Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Servoteh Broschure Eng

Caricato da

Nenad JarakovicDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Servoteh Broschure Eng

Caricato da

Nenad JarakovicCopyright:

Formati disponibili

C o mp le te a u to ma t ion

ABOUT US

Servoteh was founded in 2002.

Now, in 2016, we have about 50

employees and 2,000 square meters

of production plants.

Servoteh has

ISO9001:2008 certificate

Our main business is development, design, installation and commissioning

of complete systems for the purpose of automation of production process.

Distributor sales of components and spare parts of world well-known

manufacturers of industrial pneumatics, hydraulics, central lubrication

systems, sealing systems, filter systems, frequency converters, linear

techniques, robotic systems. We are sales partner and system integrator of

the following companies: SKF, Aventics, Bosch Rexroth AG, ABB, Cassapa,

FILTREC, HansaFlex.

2 | Servoteh - Complete automation

MECHANICAL DESIGN, DRAFTING & ENGINEERING SERVICES

From initial concept, engineering and prototype to the fully assembled machine through installation as well as after the

sale support, we possess the advanced engineering, precision machining and fabricating capabilities to produce custom

machines to automate your process.

We also have the capability to retrofit and upgrade your existing machines to automate your processes, including the re-

working and redesigning of the controls, hardware and software. We use software tools for 3D CAD/CAM design, EPLAN,

software packages for PLC and SCADA software, softwares for CNC machines.

We are focused on the design of special machines for industrial automation

CAD design of machines, production lines, tools and parts using 3D and 2D CAD software

3D tools model Processing simulation G Code CNC machine during processing

CAM – We use licensed CAM software to make G-code for machining on precise CNC machines

Servoteh - Complete automation | 3

CNC MACHINING

Our offer, within the machining, includes:

• Production of complete machines, according to customer’s or our own documentation,

• Production of sub-assemblies for different industries,

• Making tools...

MILLING

• DMC 125 FD DuoBlock -

five-axis machining center

1250mmx850mmx850mm

• DMU 50T – five-axis machining center

500 mm x 400 mm x 400 mm

• HAAS VF-1, 508 mm x 406 mm x 508

mm

• CNC milling machine MAHO 1000C,

4-axis, 1000 mm x 800 mm x 500 mm

• CNC milling machine MAHO 700C,

700 mm x 450 mm x 500 mm

• Universal milling machine REIDEN

• Radial drilling machine

DMC 125 FD DuoBlock – 5-axis machining center

TURNING

• CNC lathe CTX 500 S2

Ø450 x 1000

• CNC lathe EMCO TURN 345

Ø195 x 250

• Universal lathe - Morando PA 21

Ø275 x 1000 (Ø450 x 300)

• Universal lathe “Krasnie Proleter”

Ø220 x 1000 (Ø450 x 300)

CTX 500 S2 - CNC lathe

GRINDING

• Grinding machine for cylindrical

grinding to Ø320 mm x 1000 mm

• Surface grinder

300 mm x 500 mm,

• CNC coordinate grinding machine

MOORE G18 8400CP

600 mm x 300 mm

MOORE G18 Jig grinder DMU 50T

4 | Servoteh - Complete automation

PRODUCTION - FACILITY AND EQUIPMENT

WELDING

• TIG – 350A - arc welding in a

protective atmosphere of inert gas

by insoluble metal electrode

• MIG / MAG - 400A arc welding

in the protective atmosphere of

inert/active gas by soluble metal

electrode

• MIG - 280A arc welding in a

protective atmosphere of inert gas

by soluble metal electrode

SANDBLASTING,

PHOSPHATING,

BROWNING AND PAINTING

• We own a painting chamber -

dimension 4 m x 7m x 3.5 m.

• Sandblasting of parts

- dimension 1.3 m x 1.3 m x 1 m.

• Phosphating, cold and hot

browning

ASSEMBLY HALL

Mounting hall of 700 m2, with the crane,

load capacity 10 tons.

Servoteh - Complete automation | 5

HYDRAULICS

We can offer design, production, installation and

commissioning of complete hy-pressure hydraulic

installations. Servoteh’s personnel have the

required skills and experience to translate customer

requirements into the desired end result by exploiting

these properties to the full. The resulting solutions

are not only effective, but above all energy-efficient

and sustainable.

Our production program also includes design and

production of:

• Standard and custom made hydraulic cylinders

• Hydro power units

• Hydraulic manifolds

• Special (custom made) hydraulic valves.

6 | Servoteh - Complete automation

PRESSES

Hydraulic presses

for rings

We have developed complete range of

presses for pressing of brass rings into

groove on different cylindrical parts.

Pressing force regulating is provided

by 12 hydraulic cylinders, radially

arranged in press body.

Special purpose

hydraulic presses

We can offer different custom made

presses, according to costumer’s

specific demands. One of these is

press for producing parts from powder

materials, with constant regulating of

pressing force.

Presses could be designed in both

versions, standard and ATEX.

Friction forging presses

We can offer complete reconstruction

and modernization of all kinds of

friction presses.

After reconstruction, presses have

fully controlled work cycle and force,

and absolutely repeatability.

Servoteh - Complete automation | 7

FORGING EQUIPMENT

We can supply new, used, or rebuilt forging equipment at competitive prices.

We have successfully remade 400 tons forging presses and hydraulic hammers.

HYDRAULIC PRESS FOR FORGING

- Maximum length of the

- Maximum forging force: 400 tons - Maximum forging speed: 200 mm/S workpiece: 800 mm

The control

Press 400t Hydraulic power unit console and robot Electrical cabinets

HY-PRESSURE HYDRO TESTING EQUIPMENT

We designed and produced complex systems for hydrostatic testing of products at pressure up to 1500 bar.

Test block with

pressure

multiplicator

3D CAD model

8 | Servoteh - Complete automation

FLOW FORMING MACHINERY

Flow forming equipment provides

economically beneficial metal forming

process in production of hollow parts. Support

There are two basic principles in flow

forming process:

1. Forward (synchronous) Flow Forming,

applicable in production of hollow parts

with bottom,

2. Reverse Flow Forming, applicable in 3D model of Flow Forming machine

production of tubes

Forward

Flow Forming

Technical description:

• Outside diameter, max: 560 mm

• Outside diameter, min: 60 mm

• Workpiece length:

- forward forming: 1200 mm

- reverse forming: 4000 mm

• Spindle drive engine: 112 kW

Reverse Basic principles

• Hydraulic drive engine: 55 kW Flow Forming of Flow Forming

• Nominal electric load: 200 kVA

• Spindle speed, max: 1000 min-1

• Axial path, max: 2,100 mm

• Axial force, max: 250 kN

• Radial path transversal load,

max: 255 mm

• Radial force transversal load,

max: 300 kN

Cross section of Flow Forming machine

Flow Forming machinery

Servoteh - Complete automation | 9

PACKAGING MACHINES AND EQUIPMENT

Design and production of universal and special machines for food and beverage, chemical, pharmaceutical industry,

according to customer-specific demands.

Packaging machine in food industry

Filling and packing machine for pharmaceutical industry

We can offer equipment which we design for different industry applications:

Carton box erectors Carton box sealers Filling machines Indexing tables

CONVEYING SYSTEMS

Servoteh can offer design and production of conveyors and conveying systems.

Our specialty is building custom made conveyors, according to customer’s

specific requirements: product shape, conveying path, speed, work conditions...

Standard and special conveyors

10 | Servoteh - Complete automation

ELECTRICAL CONTROL SYSTEMS

Servoteh designs and creates automated systems based on customer ‘s ideas, needs and requirements by applying latest

technologies and solutions, including design - drawing of schemes, selection of equipment, production and/or development

of applications, supervision of works, commissioning, logistics.

ELECTRICAL ENGINEERING - PLC, CNC, HMI, SCADA PROGRAMMING

We offer PLC programming development based on your request and according to your needs, from the initial idea all the

way to the commissioning.

We do the programming of the following PLC manufacturers: Siemens, Omron, Allen Bradley, GE Fanuc, Mitsubishi,

Automation Direct. We are developing applications for HMI panels and SCADA systems. Also, we can provide integration of

modern CNC units on new or used machines and production lines (Siemens 840 D SL...)

Servoteh - Complete automation | 11

References

• Robert Bosch d.o.o. • Apatinska Pivara • Hemigum Plast d.o.o. • Mlekara Šabac

• Nestle Adriatic • Atlantic group • Hemofarm AD, Vršac • Naftna Industrija Srbije

• Grundfoss d.o.o. • Banini AD • Imlek AD, Beograd • Nelt

• US STEEL SRBIJA • BIP AD • Intercell Šabac • Potisje Kanjiža

• ARCELLOR MITAL • BMS Chemie • Jaffa AD • RB Kolubara

• Knjaz Miloš AD • Sinter AD

• John M Henderson • CIMOS Livnica Kikinda

• Kombinat Aluminijuma • Sojaprotein AD

• Fiat Automobili Srbija d.o.o. • Coca-Cola HBC Srbija

Podgorica • SPEKTAR

• Calsberg Srbija • Cooper Tyres

• Kovački centar d.o.o. • Stan Technologies d.o.o.

• Le Belier Livnica, Kikinda • Fabrika Hartije Beograd

• Krušik AD, Valjevo • Termo ELektrana Nikola

• PharmaSwiss d.o.o., Beograd • Fabrika Kartona UMKA • Laboratorija Dr. Pavlović Tesla, Obrenovac

• TARKETT SEE • Frikom AD • Luka Pančevo • Tetra Pak

• Unitec d.o.o., Beograd • GP Štamparija Borba • MBM Spikom d.o.o., Beograd • Visaris d.o.o., Beograd

• Actavis - Zdravlje Leskovac • Grand Kafa • Mecafor products d.o.o., Senta • Vlasinka AD

• ALPACK, Subotica • Grand Prom AD, Beograd • Metalac AD, Gornji Milanovac • YUHOR AD

Servoteh d.o.o.

E-70 Ugrinovačka 163 To find us on

11272 Dobanovci, Beograd Google maps:

Nikola Tesla tel: + 381 (11) 31-41-563

Airport + 381 (11) 31-41-564

fax: +381 (11) 23-99-265

office@servoteh.com

www.servoteh.com

E-75

Potrebbero piacerti anche

- Pakistan Machine Tool Factory (PVT) Ltd. (PMTF) : Design CentreDocumento33 paginePakistan Machine Tool Factory (PVT) Ltd. (PMTF) : Design CentreHaris BilalNessuna valutazione finora

- Beml Report PDFDocumento32 pagineBeml Report PDFCrazy TamizhaNessuna valutazione finora

- Hydraulic Equipment & Machinery: Hydropower Engineering SystemsDocumento4 pagineHydraulic Equipment & Machinery: Hydropower Engineering Systemsbukit_guestNessuna valutazione finora

- Liebherr Hobbing Machines lc600 2000Documento4 pagineLiebherr Hobbing Machines lc600 2000Ulp 152Nessuna valutazione finora

- Fresadora Liebherr PDFDocumento8 pagineFresadora Liebherr PDFdesetekNessuna valutazione finora

- Abraline PDFDocumento32 pagineAbraline PDFAmel DurakovicNessuna valutazione finora

- Corporate ProfileDocumento24 pagineCorporate Profiletransiente2010Nessuna valutazione finora

- 2010 PBT e InternetDocumento20 pagine2010 PBT e InternetMohammed RiyazNessuna valutazione finora

- Air Spring ManualDocumento11 pagineAir Spring ManualPremchand BeuraNessuna valutazione finora

- Welcome at Commercial Establishment Mikro-Met ® Grzegorz KłosowskiDocumento25 pagineWelcome at Commercial Establishment Mikro-Met ® Grzegorz KłosowskiVarun BaxiNessuna valutazione finora

- Robofil x40 CC UsDocumento28 pagineRobofil x40 CC UsMahdi ElgolliNessuna valutazione finora

- Tuboly-Astronic Product LeafletDocumento12 pagineTuboly-Astronic Product LeafletClaude mekinaNessuna valutazione finora

- Internship Report On BemlDocumento29 pagineInternship Report On BemlYasewn KALAWANTNessuna valutazione finora

- Vertical Turret Lathe Imo Kd4S 40: AnlagenbauDocumento6 pagineVertical Turret Lathe Imo Kd4S 40: AnlagenbauSamik MukherjeeNessuna valutazione finora

- CorimpexDocumento38 pagineCorimpexmahotkatNessuna valutazione finora

- S.D. Engrs ProfileDocumento9 pagineS.D. Engrs ProfiledinesattriNessuna valutazione finora

- Presentation VES SPM 1Documento25 paginePresentation VES SPM 1Vedant AjnadkarNessuna valutazione finora

- Imagebroschuere ENGDocumento16 pagineImagebroschuere ENGmahotkatNessuna valutazione finora

- MAE Automatic Straightening Machines - M-AHDocumento24 pagineMAE Automatic Straightening Machines - M-AHsemarasik_651536604Nessuna valutazione finora

- Final HMTDocumento45 pagineFinal HMTAnubhav SharmaNessuna valutazione finora

- Cement Testing - EquipmentDocumento16 pagineCement Testing - Equipmentgsv988Nessuna valutazione finora

- Viraj Catalouge-2Documento21 pagineViraj Catalouge-2Vinod GuptaNessuna valutazione finora

- Mining EquipmentDocumento11 pagineMining EquipmentKaushalendra Kumar Singh100% (1)

- Cam 1Documento176 pagineCam 1bm713576Nessuna valutazione finora

- One Stop Complete Machining Solution FOR Engineering ComponentDocumento6 pagineOne Stop Complete Machining Solution FOR Engineering ComponentTHE METAL COMPANYNessuna valutazione finora

- Morrison VMC Brochure v9Documento8 pagineMorrison VMC Brochure v9Jerry McCartyNessuna valutazione finora

- Production Technology Laboratory WorkshopDocumento15 pagineProduction Technology Laboratory WorkshopPride DubeNessuna valutazione finora

- Waterjet Brochure X3 and X4 PDFDocumento12 pagineWaterjet Brochure X3 and X4 PDFRamon Martz100% (1)

- Productivity Improvement of Conventional Drilling MachineDocumento38 pagineProductivity Improvement of Conventional Drilling MachineHarshad_S50% (2)

- About M.O.C Dies and MouldsDocumento11 pagineAbout M.O.C Dies and Mouldsnagarajan224100% (1)

- HomgeDocumento80 pagineHomgeRobert HarveyNessuna valutazione finora

- Final 2Documento22 pagineFinal 2prasad moreNessuna valutazione finora

- Heavy Machine Tool Plant (HMTP) : Deep Hole Boring Machine:-Main FeaturesDocumento3 pagineHeavy Machine Tool Plant (HMTP) : Deep Hole Boring Machine:-Main FeaturesShahbaz AlamNessuna valutazione finora

- UMEB Presentation 2014Documento32 pagineUMEB Presentation 2014fabiandimiNessuna valutazione finora

- I Mold Product Overview Servomold Ver1.0 enDocumento8 pagineI Mold Product Overview Servomold Ver1.0 enInderjeet SinghNessuna valutazione finora

- SchulerDocumento8 pagineSchuleraguswNessuna valutazione finora

- Business Activities ProfileDocumento35 pagineBusiness Activities ProfileKapa KamalakarNessuna valutazione finora

- 01 - 1 Headline - 36 pt/14.4 MM Second Line Mill Type and Tie Rod CylindersDocumento2 pagine01 - 1 Headline - 36 pt/14.4 MM Second Line Mill Type and Tie Rod CylindersOlivera MilenkovicNessuna valutazione finora

- Industrial: Product CatalogDocumento23 pagineIndustrial: Product CatalogPablo CamachoNessuna valutazione finora

- Profiilikeskus Catalogue EngDocumento28 pagineProfiilikeskus Catalogue EngLogan JhonyNessuna valutazione finora

- PDF4 - Rapid Masina de Rectificat Dantura PDFDocumento7 paginePDF4 - Rapid Masina de Rectificat Dantura PDFnitaNessuna valutazione finora

- Catalog Haydon Kerk 2016 LR-BDocumento265 pagineCatalog Haydon Kerk 2016 LR-Bomal06Nessuna valutazione finora

- VS 6 - FlowserveDocumento8 pagineVS 6 - FlowserveJung Jae YualNessuna valutazione finora

- Automatic Hammering MachineDocumento16 pagineAutomatic Hammering MachineErole Technologies Pvt ltd Homemade EngineerNessuna valutazione finora

- SMACO Tube Mill LineDocumento5 pagineSMACO Tube Mill LineIshtiaq bhatti Ishtiaq bhattiNessuna valutazione finora

- Ops-Ingersoll Edm EngDocumento18 pagineOps-Ingersoll Edm Engadict26Nessuna valutazione finora

- Wb213e Pusher Centrifuge SHSDocumento12 pagineWb213e Pusher Centrifuge SHSdanielmercadoiqNessuna valutazione finora

- Long Products Rolling MillsDocumento21 pagineLong Products Rolling Millsralish12Nessuna valutazione finora

- Internship Report: Training Centre - Mysore ComplexDocumento28 pagineInternship Report: Training Centre - Mysore Complexshubhashini K NNessuna valutazione finora

- Wire Forming TechnologyDocumento18 pagineWire Forming TechnologyMohamed AbudoamNessuna valutazione finora

- Hom Drillteqv - 500 2022 enDocumento20 pagineHom Drillteqv - 500 2022 encharmeduboisNessuna valutazione finora

- Dizalica Imer 300 PDFDocumento60 pagineDizalica Imer 300 PDFAnonymous CdUZMZJq73Nessuna valutazione finora

- PDFDocumento14 paginePDFmdavangeNessuna valutazione finora

- 2012 13 HydraulicsDocumento124 pagine2012 13 HydraulicsMarcelo Partes de OliveiraNessuna valutazione finora

- Flyer Mach2 en 02Documento2 pagineFlyer Mach2 en 02Abdelhamid Chergui0% (1)

- Rev AA - DCV 1480 - TI - May 2008Documento12 pagineRev AA - DCV 1480 - TI - May 2008Sasko Dimitrov100% (1)

- Presentation On Heavy Engineering Corporation LimitedDocumento20 paginePresentation On Heavy Engineering Corporation LimitedSandeepRajNessuna valutazione finora

- SEW Eurodrive Industrial Gear UnitsDocumento15 pagineSEW Eurodrive Industrial Gear UnitsSteve IpNessuna valutazione finora

- The CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Da EverandThe CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Valutazione: 5 su 5 stelle5/5 (1)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheDa EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheValutazione: 4.5 su 5 stelle4.5/5 (2)

- For Minor ProjectDocumento42 pagineFor Minor ProjectSayan DasNessuna valutazione finora

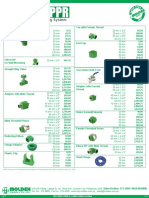

- Ecosafe PPR-Official PricelistDocumento2 pagineEcosafe PPR-Official PricelistLoui Lester BarciaNessuna valutazione finora

- Worksheet 25 PDFDocumento3 pagineWorksheet 25 PDFVijay Bhaskar100% (2)

- Control Valve Calibration Procedure (Fisher HC6010)Documento14 pagineControl Valve Calibration Procedure (Fisher HC6010)Karen Cain93% (15)

- 3 - Miedema - Drag Embedded Anchor Holding CapacityDocumento30 pagine3 - Miedema - Drag Embedded Anchor Holding Capacitycxb07164100% (1)

- Manual Perkins 2800 SeriesDocumento122 pagineManual Perkins 2800 SeriesAnonymous tXzjQAJttH100% (1)

- Sheet #6Documento2 pagineSheet #6AHMED BAKRNessuna valutazione finora

- Chapter 10: Simple Machines (f2)Documento24 pagineChapter 10: Simple Machines (f2)ummubalqis27Nessuna valutazione finora

- Hi-Lo and PRO-1 Pan Feeder PartsDocumento86 pagineHi-Lo and PRO-1 Pan Feeder Partssergiu20Nessuna valutazione finora

- Blast Valve PV-KK-WDocumento2 pagineBlast Valve PV-KK-WyousufbashaNessuna valutazione finora

- Transducer AccessoriesDocumento6 pagineTransducer AccessoriesMohan ArumugavallalNessuna valutazione finora

- Damping Mass in Mountain Bike SuspensionDocumento27 pagineDamping Mass in Mountain Bike SuspensionAnonymous rFxZ3JUUi100% (3)

- Factors Affecting MachinabilityDocumento1 paginaFactors Affecting MachinabilityPrasad WasteNessuna valutazione finora

- Emp 006Documento2 pagineEmp 006Brian FreemanNessuna valutazione finora

- Ans To IS 800 LSM CodeDocumento11 pagineAns To IS 800 LSM Codeanon_854101020% (1)

- Ex Motor Manual ML WebDocumento156 pagineEx Motor Manual ML WebVíctor Josemaria Rivero DunoNessuna valutazione finora

- Assignment QuestionDocumento15 pagineAssignment QuestionPratik WalimbeNessuna valutazione finora

- Career PathDocumento24 pagineCareer PathMandrata LimdrawanNessuna valutazione finora

- Shaft GroundingDocumento7 pagineShaft GroundingDan Alin MirceaNessuna valutazione finora

- Flexural-Torsional BucklingDocumento25 pagineFlexural-Torsional BucklingMohamed GamalNessuna valutazione finora

- Science 6 Q3 Module 8 WK 8 - v.01 CC-released-07Mar2021Documento20 pagineScience 6 Q3 Module 8 WK 8 - v.01 CC-released-07Mar2021zangNessuna valutazione finora

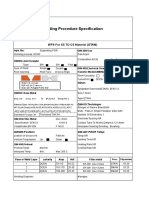

- Welding Procedure Specification: WPS For SS TO CS Material (GTAW)Documento1 paginaWelding Procedure Specification: WPS For SS TO CS Material (GTAW)Lipika GayenNessuna valutazione finora

- FDB Torsion2aDocumento3 pagineFDB Torsion2aVon Oliver RosarioNessuna valutazione finora

- Axle, Front - Differential CarrierDocumento3 pagineAxle, Front - Differential CarrierHusi NihaNessuna valutazione finora

- CSMD Al SD Tt4rev05Documento48 pagineCSMD Al SD Tt4rev05lubangjarumNessuna valutazione finora

- 2.6 Force Pulley SystemDocumento8 pagine2.6 Force Pulley SystemOmkara HiteshNessuna valutazione finora

- Transmotauto 2015Documento107 pagineTransmotauto 2015zoragiNessuna valutazione finora

- Yamaha Ek25bmhDocumento230 pagineYamaha Ek25bmhjorge gerNessuna valutazione finora

- Shell Tellus S3 M 46: Performance, Features & Benefits Main ApplicationsDocumento3 pagineShell Tellus S3 M 46: Performance, Features & Benefits Main ApplicationsSujith KarayilNessuna valutazione finora

- PHYSICAL SCIENCE MODULE 13-EditedDocumento24 paginePHYSICAL SCIENCE MODULE 13-EditedEricha Solomon88% (8)