Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ATT01 HTCT692232V0001 B Recommended Inspections

Caricato da

Fadli FadliCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ATT01 HTCT692232V0001 B Recommended Inspections

Caricato da

Fadli FadliCopyright:

Formati disponibili

1 Recommended Inspections

1.1 Type of inspections

There are three different types of inspections:

• A-Inspection, see "A-Inspection" on page 1-4

• B-Inspection, see "B-Inspection" on page 1-14

• C-Inspection, see “Dismantling & Reassembly-documents”

1.1.1 Inspection methodology

• Maintenance work can be optimized when regular inspections are performed at

appropriate intervals on the right components and operating data are continuously

recorded and analyzed.

• Such scheduled checks of the gas turbine unit are aimed at preventing, wherever

possible, unscheduled outages and assuring a long-term high availability of the

plant.

• Undertaken at regular intervals they allow prediction of the work required at the

next inspection and planning, including just in time delivery of required material and

replacement parts.

• Arrangements for inspections and maintenance should be stated sufficiently far in

advance and in close co-operation between the owner and ALSTOM to enable

proper planning of details for the performance of inspection and eventual corrective

action, and thus a short down-time for the gas turbine set.

1.1.2 Duration of the inspections

Note

For the planning of the inspections please contact your nearest ALSTOM Customer

Service Department for more information.

The duration of a gas turbine inspection depends essentially on the following factors:

• Type of inspection

• Capacity of inspection staff

• Crew qualification

• Inspection planning (inclusive of recommissioning planning)

• Availability and condition of tools, consumables, repair parts and crane

GT13E2 Preventive Maintenance HTCT 692 232 V0001B en 1-1

Recommended Inspections November 2007

© 2007 ALSTOM. All rights reserved. The information in this document is provided for information purposes only. Site-specific deviations are possible. The descriptions do not constitute any

legally binding assurance of certain properties, qualities and/or scope of delivery. Any work described in this manual must be carried out solely under the supervision of personnel expressly

authorized by ALSTOM. Failure to comply with this requirement shall void any warranties, guarantees, representations, or other types of liability which ALSTOM may have given or

undertaken. Subject to change without notice.

1 Recommended Inspections

1.1 Type of inspections

1.1.3 Preparation for inspections

Safety instructions

All personnel working with or at the machine must have read and understood the

safety instruction manual, which is part of the overall customer documentation set.

A thorough preparation is key to a successful and expedient execution of the A-, B- and

C-Inspections. Focus areas include:

• Issue a detailed timeline/work program for the expected work scope and workflow.

Focusing on a diligent engine disassembly for a C-Inspection will maximize the

time available for inspection and corrective actions. ALSTOM can assist with this

planning. The detailed program should show any additional time required for

implementation of improvements or upgrades, or corrective actions in response to

condition assessment performed during earlier scheduled visual inspections and

from analysis of operating data.

• Determination of the staffing requirements for such work based on the time

schedule and the work program. The staffing plan should establish who supplies

personnel (ALSTOM, Owner, the Operating Company and/or outside contractors),

what professional skills are required at what time and the working hours per day.

Familiarization with the plant should be undertaken and health and safety

instructions are mandatory for all people working on the A-, B- or C-Inspection

programmes.

1.1.4 Test certificates

Test certificates

The test certificates are not part of this manual and are available on request from

ALSTOM.

Inspections and checks, carried out during maintenance tasks, are detailed in the

inspection instructions.

Use copies of the test certificates and Inspection Records to record the results of the

inspection and checks. Forward the completed forms to the ALSTOM Service

Department.

1-2 HTCT 692 232 V0001B en GT13E2 Preventive Maintenance

November 2007 Recommended Inspections

© 2007 ALSTOM. All rights reserved. The information in this document is provided for information purposes only. Site-specific deviations are possible. The descriptions do not constitute any

legally binding assurance of certain properties, qualities and/or scope of delivery. Any work described in this manual must be carried out solely under the supervision of personnel expressly

authorized by ALSTOM. Failure to comply with this requirement shall void any warranties, guarantees, representations, or other types of liability which ALSTOM may have given or

undertaken. Subject to change without notice.

Recommended Inspections 1

Type of inspections 1.1

Blank Page

GT13E2 Preventive Maintenance HTCT 692 232 V0001B en 1-3

Recommended Inspections November 2007

© 2007 ALSTOM. All rights reserved. The information in this document is provided for information purposes only. Site-specific deviations are possible. The descriptions do not constitute any

legally binding assurance of certain properties, qualities and/or scope of delivery. Any work described in this manual must be carried out solely under the supervision of personnel expressly

authorized by ALSTOM. Failure to comply with this requirement shall void any warranties, guarantees, representations, or other types of liability which ALSTOM may have given or

undertaken. Subject to change without notice.

1 Recommended Inspections

1.2 A-Inspection

1.2 A-Inspection

DANGER

Confined Space

Personnel can be killed or seriously injured

Use only low voltage (less than 25V) electrical light

Make sure that the gas turbine has cooled down (TAT at least <50°C)

Wear safety equipment as required by local authorities

Be sure that there is no gas and/or fuel in the gas turbine

DANGER

Turning Rotor

Personnel can be killed or seriously injured

Always make sure that no unwanted turning of the rotor is possible

Do not wear jewelry and any loose fitting clothing that may get caught in the rotor

blades.

Caution

Foreign objects inside thermal block (gas turbine)

Serious damage will be caused to the gas turbine if it is subsequently operated or

turned by hand with foreign objects left inside the combustor

• Empty your pockets before you enter into the gas turbine

• Do not leave tools inside the turbine

• Check the entire area for foreign objects and remove them before exiting

Note

The installation preparing procedure for works (draining, purging, cleaning before and

after works, testing, disconnecting etc.) and safety measures for those works are not

subject of this document and should fulfill standard procedure for performing works

during erection phase or on installation in use.

Note

On site, all regulations of ALSTOM, the local legal regulations and the specific safety

regulations of the sub-contractor must all be considered. In each case, the higher

authority must be taken.

A-Inspections are regularly scheduled checks on the gas turbine set, involving mainly

the hot gas path parts in the gas turbine.

The inspection is used for:

• Early identification of changes in the condition of parts in the hot gas path.

• Initiation of rectification action as may be required.

1-4 HTCT 692 232 V0001B en GT13E2 Preventive Maintenance

November 2007 Recommended Inspections

© 2007 ALSTOM. All rights reserved. The information in this document is provided for information purposes only. Site-specific deviations are possible. The descriptions do not constitute any

legally binding assurance of certain properties, qualities and/or scope of delivery. Any work described in this manual must be carried out solely under the supervision of personnel expressly

authorized by ALSTOM. Failure to comply with this requirement shall void any warranties, guarantees, representations, or other types of liability which ALSTOM may have given or

undertaken. Subject to change without notice.

Recommended Inspections 1

A-Inspection 1.2

• Checking in operation settings important for availability.

• Obtaining an overall impression of the condition of the gas turbine unit

The unit is not disassembled for this purpose (only the combustion chamber should be

opened). Visual access to the blading is possible by boroscope openings, through the

combustor and the exhaust gas diffuser inspection hatches.

The main objectives are:

• Assessment of the overall condition of gas turbine hot-gas-path parts, compressor

inlet and auxiliaries by means of inspection aid provisions (e.g. boroscope), but

without engine disassembly.

• Determine the actual maintenance work to be performed during the C-Inspection.

• Carry out minor re-calibration, and adjustments as necessary.

• Issue an engine condition report including recommendations for future operation

and maintenance.

During A-Inspections, there is no scheduled replacement of hot-gas-path parts,

including combustor, liners and turbine parts. The ALSTOM EV (EnVironmental)

combustor is, in general, maintenance-free during the operation between C-Inspections.

No separate combustor inspections for maintenance are required. The simple and

robust design without movable parts allows for fast condition assessment during A- and

B-Inspection.

The unit does not need to be disassembled for the A- and B-Inspection. It is possible to

inspect the blading via boroscope inspection holes, through the combustor manhole and

the exhaust gas diffuser inspection hatches. Although the information gained from A-

and B-Inspections and from analysis of operating data is usually sufficient to assess the

potential conditions, unexpected findings during the next visual inspection could lead to

required corrective actions. Adequate spare parts should be made available to cover

such eventualities.

GT13E2 Preventive Maintenance HTCT 692 232 V0001B en 1-5

Recommended Inspections November 2007

© 2007 ALSTOM. All rights reserved. The information in this document is provided for information purposes only. Site-specific deviations are possible. The descriptions do not constitute any

legally binding assurance of certain properties, qualities and/or scope of delivery. Any work described in this manual must be carried out solely under the supervision of personnel expressly

authorized by ALSTOM. Failure to comply with this requirement shall void any warranties, guarantees, representations, or other types of liability which ALSTOM may have given or

undertaken. Subject to change without notice.

1 Recommended Inspections

1.2 A-Inspection

1.2.1 Test and checks before shutting down the gas turbine

DANGER

Running gas turbine

Personnel can be killed or seriously injured

Wear safety equipment as required by local authorities

• Record all measurements of the last operation mode (EGATROL screen print out).

– Gas turbine baseload run preferred

– Particularly vibrations- and pulsation data

– Exhaust temperature distribution

• Check for air-, oil- hot gas- and fuel leakages (safety checks).

• Check for unusual noise of the turbine and auxiliaries.

• Check the setting of the pressure reducing valves belonging to the bleed valve

system.

Fig. 1-1 Egatrol print out

1-6 HTCT 692 232 V0001B en GT13E2 Preventive Maintenance

November 2007 Recommended Inspections

© 2007 ALSTOM. All rights reserved. The information in this document is provided for information purposes only. Site-specific deviations are possible. The descriptions do not constitute any

legally binding assurance of certain properties, qualities and/or scope of delivery. Any work described in this manual must be carried out solely under the supervision of personnel expressly

authorized by ALSTOM. Failure to comply with this requirement shall void any warranties, guarantees, representations, or other types of liability which ALSTOM may have given or

undertaken. Subject to change without notice.

Recommended Inspections 1

A-Inspection 1.2

1.2.2 Record operating data

DANGER

Confined Space

Personnel can be killed or seriously injured

Use only low voltage (less than 25V) electrical light

Make sure that the gas turbine has cooled down (TAT at least <50°C)

Wear safety equipment as required by local authorities

Be sure that there is no gas and/or fuel in the gas turbine

• Record all data of the ODC (Operation Data Counter), after the shut down of the

turbine.

1.2.3 Rotor alignment

Read instructions!

For more information read the rotor alignment document HTCT 692 228.

• Check the radial position of the rotor (19, Fig. 1-2) according to the corresponding

test certificate.

1.2.4 Rotor, turbine side

Read instructions!

For more information read the boroscope inspection document HTCT 692 652.

• Check the turbine blade rows 1-5 (20, Fig. 1-2) for impact damage, cracks,

corrosion and coating defects.

• Check the binding bolts for tightness, seizing up and fretting.

1.2.5 Turbine vane carrier

Read instructions!

For more information read the boroscope inspection document HTCT 692 652.

• Check the turbine vane row 1 (3, Fig. 1-2) for impact damage, cracks, corrosion,

deposits and coating defects.

• Check the heat shield segments rows in 1 and 5 of the stator for impact damage,

cracks, corrosion, deposits and signs of rubbing.

• Check the sealing strips of the vanes.

GT13E2 Preventive Maintenance HTCT 692 232 V0001B en 1-7

Recommended Inspections November 2007

© 2007 ALSTOM. All rights reserved. The information in this document is provided for information purposes only. Site-specific deviations are possible. The descriptions do not constitute any

legally binding assurance of certain properties, qualities and/or scope of delivery. Any work described in this manual must be carried out solely under the supervision of personnel expressly

authorized by ALSTOM. Failure to comply with this requirement shall void any warranties, guarantees, representations, or other types of liability which ALSTOM may have given or

undertaken. Subject to change without notice.

1 Recommended Inspections

1.2 A-Inspection

1.2.6 Rotor, compressor side

Read instructions!

For more information read the boroscope inspection document HTCT 692 652.

• Check the compressor blade rows 1 and 2 (13, Fig. 1-2) for impact damage,

cracks, corrosion and coating defects.

• Check the variable inlet guide vanes for excessive clearance of adjustment

mechanism.

1-8 HTCT 692 232 V0001B en GT13E2 Preventive Maintenance

November 2007 Recommended Inspections

© 2007 ALSTOM. All rights reserved. The information in this document is provided for information purposes only. Site-specific deviations are possible. The descriptions do not constitute any

legally binding assurance of certain properties, qualities and/or scope of delivery. Any work described in this manual must be carried out solely under the supervision of personnel expressly

authorized by ALSTOM. Failure to comply with this requirement shall void any warranties, guarantees, representations, or other types of liability which ALSTOM may have given or

undertaken. Subject to change without notice.

Recommended Inspections 1

A-Inspection 1.2

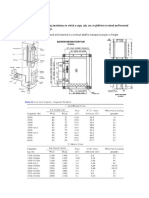

Pos. Description Pos. Description

1 Turbine-end bearing assembly, MBD10 12 Compressor housing, MBA80 HA110

2 Exhaust housing, MBA30 HA450 13 Compressor blade rows, MBA80 HB400

3 Turbine vane carrier, MBA30 HA300 14 GT support, compressor

4 Turbine vane rows; MBA30 HA400 15 Fuel distribution system, MBM31

5 EV combustor, MBM30 16 Combustor housing, MBA80 HA200

6 Inner housing 17 Turbine housing, MBA30 HA100

7 Stage 1 and 2 blow-off valves, MBA81 18 GT support, turbine

8 Air intake manifold, MBL30 19 Rotor, MBA01 HB100

9 Air inlet housing, MBA80 HA050 20 Turbine blade rows, MBA30 HB400

10 Compressor-end bearing assembly, MBD20 21 Exhaust diffuser, MBA30 HA500

11 GT support, air inlet

Fig. 1-2 Thermal Block Main Components

GT13E2 Preventive Maintenance HTCT 692 232 V0001B en 1-9

Recommended Inspections November 2007

© 2007 ALSTOM. All rights reserved. The information in this document is provided for information purposes only. Site-specific deviations are possible. The descriptions do not constitute any

legally binding assurance of certain properties, qualities and/or scope of delivery. Any work described in this manual must be carried out solely under the supervision of personnel expressly

authorized by ALSTOM. Failure to comply with this requirement shall void any warranties, guarantees, representations, or other types of liability which ALSTOM may have given or

undertaken. Subject to change without notice.

1 Recommended Inspections

1.2 A-Inspection

1.2.7 Combustor

Read instructions!

For more information read the boroscope inspection document HTCT 692 652.

• Check the cone and burner (3, Fig. 1-3) outlets plane for cracks, deformation and

overheating.

• Check the premix gas holes for erosion, soiling and coking at the burners.

• Check the burner collar for cracks, deformation, excessive clearance or blocking.

• Check the pilot gas openings for coking and erosion at the lances.

• Check the fuel oil nozzles for coking and erosion at the lances.

• Check the NOx water holes for coking and erosion at the lances.

• Check the electrode and nozzles of the ignition torches.

• Check the thermocouples measurement and high voltage coupling.

• Check the sensor at the flame monitor for overheating.

• Clean the glasses of the sight glasses and the flame scanning system.

• Check the burner hood (1, Fig. 1-3) for cracks and if any bolts are broken or loose.

• Check if there is a gap between the hood flange and the segment carrier.

• Check the manhole cover plate for cracks.

• Check the splitline cover plate for cracks.

• Check the front segments (4, Fig. 1-3) and sealings between the segments for

cracks, overheating or deformation.

• Check the welding seam of the Helmholzdampers for cracks.

• Check the restrainer ring at the transition (zone 2) for overheating and scaling.

• Check the inner and outer (zone 1) cooling segments (5 and 7, Fig. 1-3) for cracks,

overheating scaling and deformation.

• Check the zone 2 (6 and 8, Fig. 1-3) for cracks, overheating and deformation.

• Check the transition zone for oxidation and corrosion.

• Check the split line welding seam for cracks.

• Check all fasteners for tightness, cracks or deformation.

• Check the washers for deformation, fretting and cracks.

• Check the sealing segments for wear, rubbing, clearance, scaling and overheating.

1-10 HTCT 692 232 V0001B en GT13E2 Preventive Maintenance

November 2007 Recommended Inspections

© 2007 ALSTOM. All rights reserved. The information in this document is provided for information purposes only. Site-specific deviations are possible. The descriptions do not constitute any

legally binding assurance of certain properties, qualities and/or scope of delivery. Any work described in this manual must be carried out solely under the supervision of personnel expressly

authorized by ALSTOM. Failure to comply with this requirement shall void any warranties, guarantees, representations, or other types of liability which ALSTOM may have given or

undertaken. Subject to change without notice.

Recommended Inspections 1

A-Inspection 1.2

Pos. Description Pos. Description

1 Hood 5 Outer segment carrier

2 Combustor housing 6 Zone 2 outer shell

3 EV burner 7 Inner segment carrier

4 Front segments 8 Zone 2 inner shell

Fig. 1-3 Combustor assembly, overview

GT13E2 Preventive Maintenance HTCT 692 232 V0001B en 1-11

Recommended Inspections November 2007

© 2007 ALSTOM. All rights reserved. The information in this document is provided for information purposes only. Site-specific deviations are possible. The descriptions do not constitute any

legally binding assurance of certain properties, qualities and/or scope of delivery. Any work described in this manual must be carried out solely under the supervision of personnel expressly

authorized by ALSTOM. Failure to comply with this requirement shall void any warranties, guarantees, representations, or other types of liability which ALSTOM may have given or

undertaken. Subject to change without notice.

1 Recommended Inspections

1.2 A-Inspection

1.2.8 Exhaust system (exhaust housing)

• Check the exhaust housing for cracks and deformation.

• Check the exhaust diffuser for cracks and deformation.

• Check all welds on struts in the exhaust diffuser.

• Check the air guide plates between the exhaust housing and the diffuser if they are

in proper position.

• Check the air guide plates for cracks and deformation.

• Check the thermocouples for deformation and damage.

• Check the inner guidance of the exhaust thermocouples for excessive wear.

• Check the thermocouple tips for deposits.

• Check that the probes at the exhaust thermocouples are tight.

• Check the safety plate at the exhaust thermocouples.

• Check the insulation material at the compensator.

• Check the sides of the compensator for deformation and damage.

• Check the NOx-cross.

1.2.9 Air intake manifold

• Check the weather louvres for any damage.

• Check the filter for any damage and for contamination.

• Check the anti-icing system for any damage.

• Check the filter house and silencer for any damage, corrosion and loose parts.

• Check the air intake channel and air intake housing for any damage, corrosion and

loose parts.

• Check the compressor on-line and off-line system for any damage and broken

hoses.

1.2.10 Exhaust end bearing chamber

• Check the exhaust end bearing chamber for any damage and leaks.

1.2.11 Short description of the A-Inspection

Gas turbine

• Air inlet system (8 and 9, Fig. 1-2): check the general condition

• Compressor (12, Fig. 1-2): check the inlet

• Burners (3, Fig. 1-3): check the burner/nozzle condition

• Ignition system: check the function

• Combustion chamber (5, Fig. 1-2): visual check (access through manhole)

• Turbine housing (17, Fig. 1-2): check the hot section

• Exhaust diffuser (21, Fig. 1-2): check the condition

• Bearings (1 and 10, Fig. 1-2): check for leakage

1-12 HTCT 692 232 V0001B en GT13E2 Preventive Maintenance

November 2007 Recommended Inspections

© 2007 ALSTOM. All rights reserved. The information in this document is provided for information purposes only. Site-specific deviations are possible. The descriptions do not constitute any

legally binding assurance of certain properties, qualities and/or scope of delivery. Any work described in this manual must be carried out solely under the supervision of personnel expressly

authorized by ALSTOM. Failure to comply with this requirement shall void any warranties, guarantees, representations, or other types of liability which ALSTOM may have given or

undertaken. Subject to change without notice.

Recommended Inspections 1

A-Inspection 1.2

Fuel systems

• Fuel oil: leakage and filter check

• Fuel gas: leakage and filter check

• Additive: leakage and filter check

Protection/monitoring

• Check the temperature protection

• Check the overspeed protection

• Check the flame monitor

GT13E2 Preventive Maintenance HTCT 692 232 V0001B en 1-13

Recommended Inspections November 2007

© 2007 ALSTOM. All rights reserved. The information in this document is provided for information purposes only. Site-specific deviations are possible. The descriptions do not constitute any

legally binding assurance of certain properties, qualities and/or scope of delivery. Any work described in this manual must be carried out solely under the supervision of personnel expressly

authorized by ALSTOM. Failure to comply with this requirement shall void any warranties, guarantees, representations, or other types of liability which ALSTOM may have given or

undertaken. Subject to change without notice.

1 Recommended Inspections

1.3 B-Inspection

1.3 B-Inspection

DANGER

Confined Space

Personnel can be killed or seriously injured

Use only low voltage (less than 25V) electrical light

Make sure that the gas turbine has cooled down (TAT at least <50°C)

Wear safety equipment as required by local authorities

Be sure that there is no gas and/or fuel in the gas turbine

DANGER

Turning Rotor

Personnel can be killed or seriously injured

Always make sure that no unwanted turning of the rotor is possible

Do not wear jewelry and any loose fitting clothing that may get caught in the rotor

blades.

Caution

Boroscope or metal guide can be damaged

• Turn very carefully the rotor while the boroscope or the metal guide is inserted

into the blade movement area

Note

The installation preparing procedure for works (draining, purging, cleaning before and

after works, testing, disconnecting etc.) and safety measures for those works are not

subject of this document and should fulfill standard procedure for performing works

during erection phase or on installation in use.

Note

On site, all regulations of ALSTOM, the local legal regulations and the specific safety

regulations of the sub-contractor must all be considered. In each case, the higher

authority must be taken.

This inspection is a check of the gas turbine set planned for intervals of an intermediate

length. They include the same type of checks on more components than the A-

Inspection.

It includes checking of:

• The safety equipment of the gas turbine set.

• Hydraulic and electronic closed-loop control systems.

• Open-loop controls and annunciation systems.

1-14 HTCT 692 232 V0001B en GT13E2 Preventive Maintenance

November 2007 Recommended Inspections

© 2007 ALSTOM. All rights reserved. The information in this document is provided for information purposes only. Site-specific deviations are possible. The descriptions do not constitute any

legally binding assurance of certain properties, qualities and/or scope of delivery. Any work described in this manual must be carried out solely under the supervision of personnel expressly

authorized by ALSTOM. Failure to comply with this requirement shall void any warranties, guarantees, representations, or other types of liability which ALSTOM may have given or

undertaken. Subject to change without notice.

Recommended Inspections 1

B-Inspection 1.3

The B-Inspection includes an A-Inspection plus additional checks on the auxiliaries, the

generator, the controls, and the protection and monitoring system including their

settings. Such tasks may be split into groups for phased inspection.

Similar to the A-Inspection, for the B-Inspection the unit is not disassembled. Visual

access to the blading is again possible via boroscope inspection holes and through the

combustor manhole and the exhaust gas diffuser inspection hatches.

1.3.1 Short description of the B-Inspection

Gas turbine

• Air inlet system (8 and 9 Fig. 1-2): check the general condition

• Valve system: check the function and the settings

• Compressor (12, Fig. 1-2): check the inlet and the filter house

• Burners (3, Fig. 1-3): check the flames and the burner/nozzle

• Ignition system: check the function and the igniters

• Combustion chamber (5, Fig. 1-2): visual check (access through manhole)

• Turbine housing (17, Fig. 1-2): check the hot section

• Exhaust diffuser (21, Fig. 1-2): check the condition

• Bearings (1 and 10, Fig. 1-2): check for leakage

Fuel systems

• Fuel oil: leakage, system and filter check

• Fuel gas: leakage, system and filter check

• Additive: leakage, system and filter check

Protection/monitoring

• Check the temperature protection

• Check the overspeed protection

• Check the flame monitor

• Check the fire protection systems

• Check the flame monitor

• Check the turbine protection

• Check the measurement instrumentation

• Check the recorder

GT13E2 Preventive Maintenance HTCT 692 232 V0001B en 1-15

Recommended Inspections November 2007

© 2007 ALSTOM. All rights reserved. The information in this document is provided for information purposes only. Site-specific deviations are possible. The descriptions do not constitute any

legally binding assurance of certain properties, qualities and/or scope of delivery. Any work described in this manual must be carried out solely under the supervision of personnel expressly

authorized by ALSTOM. Failure to comply with this requirement shall void any warranties, guarantees, representations, or other types of liability which ALSTOM may have given or

undertaken. Subject to change without notice.

1 Recommended Inspections

1.3 B-Inspection

Blank Page

1-16 HTCT 692 232 V0001B en GT13E2 Preventive Maintenance

November 2007 Recommended Inspections

© 2007 ALSTOM. All rights reserved. The information in this document is provided for information purposes only. Site-specific deviations are possible. The descriptions do not constitute any

legally binding assurance of certain properties, qualities and/or scope of delivery. Any work described in this manual must be carried out solely under the supervision of personnel expressly

authorized by ALSTOM. Failure to comply with this requirement shall void any warranties, guarantees, representations, or other types of liability which ALSTOM may have given or

undertaken. Subject to change without notice.

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Chapter-3 Building DrawingDocumento28 pagineChapter-3 Building DrawingGech20% (5)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- 2007 Hawkeye Service Manual 9920795 PDFDocumento432 pagine2007 Hawkeye Service Manual 9920795 PDFBrianCook100% (1)

- Vortex GeneratorsDocumento12 pagineVortex GeneratorsSatyajeet NayakNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Engineering CalculatorDocumento10 pagineEngineering Calculatorspmg222Nessuna valutazione finora

- Catalogo Hino 700 - ZF 16s151Documento54 pagineCatalogo Hino 700 - ZF 16s151Lucio Pando100% (2)

- Gek105060 File0060Documento12 pagineGek105060 File0060Mauricio GuanellaNessuna valutazione finora

- Catalogo Rotofluid Eng SONDocumento40 pagineCatalogo Rotofluid Eng SONtunaNessuna valutazione finora

- MagnumDocumento16 pagineMagnumgacm98100% (1)

- DS-003-2-En - Exertherm - IR06EMSC Sensor - ScreenDocumento2 pagineDS-003-2-En - Exertherm - IR06EMSC Sensor - ScreenMohammad AsifNessuna valutazione finora

- Nirmal Traininig RUB The GOLDDocumento460 pagineNirmal Traininig RUB The GOLDPramod Kumar DwivediNessuna valutazione finora

- NoticeDocumento1 paginaNoticeam3s22Nessuna valutazione finora

- 14288190776177764897Documento1 pagina14288190776177764897Fadli FadliNessuna valutazione finora

- Curriculum Vitae Personal Data: Document Name Number Place Date of Issue Expire DateDocumento1 paginaCurriculum Vitae Personal Data: Document Name Number Place Date of Issue Expire DateFadli FadliNessuna valutazione finora

- H 7 KLMF 3 JDocumento3 pagineH 7 KLMF 3 JFadli FadliNessuna valutazione finora

- MRS Bulletin TBCsDocumento52 pagineMRS Bulletin TBCsLeandro Augusto SouzaNessuna valutazione finora

- ATT01 HTCT692232V0001 B Recommended InspectionsDocumento16 pagineATT01 HTCT692232V0001 B Recommended InspectionsFadli FadliNessuna valutazione finora

- Actuator: P Pressure GaugeDocumento2 pagineActuator: P Pressure GaugeFadli FadliNessuna valutazione finora

- Ab-1K Ab-1K Ab-1K Ab-1K Ab-1K Ab-1K: Kls Hari Jam Ke Ruang Matakuliah Pengajar Sks Ab-1KDocumento17 pagineAb-1K Ab-1K Ab-1K Ab-1K Ab-1K Ab-1K: Kls Hari Jam Ke Ruang Matakuliah Pengajar Sks Ab-1KFadli FadliNessuna valutazione finora

- Model Pump GrundfosliteratureDocumento22 pagineModel Pump GrundfosliteratureFadli FadliNessuna valutazione finora

- ? - 9, S L4?Q - ' (Igoo F+ Ts Lsooc: SolusiDocumento3 pagine? - 9, S L4?Q - ' (Igoo F+ Ts Lsooc: SolusiFadli FadliNessuna valutazione finora

- Action Poin Asset 11-02-2017Documento816 pagineAction Poin Asset 11-02-2017Fadli FadliNessuna valutazione finora

- Turbin Generator Regulator DC Aki AkiDocumento1 paginaTurbin Generator Regulator DC Aki AkiFadli FadliNessuna valutazione finora

- GN046Documento20 pagineGN046Jacky_LEOLEONessuna valutazione finora

- Building Utilities TermsDocumento9 pagineBuilding Utilities TermsKaren Dela TorreNessuna valutazione finora

- Michigan State University: EXTENSION BULLETIN 168 (Revised)Documento10 pagineMichigan State University: EXTENSION BULLETIN 168 (Revised)ArboussolsNessuna valutazione finora

- Pulwell GFRP Rebars2012Documento10 paginePulwell GFRP Rebars2012Abada Rashed Abada NadaNessuna valutazione finora

- Masteremaco S 488: Structural Repair MortarDocumento3 pagineMasteremaco S 488: Structural Repair MortarKhan ShahzebNessuna valutazione finora

- Expanded Metals PDFDocumento3 pagineExpanded Metals PDFMichael MirandaNessuna valutazione finora

- EARTHWORK (Embankment-Cleaning, Grubbing, Cutting, Filling, Leveling and FDD) (REACH 3 TO 6)Documento4 pagineEARTHWORK (Embankment-Cleaning, Grubbing, Cutting, Filling, Leveling and FDD) (REACH 3 TO 6)Ankur BarsainyaNessuna valutazione finora

- Flow CupsDocumento4 pagineFlow CupsMuhamad Dwi RamdaniNessuna valutazione finora

- Performance Based+Optimization+of+Structures+Theory+and+ApplicationsDocumento5 paginePerformance Based+Optimization+of+Structures+Theory+and+ApplicationsFariedNessuna valutazione finora

- CemFIL AntiCrak HP 6736 Product Sheet WW 10-2014 Rev8 en FinalDocumento2 pagineCemFIL AntiCrak HP 6736 Product Sheet WW 10-2014 Rev8 en FinalvliegenkristofNessuna valutazione finora

- CTG Ac20br 0107Documento36 pagineCTG Ac20br 0107kaniappan sakthivelNessuna valutazione finora

- Assignment ELEVATORDocumento7 pagineAssignment ELEVATORRenzo LopezNessuna valutazione finora

- 9013Documento4 pagine9013jimmyboyjrNessuna valutazione finora

- Ab Brass IveDocumento4 pagineAb Brass IvejengandxbNessuna valutazione finora

- Ethernet Cable: Color-Code StandardsDocumento3 pagineEthernet Cable: Color-Code StandardsCristian ParaschivNessuna valutazione finora

- BituflamepDocumento2 pagineBituflamepnkhhhNessuna valutazione finora

- Strip in Pipe Earthing Boq ElinkDocumento1 paginaStrip in Pipe Earthing Boq ElinkShrikant IyerNessuna valutazione finora

- 2013 DTH Hammer Catalog PDFDocumento61 pagine2013 DTH Hammer Catalog PDFNelson de la RosaNessuna valutazione finora

- Writing Process Poster and ChecklistDocumento4 pagineWriting Process Poster and ChecklistNur FarahinNessuna valutazione finora

- Volkswagen Polo 1.2 TSI BrochureDocumento2 pagineVolkswagen Polo 1.2 TSI BrochureBtiarAshariImanuddin100% (1)