Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Separator 3 Phasa

Caricato da

ekabudiartiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Separator 3 Phasa

Caricato da

ekabudiartiCopyright:

Formati disponibili

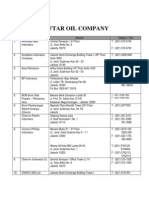

Sizing Three Phase (Gas - Oil) Horizontal Separator: As per API 12J

PARAMETERS Nomenclature

Qg 10 mmscfd Gas rate A total cross sectional area of the separator.

2

Qo 100 bbl/d Oil rate Aw cross sectional area of the separator occupied by water, ft

Qw 170 bbl/d Water rate Ao cross sectional area of the separator occupied by oil, ft 2

2

γ 0,60 Gas specific gravity Ag cross sectional area of the separator occupied by gas, ft

o

ρ'o 40 API Oil density CD drag coefficient

γo 0,83 Oil specific gravity d vessel internal diameter, in.

P 300 psia Operating pressure dm bubble or drop diameter, μm

T' 79,25 oF Operating temperature D vessel diameter, ft

T 539 oR Operating temperature h liquid height, in.

MW 19,6 lb/lbmole Molecular weight hg gas-phase space height, in.

L 7,5 ft Shell Length (assume) ho oil pad height, in.

to 5 minutes Oil retention time (Refer Table 2) hw water pad height, in.

tw 5 minutes Water retention time (Refer Table 2) K mesh capacity factor, ft/sec

Leff

Z 0,937 Gas compressibility effective length of the vessel where separation occurs, ft

or L

Lss

µg 0,0184 cP Gas viscosity seam-to-seam vessel length, ft

or Ls

K 0,35 ft/s Refer Table 1 NLL normal liquid level, %

NLL 50% Normal liquid level (assume) P operating pressure, psia

Qc continuous liquid-phase flow rate, bbl/day

CALCULATIONS Qg gas flow rate, MMSCFD or ft3/s

Qo oil flow rate, bbl/day

ρg 1,0 lb/ft3 Gas operating density W or Q

water

w flow rate, bbl/day

ρo 51,5 lb/ft3 Oil operating density Re Reynolds number

T operating temperature, °R

V liquid settling volume

Va 2,536 ft/s Va max. allowable velocity through secondary separation section

Qg,a 6,21 ft3/s Actual volume flow of gas Vm velocity of the mixture, m/s

Ag,min 2,45 ft2 Minimum gas flow area Z gas compressibility

Ag,min 2,45 ft2 μc continuous phase dynamic viscosity, cp

Error 0,00 μw water dynamic viscosity, cP

Next larger (than Dmin) and appropriate 3

Dselected 24 in ρ density, lbm/ft

size

L 7,5 ft Shell length ρg gas density, lbm/ft3

L/D 3,8 unitless Refer Note 4 ρl liquid density, lbm/ft3

3

ρo oil density, lbm/ft

ρm mean density of mixture, kg/m 3

V 2 bbl Liquid volume (excluding bottom head) ρw water density, lbm/ft3

Liquid capacity of separator should be

W 302 bpd

more than 270 bpd (input value)

Potrebbero piacerti anche

- ExamSlip - 148865 - 20190401 - 1520 VladDocumento23 pagineExamSlip - 148865 - 20190401 - 1520 VladNikolaus PanjaitanNessuna valutazione finora

- Horizontal Separator Adequacy CheckDocumento4 pagineHorizontal Separator Adequacy CheckTech ManagerNessuna valutazione finora

- M=350.17 (γ Wor Γ Gor Ρ γ: 6,000 bbl/dDocumento23 pagineM=350.17 (γ Wor Γ Gor Ρ γ: 6,000 bbl/dHoa NguyenNessuna valutazione finora

- Separator Sizing SheetDocumento8 pagineSeparator Sizing SheetCahyoNessuna valutazione finora

- PROYEK MINI LPG PLANT LAPANGAN JATA CALCULATIONDocumento6 paginePROYEK MINI LPG PLANT LAPANGAN JATA CALCULATIONDIANTORONessuna valutazione finora

- Liquid - Gas Phase SizingDocumento12 pagineLiquid - Gas Phase Sizingeke23Nessuna valutazione finora

- Separator Sizing - PPTDocumento21 pagineSeparator Sizing - PPTD K SNessuna valutazione finora

- 3-Phase Sparator Sizing (Vertical and Horizontal)Documento30 pagine3-Phase Sparator Sizing (Vertical and Horizontal)WickyNessuna valutazione finora

- Two Phase Flow HorizontalDocumento4 pagineTwo Phase Flow Horizontalnamphong_vnvnNessuna valutazione finora

- Separator Design: Rev Description Date Prepared by Client ApprovalDocumento18 pagineSeparator Design: Rev Description Date Prepared by Client ApprovalUsɱâñ Måâñ100% (1)

- Separator Sizing and DesignDocumento44 pagineSeparator Sizing and DesignKay EenNessuna valutazione finora

- Slug Catcher SizingDocumento6 pagineSlug Catcher SizingrezaNessuna valutazione finora

- CNG ADK 3,5 MMSCFD 13 Desember 2019 New Inlet Pressure with Heater After DiDocumento1 paginaCNG ADK 3,5 MMSCFD 13 Desember 2019 New Inlet Pressure with Heater After Dirandi martaNessuna valutazione finora

- Unlock Separator SizingDocumento42 pagineUnlock Separator SizingmortezasabetiNessuna valutazione finora

- Horizontal Three Phase Separator Sizing CalculationDocumento3 pagineHorizontal Three Phase Separator Sizing CalculationDazzy 265Nessuna valutazione finora

- Objective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpDocumento5 pagineObjective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpAJAY1381Nessuna valutazione finora

- 3-Phase Separator Sheet (GPSA)Documento12 pagine3-Phase Separator Sheet (GPSA)WickyNessuna valutazione finora

- Horizontal 3 Phase Separator With Boot SizingDocumento16 pagineHorizontal 3 Phase Separator With Boot Sizingzamijaka100% (1)

- Qaverage Phase-1 Phase-2 Qpeak Phase-1 Phase-2 m3/d m3/d m3/hr m3/hr M3/sec M3/secDocumento7 pagineQaverage Phase-1 Phase-2 Qpeak Phase-1 Phase-2 m3/d m3/d m3/hr m3/hr M3/sec M3/secHemantk8731100% (1)

- Electrostatic Oil - Water Treater & Desalter: Calculated AnswersDocumento2 pagineElectrostatic Oil - Water Treater & Desalter: Calculated AnswersLeonardo ChávezNessuna valutazione finora

- PDM-P-CS-002 - HP Prod SeparatorDocumento6 paginePDM-P-CS-002 - HP Prod Separatorfirman adiyantoNessuna valutazione finora

- Tube Side Velocity CalculationDocumento20 pagineTube Side Velocity CalculationNitin KurupNessuna valutazione finora

- Sizing Calculation - AC214312UJ - R0 PDFDocumento1 paginaSizing Calculation - AC214312UJ - R0 PDFPavendhan PavNessuna valutazione finora

- E3 Field Development Production Separator DesignDocumento5 pagineE3 Field Development Production Separator DesignhaiderNessuna valutazione finora

- Weymouth Gas Flow CalculationsDocumento44 pagineWeymouth Gas Flow CalculationsPierre GermaineNessuna valutazione finora

- Quick estimation compressor settle out conditionsDocumento1 paginaQuick estimation compressor settle out conditionsAhmed GattoufiNessuna valutazione finora

- Valve Sizing Calculation8Documento2 pagineValve Sizing Calculation8PIDNessuna valutazione finora

- Calculo Separador BifasicoDocumento3 pagineCalculo Separador BifasicoLuisa Garcia100% (1)

- Example 1: Size A 2-Phase Vertical Separator: Job SpecificationsDocumento20 pagineExample 1: Size A 2-Phase Vertical Separator: Job SpecificationsagusnnnNessuna valutazione finora

- Hydraulics - Summary: Including Cutting Weight & Tool JointDocumento5 pagineHydraulics - Summary: Including Cutting Weight & Tool JointAnonymous U5t9NYzhLWNessuna valutazione finora

- 31.PEAK Depressurization RATEDocumento1 pagina31.PEAK Depressurization RATEDILIP MATALNessuna valutazione finora

- Slug Catcher Sizing SpreadsheetDocumento14 pagineSlug Catcher Sizing Spreadsheettoño16Nessuna valutazione finora

- CNPCIC Field Production Test Separator GuideDocumento18 pagineCNPCIC Field Production Test Separator Guidesalahadine maideNessuna valutazione finora

- Seperator Sizing Sheet (Ken Arnold)Documento2 pagineSeperator Sizing Sheet (Ken Arnold)Hani KirmaniNessuna valutazione finora

- Waymouth CalculationDocumento8 pagineWaymouth CalculationSURJYA TAMULINessuna valutazione finora

- Pressure Reducing CalculatorDocumento12 paginePressure Reducing CalculatoralifbaharunNessuna valutazione finora

- Guide For Vessel Sizing PDFDocumento24 pagineGuide For Vessel Sizing PDFManish542Nessuna valutazione finora

- CalculationDocumento13 pagineCalculationajit kumarNessuna valutazione finora

- 3 Phase SizingDocumento2 pagine3 Phase Sizingc_nghiaNessuna valutazione finora

- GAS PROPERTIES CALCULATION SHEETDocumento56 pagineGAS PROPERTIES CALCULATION SHEETOlumuyiwa FasehunNessuna valutazione finora

- Pump & Pressure Drop CalculationDocumento42 paginePump & Pressure Drop CalculationMuhammad RizkyNessuna valutazione finora

- Heat duty calculationDocumento6 pagineHeat duty calculationwahyuriansyahNessuna valutazione finora

- LAMPIRAN C Spesifikasi PeralatanDocumento89 pagineLAMPIRAN C Spesifikasi PeralatanRahmaisa HarahapNessuna valutazione finora

- Flare Knock Out Drum Sizing ReportDocumento4 pagineFlare Knock Out Drum Sizing ReportSaid Ahmed Salem100% (1)

- Fuel gas filter sizing calculationDocumento1 paginaFuel gas filter sizing calculationIndraharja FerryNessuna valutazione finora

- كل انواع الفلاش سبريتر الطورين والثلاث اطوار مهمDocumento42 pagineكل انواع الفلاش سبريتر الطورين والثلاث اطوار مهمamir loloNessuna valutazione finora

- Tank FixturesDocumento21 pagineTank FixturesASSSSSSSSSSSSNessuna valutazione finora

- Optimizing Gas/Liquid Separator PerformanceDocumento14 pagineOptimizing Gas/Liquid Separator PerformanceWendellReeceFrankNessuna valutazione finora

- 3-Phase SeparatorDocumento6 pagine3-Phase SeparatorToniNessuna valutazione finora

- Calculation of Height of The Siphon SystemDocumento2 pagineCalculation of Height of The Siphon SystemHsein WangNessuna valutazione finora

- Oil and Gas Production Surface Facility Design SoftwareDocumento7 pagineOil and Gas Production Surface Facility Design SoftwareLeonardo Chávez0% (2)

- PH ColumnDocumento4 paginePH ColumnAnonymous oVRvsdWzfBNessuna valutazione finora

- Vertical Knock Out Drum With Wire Mesh For NDocumento1 paginaVertical Knock Out Drum With Wire Mesh For NwdyouQNessuna valutazione finora

- Calculation For Steam Blow Rev03Documento6 pagineCalculation For Steam Blow Rev03tauqeerNessuna valutazione finora

- Nozzle CriteriaDocumento2 pagineNozzle CriteriaKhalil LasferNessuna valutazione finora

- Oil and Gas SeparatorsDocumento23 pagineOil and Gas SeparatorsSofea Hanom NordinNessuna valutazione finora

- Appendix A: A.1. Three Phase SeparatorDocumento48 pagineAppendix A: A.1. Three Phase SeparatorNhaaaeyNessuna valutazione finora

- Specification Sheet For Separator: Operating Conditions SketchDocumento12 pagineSpecification Sheet For Separator: Operating Conditions SketchAngelikaOdimer100% (1)

- Cálculo de Diseño de SeparadoresDocumento4 pagineCálculo de Diseño de SeparadoresEdwardNessuna valutazione finora

- Separator SizingDocumento2 pagineSeparator SizingCahyoNessuna valutazione finora

- Aic 14600Documento12 pagineAic 14600ekabudiartiNessuna valutazione finora

- Sizing Three Phase Horizontal SeparatorDocumento1 paginaSizing Three Phase Horizontal SeparatorekabudiartiNessuna valutazione finora

- Sizing Three Phase Horizontal SeparatorDocumento1 paginaSizing Three Phase Horizontal SeparatorekabudiartiNessuna valutazione finora

- Sizing Shell and Tube Heat ExchangerDocumento17 pagineSizing Shell and Tube Heat ExchangerCallum Biggs100% (3)

- List Buku Wajib BeliDocumento1 paginaList Buku Wajib BeliekabudiartiNessuna valutazione finora

- Aspen HYSYS Simulation of CO2 Removal by Amine Absorption From A Gas Based Power PlantDocumento9 pagineAspen HYSYS Simulation of CO2 Removal by Amine Absorption From A Gas Based Power PlantLina1929Nessuna valutazione finora

- Detail Specification of Each ConsumableDocumento4 pagineDetail Specification of Each ConsumableekabudiartiNessuna valutazione finora

- Sizing of LPG Air Mix System (24mmbtu 60B-40P, 50psig)Documento1 paginaSizing of LPG Air Mix System (24mmbtu 60B-40P, 50psig)ekabudiartiNessuna valutazione finora

- Jsae Paper 2007Documento8 pagineJsae Paper 2007ekabudiartiNessuna valutazione finora

- VCR 232 Ivory by Ayola 21-22 Nov'17 - SyarifuddinDocumento1 paginaVCR 232 Ivory by Ayola 21-22 Nov'17 - SyarifuddinekabudiartiNessuna valutazione finora

- Drawing 1Documento1 paginaDrawing 1ekabudiartiNessuna valutazione finora

- Gas Density Table PDFDocumento2 pagineGas Density Table PDFAsif Mehmood KhanNessuna valutazione finora

- Aspen HYSYS Simulation of CO2 Removal by Amine Absorption From A Gas Based Power PlantDocumento9 pagineAspen HYSYS Simulation of CO2 Removal by Amine Absorption From A Gas Based Power PlantLina1929Nessuna valutazione finora

- Aspen HYSYS Simulation of CO2 Removal by Amine Absorption From A Gas Based Power PlantDocumento9 pagineAspen HYSYS Simulation of CO2 Removal by Amine Absorption From A Gas Based Power PlantLina1929Nessuna valutazione finora

- Api660 Modification BRDocumento13 pagineApi660 Modification BRbaraaazeb0% (1)

- Daftar Dan Alamat Oil CompanyDocumento16 pagineDaftar Dan Alamat Oil Companysetia wirawan100% (7)

- Aveva N Hysys ResumeDocumento3 pagineAveva N Hysys ResumeekabudiartiNessuna valutazione finora

- AdsorptionDocumento10 pagineAdsorptionekabudiartiNessuna valutazione finora

- Fluida ReservoirDocumento17 pagineFluida ReservoirTeuku Muhammad RezanNessuna valutazione finora

- Wins TeamDocumento2 pagineWins TeamekabudiartiNessuna valutazione finora

- Jump Start Aspen HYSYS V8Documento29 pagineJump Start Aspen HYSYS V8hayfronbsterNessuna valutazione finora

- Aspen EDR FamilyDocumento10 pagineAspen EDR Familyrtrajan_mech5408Nessuna valutazione finora

- TGNET AddDocumento12 pagineTGNET AddekabudiartiNessuna valutazione finora

- HVR Software PDFDocumento12 pagineHVR Software PDFekabudiartiNessuna valutazione finora

- Choosing Column InternalsDocumento7 pagineChoosing Column Internalspetrolhead1Nessuna valutazione finora

- Wish List BookDocumento1 paginaWish List BookekabudiartiNessuna valutazione finora

- Hardware - Sheet PDMS PDFDocumento8 pagineHardware - Sheet PDMS PDFekabudiartiNessuna valutazione finora

- Swedish Aircraft Noise Calculation Method 19950630Documento36 pagineSwedish Aircraft Noise Calculation Method 19950630ekabudiartiNessuna valutazione finora

- OLGA Link User GuideDocumento51 pagineOLGA Link User GuideekabudiartiNessuna valutazione finora

- ARTS 9 Q4 Week 1Documento3 pagineARTS 9 Q4 Week 1Elaissa MaglanqueNessuna valutazione finora

- Goldenberg and Reddy (2017)Documento10 pagineGoldenberg and Reddy (2017)Mariana ToniniNessuna valutazione finora

- Learner's Activity Sheet: English (Quarter 4 - Week 5)Documento5 pagineLearner's Activity Sheet: English (Quarter 4 - Week 5)Rufaidah AboNessuna valutazione finora

- Format For Handout - Comparative Models of EducationDocumento5 pagineFormat For Handout - Comparative Models of EducationAdrian AsiNessuna valutazione finora

- Biology 11th Edition Mader Test BankDocumento25 pagineBiology 11th Edition Mader Test BankAnthonyWeaveracey100% (44)

- Edtpa Lesson Plan 1Documento3 pagineEdtpa Lesson Plan 1api-364684662Nessuna valutazione finora

- Sankalp Sanjeevani NEET: PhysicsDocumento11 pagineSankalp Sanjeevani NEET: PhysicsKey RavenNessuna valutazione finora

- Final Exam IN Sample QuestionsDocumento27 pagineFinal Exam IN Sample QuestionsJI TEN100% (1)

- Chapter 1-The Indian Contract Act, 1872, Unit 1-Nature of ContractsDocumento10 pagineChapter 1-The Indian Contract Act, 1872, Unit 1-Nature of ContractsALANKRIT TRIPATHINessuna valutazione finora

- My RepublicDocumento4 pagineMy Republicazlan battaNessuna valutazione finora

- Augustine and The Devil Two BodiesDocumento12 pagineAugustine and The Devil Two BodiesAlbert LanceNessuna valutazione finora

- American Literature TimelineDocumento2 pagineAmerican Literature TimelineJoanna Dandasan100% (1)

- No-Till For Micro Farms: The Deep-Mulch Method (Lean Micro Farm)Documento20 pagineNo-Till For Micro Farms: The Deep-Mulch Method (Lean Micro Farm)Chelsea Green PublishingNessuna valutazione finora

- Pyrolysis ProjectDocumento122 paginePyrolysis ProjectSohel Bangi100% (1)

- Genigraphics Poster Template 36x48aDocumento1 paginaGenigraphics Poster Template 36x48aMenrie Elle ArabosNessuna valutazione finora

- NVH PDFDocumento3 pagineNVH PDFSubhendu BarisalNessuna valutazione finora

- Optimize Supply Network DesignDocumento39 pagineOptimize Supply Network DesignThức NguyễnNessuna valutazione finora

- UNIVERSIDAD NACIONAL DE COLOMBIA PALMIRA ENGLISH PROGRAMDocumento1 paginaUNIVERSIDAD NACIONAL DE COLOMBIA PALMIRA ENGLISH PROGRAMAlejandro PortoNessuna valutazione finora

- Nodelman 1992Documento8 pagineNodelman 1992Ana Luiza RochaNessuna valutazione finora

- Fixed Prosthodontics Provisional Materials: Making The Right Selection.Documento7 pagineFixed Prosthodontics Provisional Materials: Making The Right Selection.veloso.rossana0% (1)

- JASA SREVIS LAPTOP Dan KOMPUTERDocumento2 pagineJASA SREVIS LAPTOP Dan KOMPUTERindimideaNessuna valutazione finora

- A. Rationale: Paulin Tomasuow, Cross Cultural Understanding, (Jakarta: Karunika, 1986), First Edition, p.1Documento12 pagineA. Rationale: Paulin Tomasuow, Cross Cultural Understanding, (Jakarta: Karunika, 1986), First Edition, p.1Nur HaeniNessuna valutazione finora

- 2000 T.R. Higgins Award Paper - A Practical Look at Frame Analysis, Stability and Leaning ColumnsDocumento15 pagine2000 T.R. Higgins Award Paper - A Practical Look at Frame Analysis, Stability and Leaning ColumnsSamuel PintoNessuna valutazione finora

- French Revolution ChoiceDocumento3 pagineFrench Revolution Choiceapi-483679267Nessuna valutazione finora

- Strategicmanagement Finalpaper 2ndtrisem 1819Documento25 pagineStrategicmanagement Finalpaper 2ndtrisem 1819Alyanna Parafina Uy100% (1)

- Dental Management of Patients With HemophiliaDocumento5 pagineDental Management of Patients With HemophiliaarjayNessuna valutazione finora

- Newly Constructed Masculinity' in Mahesh Dattani's Dance Like A ManDocumento4 pagineNewly Constructed Masculinity' in Mahesh Dattani's Dance Like A ManIJELS Research JournalNessuna valutazione finora

- Catalogue PDFDocumento4 pagineCatalogue PDFShivam GuptaNessuna valutazione finora

- Linked ListDocumento83 pagineLinked Listshahida18Nessuna valutazione finora

- Tiger Tales: From Colonial MalayaDocumento16 pagineTiger Tales: From Colonial MalayamatarsNessuna valutazione finora