. No. L - 34583, 1931Nikko AlelojoNessuna valutazione finora

- Morales v. Lockheed Martin, 10th Cir. (2000)Documento2 pagineMorales v. Lockheed Martin, 10th Cir. (2000)Scribd Government DocsNessuna valutazione finora

- OPERATING MANUAL Micro Powder MillDocumento51 pagineOPERATING MANUAL Micro Powder MillSher AhmadNessuna valutazione finora

- EPM Cloud Tax Reporting Overview - EMEA Training May 2020Documento25 pagineEPM Cloud Tax Reporting Overview - EMEA Training May 2020zaymounNessuna valutazione finora

- Chapter 01Documento26 pagineChapter 01zwright172Nessuna valutazione finora

- HRM Ass1Documento3 pagineHRM Ass1asdas asfasfasdNessuna valutazione finora

- Burndown Sample ClayDocumento64 pagineBurndown Sample ClaybluemaxNessuna valutazione finora

- Pac All CAF Subject Referral Tests 1Documento46 paginePac All CAF Subject Referral Tests 1Shahid MahmudNessuna valutazione finora

- Unilever Financial PerformanceDocumento9 pagineUnilever Financial PerformanceAbdul QayumNessuna valutazione finora

- Transport StrikeDocumento9 pagineTransport StrikeYsrael Von ArcillaNessuna valutazione finora