Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

HSEM TH 11-1 Fire Prevention

Caricato da

abdullah amanullahCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

HSEM TH 11-1 Fire Prevention

Caricato da

abdullah amanullahCopyright:

Formati disponibili

HSEM 11.

1 Page 2 of 7

Fire Prevention Rev. A, 25 Jan 2016

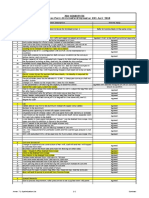

Table of Contents

1.0 PURPOSE AND SCOPE ................................................................................................................................... 3

2.0 RESPONSIBILITIES ......................................................................................................................................... 3

2.1. Site Management ................................................................................................................................. 3

2.2. Supervision ........................................................................................................................................... 3

2.3. Employee ............................................................................................................................................. 3

2.4. Site HSE Supervisor ............................................................................................................................. 3

3.0 DEFINITIONS .................................................................................................................................................... 3

4.0 PROCEDURE .................................................................................................................................................... 3

4.1. General ................................................................................................................................................. 3

4.2. Classes of Fire...................................................................................................................................... 4

4.3. Flammable Liquids (Flash Point 37.8C (100° F) or Less).................................................................... 4

4.4. Good Housekeeping to Prevent Fires ................................................................................................... 5

4.5. Safe Handling of Flammable & Combustible Materials ......................................................................... 5

4.6. Proper Use of Fire Fighting Equipment ................................................................................................ 5

4.7. Inspection and Storage ......................................................................................................................... 6

4.7.1. Inspection .................................................................................................................................... 6

4.7.2. Storage ........................................................................................................................................ 6

4.8. Training ................................................................................................................................................ 7

5 REFFERENCE .................................................................................................................................................. 7

Copyright©2011, Jacobs Engineering Group Inc.

HSEM 11.1 Page 3 of 7

Fire Prevention Rev. A, 25 Jan 2016

1.0 PURPOSE AND SCOPE

This Procedure provides the minimum procedures to be followed for fire prevention in the

workplace, and is a key to ensuring the safety and health of employees.

This Procedure applies to all employees and subcontractors engaged in operations covered by the

Company HSE Program.

2.0 RESPONSIBILITIES

General responsibilities for HSE procedures implementation and position descriptions are stated in

HSEM TH1.4. Additional responsibilities specific to this Procedure include the following.

2.1. Site Management

Site Management must assume ownership and responsibility for implementation of the policy and

procedures found in this Manual.

2.2. Supervision

Supervisors responsible for employees performing work covered by the Company’s Fire Prevention

Procedure must:

Continuously monitor the work to assure compliance with this Procedure.

Confirm each job has been properly evaluated for fire hazards, and these hazards have been

properly eliminated or controlled.

Ensure employees are aware of any hazards associated with their work.

2.3. Employee

Employees must comply with the provisions of this Procedure according to instructions and training

received.

2.4. Site HSE Supervisor

The Site HSE Supervisor shall assist Site Management in compliance with this Procedure, as well

as monitor field activity for compliance.

3.0 DEFINITIONS

None

4.0 PROCEDURE

4.1. General

All fire incidents shall be reported immediately, no matter how small the fire or even the fire has

been distinguished already.

The prevention of fires is of utmost importance. Good housekeeping and equipment maintenance

must be followed to keep fire hazards at a minimum.

Matches and cigarette lighters should not be carried into any area where an explosive atmosphere

may be present.

Smoking must be confined to areas specifically designated and shall be provide with fire

extinguishers.

Copyright©2011, Jacobs Engineering Group Inc.

HSEM 11.1 Page 4 of 7

Fire Prevention Rev. A, 25 Jan 2016

Smoking is not permitted in the immediate vicinity of tank batteries, oil and gas wells, or in any area

suspected or known to contain flammable vapors, regardless of whether or not a "no smoking"

signage is displayed. Any area subject to contamination by flammable liquids or gas should be

designated as a "no smoking area,” and a sign to that effect should be displayed.

Before an open flame (such as a welding torch) is carried into a closed building or tank, a test

should be made to detect the presence of gas using an approved combustible gas indicator.

The use of gasoline as a cleaning agent is strictly forbidden.

Oil or gasoline from leaks should be cleaned up and disposed of in a prescribed manner.

All leaks should be reported and repaired immediately, if practicable. If immediate repair is not

possible, adequate warning signs must be posted and extra precaution against fires instituted.

In the event of a gas leak, all open flame operation and engines should be shut down immediately.

When testing for gas leaks, use soap suds or approved leak detector fluid. Never use an open

flame.

Since paint and insect sprays and most paint removers are usually flammable, their use near open

flames or other sources of ignition must be avoided. Read the labels on the containers.

4.2. Classes of Fire

Class "A" fires are those that occur in ordinary materials such as wood, paper, rags, and rubbish.

The quenching and cooling effects of water or of solutions containing large percentages of water

are of first importance in extinguishing these fires.

Class "B" fires are those that occur in the vapor-air mixture over the surface of flammable liquids

such as gasoline, oil, grease, paints and thinners. The limiting of air is of primary importance.

Generally, regular dry chemical, multi-purpose dry chemical, carbon dioxide, and foam may be

used depending on the circumstances of the fire. Solid streams of water are likely to spread the

fire, but on large fires of this class, water fog nozzles prove effective.

Class "C" fires are those which occur in or near electrical equipment where non-conducting

extinguishing agents shall be used. Dry chemical, carbon dioxide, compressed gas, or vaporizing

liquid may be used. Foam or a solid stream of water should not be used because both are good

conductors and can expose the operator to a severe shock hazard.

Class "D" fires are those that occur in combustible metals such as magnesium, titanium, zirconium,

lithium and sodium. Specialized techniques, extinguishing agents, and extinguishing equipment are

needed to control and extinguish fires of this type. Normal extinguishing agents generally should

not be used as there is a danger in most cases of increasing intensity of the fire because of a

chemical reaction between some extinguishing agents and the burning metal.

4.3. Flammable Liquids (Flash Point 37.8C (100° F) or Less)

Flammable liquids such as gasoline, benzene, naphtha, and lacquer thinner must not be used for

cleaning purposes.

Spills or overflow of flammable liquids should be avoided. However, in the event of spillage,

immediate steps should be taken to clean up and minimize the danger of fire.

When liquids such as condensates, gasoline, and some crude oils are drawn into open metal

containers, the open container must be grounded by means of either threaded connections or a

bonding wire to the vessel or piping in order to prevent any possible ignition source from

generation of static electricity.

Copyright©2011, Jacobs Engineering Group Inc.

HSEM 11.1 Page 5 of 7

Fire Prevention Rev. A, 25 Jan 2016

With exceptions of gasoline and oil, the mixing of two or more flammable liquids is prohibited.

When pumping highly flammable liquids from one container to another, metallic contact should

always be maintained between the two containers.

4.4. Good Housekeeping to Prevent Fires

Good housekeeping should be maintained at all work locations and in all vehicles.

Paper and other combustible materials should not be allowed to accumulate.

4.5. Safe Handling of Flammable & Combustible Materials

Never handle a flammable substance near a heat source or bring a heat source near a flammable

substance.

Safe transfers of flammable liquids are made in an open, well ventilated area where the vapors will

be diluted and dissipated by large quantities of fresh air. Make sure you have a bond between

containers to eliminate static electricity.

Using funnels and spouted cans makes for a quick transfer and helps prevent dangerous spills.

Flammable and combustible liquid spills should be cleaned up immediately.

When refueling or lubricating machinery, be certain that it is shut down first. Pieces of machinery

like exhaust pipes and bearings radiate heat, and electrical systems generate sparks that can

ignite in an accidental spill. If fuel is dispensed from a fuel truck, the truck should be grounded to

equipment being filled.

Be certain that an engine is supplied with the proper type of fuel and the fuel supply is shut off by a

valve when the engine is not in use.

Never use gasoline as a solvent - it produces dangerous amounts of vapor. Always use a high

flashpoint solvent or thinner for cleaning off paint, grease, or oil around equipment.

4.6. Proper Use of Fire Fighting Equipment

When fighting a fire with a standard portable fire extinguisher, use the following procedure in

extinguishing the fire.

Always use the handle to carry an extinguisher. Walk at a rapid pace -- do not run to a fire.

Proceed to the upwind side of a fire. Stay well clear of the flames. When you are

approximately 3 meters upwind of the near edge, stop and ready your extinguisher for

discharge.

Once your extinguisher is set for discharge, position yourself within 2.6 m of the near edge

upwind of the fire. From this position, the air currents help carry the agent into the fire

assuring maximum visibility and providing protection from the heat.

When discharging the extinguishing agent, aim your stream just short of the near edge at

the base of the fire.

Apply the agent in a side-to-side sweeping action across the full width of the fire. Make

sure each sweep of the extinguishing agent is slightly wider than the near or leading edge

of fire.

Advance forward only as fast as the extinguishing action of your agent will permit. Do not

outrun your protection. Do not raise your stream to chase the flame. Keep it down in front

of the flame edge.

Stop short of the already extinguished fuel area. Do not become involved in the fire.

Above all, maintain your side-to-side sweeping action until the fire is extinguished. Once

Copyright©2011, Jacobs Engineering Group Inc.

HSEM 11.1 Page 6 of 7

Fire Prevention Rev. A, 25 Jan 2016

the fire is out, stand by for a few minutes. Make sure there is no danger of a re-flash. Do

not ever turn your back on an apparently extinguished fire.

4.7. Inspection and Storage

4.7.1. Inspection

Inspection and maintenance of all fire fighting equipment will be performed by a competent

inspector. Records of inspection and maintenance must be maintained. The following

general guidelines will be observed:

Portable fire extinguishers shall be inspected at least monthly. At regular intervals, not

more than one year apart, extinguishers shall be thoroughly examined and/or

recharged or repaired to ensure operability and safety or replaced as needed. Each

extinguisher shall have a durable tag securely attached to show the maintenance or

recharge date and the initial or signature of the person performing the service.

Fire extinguisher hose nozzles should be kept free of obstruction at all times.

In areas where insects tend to nest in protected small areas, the nozzle should be

covered with small cloth or plastic bag to keep it free of obstructions.

A fire extinguisher that is empty, defective, or has been discharged should never be re-

hung until it has been serviced or repaired. It is necessary that extinguishers operate

at top efficiency the instant they are used. Fire extinguishers should be kept filled.

Manufacturer's instructions for refilling and maintaining extinguishers must be followed.

Due diligence must be used in keeping sprinkler systems in good operating condition.

4.7.2. Storage

All flammable liquids/solvents should be kept in approved, properly labeled containers.

Small quantities of flammable liquids such as gasoline and solvents should be handled,

transported, dispensed and stored in approved, marked safety cans. Safety cans have

self-closing caps, flame arrestors, and pressure relief vents. The contents must be

properly labeled.

Cans of oil, kerosene, oily rags, waste, etc., must not be allowed near stoves or gas fires.

Gasoline, kerosene, or other flammable liquids must not be stored in glass containers.

Do not store flammable liquids in open containers.

Flammable and combustible materials such as oil or gasoline soaked rags/clothing, oily

waste and shavings must not be left lying around or piled on the ground. Spontaneous

combustion is likely to result and cause a fire. These materials must be stored in approved

and covered metal containers. These containers should have self closing lids, and should

be emptied daily to maintain the premises in a safe and sanitary condition.

Because of their convenient size, aerosol cans are often stored or set down in unsafe

places. Keep in mind that all aerosol cans are pressurized and that this pressure

increases when exposed to heat. If the can is overheated, it will explode like a hand

grenade. Aerosol spray cans containing various commodities are typically labeled as

flammable. If the product isn’t flammable, the propellant usually is. Do not store

pressurized aerosol flammable cans in non-approved storage containers.

Storage cabinets, rooms, or particular areas should be designated to store flammable

liquids. Cabinets should be labeled:

"FLAMMABLE - KEEP FIRE AWAY".

Not more than 228 litres (60 gallons) of flammable, or 455 litres (120 gallons) of

combustible liquid shall be shored in any one storage cabinet or container.

Copyright©2011, Jacobs Engineering Group Inc.

HSEM 11.1 Page 7 of 7

Fire Prevention Rev. A, 25 Jan 2016

Not more than 95 litres (25 gallons) of flammable liquids shall be stored outside an

approved storage cabinet, unless a designated area has been provided which meets all

regulatory requirements.

Dispensing drums should be equipped with special self-closing faucets and pressure

vacuum relief vents. Also, a ground wire should be attached.

Large quantities of flammable liquids should be stored well away from the immediate work

area.

Outside portable tank storage shall be located no closer than 7.6 meters from any building.

Fire fighting equipment is for fire use only and shall be kept in its designated place at all

times when not in use.

All fire protection equipment must be located in designated areas that are clearly identified

with appropriate markings. This equipment should be located in the vicinity of likely fire

hazards, but it must be accessible to operating personnel. The number, type, and location

of extinguishers must meet all applicable standards.

4.8. Training

All employees shall be properly trained in accordance with this Procedure.

Fire drills should be held at regular intervals to familiarize employees with the emergency/fire

response procedures for the work site as well as the location and operation of fire extinguishing

equipment.

All employees should be instructed in the proper use of available fire fighting equipment. Those

working at places where special precautions against fire must be taken are required to be so

instructed.

5 REFFERENCE

Regulations set the standard in management and implementation of Safety Health and

Environment to work on the prevention and extinguishing of 2555

Regulation of the units training and fire drill 2556

Copyright©2011, Jacobs Engineering Group Inc.

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- PT2 Revision Worksheet EnglishDocumento3 paginePT2 Revision Worksheet Englishabdullah amanullahNessuna valutazione finora

- Carregadeira LiebherrDocumento17 pagineCarregadeira Liebherrsanches pita100% (5)

- Annex 7.1 Optimization ListDocumento5 pagineAnnex 7.1 Optimization Listabdullah amanullahNessuna valutazione finora

- 10.final Master Plan ParadipDocumento128 pagine10.final Master Plan Paradipabdullah amanullahNessuna valutazione finora

- Aspen Plus Gettingstarted ElectrolytesDocumento63 pagineAspen Plus Gettingstarted ElectrolytessamrickyNessuna valutazione finora

- AD R 004 Acoustic ReportDocumento43 pagineAD R 004 Acoustic Reportabdullah amanullahNessuna valutazione finora

- Solubility CurveDocumento2 pagineSolubility CurveDanni SulaimanNessuna valutazione finora

- Exp 2 Total Suspended SolidsDocumento3 pagineExp 2 Total Suspended Solidssaras8788% (8)

- 3.1 WeatheringDocumento25 pagine3.1 WeatheringSipu GiriNessuna valutazione finora

- Fertilizer Subsidieswhich Way Forward 2 21 2017 PDFDocumento327 pagineFertilizer Subsidieswhich Way Forward 2 21 2017 PDFsharemwNessuna valutazione finora

- Worksheet - WaterDocumento2 pagineWorksheet - Waterabdullah amanullah100% (2)

- Nonmetal Ducts - Guide Specification - Updated 6-2019Documento17 pagineNonmetal Ducts - Guide Specification - Updated 6-2019abdullah amanullahNessuna valutazione finora

- Aurora Fire PumpDocumento8 pagineAurora Fire Pumpabdullah amanullahNessuna valutazione finora

- Mohamed Anas.S: Job ObjectiveDocumento3 pagineMohamed Anas.S: Job Objectiveabdullah amanullahNessuna valutazione finora

- Sabb-Gray Water WsfuDocumento22 pagineSabb-Gray Water Wsfuabdullah amanullahNessuna valutazione finora

- CR Architecture + Design Kroger J717 Indianapolis, IN CR# 516361 May 4, 2016Documento5 pagineCR Architecture + Design Kroger J717 Indianapolis, IN CR# 516361 May 4, 2016abdullah amanullahNessuna valutazione finora

- New Indian Model School, Sharjah: Islamic Holidays' Assignment Primary SectionDocumento1 paginaNew Indian Model School, Sharjah: Islamic Holidays' Assignment Primary Sectionabdullah amanullahNessuna valutazione finora

- Science Summer Break - Holiday Assignment 2019 - 20Documento2 pagineScience Summer Break - Holiday Assignment 2019 - 20abdullah amanullahNessuna valutazione finora

- L-4 Environment NotesDocumento2 pagineL-4 Environment Notesabdullah amanullahNessuna valutazione finora

- English Summer Break - Holiday Assignment 2019 - 20Documento2 pagineEnglish Summer Break - Holiday Assignment 2019 - 20abdullah amanullahNessuna valutazione finora

- Tamil (Second Language) Summer Break - Holiday Assignment 2019 - 20Documento2 pagineTamil (Second Language) Summer Break - Holiday Assignment 2019 - 20abdullah amanullahNessuna valutazione finora

- New Indian Model School, Sharjah: Holiday Homework Hindi - Grade 3Documento3 pagineNew Indian Model School, Sharjah: Holiday Homework Hindi - Grade 3abdullah amanullahNessuna valutazione finora

- 15730-DX Cooling Units Rev 01Documento10 pagine15730-DX Cooling Units Rev 01abdullah amanullahNessuna valutazione finora

- Uae Social Studies Summer Break - Holiday Assignment 2019 - 20Documento2 pagineUae Social Studies Summer Break - Holiday Assignment 2019 - 20abdullah amanullahNessuna valutazione finora

- Revision SSTDocumento2 pagineRevision SSTabdullah amanullahNessuna valutazione finora

- Sub Enrichment - Gr-3 - Our BodyDocumento2 pagineSub Enrichment - Gr-3 - Our Bodyabdullah amanullahNessuna valutazione finora

- Automatedmeterreadingtechnology PDFDocumento5 pagineAutomatedmeterreadingtechnology PDFabdullah amanullahNessuna valutazione finora

- 0.list of Drawing - Lower LevelDocumento1 pagina0.list of Drawing - Lower Levelabdullah amanullahNessuna valutazione finora

- Technical Review Report: Applicant InformationDocumento3 pagineTechnical Review Report: Applicant Informationabdullah amanullahNessuna valutazione finora

- Annex 13 Exclusion ListDocumento1 paginaAnnex 13 Exclusion Listabdullah amanullahNessuna valutazione finora

- A) Condition Unable To Understand Something: IV Match The MeaningsDocumento2 pagineA) Condition Unable To Understand Something: IV Match The Meaningsabdullah amanullahNessuna valutazione finora

- New Indian Model School, SharjahDocumento2 pagineNew Indian Model School, Sharjahabdullah amanullahNessuna valutazione finora

- Infrastructure Charges Notice CalculatorDocumento1 paginaInfrastructure Charges Notice Calculatorabdullah amanullahNessuna valutazione finora

- Annex 11 List of Spare Parts For 2 Year OperationDocumento16 pagineAnnex 11 List of Spare Parts For 2 Year Operationabdullah amanullahNessuna valutazione finora

- 1 Extra External Piping Going To Each Lab MTR 250 100 25000.00 2 Extra Point For Kitchen MTR 50 20 1000Documento5 pagine1 Extra External Piping Going To Each Lab MTR 250 100 25000.00 2 Extra Point For Kitchen MTR 50 20 1000abdullah amanullahNessuna valutazione finora

- Deliverable SDocumento2 pagineDeliverable Sabdullah amanullahNessuna valutazione finora

- Biological Molecules: Grade 9 BiologyDocumento28 pagineBiological Molecules: Grade 9 BiologyHeyitsyasi xoxNessuna valutazione finora

- Selection of Pectin As Pharmaceutical Excepient On The Basis of Rheological BehaviorDocumento3 pagineSelection of Pectin As Pharmaceutical Excepient On The Basis of Rheological BehaviorВладимир КондратенкоNessuna valutazione finora

- Geographical Organisation: Marketing ManagerDocumento10 pagineGeographical Organisation: Marketing ManagerVinod MalkarNessuna valutazione finora

- Gardex Catalogue 2010Documento35 pagineGardex Catalogue 2010dongheep811Nessuna valutazione finora

- Gangadharan Nair Pulingat 2014 5Documento53 pagineGangadharan Nair Pulingat 2014 5Kedar A. MalusareNessuna valutazione finora

- Sinomarin (R)Documento3 pagineSinomarin (R)mesaimeerNessuna valutazione finora

- S - Amlo BesylateDocumento20 pagineS - Amlo BesylateDrkrishnasarma pathyNessuna valutazione finora

- Stability of PVDF Hollow Fibre Membranes in Sodium Hydroxide Aqueous SolutionDocumento11 pagineStability of PVDF Hollow Fibre Membranes in Sodium Hydroxide Aqueous SolutionrameshNessuna valutazione finora

- Commpany Profile - Hipack LabelprinDocumento4 pagineCommpany Profile - Hipack LabelprinAzharul FuadNessuna valutazione finora

- An Improved Isolation of Trimyristin From Myristica Fragrans As A Renewable Feedstock With The Assistance of Novel Cationic Gemini SurfactantDocumento16 pagineAn Improved Isolation of Trimyristin From Myristica Fragrans As A Renewable Feedstock With The Assistance of Novel Cationic Gemini SurfactantNabila PutriNessuna valutazione finora

- Chemical Bonding 2Documento16 pagineChemical Bonding 2yvg95100% (1)

- Investigation of Mechanical Properties of Rice Straw Fiber Epoxy CompositeDocumento8 pagineInvestigation of Mechanical Properties of Rice Straw Fiber Epoxy CompositeAnson DsouzaNessuna valutazione finora

- Subject: Chemistry Chapter #: 6: Quantitative Chemistry - How Much? (Moles)Documento26 pagineSubject: Chemistry Chapter #: 6: Quantitative Chemistry - How Much? (Moles)Haider Ali100% (2)

- Bioinspiration and BiomimeticsDocumento7 pagineBioinspiration and BiomimeticsAyush 100niNessuna valutazione finora

- A Look at Perfusion - The Upstream Continuous ProcessDocumento2 pagineA Look at Perfusion - The Upstream Continuous ProcessFISHNessuna valutazione finora

- Satyam Bhuyan Wear 2010Documento6 pagineSatyam Bhuyan Wear 2010satyambhuyan_5338070Nessuna valutazione finora

- Dowtherm sr-1Documento16 pagineDowtherm sr-1Rafael LealNessuna valutazione finora

- Vessel Heads BottomDocumento9 pagineVessel Heads BottomFahad RockingNessuna valutazione finora

- ArmaFlex Application UkDocumento36 pagineArmaFlex Application UkDave StaelensNessuna valutazione finora

- Dynamic Shaft SealDocumento1 paginaDynamic Shaft SealSathishkumarNessuna valutazione finora

- Why Slabs Curl - Part2Documento6 pagineWhy Slabs Curl - Part2Tim LinNessuna valutazione finora

- KS3 Science 2009 L3 6 1Documento32 pagineKS3 Science 2009 L3 6 1Beamerglitz0% (1)

- Experiment 3 - Themodynamic Functions From EMF MeasurementsDocumento5 pagineExperiment 3 - Themodynamic Functions From EMF MeasurementsjojoNessuna valutazione finora

- Tegreen PIP PH 11-2019Documento2 pagineTegreen PIP PH 11-2019Jane Tai100% (1)