Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Flexible Saddle Peak Stress

Caricato da

Oswaldo GuerraCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Flexible Saddle Peak Stress

Caricato da

Oswaldo GuerraCopyright:

Formati disponibili

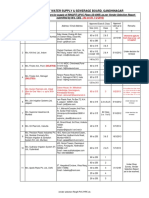

1 Flexible Saddle Peak Stress 1.

1 27-Oct-08 Page 19 of 23

2 L.S. Ong - Journal PVT Nov 1995 www.pveng.com

3

4 Horizontal Retention Tank <- Vessel Saddle Peak Stress <- Description

5

8

tc A C A

9 Bp

OD

10 tp 174º

11 90º 150º

tp

12

13

14

15

16 See program "Flexible Saddle" for the proper design of this saddle

17

18 Dimensions

19 96.000 <- OD - Outside Diameter (inch) 2Beta = 120º Fixed

20 0.3125 <- tc - Nominal Wall Thickness (inch) Alpha = 12º Fixed

21 0.375 <- tp - Wear Plate Thickness (inch)

22 96.000 <- Saddle Spacing - C (inch)

23 13.500 <- Overhang - A (inch)

24 12.000 <- Width - Bp (inch)

25 23,500 <- Weight on one saddle, Q (lbs)

26

27 Length = C + 2*A = 96 + 2*13.5 Length = 123.00

28 R = (OD-tc)/2 = (96 - 0.3125)/2 R = 47.84

29

30 Graph Factors

31 AlphaA = (A/R)*Sqrt(tc/r) = (13.5/47.84375)*Sqrt(0.3125/47.84375) AlphaA = 0.023

32 AlphaB = (Bp/R)*Sqrt(tc/r) = (12/47.84375)*Sqrt(0.3125/47.84375) AlphaB = 0.020

33 AlphaC = (C/R)*Sqrt(tc/r) = (96/47.84375)*Sqrt(0.3125/47.84375) AlphaC = 0.162

34 AlphaS = AlphaB^0.33*(tp/tc) = 0.02^0.33*(0.375/0.3125) AlphaS = 0.327

35

36 Lookup Factors (interpolated)

37 Ka = From graph "Fig. 1 - Support location factor" Ka = 0.339

38 Kb = From graph "Fig. 2 - Support width factor" Kb = 1.787

39 Kc = From graph "Fig. 3 - Support spacing factor" Kc = 0.885

40 Ks1 = From graph "Fig. 4 - Stress reduction factor at wear plate" Ks1 = 0.211

41 Ks2 = From graph "Fig. 4 - Stress reduction factor at wear plate" Ks2 = 0.548

42 Ks = Max(Ks1,Ks2) = Max(0.211 , 0.548) Ks = 0.548

43

44 Stress

45 Basic Stress = (Q/t^2) * sqrt(tc/r) = 19448

= (23500 / 0.3125^2) * sqrt(0.3125 / 47.844)

47

48 Stress = Basic Stress * Ka * Kb * Kc * Ks Stress = 5701

49 = 19448 * 0.339 * 1.787 * 0.885 * 0.548 Max circ stress in the saddle region

50

51

52

Potrebbero piacerti anche

- Z Blokrefractoryfibremodulesenglish New PDFDocumento2 pagineZ Blokrefractoryfibremodulesenglish New PDFOswaldo GuerraNessuna valutazione finora

- SPFM 001 PDFDocumento1 paginaSPFM 001 PDFOswaldo GuerraNessuna valutazione finora

- Compressor Magazine March 2014 PDFDocumento97 pagineCompressor Magazine March 2014 PDFOswaldo GuerraNessuna valutazione finora

- Honeywell Slate PDFDocumento136 pagineHoneywell Slate PDFOswaldo GuerraNessuna valutazione finora

- LV Line Burner MaxonDocumento44 pagineLV Line Burner MaxonOswaldo GuerraNessuna valutazione finora

- Description: North America: +1 (0) 706 796 4200 / Asia: +65 (0) 6595 0000Documento2 pagineDescription: North America: +1 (0) 706 796 4200 / Asia: +65 (0) 6595 0000Oswaldo GuerraNessuna valutazione finora

- CD-0218 Car Tank DesignDocumento38 pagineCD-0218 Car Tank DesignOswaldo GuerraNessuna valutazione finora

- ASTM A182 Grade F22Documento2 pagineASTM A182 Grade F22Oswaldo GuerraNessuna valutazione finora

- 461-DB02 Rev1Documento174 pagine461-DB02 Rev1Oswaldo GuerraNessuna valutazione finora

- Analisis of Stress in BellowsDocumento101 pagineAnalisis of Stress in BellowsOswaldo GuerraNessuna valutazione finora

- Juntas Segun Ejma.20150301.12Documento10 pagineJuntas Segun Ejma.20150301.12Oswaldo GuerraNessuna valutazione finora

- Case 1 e 002 D - H Rev 0Documento16 pagineCase 1 e 002 D - H Rev 0Oswaldo GuerraNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Folder Fiamm Neptune 2010 EngDocumento4 pagineFolder Fiamm Neptune 2010 EngchokribNessuna valutazione finora

- Cache MemoryDocumento20 pagineCache MemoryKeshav Bharadwaj RNessuna valutazione finora

- ZF CAT EBook Oil-Filters-Construction-Agricultural-Machinery-Transmissions 50114 201806 V02 IN PDFDocumento142 pagineZF CAT EBook Oil-Filters-Construction-Agricultural-Machinery-Transmissions 50114 201806 V02 IN PDFdeisy ortegaNessuna valutazione finora

- Materials Today: Proceedings: Avula Suresh, T. Nancharaiah, Ravikumar Dumpala, B. Ratna SunilDocumento5 pagineMaterials Today: Proceedings: Avula Suresh, T. Nancharaiah, Ravikumar Dumpala, B. Ratna SunilBart MaxNessuna valutazione finora

- CH 4 Data CommDocumento4 pagineCH 4 Data CommHenna ShainaNessuna valutazione finora

- Ism CodeDocumento9 pagineIsm CodePraneel KurhadeNessuna valutazione finora

- Methods of Tube Expansion in Tube To TubDocumento19 pagineMethods of Tube Expansion in Tube To Tubkurcek100% (1)

- GWSSB Vendor List 19.11.2013Documento18 pagineGWSSB Vendor List 19.11.2013sivesh_rathiNessuna valutazione finora

- V.K Jain-Advanced Machining Processes-Allied Publications PDFDocumento370 pagineV.K Jain-Advanced Machining Processes-Allied Publications PDFMayank Vyas100% (1)

- IEM PI A401 - ANNEXE - Design & Site ExperienceDocumento5 pagineIEM PI A401 - ANNEXE - Design & Site ExperienceapiplajengilaNessuna valutazione finora

- IBM System Storage DS8000 - A QuickDocumento10 pagineIBM System Storage DS8000 - A Quickmuruggan_aNessuna valutazione finora

- Manual PC Soundcard Scope 1.4.5Documento17 pagineManual PC Soundcard Scope 1.4.5NatashaKillerNessuna valutazione finora

- Programming Bayes Rule OptionalDocumento17 pagineProgramming Bayes Rule OptionalajuhaseenNessuna valutazione finora

- Product Management Self-Learning ManualDocumento261 pagineProduct Management Self-Learning ManualAbhishek Arekar100% (1)

- 20105-AR-HOT-07-105-01 Rev 00Documento1 pagina20105-AR-HOT-07-105-01 Rev 00Bahaa MohamedNessuna valutazione finora

- Siemens Engineering Manual V7Documento338 pagineSiemens Engineering Manual V7Jeremy Branch100% (2)

- Diesel Generator Set QSL9 Series Engine: Power GenerationDocumento4 pagineDiesel Generator Set QSL9 Series Engine: Power Generationsdasd100% (1)

- State ManagementDocumento16 pagineState Managementnegikamal703Nessuna valutazione finora

- Wiring Color and Pin-Out Schematic Electronic Vessel Control EVC - C, D4/D6-DPH/DPRDocumento2 pagineWiring Color and Pin-Out Schematic Electronic Vessel Control EVC - C, D4/D6-DPH/DPRSivan Raj50% (2)

- Iftekhar Sea Service TestimonialDocumento2 pagineIftekhar Sea Service TestimonialTomenko OleksiiNessuna valutazione finora

- Bernard D. Marquez Eduardo M. Axalan Engr. William A.L.T. NGDocumento1 paginaBernard D. Marquez Eduardo M. Axalan Engr. William A.L.T. NGRhon Nem KhoNessuna valutazione finora

- D6489 PDFDocumento3 pagineD6489 PDFKalindaMadusankaDasanayakaNessuna valutazione finora

- GM Passlock II SystemDocumento14 pagineGM Passlock II Systemalmia tronicsNessuna valutazione finora

- 4 Rec. ITU-R BS.775-3: Reference Loudspeaker Arrangement With Loudspeakers L/C/R and LS/RSDocumento3 pagine4 Rec. ITU-R BS.775-3: Reference Loudspeaker Arrangement With Loudspeakers L/C/R and LS/RSPaulo PiresNessuna valutazione finora

- NBN Co: Financial Management SolutionDocumento2 pagineNBN Co: Financial Management SolutionAccentureAustraliaNessuna valutazione finora

- Biomasse-HKW Sandreuth E NQDocumento8 pagineBiomasse-HKW Sandreuth E NQValeriu StanNessuna valutazione finora

- Steel Top Hats Battens Capacitytables Product Technical ManualDocumento16 pagineSteel Top Hats Battens Capacitytables Product Technical ManualbhukthaNessuna valutazione finora

- Trial Manufacture of A Fluid-Type Static Induction TransistorDocumento4 pagineTrial Manufacture of A Fluid-Type Static Induction TransistorStanley ClermontNessuna valutazione finora

- Alien Vault Lab2Documento28 pagineAlien Vault Lab2DukeNessuna valutazione finora