Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Wills1998 - Water Activity and Its Importance in Making Candy

Caricato da

KSXDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Wills1998 - Water Activity and Its Importance in Making Candy

Caricato da

KSXCopyright:

Formati disponibili

Water Activity and its

Importance in Making

Candy

Doug Wills

LMC International

Water activity of a confection can be

W ater is one of the most important

ingredients in candymaking. We

usually take water for granted and do not

determined by measuring the equilib-

rium humidity in the air in a sealed con-

completely understand its function in con- tainer that holds a sample of the confec-

fectionery products. We commonly know tion. This equilibrium develops after a

the quantity of water in a product, but we period of time.

need to better understand its form and When a liquid is placed in a closed con-

As executive vice presi-

location to really grasp its function. tainer, the rate at which the molecules dent of sales and mar-

To better understand the function of escape from the liquid phase is constant. keting, Wills travels

internationally as a

water in confections we can use water Evaporation is temperature dependent. problem-solver for

activity as an analytical tool. This tool can The rate at which molecules condense is LMC International’s

proportional to the number of molecules in customers. His training

help us control texture, appearance, flavor

is in physical science,

and keeping quality in our finished prod- the vapor. Equilibrium is reached when candymaking, baking

ucts. As the title indicates, this paper will evaporation rate equals condensation rate and brewing.

focus on the importance of water activity (Figure 1). He is a member of the

Water activity (Aw) is related to equi- Institute of Food

in candymaking.

Technologists and the

We have known for years that water librium relative humidity (ERH ) through American Association

content is important in candymaking. We the formula: (ERH ) = (100) (Aw). Water of Candy Technologists.

measure the total water in a product or activity of a confection is also defined as

ingredient by driving off the water in an the vapor pressure exerted by that con-

oven. However, this measurement does not fection divided by the vapor pressure of

always explain why materials are not com- pure water at the same temperature:

patible, why some products have a short Aw = VPcandy / VPwater.

shelf life or why some confections spoil. The concept of water activity (and erh)

Measuring a confection’s level of water is not new. But it was an awkward ana-

activity can give us an understanding of lytical tool. In the past, the fundamental

these observations. way we had to measure water activity Doug Wills

The Manufacturing Confectioner • August 1998 71

Water Activity and its Importance in Making Candy

Equilibrium is CHOCOLATE COATING

Equilibrium Vapor Pressure

reached when Consider, for example, chocolate-coated

12

evaporation rate raisins. Raisins have a moisture content of

10

about 15 percent. Chocolate has moisture

equals 8

of less than 0.5 percent. Yet despite this

Rate

condensation 6

large difference in moisture, chocolate-

rate. 4

coated raisins are very stable. Water does

2

Rate of evaporation

Rate of condensation

not move quickly from the raisins into

0

0 1 2 3 4 5 6 7 8 9 10 the chocolate.

Time

Figure 1 On the other hand, pecans, which are

much lower in moisture than raisins, must

was by using dessicators holding various be sealed before they can be successfully

saturated salt solutions of known water coated with chocolate. If uncoated, mois-

activity. Into these we placed samples, ture moves quickly from the pecans into

which would come to equilibrium within the chocolate. This can cause an unac-

a few days. The samples would gain ceptable change in the chocolate emul-

weight by taking in water, or lose weight sion and a change in the chocolate’s

by giving up water to the atmosphere in appearance.

the dessicators. We could then estimate Moisture movement between materi-

the water activity of a sample by mea- als is predetermined by water activity.

suring how much weight the sample Moisture moves from materials of higher

gained or lost. This technique was very water activity to materials of lower water

time consuming and not so accurate. activity, so before multicomponent con-

fections are developed, the components’

Today, we have laboratory instruments

water activity levels should be known.

that can provide an accurate water activ-

Although chocolate has a low water

ity measurement within minutes. Analysis

content, it has a rather high water activity

times of 2.5 – 5.0 minutes are routine.

of 0.5. What water it has is not bound

Operation of the water activity meter

tightly. Raisins have a water activity com-

requires only the filling of a sample cup

parable to chocolate. This is why raisins

(usually disposable), putting it in a cham-

coated with chocolate are stable. There is

ber and pushing the button.

not a tendency for water to migrate from

Why is it important to know the water

the raisins into the chocolate coating.

activity of a confection or of an ingredient?

Pecans, however, have a lower water con-

The water activity in a confection can

tent than raisins, but have a water activity

be divided into two categories, inactive

of about 0.65. Therefore, pecans should

water and free water. Water activity is a

be sealed with a water barrier before

measure of how tightly the water in a

being coated with chocolate.

confection is bound or how much of the

water in a confection is free to support

microbial activity or migrate into adjoin- FONDANT

ing components. Let us consider the importance of water

The portion of the water that is bound activity in making fondant. Fondant can be

in a confection is attached to hydroxyl both a finished product and an ingredient.

groups in polysaccharides, the carbonyl Fondant is a two-phase system. Fon-

and amino groups in proteins and other dant has a syrup phase which consists of

polar sites. corn syrup solids and sucrose dissolved

72 August 1998 • The Manufacturing Confectioner

Water Activity and its Importance in Making Candy

in water; further, fondant has a solid phase ious concentrations of corn syrup will have The keeping

of crystallized sugar. Hopefully, the sugar different water activity levels.With the help propoerties and

crystals are of sufficiently small size so as of a water activity meter, one can match his

resistance to

to be unnoticed by the palate. But since formula with the needed water activity for

microbial

these crystals are no longer dissolved, and best stability.

no matter how small they are, they take no It is easier to stop a potential problem in spoilage

part in determining the water activity and the beginning than to correct a problem. depend on the

thus the stability of the fondant. That is the basis for the saying, “An ounce concentration of

The shelf life and resistance to micro- of prevention is worth a pound of cure.” the syrup phase.

bial spoilage depends on the concentra- The cost of preventing a problem is less Sucrose which

tion of the syrup phase. Sucrose that has than reworking or destroying poor finished has crystallized

crystallized does not contribute to micro- product. Using a water activity meter is

does not

biological stability. Sucrose that has crys- like having an insurance policy against

microbial spoilage.

contribute to

tallized in a fondant lowers the concen-

tration of the syrup phase. Measuring the

microbiological

total solids in a fondant does not ade- stability.

HARD CANDY AND CARAMELS

quately describe the keeping properties of Candies that contain proteins and simple

a fondant. One needs to know the water carbohydrates are prone to non-enzy-

activity too. matic browning reactions during cook-

Upon aging, sucrose dissolved in the liq- ing. This is known as the Maillard brown-

uid phase of the fondant can come out of ing reaction and in making caramels this

solution. This lowers the concentration of is a desired reaction.

the liquid phase and leaves the fondant The formation of Maillard browning

more susceptible to microbial spoilage. products increases as the water activity

Therefore the water activity of a fondant increases. When the water activity of the

can change over time, especially if the fon- candy mass is in the 0.6 – 0.7 range, the

dant is permitted to stand in a warm area. desired browning will result most quickly.

Warmth lowers the viscosity of the syrup Usually, the browning is accomplished by

phase and hastens crystallization. controlled heating during the manufacturing

Spoilage organisms are everywhere in process. It is at this point in the process

our environment. When the water activity where control of water activity is important

of a fondant rises to the spoilage organ- too. Later, solids are increased to 92–95 per-

ism’s tolerance range, activity is soon to cent and this yields a finished water activity

follow.The spoilage organisms break down of 0.4–0.5.

the fondant into energy, water, carbon diox- Many of us have used the method of

ide, alcohol and more noxious materials. estimating the amount of reducing sugar

The initial microbial activity also raises in candy to decide if our formula is cor-

water activity, which invites other microor- rect. I suggest that we can use water activ-

ganisms to join the banquet. ity for more reliable results. When adding

If the water activity of a fondant is mea- rework to candy we can tell if too much

sured, then one knows if it is going to be sta- reducing sugar has been added with the

ble. For example, fondants that are pro- rework if we test the rework and finished

duced quickly with small crystals, like in candy for water activity. This will avoid

fondant machines, show lower water activ- making low water activity candy, which

ities than fondants made with dry mixes or can have a short shelf life.

on beating tables. Fondants made with var- One of the questions I have been asked

The Manufacturing Confectioner • August 1998 73

Water Activity and its Importance in Making Candy

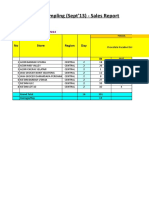

Water Activity Levels of Various Confections

Confection Moisture A/W

Hard candy 0.5–2.0 0.2–0.35

Caramel 5.0–8.0 0.4–0.5

Fudge 7–10 0.65–0.75

Fondant 10.5–11.5 0.75–0.77

Jelly bean coating 4–5 0.45–0.55

Jellies 18–22 0.65–0.75

Grain marshmallows 5–6 0.6–0.7

Marshmallows 15–18 0.65–0.75

Raisins 14.5–15.5 0.5–0.55

Chocolate 0.1–0.5 0.4–0.5

Figure 2

over the years is, “How much corn syrup unchanged, but the sugar, corn syrup and

should I use?” The other most common starch solution did not cook out as in the

question is, “What kind of corn syrup original formula. The starch was under-

should I use?” These are important eco- cooked even though the final tempera-

nomic questions in many parts of the world ture was unchanged.

since corn syrup costs more than sucrose in The water in the formula was the same,

many places. The answer to each is quite but all of the water was not available for

simple. One needs to add the amount of starch gelatinization. The water activity of

corn syrup that will give the preferred tex- the starting solution was reduced by the

ture (viscosity) and the needed water activ- formula change and therefore starved the

ity. The same answer applies to the type of starch of available water.

corn syrup employed. If the water activity When changing formulation in jelly can-

of your finished hard candy is too low, dies, consideration of available water is

making it susceptible to rapid moisture important in making a consistently high

uptake from the environment, more corn quality candy. The water activity meter can

syrup can be added. Limiting the amount be a useful tool in making sure sufficient

of invert in your candy through improved water is available.

cooking will also raise the water activity of We have looked at water activity in

the finished hard candy and yield a longer just five candymaking applications: choco-

shelf life. late coating, caramels, hard candy, jelly

candy and fondant. In each case, water

JELLY CANDY activity is noted as an important para-

meter in formulation and process (Fig-

Adequate free water is necessary to gela-

ure 2). Water activity is important and

tinize starch when making starch jelly can-

dies. When inadequate starch gelatiniza- today, water activity meters are user-

tion results during cooking, poor-setting friendly and reliable. We need to consider

jellies result. I have seen candymakers water activity as we develop new products

change a formula by employing more and as we produce established products.

It will improve our craft. ■

reducing sugars to make a softer jelly

candy. The total solids of the formula were Presented at the National AACT Technical Seminar.

74 August 1998 • The Manufacturing Confectioner

Potrebbero piacerti anche

- Confectionery and Chocolate Engineering: Principles and ApplicationsDa EverandConfectionery and Chocolate Engineering: Principles and ApplicationsNessuna valutazione finora

- Moistuer and Sugar in Shelf Life PDFDocumento32 pagineMoistuer and Sugar in Shelf Life PDFNhật Nguyễn SĩNessuna valutazione finora

- Panning Technical KitDocumento7 paginePanning Technical Kitchen leeNessuna valutazione finora

- Adam Lechter: Resident Course in Confectionery TechnologyDocumento73 pagineAdam Lechter: Resident Course in Confectionery TechnologyJulio KinenNessuna valutazione finora

- Chocolate ProcessDocumento49 pagineChocolate Processsarpal1234Nessuna valutazione finora

- Xanthan Gum 2006Documento6 pagineXanthan Gum 2006mobeenahadNessuna valutazione finora

- Nappage eDocumento16 pagineNappage eDayana AriasNessuna valutazione finora

- Extruded Marshmallow NCA Candy School Pilot Plant Exercise: Ingredients Weight For 1500 GMDocumento10 pagineExtruded Marshmallow NCA Candy School Pilot Plant Exercise: Ingredients Weight For 1500 GMJulio KinenNessuna valutazione finora

- Ruby y Jengibre Bombons Ryan Stevenson - 3Documento2 pagineRuby y Jengibre Bombons Ryan Stevenson - 3Daniela NorrmannNessuna valutazione finora

- Introduction To Molecular Gastronomy: Molecule-R Flavors 5425 de Bordeaux #402, Montreal (Quebec) Canada H2H 2P9Documento7 pagineIntroduction To Molecular Gastronomy: Molecule-R Flavors 5425 de Bordeaux #402, Montreal (Quebec) Canada H2H 2P9poivioNessuna valutazione finora

- Hard Sugar Panning W Vink (Read-Only)Documento50 pagineHard Sugar Panning W Vink (Read-Only)Santiago Del Rio Oliveira100% (1)

- Soft Nougat Concept March12 V2Documento1 paginaSoft Nougat Concept March12 V2Shofwatur RohmanNessuna valutazione finora

- Ganache Formulation PDFDocumento4 pagineGanache Formulation PDFtavibasti100% (1)

- CW Concept PDFDocumento23 pagineCW Concept PDFShaik Riyaz PeerNessuna valutazione finora

- Chocolate Functional FoodDocumento0 pagineChocolate Functional FoodrendaoNessuna valutazione finora

- Xanthan GumDocumento4 pagineXanthan GumA MahmoodNessuna valutazione finora

- Fat Bloom in Chocolate and Compound CoatingDocumento34 pagineFat Bloom in Chocolate and Compound CoatingSartika Mutiarasani100% (1)

- Caramel - Raw Materials and Formulations: Back To Basics - CaramelDocumento7 pagineCaramel - Raw Materials and Formulations: Back To Basics - CaramelJulio KinenNessuna valutazione finora

- Air It Well PDFDocumento3 pagineAir It Well PDFcklcat1437Nessuna valutazione finora

- Wafers: Basic Wafer TypesDocumento7 pagineWafers: Basic Wafer TypesSebastianHornaNessuna valutazione finora

- Emulsifiers in Chocolate V7Documento26 pagineEmulsifiers in Chocolate V7Prasanna GopalrathinamNessuna valutazione finora

- AW ApplicationNote ChocolateDocumento4 pagineAW ApplicationNote Chocolateulva mohtarNessuna valutazione finora

- 10 1 1 497 9667Documento12 pagine10 1 1 497 9667DollyNessuna valutazione finora

- Invert Sugars and Blends Offer Solutions To A Range ofDocumento4 pagineInvert Sugars and Blends Offer Solutions To A Range ofcinnamaldehidNessuna valutazione finora

- Al Wolff DrageeDocumento3 pagineAl Wolff Drageecklcat1437Nessuna valutazione finora

- Palsgaard Ice CreamDocumento2 paginePalsgaard Ice Creamcklcat1437Nessuna valutazione finora

- Confectionery Gum and Jelly ProductsDocumento31 pagineConfectionery Gum and Jelly ProductsercanefeogluNessuna valutazione finora

- XanthanDocumento7 pagineXanthanAsadZahidNessuna valutazione finora

- Nougat, Fruit Chews & Taffy: Barb KlubertanzDocumento45 pagineNougat, Fruit Chews & Taffy: Barb KlubertanzJulio Kinen100% (1)

- AWT Pectin Amid CS 005Documento8 pagineAWT Pectin Amid CS 005Dayana AriasNessuna valutazione finora

- Aerated Food GelsDocumento12 pagineAerated Food GelsOana SilviaNessuna valutazione finora

- Chocolate Making NotesDocumento6 pagineChocolate Making Notesapi-240759474Nessuna valutazione finora

- Texture IcecreamDocumento12 pagineTexture Icecreameski vedegerliNessuna valutazione finora

- Soft Caramel ReportDocumento14 pagineSoft Caramel ReportHans Demas Kosasih100% (1)

- AWT Use of H F Pectins To Increase TempDocumento7 pagineAWT Use of H F Pectins To Increase TempDayana AriasNessuna valutazione finora

- General Characteristics of Pectin. SolubilityDocumento2 pagineGeneral Characteristics of Pectin. SolubilityAnonymous VIwig8iwNessuna valutazione finora

- Design of A Cocoa Pod Splitting MachineDocumento14 pagineDesign of A Cocoa Pod Splitting MachinejayNessuna valutazione finora

- Pastry Arts Recipes 2023Documento1 paginaPastry Arts Recipes 2023AshNessuna valutazione finora

- Nutela WikiDocumento3 pagineNutela WikinecitacNessuna valutazione finora

- Ice-Cream Part IDocumento8 pagineIce-Cream Part IMD Rajib HasanNessuna valutazione finora

- 010-Particle Size Analysis of Cocoa PowdersDocumento3 pagine010-Particle Size Analysis of Cocoa PowdersAlvian Maulana SNessuna valutazione finora

- Chocolate (Pralines) : NeededDocumento5 pagineChocolate (Pralines) : NeededCristian VasilescuNessuna valutazione finora

- Conquering Shelf-Life Issues of Chocolate PDFDocumento5 pagineConquering Shelf-Life Issues of Chocolate PDFtavibastiNessuna valutazione finora

- GS Recipe Library: Bakery Filling CreamsDocumento3 pagineGS Recipe Library: Bakery Filling CreamsfernandoferozNessuna valutazione finora

- Eng Dark DropDocumento2 pagineEng Dark DropDorjana LaskuNessuna valutazione finora

- Callebaut NXT - Education Guide - LRDocumento29 pagineCallebaut NXT - Education Guide - LRPavel TanevNessuna valutazione finora

- Chocolate Caramel CakeDocumento2 pagineChocolate Caramel CakeAbbyNessuna valutazione finora

- Recipe Quantity Recipe Number Grand Cru Sambirano 68% TrufflesDocumento2 pagineRecipe Quantity Recipe Number Grand Cru Sambirano 68% TrufflesFernanda HackbartNessuna valutazione finora

- Whipping Up Egg Whites: Chef Mark SeamanDocumento20 pagineWhipping Up Egg Whites: Chef Mark SeamanAndrea MartinezNessuna valutazione finora

- AWT Pectin As Gelling AgentDocumento4 pagineAWT Pectin As Gelling AgentDayana AriasNessuna valutazione finora

- American Bagin Essentials 6Documento10 pagineAmerican Bagin Essentials 6api-3777196Nessuna valutazione finora

- ADM Cocoa ProductsDocumento4 pagineADM Cocoa ProductsJurislav BabicNessuna valutazione finora

- PVN - Recipes Cedric Grolet PDFDocumento1 paginaPVN - Recipes Cedric Grolet PDFMehwish KashimjiNessuna valutazione finora

- AWT Pectin Classic As 511Documento3 pagineAWT Pectin Classic As 511Dayana AriasNessuna valutazione finora

- Frozen DessertsDocumento38 pagineFrozen DessertsKHOZA SBUSISIWENessuna valutazione finora

- Chocolate 101 - Cacao MagazineDocumento10 pagineChocolate 101 - Cacao MagazineCati Gutierrez RNessuna valutazione finora

- The Little Book of Questions on Caramels (Q & A Series)Da EverandThe Little Book of Questions on Caramels (Q & A Series)Nessuna valutazione finora

- The Production of ChocolateDocumento5 pagineThe Production of ChocolateKSXNessuna valutazione finora

- United Nations Conference On Trade and Development: Study Prepared by The UNCTAD SecretariatDocumento70 pagineUnited Nations Conference On Trade and Development: Study Prepared by The UNCTAD SecretariatKSXNessuna valutazione finora

- United States Patent (19) : TaskinenDocumento6 pagineUnited States Patent (19) : TaskinenKSXNessuna valutazione finora

- Mars 200% Caramel Chocolate Bar 48G - WoolworthsDocumento3 pagineMars 200% Caramel Chocolate Bar 48G - WoolworthsKSXNessuna valutazione finora

- Setting The Joy Free' With Cadbury UKDocumento63 pagineSetting The Joy Free' With Cadbury UKKSXNessuna valutazione finora

- Dell Precision Tower 7000 Series 7810 Spec SheetDocumento2 pagineDell Precision Tower 7000 Series 7810 Spec Sheetanon_625022382Nessuna valutazione finora

- Environmental Impacts of Cocoa ProductionDocumento6 pagineEnvironmental Impacts of Cocoa ProductionKSXNessuna valutazione finora

- Choc Guide PDFDocumento27 pagineChoc Guide PDFKSXNessuna valutazione finora

- Bangmarigu QinetiDocumento11 pagineBangmarigu QinetiKathir KNessuna valutazione finora

- Environmental Impacts of Chocolate Production and Consumption in The UKDocumento32 pagineEnvironmental Impacts of Chocolate Production and Consumption in The UKKSXNessuna valutazione finora

- Forced Child Labor and Cocoa Production in West Africa: by Marjie SackettDocumento16 pagineForced Child Labor and Cocoa Production in West Africa: by Marjie SackettAnurag AnandNessuna valutazione finora

- Entypo E3Documento6 pagineEntypo E3KSXNessuna valutazione finora

- 1 SM PDFDocumento6 pagine1 SM PDFKSXNessuna valutazione finora

- Jurnal Kakao HilirDocumento8 pagineJurnal Kakao HilirSiti SyamsiyahNessuna valutazione finora

- Ruby Chocolate - Bioactive Potential and Sensory Quality Characteristics Compared With Dark, Milk and White ChocolateDocumento8 pagineRuby Chocolate - Bioactive Potential and Sensory Quality Characteristics Compared With Dark, Milk and White ChocolateKSXNessuna valutazione finora

- Al69 10eDocumento34 pagineAl69 10eKSXNessuna valutazione finora

- ChocolateDocumento7 pagineChocolateKSXNessuna valutazione finora

- Acticoa Chocolate & Powder GuidanceDocumento1 paginaActicoa Chocolate & Powder GuidanceKSXNessuna valutazione finora

- Chocolate Functional FoodDocumento0 pagineChocolate Functional FoodrendaoNessuna valutazione finora

- From Amadeus To Galileo PDFDocumento12 pagineFrom Amadeus To Galileo PDFOommen ChiramelkuruvillaNessuna valutazione finora

- Less Metal Transfer During Cocoa Grinding Process - Sweets Processing Archive - SWEETS GLOBAL NETWORKDocumento4 pagineLess Metal Transfer During Cocoa Grinding Process - Sweets Processing Archive - SWEETS GLOBAL NETWORKKSXNessuna valutazione finora

- Chocolate Mass Processing Technologies - An Overview PDFDocumento16 pagineChocolate Mass Processing Technologies - An Overview PDFKSXNessuna valutazione finora

- Daily ReportDocumento7 pagineDaily ReportSol IturriagaNessuna valutazione finora

- Chocolate Liquor HACCPDocumento5 pagineChocolate Liquor HACCPKSXNessuna valutazione finora

- China Education Fund Press Release Final PDFDocumento2 pagineChina Education Fund Press Release Final PDFKSXNessuna valutazione finora

- TTF Buyer List - 1Documento1 paginaTTF Buyer List - 1KSX100% (2)

- Contact Us - Sasseur ReitDocumento1 paginaContact Us - Sasseur ReitKSXNessuna valutazione finora

- UCIC UCIC Contracted Agent ListDocumento22 pagineUCIC UCIC Contracted Agent ListKSXNessuna valutazione finora

- 137 ResultsDocumento12 pagine137 ResultsKSXNessuna valutazione finora

- Guideline: Negotiating and Dealing With Chinese Business PartnersDocumento23 pagineGuideline: Negotiating and Dealing With Chinese Business PartnersKSXNessuna valutazione finora

- Global Confectionery MarketDocumento1 paginaGlobal Confectionery MarketDivya PrakashNessuna valutazione finora

- NPL - APAC Report - H1 - 2022 (Bak - Pat - Cho)Documento49 pagineNPL - APAC Report - H1 - 2022 (Bak - Pat - Cho)Xuan Loc MaiNessuna valutazione finora

- The Chocolate Lava CakeDocumento4 pagineThe Chocolate Lava CakeMariiaNessuna valutazione finora

- Chocolate Confectionery in PeruDocumento10 pagineChocolate Confectionery in Perujimmy tipoNessuna valutazione finora

- Business Proposal 2020Documento4 pagineBusiness Proposal 2020KAGISO TAMAPONessuna valutazione finora

- Certified Establishments List January 2023Documento4 pagineCertified Establishments List January 2023Muhammad PandorNessuna valutazione finora

- Board Game Maths in English Games 14381Documento1 paginaBoard Game Maths in English Games 14381juliaNessuna valutazione finora

- Bean To BarDocumento2 pagineBean To Baralfredojsm1812Nessuna valutazione finora

- Mind Mapping of The Parle Products From The BCG Matrix and The Swot Analysis of The Parle ProductsDocumento1 paginaMind Mapping of The Parle Products From The BCG Matrix and The Swot Analysis of The Parle ProductsParav BansalNessuna valutazione finora

- PDM Minimum Guidelines and Indicators Mpca Jan 2022Documento9 paginePDM Minimum Guidelines and Indicators Mpca Jan 2022Pan PanNessuna valutazione finora

- Job SatisfactionDocumento57 pagineJob SatisfactionYugendra Babu KNessuna valutazione finora

- Bakery SummaryDocumento65 pagineBakery SummaryHafiz Iqbal Maulana IPBNessuna valutazione finora

- 8th GradeDocumento3 pagine8th GradeMauricio QuirogaNessuna valutazione finora

- Food Additives Lab Session 1 TLMDocumento23 pagineFood Additives Lab Session 1 TLMVanessa ElliviaNessuna valutazione finora

- 12 - Written TestDocumento5 pagine12 - Written TestJanu MaglenteNessuna valutazione finora

- Chocolate Confectionery in VietnamDocumento11 pagineChocolate Confectionery in Vietnamvuong100% (2)

- April 2021 Entrepreneur India Monthly MagazineDocumento36 pagineApril 2021 Entrepreneur India Monthly Magazinecryptocoin lendNessuna valutazione finora

- Japanese Castella Cake - Just One CookbookDocumento6 pagineJapanese Castella Cake - Just One CookbookPetra CsépánNessuna valutazione finora

- Munson's Chocolate CatalogueDocumento7 pagineMunson's Chocolate CataloguePatricia DillonNessuna valutazione finora

- Almacen JR S.A.S Nit: 827.000.975-6 Avenida Duarte Blum Kra 5 # 3-05 San Andres Islas Colombia Telf.: 5124725 5123899Documento2 pagineAlmacen JR S.A.S Nit: 827.000.975-6 Avenida Duarte Blum Kra 5 # 3-05 San Andres Islas Colombia Telf.: 5124725 5123899Angel CervantesNessuna valutazione finora

- Cadbury PLCDocumento13 pagineCadbury PLCvinayak0304Nessuna valutazione finora

- LESSON 7 Icing or FrostingDocumento17 pagineLESSON 7 Icing or FrostingTherese PinedaNessuna valutazione finora

- Summative Assessment Strategic Marketing: Module Title Module Code Module Convener Tutor Student ID Student NameDocumento21 pagineSummative Assessment Strategic Marketing: Module Title Module Code Module Convener Tutor Student ID Student NameAshley WoodNessuna valutazione finora

- Gummy Turkey Halal - Prices and Promotions - Og 2Documento1 paginaGummy Turkey Halal - Prices and Promotions - Og 2razaliaNessuna valutazione finora

- Häagen-Dazs Report - EVA Ministick BarDocumento6 pagineHäagen-Dazs Report - EVA Ministick BarAntasha Arifin Al-JufriNessuna valutazione finora

- GroupAssignment3 - Selecta and Porter's 5 Forces v1.3 HanzDocumento5 pagineGroupAssignment3 - Selecta and Porter's 5 Forces v1.3 HanzHanz SoNessuna valutazione finora

- GB 31604.1 (Food Simulant)Documento22 pagineGB 31604.1 (Food Simulant)Adel AdielaNessuna valutazione finora

- Besa Trading Price List 15 June - 2023Documento1 paginaBesa Trading Price List 15 June - 2023creativegirl328Nessuna valutazione finora

- Vanilin KirkDocumento13 pagineVanilin KirkputrikurniawatiNessuna valutazione finora

- Sweet Papaya: Business PlanDocumento33 pagineSweet Papaya: Business PlanFarhana25111988Nessuna valutazione finora