Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

MV Motor Protection PDF

Caricato da

Oliver HermosaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MV Motor Protection PDF

Caricato da

Oliver HermosaCopyright:

Formati disponibili

Feature

by Mark Standifer, Shermco Industries

Medium-Voltage Motor Starters

and Protection

W

hat would industry do without motors? Can you imagine the energized. Door interlocks are used

processes and products that would not be available to us today if to insure that the starter is shutdown

and racked out from a live bus before

we did not utilize motors of all sizes and types? Of course there one can gain access to them.

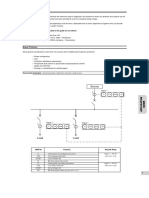

must be some safe way of controlling and protecting the large investments and A modern day 5 kV medium-volt-

age starter as seen in Figure 1 shows

maintaining a safe environment. Medium-voltage (2.3 kV to 15 kV) starters have the current limiting fuses which are

been around for many years and we have very complex ways of controlling and bolted into place, the isolation switch,

protecting the circuits and the motors. The higher voltage presents higher levels the operation handle, and the vacuum

contactor. When the operation handle

of safety concern and manufacturers have incorporated interlocks designed to is placed in the off position, the in-

protect us. Those methods include both electrical and mechanical interlocks, all coming source supply is isolated from

of which an electrician or technician must have a full understanding of how they the starter by the isolation switch and

the components in the cubicle are

work and how to work safely. Medium-voltage motor starters have interlocks grounded for safety. The door inter-

and protection not usually found in low-voltage equipment. This article will lock releases the door to the power

components allowing access to the

concentrate on mechanical and electrical interlocks that all ANSI compliant fuses, current transformers, contac-

medium-voltage motor starting equipment must have as well as motor protection tor, and motor cable connections. The

that includes thermal algorithms, number-of-starts limitation, negative sequence motor control circuits and protection

are installed in a separate low-voltage

protection, resistance temperature detectors (RTDs), and more. compartment above medium-voltage

Medium-voltage compartment. The control compart-

starters usually have ment allows safe troubleshooting

current limiting fuses of the circuits without exposing the

for motor protection technician to the higher voltages.

which respond ex- From a safety aspect, working

tremely fast to protect around medium-voltage equipment

the equipment from requires a greater knowledge base

large current levels of the switchgear and equipment

during faults on the and heightened awareness for safety.

system. The fuses are NFPA 70E places the typical job tasks

large in comparison to for medium-voltage motor switchgear

low-voltage fuses, and to be levels 3 to 4 which require FR

they must be installed rated clothing and arc-flash suits to

in such a manner as be worn during testing, racking, and

to keep the techni- troubleshooting. Door interlocks,

cian from obtaining keyed interlocks, electrical interlocks,

Figure 1 and more must be fully understood and

access when they are

www.netaworld.org Fall 2010 NETA WORLD 1

Upper door interlocks prevent access to compart-

ments that are energized with higher voltages.

Figure 2

never bypassed without the required skills and knowledge

of their function and purpose and then only performed by

qualified personnel.

The use of appropriate test instruments designed for this

application cannot be overstressed. Shock hazards must be Figure 4

observed and proper voltage-rated PPE must be used.

Additional protection features include:

Start inhibit for number of starts

Start inhibit for available thermal capacity

RTD temperature protection

50 - Instantaneous overcurrent

51 – Time delayed overcurrent

27 – Undervoltage

59 – Overvoltage

67 – Directional overcurrent

46 – Negative sequence overcurrent

Figure 3

32 – Reverse Power

40 – Loss of Field

Medium-Voltage Starter Protection 49 – Thermal Capacity

Many different types of relays for motor and motor 60 – Voltage Balance

circuit protection are installed on medium-voltage starters

such as shown below. Microprocessor relays have provided 81 – Frequency

protection for motors at new levels that offer some 75 pro- 87 – Differential

tection function including motor starting limitation and 86 – Lockout Relay

temperature monitoring to name a few. Microprocessor

based relays can learn the normal starting parameters and The NEMA device function numbers listed above are

cooling times of the motor. All modern relays have computer only a few of the protection functions that can be used to

interface such as RS-232 and RS-485 communications that protect a motor.

allow users to set parameters, look at real time running data,

observe vectors of current and voltages, diagnose complex

problems by observing event records and sequence of events.

2 NETA WORLD Fall 2010 www.netaworld.org

When applying protective relays to motors or any other Starting times depend on motor design and load torque

equipment, a question to be answered is “How much pro- characteristics and must be determined for each application.

tection is enough”? The answer may depend on rewind cost, Although starting times of 2 to 20 seconds are common,

loss of production, effect on downtime, the consequences high inertia loads may take several minutes to bring to full

of a motor failure on the electrical system and process and speed. Starting time is increased if bus voltage is less than

other considerations. nominal.

Differential protection is used on motors where the avail- The life of the motor is reduced if the winding tempera-

able short-circuit current is close to the value of locked-rotor tures are allowed to exceed their insulation class levels for

current. It is also frequently used because of the ability to a significant time. It is usually assumed that for every 10

provide extremely sensitive settings as compared to phase degrees C above the design temperature limit, the life of

overcurrent settings. Differential protection is always a pre- the motor is reduced by a factor of 2.6

ferred protection. However, it costs more than instantaneous When normal cooling conditions and ambient tempera-

overcurrent relaying because all six leads must be brought tures exist, the temperature of the stator winding is directly

out of the motor to the terminal box and additional current related to the stator current, and the running thermal over-

transformers are required. The selection of the protective load limit can be shown on a time-current plot as recom-

relays must include differential protection, which may add mended in IEEE STD 620. Running thermal overload can

to the cost. thus be provided by an overcurrent relay which has a time-

When a motor stator winding is energized with the rotor current characteristic similar to the thermal overload limit.

stationary, stator winding currents may range from three to The protection provided for any motor may be deter-

seven times rated full-load value depending on motor design mined by a mixture of things such as the motor cost, the

and supply system impedance. Actual values of locked-rotor motor application, the criticality of the load, repair costs,

current are part of the motor data supplied by the motor the process down time to repair or replace the motor, and

manufacturer. Heating in the stator winding, proportional many more!

to I2t, is 10 to 50 times rated conditions and the winding

is without benefit of the ventilation normally produced by

Mark S. Standifer is currently working as a Senior

rotation of the rotor. Training Specialist for Shermco Industries and

works out of Oklahoma City. Mark travels all over

the country teaching classes from electrical safety to

power generation to clients including large utilities

such as Exelon Corp., Dynegy, NY, Tractor Bell,

TX., PGE, PP&L and many others. He conducts

speaking engagements on electrical safety at safety

conferences, and is considered to be one of the most

knowledgeable trainers on NFPA70E and power

generation. Mark has traveled from the East Coast to the West and to

Canada, Hawaii and Alaska in conducting training for electricians.

U.S. Navy Class A and Class B Electricians School, , Nuclear Plant

Systems, Programmable Controllers, Circuit Breaker Maintenance,

Watthour Meter Maintenance, Electrical System Maintenance I &

II, Coordination, Utility Protective Relay Maintenance, DC Drives,

Applied Protective Relaying, Gas Turbines, Electrohydraulic Governor

Systems, Stationary Power, Nuclear Power Plant Operator Course, and

Thermographic Survey, Level One.

Associations: INPO Nuclear Instructor, American Society of Training

& Development, International Association of Electrical Inspectors, and

WISHA, Washington Oregon, Idaho, Nevada, Wyoming, and Alaska

State approved instructor.

Figure 5

Depending on the design, a motor may be thermally

limited by the stator or the rotor during locked-rotor con-

ditions. The motor manufacturer can furnish the allowable

locked-rotor time only after the motor design is completed.

This is given as time at rated locked-rotor current starting

from either rated ambient temperature or rated operating

temperature also referred to as cold stall time or hot stall

time. It also is given as part of the motor time-current curve

defined by IEEE Standard 620-1996.

www.netaworld.org Fall 2010 NETA WORLD 3

Potrebbero piacerti anche

- 7UM6 Gen Prot-Schemes EDocumento10 pagine7UM6 Gen Prot-Schemes EruslaninstNessuna valutazione finora

- Item 1 - Transformer Rectifier UnitDocumento8 pagineItem 1 - Transformer Rectifier UnitNoor A QasimNessuna valutazione finora

- Protection Phillosphy With ScadaDocumento11 pagineProtection Phillosphy With ScadaPrashant TrivediNessuna valutazione finora

- Canada Power Sf6Documento22 pagineCanada Power Sf6alfonso.parkerNessuna valutazione finora

- Dry Type Transformer For Mangdechu PDFDocumento6 pagineDry Type Transformer For Mangdechu PDFRinzinNessuna valutazione finora

- 11kV SPBD General TechnicalDocumento12 pagine11kV SPBD General TechnicalNihar SenapatiNessuna valutazione finora

- Cap P13Documento5 pagineCap P13Siva NandhamNessuna valutazione finora

- IEEMA Article On Over Current ProtectionDocumento5 pagineIEEMA Article On Over Current ProtectionHari Krishna.MNessuna valutazione finora

- Type P8n, PQ8n, PN8n: Auxiliary RelayDocumento7 pagineType P8n, PQ8n, PN8n: Auxiliary RelayDinesh ThevanNessuna valutazione finora

- National Grid: Checklist For Commissioning of Oil-Immersed Power TransformerDocumento8 pagineNational Grid: Checklist For Commissioning of Oil-Immersed Power TransformerSanthosh Kumar VinayagamNessuna valutazione finora

- Data Book-CVT PDFDocumento97 pagineData Book-CVT PDFĐỗ Hồng Sơn100% (1)

- Easun Reyrolle: Figure 11. Star Connected Bank, Two Limbs Per PhaseDocumento20 pagineEasun Reyrolle: Figure 11. Star Connected Bank, Two Limbs Per PhaseE.AvinashNessuna valutazione finora

- Ici-C&C/Seupptcl/A - S (Sup.) /2011-12/001: Tested by WitnessedDocumento7 pagineIci-C&C/Seupptcl/A - S (Sup.) /2011-12/001: Tested by WitnessedkamarajkanNessuna valutazione finora

- IEEE STD C57.19.00-2004 (CN - EN)Documento18 pagineIEEE STD C57.19.00-2004 (CN - EN)pdrich8Nessuna valutazione finora

- Site Test Report For Skid Mounted SubstationDocumento12 pagineSite Test Report For Skid Mounted SubstationSoumya BhowmickNessuna valutazione finora

- 11 KV Bay EquipmentDocumento22 pagine11 KV Bay EquipmentSudhir ShindeNessuna valutazione finora

- ! - 1979 - Drouet, M., & Nadeau, F. - Pressure Waves Due To Arcing Faults in A SubstationDocumento4 pagine! - 1979 - Drouet, M., & Nadeau, F. - Pressure Waves Due To Arcing Faults in A SubstationMikeNessuna valutazione finora

- Auto Transformer Protection SchemesDocumento3 pagineAuto Transformer Protection SchemesArogya Raju PudhotaNessuna valutazione finora

- BCUDocumento8 pagineBCUJigyesh SharmaNessuna valutazione finora

- ABB 11KV Vmax VCB CatalogueDocumento40 pagineABB 11KV Vmax VCB CatalogueDan Juson60% (5)

- Trip Circuit Supervisory Relay: Type: ATSR31ADocumento3 pagineTrip Circuit Supervisory Relay: Type: ATSR31ADarius Balakauskas100% (1)

- REL 531-1-0 Line Distance Protection TerminalDocumento20 pagineREL 531-1-0 Line Distance Protection Terminalsenthil kumarNessuna valutazione finora

- Guaranteed Technical Particulars of Vacuum Interrupter Type Vg4-02 Equivalent To V-207 GBDocumento3 pagineGuaranteed Technical Particulars of Vacuum Interrupter Type Vg4-02 Equivalent To V-207 GBLalit SoniNessuna valutazione finora

- IRI PRO V3 CatalogueDocumento14 pagineIRI PRO V3 CatalogueThomas Joseph100% (2)

- A New Approach To Arc Resistance CalculationDocumento7 pagineA New Approach To Arc Resistance Calculationautomation vguardNessuna valutazione finora

- Transformer Design (Electrical) WO. No. Guaranteed Technical Particulars Bharat Bijlee Ltd. Transformer DivisionDocumento3 pagineTransformer Design (Electrical) WO. No. Guaranteed Technical Particulars Bharat Bijlee Ltd. Transformer Divisionswarupkumarnayak100% (1)

- Relay Settings of Electrical GeneratorDocumento21 pagineRelay Settings of Electrical GeneratormagrinraphaelNessuna valutazione finora

- GTP of 132 KV CT & PTDocumento5 pagineGTP of 132 KV CT & PTgohilnarendraNessuna valutazione finora

- Commissioning of DAVRDocumento70 pagineCommissioning of DAVRPMG Bhuswal Project100% (1)

- CA VD4-50kA (EN) Y 1VCP000001Documento144 pagineCA VD4-50kA (EN) Y 1VCP000001linh tran100% (1)

- DBR Elec CCPPDocumento29 pagineDBR Elec CCPPParmeshwar Nath TripathiNessuna valutazione finora

- A3 - Drawing ROSE MALL, KYLMDocumento8 pagineA3 - Drawing ROSE MALL, KYLMHafiz RahimNessuna valutazione finora

- Simoprime Catalog English Aug2010Documento16 pagineSimoprime Catalog English Aug2010muktivarNessuna valutazione finora

- VCB PDFDocumento6 pagineVCB PDFSHAJAHANNessuna valutazione finora

- DGA of CT OilDocumento13 pagineDGA of CT Oilraza239Nessuna valutazione finora

- Solkor Application Guide 2003 4Documento32 pagineSolkor Application Guide 2003 4rashid rahmanNessuna valutazione finora

- 11 KV HT Panel ReportDocumento66 pagine11 KV HT Panel ReportVishakha PandeyNessuna valutazione finora

- Technical Data Sheet - 250kva TransformersDocumento2 pagineTechnical Data Sheet - 250kva TransformerspavanNessuna valutazione finora

- 07a Backup OCEF Relay - Tech. Data Check List CompletedDocumento6 pagine07a Backup OCEF Relay - Tech. Data Check List CompletedAnupam0103Nessuna valutazione finora

- Diff Protection PDFDocumento14 pagineDiff Protection PDFarunNessuna valutazione finora

- 33 KV Outdoor VCB Pv1750bDocumento4 pagine33 KV Outdoor VCB Pv1750bAnoop Kumar PandayNessuna valutazione finora

- Tested by M/S Siemens Organized by M/S Emc Witnessed by M/S Pgcil Name G Ramesh Designation SignatureDocumento2 pagineTested by M/S Siemens Organized by M/S Emc Witnessed by M/S Pgcil Name G Ramesh Designation SignatureRK KNessuna valutazione finora

- KKMurty Sir Tutorial On Differential Protn CKT - IEEMA Journal May'22Documento6 pagineKKMurty Sir Tutorial On Differential Protn CKT - IEEMA Journal May'22Amit BiswasNessuna valutazione finora

- Approved - 400kV LADocumento22 pagineApproved - 400kV LAGuru MishraNessuna valutazione finora

- Pdtspec4 - 01 (MIB 202) PDFDocumento4 paginePdtspec4 - 01 (MIB 202) PDFAnonymous LAgHIKY65i100% (1)

- Instrument CablesDocumento2 pagineInstrument CableskapilNessuna valutazione finora

- Protocol Convert PCS-9794Documento3 pagineProtocol Convert PCS-9794ganeshNessuna valutazione finora

- Heat DissipationDocumento17 pagineHeat DissipationAsif SajwaniNessuna valutazione finora

- Transmission Line ProtectionDocumento38 pagineTransmission Line ProtectionE.AvinashNessuna valutazione finora

- GTP BatteryDocumento17 pagineGTP Batteryraj_stuff006Nessuna valutazione finora

- Transformer ProtectionDocumento19 pagineTransformer ProtectionBassem MostafaNessuna valutazione finora

- Introductory: Capacity They Momentarily Interrupt TheyDocumento19 pagineIntroductory: Capacity They Momentarily Interrupt Theysravani dhulipallaNessuna valutazione finora

- Ee 16 - Finals ReviewerDocumento13 pagineEe 16 - Finals ReviewerSantos, Jewella C.Nessuna valutazione finora

- Beri FINALSDocumento31 pagineBeri FINALSSantos, Jewella C.Nessuna valutazione finora

- z131 148 PDFDocumento19 paginez131 148 PDFgulatimanish1985Nessuna valutazione finora

- PR-14D Operating Instructions: 144 X 144 X 50 MMDocumento2 paginePR-14D Operating Instructions: 144 X 144 X 50 MMMladen MuskinjaNessuna valutazione finora

- Upustvo Za Regulator PR-14DDocumento2 pagineUpustvo Za Regulator PR-14DMarko KosanovićNessuna valutazione finora

- MSAN-139: Protection Networks For Telecommunications SystemsDocumento8 pagineMSAN-139: Protection Networks For Telecommunications Systemsseyed mohammadNessuna valutazione finora

- Paul Gill - Eqpt Maint & TestingDocumento1 paginaPaul Gill - Eqpt Maint & TestingOliver HermosaNessuna valutazione finora

- Copper Bus Bar Ampacity - TablesDocumento4 pagineCopper Bus Bar Ampacity - TablesOliver HermosaNessuna valutazione finora

- Panel Wiring Cable SpecsDocumento8 paginePanel Wiring Cable SpecsOliver HermosaNessuna valutazione finora

- Turn StilDocumento3 pagineTurn StilOliver HermosaNessuna valutazione finora

- HV Sheath Voltage Calculation - SampleDocumento8 pagineHV Sheath Voltage Calculation - SampleOliver HermosaNessuna valutazione finora

- 3PH Electric Chain Hoist ManualDocumento48 pagine3PH Electric Chain Hoist ManualOliver HermosaNessuna valutazione finora

- Cutler Hammer Bus DuctsDocumento28 pagineCutler Hammer Bus DuctsOliver HermosaNessuna valutazione finora

- Farnell SS Cable TiesDocumento5 pagineFarnell SS Cable TiesOliver HermosaNessuna valutazione finora

- Schneider (1000A) Bus DuctDocumento342 pagineSchneider (1000A) Bus DuctOliver HermosaNessuna valutazione finora

- Tyco Plastic ConduitsDocumento6 pagineTyco Plastic ConduitsOliver HermosaNessuna valutazione finora

- Steel Conduit Install Guide PDFDocumento32 pagineSteel Conduit Install Guide PDFOliver Hermosa100% (1)

- Cannon Cable PrinterDocumento6 pagineCannon Cable PrinterOliver HermosaNessuna valutazione finora

- Cannon Cable Printer PDFDocumento2 pagineCannon Cable Printer PDFOliver HermosaNessuna valutazione finora

- Apollo Swing GateDocumento25 pagineApollo Swing GateOliver HermosaNessuna valutazione finora

- Stauff Surface Cable ClampsDocumento54 pagineStauff Surface Cable ClampsOliver HermosaNessuna valutazione finora

- Bentel by Tyco Fire Catalgoye PDFDocumento36 pagineBentel by Tyco Fire Catalgoye PDFOliver HermosaNessuna valutazione finora

- Caddy Electrical FixingsDocumento36 pagineCaddy Electrical FixingsOliver HermosaNessuna valutazione finora

- Manual Intelligent Barriers Instruction: Pdf 文件使用 "Pdffactory Pro" 试用版本创建Documento14 pagineManual Intelligent Barriers Instruction: Pdf 文件使用 "Pdffactory Pro" 试用版本创建Oliver HermosaNessuna valutazione finora

- Labgear Communication Terminals PDFDocumento11 pagineLabgear Communication Terminals PDFOliver HermosaNessuna valutazione finora

- Cable Gland Size TableDocumento1 paginaCable Gland Size TableOliver HermosaNessuna valutazione finora

- GE Harmonic Mitigating TransformerDocumento4 pagineGE Harmonic Mitigating TransformerOliver HermosaNessuna valutazione finora

- Timers and Clock ZT1490Documento2 pagineTimers and Clock ZT1490Oliver HermosaNessuna valutazione finora

- Discount Steel: Gage Number ConversionDocumento1 paginaDiscount Steel: Gage Number ConversionOliver HermosaNessuna valutazione finora

- ABB Serial Data Documentation PDFDocumento16 pagineABB Serial Data Documentation PDFOliver HermosaNessuna valutazione finora

- Accessories: International IncDocumento2 pagineAccessories: International IncOliver HermosaNessuna valutazione finora

- CSE101 Computer Programming: Lecture #0Documento28 pagineCSE101 Computer Programming: Lecture #0t iwariNessuna valutazione finora

- Fundamentals of ANNDocumento213 pagineFundamentals of ANNJosi MoNessuna valutazione finora

- Beluru Sudarshana Profile in BriefDocumento1 paginaBeluru Sudarshana Profile in BriefbeluruNessuna valutazione finora

- 1 IntroductionDocumento45 pagine1 IntroductionSylvester BelloNessuna valutazione finora

- Indian Company List - MalaysiaDocumento21 pagineIndian Company List - MalaysiaNavajyoti DasNessuna valutazione finora

- Oracle Database Disaster Recovery Using Dell Storage Replication SolutionsDocumento25 pagineOracle Database Disaster Recovery Using Dell Storage Replication SolutionsvivekNessuna valutazione finora

- EMC Cloud Solution - Security AssignmentDocumento40 pagineEMC Cloud Solution - Security AssignmentwhatstubesNessuna valutazione finora

- 3.4.4 Lab - Research Networking StandardsDocumento5 pagine3.4.4 Lab - Research Networking StandardsCT KHNessuna valutazione finora

- RULE7-8 ProblemAnalysis PDFDocumento109 pagineRULE7-8 ProblemAnalysis PDFMhae Torres100% (1)

- C674x CPU FeaturesDocumento23 pagineC674x CPU FeaturesbibiameenaNessuna valutazione finora

- Nursing Informatics 2018Documento66 pagineNursing Informatics 2018Undher Ground Maker100% (5)

- Systems Engineering: Designing, Implementing, Deploying and Operating Systems Which Include Hardware, Software and PeopleDocumento47 pagineSystems Engineering: Designing, Implementing, Deploying and Operating Systems Which Include Hardware, Software and Peoplebilal ahmadNessuna valutazione finora

- BRKRST-2338 - 2014 San FranciscoDocumento110 pagineBRKRST-2338 - 2014 San FranciscofezzfezzNessuna valutazione finora

- Ds Futro x923Documento6 pagineDs Futro x923conmar5mNessuna valutazione finora

- Hololens - Presentation With VideoDocumento23 pagineHololens - Presentation With VideoAkshit GuptaNessuna valutazione finora

- Training Calendar 2011Documento44 pagineTraining Calendar 2011riteshsamantray521383Nessuna valutazione finora

- CAA66 ManualDocumento52 pagineCAA66 Manualferna2420Nessuna valutazione finora

- Elwave ManualDocumento109 pagineElwave ManualNo Name100% (1)

- Cloud Native AttitudeDocumento28 pagineCloud Native AttitudeRaghu VeerNessuna valutazione finora

- Prinect Metadimension Manual UsoDocumento2 paginePrinect Metadimension Manual UsohdzsNessuna valutazione finora

- SEO AdTech Dave ChaffeyDocumento44 pagineSEO AdTech Dave ChaffeysrinivasNessuna valutazione finora

- Knowledge 1Documento1 paginaKnowledge 1benciusilviuNessuna valutazione finora

- Observed Impact of Internet Café Near The School Vicinity To The Students Academics Performances On VnhsDocumento19 pagineObserved Impact of Internet Café Near The School Vicinity To The Students Academics Performances On VnhsMichelle Renee DaqueNessuna valutazione finora

- Lock RekeyingDocumento17 pagineLock RekeyingPrathusha RNessuna valutazione finora

- Benchmark - Big Haul Manual.1733Documento20 pagineBenchmark - Big Haul Manual.1733James GillenwaterNessuna valutazione finora

- Data Sheet 6ES7234-4HE32-0XB0: General InformationDocumento4 pagineData Sheet 6ES7234-4HE32-0XB0: General Informationnik amirulNessuna valutazione finora

- 000 J PQP 50001 001 R0aDocumento11 pagine000 J PQP 50001 001 R0aHerwin MaghinayNessuna valutazione finora

- Manual Swan Quad CrowDocumento2 pagineManual Swan Quad CrowApex PredatorNessuna valutazione finora