Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Force Calibration Guide

Caricato da

David Lizandro RojasTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Force Calibration Guide

Caricato da

David Lizandro RojasCopyright:

Formati disponibili

FORCE CALIBRATION

GUIDE 256R3

Accredited Force Calibration Service

ISO/IEC 17025 Accredited Force Calibration Service:

Load Cells (indicated or mV/V)

Proving Rings

Force Gauges

Crane Scales & Traction Dynamometers

Brinell Calibrators

Aircraft Scales

Other force measuring instruments

Forces Ranging from:

0.1 lbf to 2,250,000 lbf in compression

0.1 lbf to 1,000,000 lbf tension

Unquestionable accuracy of deadweight primary standards,

certified by the U.S. National Institute of Standards & Technolo-

gy up to 120,000 lbf, or equivalent kgf/Newtons. All Calibrations

certified traceable to SI units, through N.I.S.T.

Calibrations in accordance with ASTM E74, ISO 376, other

specifications, and customer specified requirements.

ASTM E74 Class AA calibrations for capacities up to 120,000

lbf, or equivalent KGF/Newtons.

ASTM E74 Class A calibrations for capacities up to 2,250,000

lbf, or equivalent KGF/Newtons.

Calibration

Calibration is defined as “the set of operations which establish, under specified conditions, the relationship between values

indicated by a measuring instrument or measuring system, and the corresponding standard or known values derived from the

standard”. It is not just a binding specification, but a method to obtain values that can be repeated and traced to national

standards. Morehouse performs all calibrations using force standards with an unbroken chain of traceability to SI through the

United States National Institute of Standards and Technology (NIST).

Most government, military, and industrial specifications, together with good judgment, dictate force measuring and cali-

brating instruments and systems be calibrated at specified intervals of time. The interval of time between calibrations should

be established and maintained to assure accuracy and reliability.

Accreditation & Compliance

The Force Calibration Laboratory at Morehouse is accredited for calibration to ISO/IEC 17025 and ANSI/NCSL Z540.3

by A2LA (Certificate Number: 1398.01). This accreditation demonstrates technical competence in force calibration and the

operation of a laboratory quality management system. The Force Calibration Laboratory and procedures are compliant with 10

CFR 50 Appendix B: United States Nuclear Regulatory Commission Quality Assurance Criteria for Nuclear Power Plants, 10

CFR Part 21: United States Nuclear Regulatory Commission Reporting of Defects and Noncompliance.

Morehouse Instrument Company, Inc.

717-843-0081 1742 Sixth Avenue, York, PA. 17403-2675 USA WWW.MHFORCE.COM

FORCE CALIBRATION

GUIDE 256R3

ISO/IEC 17025 Accredited ASTM E74 Force Calibration

ASTM E74 requires instruments used as secondary calibration standards to be calibrated by comparison with

deadweights. Morehouse Instrument Company is the only commercial laboratory offering force calibration through

120,000 lbf using deadweights certified by the United States National Institute of Standards and Technology (NIST), by direct

comparison to national standards of mass. Weights have been corrected for Gravity, Material Density and Air Density. Ac-

counting for these variables Morehouse Instrument Company is able to offer force calibrations with an uncertainty of better

than 0.002 % of applied force, through 120,000 lbf.

ASTM requires the loading range not include forces less than the first non-zero point applied during calibra-

tion. Morehouse Instrument Company follows the procedure and guidelines of ASTM-E74 by applying 11 increasing forces

with the first point being well below 10 % of capacity to ensure our customers ASTM Class A lower limits comply with ASTM-

E74. The first test point is the greater of 400 times the resolution for Class A, 2000 times the resolution for Class AA, or 2 %

of the maximum applied force.

Morehouse provides force points below 10 %, so our customers can be in compliant with the following ASTM

E74 sections:

Section 7.2.1: “If the lower limit of the loading range of the device (see 8.6.1) is anticipated to be less than one-tenth of the

maximum force applied during calibration, then forces should be applied at or below this lower limit.”

Section 7.2.1 of ASTM E74-13a: “In no case should the smallest force applied be below the lower limit of the instrument as

defined by the values: 400 x resolution for Class A loading range and 2000 x resolution for Class AA loading range. ”

Section 8.6 of ASTM E74-13a: “The loading range shall not include forces outside the range of forces applied during the cali-

bration.”

Section 8 note 11 of ASTM E74-13a: “It is recommended that the lower force limit be not less than 2 % (1⁄50) of the capacity

of the instrument.”

Calibration Process

Prior to Calibration

We verify work instructions are clear and all equipment is in good working order.

We verify adapters such as pins, loading blocks, cables etc.., were included.

If applicable, we replace used batteries with new ones.

During The Calibration

Calibration is verified against what had been performed previously.

The results are checked to ensure the expected output is in line with previous cali-

brations or like instruments.

Post Calibration

Results are checked to determine if the calibration has changed significantly from

the previous calibration.

Special notes are added about loading conditions, or how we loaded the device to

ensure repeatable measurements the end user can replicate.

Software is programmed, if needed.

Calibration label, with QR code, to allow end user access their calibration report via

the internet is printed.

If ordered, a custom foam fitted case is made.

Packing contents are checked against incoming receiving report to ensure order is

complete, all incoming equipment is accounted for, and makes its way back to the

customer.

Morehouse Instrument Company, Inc.

717-843-0081 1742 Sixth Avenue, York, PA. 17403-2675 USA WWW.MHFORCE.COM

FORCE CALIBRATION

GUIDE 256R3

Calibrations up to 2,250,000 lbf or 10MN

We offer calibration services in compression up to 2,250,000 lbf

(10,000,000 Newtons). This is accomplished using three load cells setup

in a triangular configuration. This configuration allows us to minimize

cosine and bending errors that are common with using two load cells.

We use our custom software to sum the output of all three load cells.

The only way to assign ASTM E74 class A loading ranges is to have the

secondary standard calibrated by Primary Standards. Each of these load

cells is calibrated by NIST in their 1,000,000 lbf (4,400,000 Newton)

deadweight frame, and assigned an ASTM E74 Class AA loading range.

The three load cell’s Lower Limit Factors are root sum squared, and mul-

tiplied by 2000, to give us a Class AA loading range. Morehouse can then

use this system to assign Class A loading ranges.

Measurement Uncertainty

Your measurement uncertainty is directly

affected by the standard used to perform

the calibration. Morehouse primary stand-

ards have uncertainties that are typically 10

- 50 times better than accredited calibration

service suppliers using secondary stand-

ards.

Measurement traceability for force traces

back to the BIPM. Force is derived from the

meter, second and kilogram. The next step

in the pyramid is the National Metrology

Institute (NMI). The NMI is where most Pri-

mary Reference Laboratories have their

equipment calibrated. The purpose of the

diagram on the left is to illustrate measure-

ment uncertainty and how uncertainty increases. Morehouse offers deadweight calibrations with calibration and measure-

ment capability of 0.0008 % (8 ppm) of applied force. When we use secondary standards, we maintain 0.005 % (50 ppm)

of applied force. This is for one standard deviation and is much lower than several other primary and secondary laboratories.

The reference standard uncertainty must be included in any uncertainty budget. The way we keep such low uncertainties is

by manufacturing the best standards and having them calibrated by N.I.S.T.

Morehouse Instrument Company, Inc.

717-843-0081 1742 Sixth Avenue, York, PA. 17403-2675 USA WWW.MHFORCE.COM

FORCE CALIBRATION

GUIDE 256R3

Calibration Adapters

We take great pride in our line of accessories and adapters. We design adapters to allow us to replicate use, while elimi-

nating off axis or eccentric loading conditions. These adapters we use in our lab are available to purchase. Our tension

quick change adapters meet the requirements of the international force standard ISO 376. Section A4 of the standard states,

“Loading fittings should be designed in such a way that the line of force application is not distorted. As a rule, tensile force

transducers should be fitted with two ball nuts, two ball cups and, if necessary, with two intermediate rings,

while compression force transducers should be fitted with one or two compression pads.”

The adapters above are a result of Morehouse employees attending a lean manufacturing course. Part of this course em-

phasized reducing cycle time, by reducing the amount of time it would take to set up equipment for a load cell calibration.

These adapters simplified our laboratory setups, improved our performance with better alignment, and were cost-effective

compared to the alternative of multiple pieces of threaded rod or multiple rod end type setups. As a result of optimizing the

calibration setup, we were able to standardize production flow, provide better measurements, and free additional floor space

for future expansion. A full product guide on Quick Change Tension Members can be downloaded at our web site.

Commitment to Quality

Quality manufacturing and services has been the unchanged Morehouse principle since 1925. Maintaining the most accu-

rate standards, such as our deadweight machines, ensures Morehouse customers and their end users obtain the lowest possi-

ble uncertainties in their force measurements. Our calibration services are tailored and customized for each customer, to en-

sure reliable and accurate test results for their specific needs.

Call today to start improving your force measurement uncertainties.

Morehouse Instrument Company, Inc.

717-843-0081 1742 Sixth Avenue, York, PA. 17403-2675 USA WWW.MHFORCE.COM

Potrebbero piacerti anche

- The New Art of Photographing Nature - ExcerptDocumento15 pagineThe New Art of Photographing Nature - ExcerptCrown Publishing GroupNessuna valutazione finora

- Bill of Quantities 16FI0009Documento1 paginaBill of Quantities 16FI0009AJothamChristianNessuna valutazione finora

- Domesticity and Power in The Early Mughal WorldDocumento17 pagineDomesticity and Power in The Early Mughal WorldUjjwal Gupta100% (1)

- ArresterFacts 033 IEC Energy Handling Tests PDFDocumento9 pagineArresterFacts 033 IEC Energy Handling Tests PDFbinodeNessuna valutazione finora

- ASTM E74-and-Uncertainty-Calculation-ExampleDocumento48 pagineASTM E74-and-Uncertainty-Calculation-ExampleLuân Nguyễn QuỳnhNessuna valutazione finora

- Seismic Capability of BushingsDocumento6 pagineSeismic Capability of Bushingsfvicunae100% (1)

- ArresterFacts 033 IEC Energy Handling TestsDocumento8 pagineArresterFacts 033 IEC Energy Handling TestsSanjay DevrajNessuna valutazione finora

- New 2018 Version of ASTM E74 Standard Explained Webinar PDFDocumento70 pagineNew 2018 Version of ASTM E74 Standard Explained Webinar PDFrobert0% (1)

- Lr5Kplus: 5 KN Universal Materials Testing MachineDocumento3 pagineLr5Kplus: 5 KN Universal Materials Testing Machinebrayan jimenezNessuna valutazione finora

- Procedure Rev 001Documento8 pagineProcedure Rev 001Mustafa ZakiedinNessuna valutazione finora

- ISO 376 Explained PDFDocumento67 pagineISO 376 Explained PDFrobertNessuna valutazione finora

- Force Measurement Services at NIST: Equipment, Procedures, and UncertaintyDocumento11 pagineForce Measurement Services at NIST: Equipment, Procedures, and Uncertaintygto303Nessuna valutazione finora

- Lr100Kplus 100 KN Universal Materials Testing Machine: FeaturesDocumento2 pagineLr100Kplus 100 KN Universal Materials Testing Machine: FeaturesSoup PongsakornNessuna valutazione finora

- ASTM E74 ExplainedDocumento62 pagineASTM E74 ExplainedCharlo GordoNessuna valutazione finora

- 1828 1 PDFDocumento16 pagine1828 1 PDFsunitkghosh1Nessuna valutazione finora

- Recloser and Breaker Standards Comparison Information Td280024enDocumento8 pagineRecloser and Breaker Standards Comparison Information Td280024enanant84Nessuna valutazione finora

- 1996april June PDFDocumento4 pagine1996april June PDFmadhan_22Nessuna valutazione finora

- Calibration of Working Standards - ResistanceDocumento15 pagineCalibration of Working Standards - Resistanceahmed AwadNessuna valutazione finora

- Part 8 - Laboratory Testing EquipmentDocumento23 paginePart 8 - Laboratory Testing EquipmentYarisel Shosha MuñozNessuna valutazione finora

- Chapter 2 PQ StandardsDocumento31 pagineChapter 2 PQ StandardsruhaizadNessuna valutazione finora

- Performance Tests: Air Handling UnitsDocumento4 paginePerformance Tests: Air Handling UnitseslamNessuna valutazione finora

- Test Facilities Condition Monitoring Infrastructure: ComponentsDocumento2 pagineTest Facilities Condition Monitoring Infrastructure: ComponentsKiranNessuna valutazione finora

- D3233Documento10 pagineD3233tritihNessuna valutazione finora

- Distribution Transformer TestingDocumento2 pagineDistribution Transformer TestingjamilsoriaNessuna valutazione finora

- Procedura Za Proveru VagaDocumento4 pagineProcedura Za Proveru VagaDragan LazicNessuna valutazione finora

- New Isa Web Site: The Four New Features On CBA 2000 AreDocumento2 pagineNew Isa Web Site: The Four New Features On CBA 2000 AreSlobodan SavicNessuna valutazione finora

- Calibration of Force-Measuring Instruments For Verifying The Force Indication of Testing MachinesDocumento18 pagineCalibration of Force-Measuring Instruments For Verifying The Force Indication of Testing MachinesMiguel BazalduaNessuna valutazione finora

- Multi-Functional Primary Test System For Substation Commissioning and MaintenanceDocumento44 pagineMulti-Functional Primary Test System For Substation Commissioning and MaintenanceMajid Raja ChauhanNessuna valutazione finora

- CPC 100 Brochure ENUDocumento44 pagineCPC 100 Brochure ENUanon_793851477Nessuna valutazione finora

- SC17A-Harmonization - IEC-IEEE StandardsDocumento16 pagineSC17A-Harmonization - IEC-IEEE StandardsDante FilhoNessuna valutazione finora

- Multi-Functional Primary Test System For Substation Commissioning and MaintenanceDocumento44 pagineMulti-Functional Primary Test System For Substation Commissioning and MaintenanceAbdul HadiNessuna valutazione finora

- CPC 100 Brochure ENUDocumento44 pagineCPC 100 Brochure ENUhuanNessuna valutazione finora

- Principles of CalibrationDocumento10 paginePrinciples of CalibrationClark Joshua Fernandez100% (1)

- Universal Calibrating Machines UCM Datasheet PD 5201Documento4 pagineUniversal Calibrating Machines UCM Datasheet PD 5201Rocky TongiaNessuna valutazione finora

- Load Cells: General DescriptionDocumento4 pagineLoad Cells: General DescriptionHaikalNessuna valutazione finora

- Ntepbk 2Documento2 pagineNtepbk 2Angel Eduardo PeñaNessuna valutazione finora

- Transfer Switch SelectionDocumento8 pagineTransfer Switch SelectionSimoncarter LawNessuna valutazione finora

- 10-31-2018-10-59-15-AMLiterature Portable UCMDocumento2 pagine10-31-2018-10-59-15-AMLiterature Portable UCMBHAART PANCHALNessuna valutazione finora

- Airbus. Test EquipmentDocumento14 pagineAirbus. Test EquipmentСергей НиколаевNessuna valutazione finora

- CPC 100 Brochure ENU PDFDocumento44 pagineCPC 100 Brochure ENU PDFudomkarn SamanmitNessuna valutazione finora

- Ansi C84Documento6 pagineAnsi C84Ramiro Magbanua FelicianoNessuna valutazione finora

- Commissioning Services Department Commissioning Manual Factory Type and Routine TestsDocumento19 pagineCommissioning Services Department Commissioning Manual Factory Type and Routine Testsm khNessuna valutazione finora

- Tansfomer SizeDocumento3 pagineTansfomer Sizerovic.esprelaNessuna valutazione finora

- How To Test An RF Coaxial Cable Using A VNADocumento5 pagineHow To Test An RF Coaxial Cable Using A VNAStefanvnvNessuna valutazione finora

- Partial Discharge 1 PDFDocumento8 paginePartial Discharge 1 PDFsamsungloverNessuna valutazione finora

- Votano 100: Voltage Transformer Testing, Calibration and AssessmentDocumento16 pagineVotano 100: Voltage Transformer Testing, Calibration and AssessmentanuragpugaliaNessuna valutazione finora

- Votano 100: Voltage Transformer Testing, Calibration and AssessmentDocumento16 pagineVotano 100: Voltage Transformer Testing, Calibration and AssessmentHugo AguiarNessuna valutazione finora

- Votano 100 Brochure EnuDocumento16 pagineVotano 100 Brochure EnudwijanuarpribadiNessuna valutazione finora

- Electrical Test & Measurement Power Product Catalog: Next Generation of Testing TechnologyDocumento19 pagineElectrical Test & Measurement Power Product Catalog: Next Generation of Testing TechnologyWilliam RaicoNessuna valutazione finora

- Accreditation 2019 ZwickRoell Perry JohnsonDocumento7 pagineAccreditation 2019 ZwickRoell Perry JohnsonLuis Angeles SotoNessuna valutazione finora

- 1996oct Dec PDFDocumento6 pagine1996oct Dec PDFJothimanikkam SomasundaramNessuna valutazione finora

- Stcal: Spark Test Calibration SystemDocumento2 pagineStcal: Spark Test Calibration SystemPaul CruzNessuna valutazione finora

- Iecre Flyera4 Retl LRDocumento2 pagineIecre Flyera4 Retl LRBalaji_Rajaman_2280Nessuna valutazione finora

- Astm E74 18Documento10 pagineAstm E74 18José BellónNessuna valutazione finora

- 345KV Autotransformer Spec (08.29.2012)Documento56 pagine345KV Autotransformer Spec (08.29.2012)Dante FilhoNessuna valutazione finora

- (09-0a) Transformer Testing Systems - v1.9Documento8 pagine(09-0a) Transformer Testing Systems - v1.9SrinivasanNessuna valutazione finora

- IEC 60060-3 Revisión 1 - SRDocumento37 pagineIEC 60060-3 Revisión 1 - SRluis lopezNessuna valutazione finora

- Basic Requirement For MVSG SelectionDocumento50 pagineBasic Requirement For MVSG SelectionElsan BalucanNessuna valutazione finora

- Proficiency Test Sheet: MorehouseDocumento25 pagineProficiency Test Sheet: MorehouseallaboutfreeNessuna valutazione finora

- Method of Statement For Power Cables: Owner/Client Consultant ContractorDocumento7 pagineMethod of Statement For Power Cables: Owner/Client Consultant ContractorPandrayar MaruthuNessuna valutazione finora

- Handbook of Microwave Component Measurements: with Advanced VNA TechniquesDa EverandHandbook of Microwave Component Measurements: with Advanced VNA TechniquesValutazione: 4 su 5 stelle4/5 (1)

- Institutions and StrategyDocumento28 pagineInstitutions and StrategyFatin Fatin Atiqah100% (1)

- Entrepreneurship - PPTX Version 1 - Copy (Autosaved) (Autosaved) (Autosaved) (Autosaved)Documento211 pagineEntrepreneurship - PPTX Version 1 - Copy (Autosaved) (Autosaved) (Autosaved) (Autosaved)Leona Alicpala67% (3)

- Tenses English Grammar PresentationDocumento14 pagineTenses English Grammar PresentationMaz Gedi60% (5)

- 02 CT311 Site WorksDocumento26 pagine02 CT311 Site Worksshaweeeng 101Nessuna valutazione finora

- Saudi Methanol Company (Ar-Razi) : Job Safety AnalysisDocumento7 pagineSaudi Methanol Company (Ar-Razi) : Job Safety AnalysisAnonymous voA5Tb0Nessuna valutazione finora

- Investigation Data FormDocumento1 paginaInvestigation Data Formnildin danaNessuna valutazione finora

- Capgemini - 2012-06-13 - 2012 Analyst Day - 3 - Michelin - A Better Way ForwardDocumento12 pagineCapgemini - 2012-06-13 - 2012 Analyst Day - 3 - Michelin - A Better Way ForwardAvanish VermaNessuna valutazione finora

- Art Appreciation Chapter 3 SummaryDocumento6 pagineArt Appreciation Chapter 3 SummaryDiego A. Odchimar IIINessuna valutazione finora

- MSCM Dormitory Housing WEB UpdateDocumento12 pagineMSCM Dormitory Housing WEB Updatemax05XIIINessuna valutazione finora

- Ultimate Trading Guide - Flash FUT 2023Documento33 pagineUltimate Trading Guide - Flash FUT 2023marciwnw INessuna valutazione finora

- Auditing Principles and Practices-IDocumento8 pagineAuditing Principles and Practices-IMoti BekeleNessuna valutazione finora

- Fin Accounting IFRS 2e Ch13Documento62 pagineFin Accounting IFRS 2e Ch13Nguyễn Vinh QuangNessuna valutazione finora

- Present Tenses ExercisesDocumento4 paginePresent Tenses Exercisesmonkeynotes100% (1)

- Sheetal PatilDocumento4 pagineSheetal PatilsheetalNessuna valutazione finora

- PDF BrochureDocumento50 paginePDF BrochureAnees RanaNessuna valutazione finora

- Oil List: Audi Front Axle DriveDocumento35 pagineOil List: Audi Front Axle DriveAska QianNessuna valutazione finora

- 5045.CHUYÊN ĐỀDocumento8 pagine5045.CHUYÊN ĐỀThanh HuyềnNessuna valutazione finora

- City Limits Magazine, December 1981 IssueDocumento28 pagineCity Limits Magazine, December 1981 IssueCity Limits (New York)Nessuna valutazione finora

- JEE Mains Paper 1 (12 Apr 2019 Shift 2) EnglishDocumento131 pagineJEE Mains Paper 1 (12 Apr 2019 Shift 2) EnglishRudraksha KushwahaNessuna valutazione finora

- Solutions DPP 2Documento3 pagineSolutions DPP 2Tech. VideciousNessuna valutazione finora

- Fertilisation and PregnancyDocumento24 pagineFertilisation and PregnancyLopak TikeNessuna valutazione finora

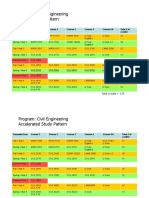

- HKUST 4Y Curriculum Diagram CIVLDocumento4 pagineHKUST 4Y Curriculum Diagram CIVLfrevNessuna valutazione finora

- Lab Science of Materis ReportDocumento22 pagineLab Science of Materis ReportKarl ToddNessuna valutazione finora

- Vest3000mkii TurntableDocumento16 pagineVest3000mkii TurntableElkin BabiloniaNessuna valutazione finora

- Eng Notes2Documento10 pagineEng Notes2Arti KapurNessuna valutazione finora

- Legrand Price List-01 ST April-2014Documento144 pagineLegrand Price List-01 ST April-2014Umesh SutharNessuna valutazione finora

- Final SEC Judgment As To Defendant Michael Brauser 3.6.20Documento14 pagineFinal SEC Judgment As To Defendant Michael Brauser 3.6.20Teri BuhlNessuna valutazione finora