Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Industrial Eng Standards - SCE

Caricato da

imran_chaudhryDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Industrial Eng Standards - SCE

Caricato da

imran_chaudhryCopyright:

Formati disponibili

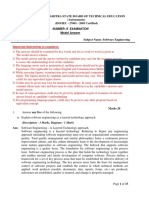

Industrial Engineering Standards 9341 ، محرم91

Professional Engineer Exam 𝚰

Industrial Engineering Standards

الصفحة1 Professional Engineer Exam 𝚰

Industrial Engineering Standards 9341 ، محرم91

Introduction

Engineering standards are the set of knowledge, abilities, and professional attributes

necessary to practice the engineering profession [3-5]. Every Engineering Standard is linked

to a number of indicators. These indicators can be viewed as instruments that measure the

examinee fulfillment of the corresponding standard. In other words, a Standard is a broad

statement about a specific topic, whereas, the Indicators are specific requirements extracted

from the Standard and directly linked to the exam question.

Some of these first level standards are drawn from the completion of a Bachelor of

Engineering degree from an accredited engineering college. An accredited engineering

degree program usually has the breadth of understanding of a wide range of technologies and

applications. It also usually has sufficient depth in at least one specific area of practice to

develop competence in handling technically complex problems [6].

The knowledge part of the first level standards include, generally, knowledge of science and

engineering fundamentals, in-depth technical competence in an engineering discipline,

knowledge of theoretical and experimental techniques, knowledge of basic business and

project management practices, and broad general knowledge.

The ability part of the first level standards include, generally, the ability to identify,

formulate, and solve problems, ability to understand environmental and social issues, ability

to deal with ambiguity and complex problems, ability to perform engineering design, and an

ability to interpret and visualize data [3-5].

The professional Attributes part of the first level standards are the sets of skills often sought

by employers for hiring engineers either fresh graduates or experienced. They are sometimes

called “soft” or “general” skills. They include capacity for effective communication [7] with

the engineering team and costumers, capacity for effective work within multidisciplinary and

multicultural teams, capacity for lifelong learning and professional development, self-drive

and motivation, creativity and innovation, leadership, and capacity to maintain a professional

image in all circumstances [3-5].

الصفحة2 Professional Engineer Exam 𝚰

Industrial Engineering Standards 9341 ، محرم91

Industrial Engineering Standards

The Engineering Standards for the Industrial Engineering Discipline are structured around

eight core topics:

1. Engineering Economics

2. Probability and Statistics

3. Modeling and Computation

4. Industrial Management

5. Manufacturing and Production Systems

6. Facilities and Logistics

7. Human Factors, Productivity, Ergonomics, and Work Design

8. Quality Engineering

Each Indicator is projected onto three Learning Levels (obtained by combining every two

consecutive levels in the revised Bloom’s taxonomy into one level)

1. Remembering and Understanding

2. Applying and Analyzing

3. Evaluating and Creating

Standards are coded IE-TJ where:

IE denotes Industrial Engineering

TJ denotes Topic Number J

Indicators are coded IE-TJ-K (where K denotes the Indicator number).

Example

Topic: T1: Engineering Economics

Standard: IE-T1: Industrial engineers should possess the ability to apply

engineering economics fundamentals to perform cost analysis and

estimation, and support decision making.

Indicator: IE-T1-05: Utilize engineering Economics analysis in decision making

(budgeting, replacement, risk, and uncertainty).

Learning Level: Applying and Analyzing (AA)

الصفحة3 Professional Engineer Exam 𝚰

Industrial Engineering Standards 9341 ، محرم91

T1: Engineering Economics (14%)

IE-T1 Industrial engineers should possess the ability to apply engineering economics

fundamentals to perform cost analysis and estimation, and support decision

making. The following Indicators are addressed in the Test Questions on this

Topic Area:

T1-Indicators

IE-T1-01 Recognize and demonstrate use of fundamentals of engineering economics

(role in decision making, interest rate, rate of return, cash flows, cost types,

compounding factors)

IE-T1-02 Apply fundamentals of engineering economics (cost types, cost analysis, worth

analysis, cost accounting, taxes, depreciation, inflation)

IE-T1-03 Utilize tools of worth analysis and discounted cash flows (present worth,

future worth, capitalized cost analysis, annual worth)

IE-T1-04 Evaluate alternatives (replacement and retention, payback, breakeven analysis)

IE-T1-05 Utilize engineering economics analysis in decision making (budgeting, taxes,

depreciation, inflation, risk and uncertainty)

الصفحة4 Professional Engineer Exam 𝚰

Industrial Engineering Standards 9341 ، محرم91

T2: Probability and Statistics (14%)

IE-T2 Industrial engineers should possess the ability to utilize probability and

statistics fundamentals and tools to represent data, test hypothesis, and design

experiments. The following Indicators are addressed in the Test Questions on

this Topic Area:

T2-Indicators

IE-T2-01 Recognize and utilize probability theory and probability distributions of

random variables (continuous, discrete)

IE-T2-02 Apply principles and tools of statistics (descriptive statistics, estimation,

confidence intervals, sampling and sample sizes)

IE-T2-03 Utilize tools of statistical analysis (hypothesis testing, analysis of variance,

regression and correlation, discrete variables, continuous variables)

IE-T2-04 Apply rules of hypothesis testing (parametric and nonparametric variables)

IE-T2-05 Apply rules of regression analysis (linear and multiple)

IE-T2-06 Demonstrate use of factorial designs and apply fundamentals of design of

experiments (ANOVA, 2k, block design)

الصفحة5 Professional Engineer Exam 𝚰

Industrial Engineering Standards 9341 ، محرم91

T3: Modeling and Computation (14%)

IE-T3 Industrial engineers should possess the ability to model industrial systems,

determine, predict and monitor their performance parameters. The following

Indicators are addressed in the Test Questions on this Topic Area:

T3-Indicators

IE-T3-01 Apply the concepts of mathematical programming and optimization (linear

programing, integer, Deterministic Dynamic Programming, transportation)

IE-T3-02 Use the principles and elementary constructs of systems models including

discrete-time and state system theories, and life-cycle performance

IE-T3-03 Use concepts of mathematical programming and optimization (decision

variables, objective functions, constraints, sensitivity analysis)

IE-T3-04 Apply the principles of Minimum Spanning Tree (MST), Shortest Path (SP)

and Maximum Flow Minimum Cut Problems (MFMCP)

IE-T3-05 Utilize stochastic models (queuing, Markov, simulation)

IE-T3-06 Use IT techniques to gather, record, analyze and present the data

IE-T3-07 Test and validate models using simulation techniques

الصفحة6 Professional Engineer Exam 𝚰

Industrial Engineering Standards 9341 ، محرم91

T4: Industrial Management (10%)

IE-T4 Industrial engineers should possess the ability of applying engineering

management principles to engineering projects. The following Indicators are

addressed in the Test Questions on this Topic Area:

T4-Indicators

IE-T4-01 Define the principles of production management systems (planning,

organizing, and controlling of production systems)

IE-T4-02 Utilize project management techniques (scheduling, CPM, PERT, crashing,

time control, cost control and organization)

IE-T4-03 Plan job evaluation and compensation strategies

الصفحة7 Professional Engineer Exam 𝚰

Industrial Engineering Standards 9341 ، محرم91

T5: Manufacturing and Production Systems (14%)

IE-T5 Industrial engineers should possess the ability to apply production planning

and control to improve industrial systems’ performance. Industrial engineers

should also be able to apply modern manufacturing systems techniques in

automation and material handling for better performance. The following

Indicators are addressed in the Test Questions on this Topic Area:

T5-Indicators

IE-T5-01 Recognize engineering materials properties, fundamentals of engineering

materials and processing parameters

IE-T5-02 Recognize characteristics of integrated manufacturing systems (material

handling, production lines, manual assembly lines, automated, flexible,

cellular, lean, CIM)

IE-T5-03 Recognize automation fundamentals

IE-T5-04 Utilize production planning and control techniques (forecasting, scheduling,

aggregate planning, MRP, JIT, MRPII, ERP and inventory control)

IE-T5-05 Utilize automation technology (CNCs, industrial robotics and CIM)

IE-T5-06 Apply principles of manufacturing support systems (process planning,

concurrent engineering and design for manufacturability)

IE-T5-07 Design production systems (equipment selection, labor selection, training,

methods and production line balancing)

الصفحة8 Professional Engineer Exam 𝚰

Industrial Engineering Standards 9341 ، محرم91

T6: Facilities and Logistics (12%)

IE-T6 Industrial engineers should possess the ability to design and locate industrial

facilities. Industrial engineers should also possess the ability to design supply

chain and logistics systems. The following Indicators are addressed in the Test

Questions on this Topic Area:

T6-Indicators

IE-T6-01 Recognize facility location factors and types of plant layout

IE-T6-02 Utilize computer aided layout design techniques

IE-T6-03 Analyze facility location and layout (single, multiple, storage, distance

metrics)

IE-T6-04 Design automated handling and storage systems

IE-T6-05 Design supply chain

IE-T6-06 Evaluate alternate locations

الصفحة9 Professional Engineer Exam 𝚰

Industrial Engineering Standards 9341 ، محرم91

T7: Human Factors, Productivity, Ergonomics, and Work Design (12%)

IE-T7 Industrial engineers should possess the ability to utilize work design and

human factors theory, principles and data in order to optimize human well-

being and overall system performance. The following Indicators are addressed

in the Test Questions on this Topic Area:

T7-Indicators

IE-T7-01 Identify occupational hazards and risk factors (MSD, toxicology, fire)

IE-T7-02 Utilize basic work measurement techniques for task analysis and evaluation

(methods engineering, charting, motion analysis, time study, work sampling,

MTM, MOST, standard data systems)

IE-T7-03 Design workplace (tasks, layouts, displays, controls, interfaces, workload)

IE-T7-04 Design workplace environment (lighting, noise, temperature, noise)

IE-T7-05 Evaluate physical and mental workload and plan work/rest schedules

IE-T7-06 Utilize ergonomics assessment techniques to evaluate workplace risk factors

(checklists, questionnaires, anthropometry, biomechanical models)

الصفحة10 Professional Engineer Exam 𝚰

Industrial Engineering Standards 9341 ، محرم91

T8: Quality Engineering (10%)

IE-T8 Industrial engineers should possess the ability to observe quality and recognize

its concepts. Industrial engineers should be able to utilize quality tools and

principles to effectively monitor and improve systems’ quality. The following

Indicators are addressed in the Test Questions on this Topic Area:

T8-Indicators

IE-T8-01 Define the basic concepts of quality, TQC, TQM, DOE, process

capability, overall quality program management and implementation

IE-T8-02 Recognize quality costs and their relevant quality improvement strategies

IE-T8-03 Use quality improvement techniques (Pareto diagram, matrix analysis, check

sheets, etc.)

IE-T8-04 Apply principles of statistical quality control (control charts, process

capability)

IE-T8-05 Apply fundamentals of analytical tools (fault trees, cause and effect)

IE-T8-06 Apply six sigma

الصفحة11 Professional Engineer Exam 𝚰

Industrial Engineering Standards 9341 ، محرم91

REFERENCES

[1] C. R. Litecky, K. P. Arnett, and B. Prabhakar, “The Paradox of soft skills versus

technical Skills in IS hiring”, The Journal of Computer Information Systems, Vol. 45, 2004,

p. 69.

[2] I. Markes, “A review of literature on employability skills needs in engineering”,

European Journal for Engineering Education, Vol. 31, 2006, p. 637.

[3] Engineers Australia, Engineers Australia National Generic Competency Standards -

Stage 1 Competency Standards for Professional Engineers, Engineers Australia, Barton,

2005.

[4] S. A. Male, M. B. Bush and E. S. Chapman, “Identification of competencies required by

engineers graduating in Australia”, Proceeding of the 20th Conference of the Australasian

Association for Engineering Education, Adelaide, Sep. 6-9, 2009.

[5] M. Saharf, A. Alsadaawi, M. Elmadany, S. Al-Zahrani and A. Ajbar, “Identification of

top competencies required from engineering graduates: a case study of Saudi Arabia”,

International Journal of Engineering Education, Vol. 29, 2013, p. 967.

[6] C. Arlett, F. Lamb, R. Dales, L. Willis and E. Hurdle, “Meeting the needs of industry:

the drivers for change in engineering education”, Engineering Education, Vol. 5, 2010, p.

18.

[7] H. Idrus, R. Salleh and M.R.T. Abdullah, “Oral communications ability in English: An

essential skill for engineering graduates”, Asia Pacific Journal of Educators and Education,

Vol. 26, 2011, p. 107.

الصفحة12 Professional Engineer Exam 𝚰

Potrebbero piacerti anche

- Solutions: Solutions Manual For Introduction To Management Science 13Th Edition TaylorDocumento69 pagineSolutions: Solutions Manual For Introduction To Management Science 13Th Edition TaylorFarjana Mou100% (3)

- Midterm - Suggested Solution - P1Documento19 pagineMidterm - Suggested Solution - P1Mr. JarmenNessuna valutazione finora

- University of WindsorDocumento8 pagineUniversity of Windsorsinto johnsonNessuna valutazione finora

- 01 - Introduction To Industrial Eng - r1Documento23 pagine01 - Introduction To Industrial Eng - r1Eddy FazwanNessuna valutazione finora

- Scheme - e Fifth Semester (Co, CM)Documento55 pagineScheme - e Fifth Semester (Co, CM)anmolmaneNessuna valutazione finora

- Topic 03 - Simplex MethodDocumento181 pagineTopic 03 - Simplex Methodimran_chaudhryNessuna valutazione finora

- Topic 03 - Simplex MethodDocumento181 pagineTopic 03 - Simplex Methodimran_chaudhryNessuna valutazione finora

- Mechanical Eng StandardsDocumento12 pagineMechanical Eng StandardsAhmed ELmlahyNessuna valutazione finora

- General Engineering StandardsDocumento20 pagineGeneral Engineering StandardsEmal khanNessuna valutazione finora

- IEM Content and IntroDocumento15 pagineIEM Content and IntroBhoomika R ReddyNessuna valutazione finora

- Maharashtra State Board of Technical Education (Autonomous) (ISO/IEC - 27001 - 2005 Certified)Documento33 pagineMaharashtra State Board of Technical Education (Autonomous) (ISO/IEC - 27001 - 2005 Certified)Ketan_AgawaneNessuna valutazione finora

- Mirpur University of Science and Technology: Deparment Software EngineeringDocumento22 pagineMirpur University of Science and Technology: Deparment Software EngineeringahsanNessuna valutazione finora

- Mechanical Eng StandardsDocumento16 pagineMechanical Eng StandardsMuhammad ImranNessuna valutazione finora

- Mechanical Eng Study GuideDocumento31 pagineMechanical Eng Study Guideeng bassimNessuna valutazione finora

- EBILE3A - GA7 & 11 SMTR Assignments - 2023-1Documento9 pagineEBILE3A - GA7 & 11 SMTR Assignments - 2023-1ThabangNessuna valutazione finora

- Prepared by Dr. Musa Alyaman Introduction To Engineering (0908200)Documento24 paginePrepared by Dr. Musa Alyaman Introduction To Engineering (0908200)Haneen RNessuna valutazione finora

- 5 6052945999217820047 PDFDocumento93 pagine5 6052945999217820047 PDFFifa HDNessuna valutazione finora

- Industrial EnggDocumento75 pagineIndustrial EnggAlthaf VANessuna valutazione finora

- EngineerDocumento8 pagineEngineerapi-77555026Nessuna valutazione finora

- ELCE 3012 Engineering Economic: Management. Technomic Publishing Company, IncDocumento3 pagineELCE 3012 Engineering Economic: Management. Technomic Publishing Company, IncSahmi Abdulqahar NizoriNessuna valutazione finora

- EIT Masters Engineering Mechanical MME BrochureDocumento4 pagineEIT Masters Engineering Mechanical MME BrochureMuhammad ImranNessuna valutazione finora

- CTS Technician Mechatronics CTS NSQF-5Documento77 pagineCTS Technician Mechatronics CTS NSQF-5Mohammad AbdullahNessuna valutazione finora

- B-2 Industrial and Systems Engineering Body of Knowledge 2021Documento60 pagineB-2 Industrial and Systems Engineering Body of Knowledge 2021Rahmaniyah Dwi AstutiNessuna valutazione finora

- Shri G. S. Institute of Technology and ScienceDocumento32 pagineShri G. S. Institute of Technology and Scienceabhaymvyas1144Nessuna valutazione finora

- ME 4103 - IE-1. IntroductionDocumento31 pagineME 4103 - IE-1. IntroductionasanNessuna valutazione finora

- IEC 61511 Implementation - The Execution ChallengeDocumento7 pagineIEC 61511 Implementation - The Execution Challengehmatora72_905124701Nessuna valutazione finora

- Components of Industrial Engineering Class 2Documento13 pagineComponents of Industrial Engineering Class 2Vikash KumarNessuna valutazione finora

- Ingles Instrumental Ativ. 04Documento4 pagineIngles Instrumental Ativ. 04Lara StephanieNessuna valutazione finora

- Nibal MechanicalDocumento3 pagineNibal MechanicalLiliane AlameddineNessuna valutazione finora

- Important Instructions To Examiners:: (2 Marks For Each Definition)Documento26 pagineImportant Instructions To Examiners:: (2 Marks For Each Definition)mahesh mohiteNessuna valutazione finora

- Quality Assurance For Power Plant Simulation: June 2013Documento5 pagineQuality Assurance For Power Plant Simulation: June 2013Cyril DIPANDANessuna valutazione finora

- ENGINEERING TECHNICAL REPORT WRITING Format Coca ColaDocumento15 pagineENGINEERING TECHNICAL REPORT WRITING Format Coca Colaultra engineeringltdNessuna valutazione finora

- Industrial Engineering Mod 1Documento27 pagineIndustrial Engineering Mod 1will billNessuna valutazione finora

- What Is So Special About Engineering Technology ?: Engineering Technologist in Society (CLB 40002) Group Assignment 1Documento4 pagineWhat Is So Special About Engineering Technology ?: Engineering Technologist in Society (CLB 40002) Group Assignment 1Theyvan T-vanNessuna valutazione finora

- SE RecordDocumento75 pagineSE Recordyogeshwaran.r2022lcseNessuna valutazione finora

- An Industrial Engineering Body of KnowledgeDocumento11 pagineAn Industrial Engineering Body of KnowledgeMenaka ChathurangaNessuna valutazione finora

- CIM Course PlanDocumento8 pagineCIM Course PlanKamal Vijay Ram R SNessuna valutazione finora

- Pre-Requisite: Thermal Engineering: Automobile Engineering LTPC 3 0 0 3 ObjectiveDocumento10 paginePre-Requisite: Thermal Engineering: Automobile Engineering LTPC 3 0 0 3 ObjectiveVpr NaturalsNessuna valutazione finora

- FINAL Compulsory 11 ME5465 Ind. Engg. Lab Manual-1Documento72 pagineFINAL Compulsory 11 ME5465 Ind. Engg. Lab Manual-1Parth MaldhureNessuna valutazione finora

- The R&D Concept: Research (R) and Development (D) and Their Use in IndustryDocumento53 pagineThe R&D Concept: Research (R) and Development (D) and Their Use in IndustryStefan ChooNessuna valutazione finora

- Scheme - e Fifth Semester - Co, CM - 1Documento55 pagineScheme - e Fifth Semester - Co, CM - 1surajit153Nessuna valutazione finora

- MEM14061A Plan and Design Mechanical Engineering Projects: Release: 1Documento13 pagineMEM14061A Plan and Design Mechanical Engineering Projects: Release: 1rezaNessuna valutazione finora

- Lec 1Documento24 pagineLec 1Online WorkerNessuna valutazione finora

- 01 - Introduction To Industrial EngDocumento16 pagine01 - Introduction To Industrial EngsoqhNessuna valutazione finora

- GD&T TrainingDocumento3 pagineGD&T TrainingKeith AdminNessuna valutazione finora

- EiDocumento5 pagineEixxcxxzzNessuna valutazione finora

- Group 01Documento8 pagineGroup 01kongrenu71Nessuna valutazione finora

- Basic DesignDocumento18 pagineBasic DesignM AhmadNessuna valutazione finora

- Asset Integrity Management On-Demand Training CoursesDocumento8 pagineAsset Integrity Management On-Demand Training CoursesIslam M. RedaNessuna valutazione finora

- EEE3999 Technical Answers For Real World Problems (TARP) Project Description ReportDocumento2 pagineEEE3999 Technical Answers For Real World Problems (TARP) Project Description ReportAbhishek RajNessuna valutazione finora

- RME 2013 Brochure PDFDocumento2 pagineRME 2013 Brochure PDFHans franckNessuna valutazione finora

- Eng'g103 Module 1Documento2 pagineEng'g103 Module 1Ellaisa Molina GrabanzorNessuna valutazione finora

- MTechPDD Autonomous Syllabus Wef 17-18Documento63 pagineMTechPDD Autonomous Syllabus Wef 17-18BVoc AutomobileNessuna valutazione finora

- Unit 25 Selecting and Using Programmable Controllers PDFDocumento12 pagineUnit 25 Selecting and Using Programmable Controllers PDFahmed357Nessuna valutazione finora

- Industrial Engineering & Ergonomics (Me 392)Documento35 pagineIndustrial Engineering & Ergonomics (Me 392)Sampson DziwornuNessuna valutazione finora

- Mechanical Design BasicsDocumento18 pagineMechanical Design BasicsBobi PitropNessuna valutazione finora

- Amec FeedDocumento8 pagineAmec Feedjkj_13874Nessuna valutazione finora

- Model-Driven and Software Product Line EngineeringDa EverandModel-Driven and Software Product Line EngineeringNessuna valutazione finora

- Engineering Applications: A Project Resource BookDa EverandEngineering Applications: A Project Resource BookValutazione: 2.5 su 5 stelle2.5/5 (1)

- Software Reliability: State of the Art Report 14:2Da EverandSoftware Reliability: State of the Art Report 14:2A. BendellNessuna valutazione finora

- Static Analysis of Software: The Abstract InterpretationDa EverandStatic Analysis of Software: The Abstract InterpretationNessuna valutazione finora

- Topic 03 - Saudi Arabia RegulationsDocumento31 pagineTopic 03 - Saudi Arabia Regulationsimran_chaudhryNessuna valutazione finora

- Topic 01 - IntroductionDocumento42 pagineTopic 01 - Introductionimran_chaudhry100% (1)

- Topic 00 - Course IntroductionDocumento7 pagineTopic 00 - Course Introductionimran_chaudhryNessuna valutazione finora

- Topic 03-01 - Saudi Arabia RegulationsDocumento34 pagineTopic 03-01 - Saudi Arabia Regulationsimran_chaudhryNessuna valutazione finora

- Topic 02 - ILO, IsO EtcDocumento49 pagineTopic 02 - ILO, IsO Etcimran_chaudhryNessuna valutazione finora

- Measuring The Quality of Health Services Provided at A Greek Public Hospital Through Patient SatisfactionDocumento15 pagineMeasuring The Quality of Health Services Provided at A Greek Public Hospital Through Patient Satisfactionimran_chaudhryNessuna valutazione finora

- Determining The Impact of Service Quality On Customer Satisfaction and LoyaltyDocumento178 pagineDetermining The Impact of Service Quality On Customer Satisfaction and Loyaltyimran_chaudhryNessuna valutazione finora

- Topic 02 - Linear ProgrammingDocumento90 pagineTopic 02 - Linear Programmingimran_chaudhryNessuna valutazione finora

- A Study of Patient Satisfaction Level in Inpatient Spine Department of A Tertiary Care Multi-Speciality HospitalDocumento6 pagineA Study of Patient Satisfaction Level in Inpatient Spine Department of A Tertiary Care Multi-Speciality Hospitalimran_chaudhryNessuna valutazione finora

- Decision Analysis Using Microsoft Excel PDFDocumento400 pagineDecision Analysis Using Microsoft Excel PDFimran_chaudhryNessuna valutazione finora

- Evaluating Patients' Perception of Service Quality at Hospitals in Nine Chinese Cities by Use of The ServQual Scale 01Documento9 pagineEvaluating Patients' Perception of Service Quality at Hospitals in Nine Chinese Cities by Use of The ServQual Scale 01imran_chaudhryNessuna valutazione finora

- Introduction To Linear ProgrammingDocumento51 pagineIntroduction To Linear Programmingimran_chaudhry100% (2)

- Topic 01 - Introduction To ORDocumento29 pagineTopic 01 - Introduction To ORimran_chaudhryNessuna valutazione finora

- Integer Programming: The Branch & Bound MethodDocumento19 pagineInteger Programming: The Branch & Bound Methodimran_chaudhry100% (1)

- Lecture 07 - Goal ProgrammingDocumento24 pagineLecture 07 - Goal Programmingimran_chaudhryNessuna valutazione finora

- Chapter 06 - ALDEP PresentationDocumento15 pagineChapter 06 - ALDEP Presentationimran_chaudhryNessuna valutazione finora

- Business Applications of Operations ResearchDocumento162 pagineBusiness Applications of Operations Researchimran_chaudhryNessuna valutazione finora

- Deriving Industrial Logistics Hub Reference Models For Manufacturing Based EconomiesDocumento10 pagineDeriving Industrial Logistics Hub Reference Models For Manufacturing Based Economiesimran_chaudhryNessuna valutazione finora

- A Genetic Approach To Automate Preliminary Design of Gear DrivesDocumento10 pagineA Genetic Approach To Automate Preliminary Design of Gear Drivesimran_chaudhryNessuna valutazione finora

- VBA Programming in Excel For Decision Support SystemsDocumento22 pagineVBA Programming in Excel For Decision Support Systemsimran_chaudhryNessuna valutazione finora

- Mechanical Engineering Objective Type QuestionsDocumento441 pagineMechanical Engineering Objective Type Questionsimran_chaudhry100% (1)

- A Literature Survey of Cost of Quality ModelsDocumento10 pagineA Literature Survey of Cost of Quality Modelsimran_chaudhryNessuna valutazione finora

- Ac2 10 MPCDocumento37 pagineAc2 10 MPCRaja BalanNessuna valutazione finora

- Help - Fsolve - MATLABDocumento12 pagineHelp - Fsolve - MATLABGanderNessuna valutazione finora

- Gurobi OptimizationDocumento26 pagineGurobi OptimizationAakriti AgarwalNessuna valutazione finora

- Business Model and ApplicationDocumento6 pagineBusiness Model and ApplicationCHAU NGUYEN PHUOC QUYNessuna valutazione finora

- LPP1992 PDFDocumento15 pagineLPP1992 PDFpramod sagarNessuna valutazione finora

- Daryani Dkk. (2024)Documento20 pagineDaryani Dkk. (2024)Arya RifaNessuna valutazione finora

- DKP Advanced Excel and R - Session 1-2Documento52 pagineDKP Advanced Excel and R - Session 1-2kanika gargNessuna valutazione finora

- Master of Science in Engineering Management (MEM) ProgramDocumento9 pagineMaster of Science in Engineering Management (MEM) ProgramAzeddine DjeNessuna valutazione finora

- Unbalanced TransportationDocumento24 pagineUnbalanced TransportationMeg sharkNessuna valutazione finora

- TDesign and Analysis 4Documento28 pagineTDesign and Analysis 4SUSAN KHADKANessuna valutazione finora

- Outpatient Appointment Systems in Healthcare - A Review of Optimization StudiesDocumento32 pagineOutpatient Appointment Systems in Healthcare - A Review of Optimization Studiesgabrieelcrazy100% (1)

- Flexsim CTDocumento6 pagineFlexsim CTAhmed SamyNessuna valutazione finora

- Body Structures and Chassis OptimizationDocumento17 pagineBody Structures and Chassis OptimizationJennyvi NapodNessuna valutazione finora

- B SC - Honours - Operational Research - Syllabus PDFDocumento40 pagineB SC - Honours - Operational Research - Syllabus PDFShakya DushyantNessuna valutazione finora

- Developing An Improved Approach To Solving A New Gas Lift Optimization ProblemDocumento25 pagineDeveloping An Improved Approach To Solving A New Gas Lift Optimization ProblemZaur YarehmedovNessuna valutazione finora

- Edumatsains: Pemodelan Matematika: Model Dan Simulasi Jalur Evakuasi Korban Bencana Gempa Bumi Di Bangunan BertingkatDocumento12 pagineEdumatsains: Pemodelan Matematika: Model Dan Simulasi Jalur Evakuasi Korban Bencana Gempa Bumi Di Bangunan BertingkatarchiNessuna valutazione finora

- Gromacs Manual 4.5.3Documento374 pagineGromacs Manual 4.5.3yorka11Nessuna valutazione finora

- High-Quality and Efficient Volume ResamplingDocumento129 pagineHigh-Quality and Efficient Volume ResamplingBalazs DomonkosNessuna valutazione finora

- Ls Tasc 2.0 ManualDocumento78 pagineLs Tasc 2.0 ManualChandan K MozumderNessuna valutazione finora

- Linear Programming Method Application in A Solar CellDocumento12 pagineLinear Programming Method Application in A Solar CellKaty Flores OrihuelaNessuna valutazione finora

- SopDocumento33 pagineSopcrocoreaderNessuna valutazione finora

- Model Predictive ControlDocumento17 pagineModel Predictive Controlgummadi2010Nessuna valutazione finora

- Note1 Model FormulationDocumento17 pagineNote1 Model Formulationアユ ギタ100% (1)

- Backtesting CryptoDocumento2 pagineBacktesting CryptoAwesome TreehouseNessuna valutazione finora

- Morphing Wing Design Via Aeroelastic Tailoring: NomenclatureDocumento19 pagineMorphing Wing Design Via Aeroelastic Tailoring: NomenclaturemihailmiNessuna valutazione finora

- Smart Home Energy Management System ReviewDocumento7 pagineSmart Home Energy Management System ReviewAdhitya Rahman DwitomoNessuna valutazione finora

- Phylosophy of Industrial Engineering (TM1)Documento30 paginePhylosophy of Industrial Engineering (TM1)Fajar JossNessuna valutazione finora

- Vectorial Method of Minimum Zone Tolerance For Flatness, Straightness, and Their Uncertainty EstimationDocumento14 pagineVectorial Method of Minimum Zone Tolerance For Flatness, Straightness, and Their Uncertainty Estimationakjeevanantham79Nessuna valutazione finora