Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Rcoppage Cmmarpdf Final

Caricato da

api-308735650100%(1)Il 100% ha trovato utile questo documento (1 voto)

5K visualizzazioni2 pagineTitolo originale

rcoppage cmmarpdf final

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

100%(1)Il 100% ha trovato utile questo documento (1 voto)

5K visualizzazioni2 pagineRcoppage Cmmarpdf Final

Caricato da

api-308735650Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

TECHNO FILE

carbon trapping by Ryan Coppage, PhD

Most potters are familiar with carbon-trapping: on shino glazes, in a typical reduction firing or in wood, soda,

and salt kilns, and even the process of creating conditions for heavy soot production to trap carbon on

ceramic surfaces. Some covet black blossoms and spots on surfaces caused by carbon trapping as their

most prized firing results. Learn how it happens, what causes carbon-trapping, and how can you control it.

Defining the Terms Shinos

Body Reduction: An increased-reduction Shinos represent a range of glazes that occupy many potters’ hearts. They are incredibly

period in firing in which oxygen access to technical, complex, possess unmatched beauty in a wide range of colors, and still possess

the kiln is decreased, often resulting in

early iron reduction in the clay body after many facets that most do not understand.

clay inversion has taken place. About the only thing that shino recipes have in common is their higher-than-normal clay

content and presence of soda ash. They have a uniquely large amount of clay, which interacts

Carbon Trapping: The action of trapping

soot on a ceramic surface, often at high to varying degrees with iron depending on the iron in the glaze or clay body, and almost

points or in spotted patterns and to all will trap carbon to some degree or another. Dichotomously, shinos with a low soda-ash

varying degrees. content do not trap much carbon at all (Gustin Shino, 4% soda ash), whereas those with

Concentration Gradient: A range of high soda-ash content (Malcolm Davis Shino, 16.3%) can trap so much carbon that the entire

high material prevalence to low material surface can turn black.

prevalence in any particular area or across These glazes are all fired in a gas kiln using a similar firing schedule: Candle at a low

a surface. temperature for a few hours or overnight if possible. Fire the kiln in oxidation up to 1560ºF

Growth: The deposition of additional (849°C), cone 013, (ssshhhh, super secret tech here!). As soon as cone 013 starts to bend,

material to a nucleation site, often decrease the damper opening or increase the fuel:oxygen ratio such that soot is being produced

changing phase (from dissolved ions to in the kiln at an earlier-than-normal body reduction. You can often see soot rolling up and

precipitated solid material), which results out of the kiln. It will smell faintly of tar/creosote/greasy railroad ties. It is normal for the kiln

in crystal growth as a solid material crystal

expands outward. to stall or barely climb in temperature at all during body reduction. This is the carbon-trapping

phase. After around 45 minutes to an hour of heavy reduction, start opening the damper and

Nucleation: The first atom or central site increasing air access until a light reduction results in steady temperature gain. Maintain this

of crystal growth, often at a high point

or high concentration area, which is a soft reduction for the remainder of your firing, until cone 10 is softly bent. Note that most

transition from dissolved salt material to shinos are formulated for cone 9 maturation, as they were traditionally fired in saggars and

precipitated, solid material. were one cone colder than the rest of the kiln. Firing beyond 10 will occasionally destroy the

Shino: A high-clay ceramic glaze that bursts of color for which shinos are known.

often has a substantial amount of soda

ash in its formulation as both a flux and a Soda Ash

facilitator for carbon trapping. The true workhorse of shino glazes is also one of the ingredients used in smaller amounts.

Soda Ash: A somewhat caustic salt, soda Soda ash fluxes the glaze, helps manage the extremely high-clay content in all recipes, easily

ash is an aggressive flux, does most of gasses off CO2, and does something much more interesting and less commonly known. Just

the legwork in soda firing, and gasses off like most salts, soda ash crystallizes when it dries. Akin to the salt patterns you see on the

CO2, leaving behind mostly sodium oxide

side of the road after a big snow (and resulting road-salting), soda ash forms salt crystals in

after being fired.

shino glazes. These crystals form at the surface of the glaze and can vary in nature depending

on how the glaze dries, which direction a breeze was

coming from, the presence of wax on the surface, or by

varying the length of time it was allowed to dry before

being fired. Each of these effects will be different based

on the amount of soda ash in the glaze. These crystals

effectively allow carbon trapping to take place, directing

where soot will stick to the surface and become those

black blushes and blossoms on your fired work.

1 Two different shino vessels, fired side-by-side: left: one

week dry time, right: less than one hour dry time prior to

firing. This results in two things: soda ash crystal patterns

are grown that will control carbon trapping and glaze

vitrification temperatures change. During the firing, soda ash

is also pulled away from other places, effectively taking flux

away from the areas where crystals did not form.

62 march 2018 www.ceramicsmonthly.org

2 Liners of shino vessels (a) glazed

a week prior to firing and (b) glazed

immediately before loading and firing.

Take note of the carbon trapping, luster,

and vitrification differences.

Soda Ash and Timing

When a vessel is dipped in a shino glaze slurry, the still-wet glaze that carbon-trapping patterns by spraying (and respraying, if desired!)

adheres to the pot includes a dissolved solution of soda ash. The glaze salt-crystal formations with hot water until you get a pattern you

will start to dry, with high points on the vessel losing the most water like. You can vary the time you allow vessels to dry to modify carbon-

first. Here, soda ash crystals will form as nucleation sites for salt crystal trapping spot size, randomness, and even liner glaze vitrification if less

growth. As soon as some small amount of solid salt crystals form, the soda ash was allowed to migrate to areas where salt crystals formed.

remainder of the wet glaze will start to transport dissolved soda ash You can start nucleation sites by dropping single crystals of soda ash

to the salt crystal sites (thermodynamically driven via a concentration onto vessels freshly-dipped into shino glazes. You can obtain vastly

gradient), effectively continuing to grow salt crystals as the glaze dries, different carbon trapping and shino aesthetics by just glazing your

until the dissolved soda ash has been consumed. This results in two vessels at various times, being mindful of the mechanism by which

things: soda ash crystal patterns are grown that will control carbon carbon trapping takes places, and finding new methods to control

trapping. During the firing soda ash is also pulled away from other soda ash crystal formation.

places, effectively taking flux away from the areas where crystals did

not form. Interestingly, the inside of vessels glazed with Malcolm Davis All glaze work, firing, and thanks go to the Visual Arts Center of

Shino are flat, orange, and appear unfluxed, as soda ash migrates to Richmond. This work was informally requested and inspired by Al

the outside of the vessel during salt crystal formation and decreases Pellenberg, a fellow instructor, at the Visual Arts Center of Richmond.

the vitrification temperature of the glaze there. If glazed and fired

immediately, only minimal soda ash is allowed to migrate to the the author Ryan Coppage is currently Chemistry Faculty at the

outside of the vessel and the liner glaze is still shiny, gold, and vitrified. University of Richmond in Richmond, Virginia. He teaches a Japanese

The melting point of soda ash is 1564°F (851°C) or effectively Ceramics and Glaze Design class at the Visual Arts Center of Richmond

cone 013. That means that right at cone 013, where we talked about and still makes far too many pots. www.ryancoppage.com.

starting body reduction, soda-ash crystals are starting to become

tacky and soft. They are starting to melt. Soot will stick to them and

be absorbed into these freshly melted salt pools, which is effectively

carbon trapping at the surface. The patterns of salt crystals that are Have an idea for a technical article? Want to write a

visible on the surface of your dried vessel will be the same as your technical article? Have a question about a technical process?

Send your technical topic ideas to Ceramics Monthly at

patterns of carbon trapping. The soda-ash crystals are what allow

editorial@ceramicsmonthly.org.

that carbon trapping to take place. This means that you can alter

3 Salt crystals growing on the surface of the glaze as a result of drying.

www.ceramicsmonthly.org march 2018 63

Potrebbero piacerti anche

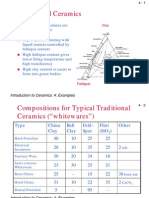

- 08 Chapter 4Documento8 pagine08 Chapter 4Ali AliNessuna valutazione finora

- How To Fire Pottery and Ceramics - How To Fire A Kiln - and Kiln Firing Techniques - HubPagesDocumento6 pagineHow To Fire Pottery and Ceramics - How To Fire A Kiln - and Kiln Firing Techniques - HubPagesCAMELIA Neagu-COGALNICEANUNessuna valutazione finora

- 43vocabulary Basic CeramicsDocumento6 pagine43vocabulary Basic CeramicsReshmi VarmaNessuna valutazione finora

- Stoneware MaturityDocumento3 pagineStoneware MaturityLNessuna valutazione finora

- Rutile Oct17Documento2 pagineRutile Oct17api-308735650100% (3)

- Creating A EngobeDocumento105 pagineCreating A Engobeduyen nguyen chi luongNessuna valutazione finora

- Pigments and Engobes For Crystalline Glazes: KnowledgeDocumento2 paginePigments and Engobes For Crystalline Glazes: KnowledgeJesus MorenoNessuna valutazione finora

- Ceramic Pigments and GlassesDocumento19 pagineCeramic Pigments and GlassesalbaqueNessuna valutazione finora

- Crystalline Glaze Class Dan DermerDocumento4 pagineCrystalline Glaze Class Dan DermerJesus MorenoNessuna valutazione finora

- STA Decorating SlipDocumento2 pagineSTA Decorating SlipmohanNessuna valutazione finora

- Ceramic Sculpture GordonDocumento4 pagineCeramic Sculpture GordonHugo De Oliveira AssisNessuna valutazione finora

- FritDocumento4 pagineFritaymanfawzyNessuna valutazione finora

- Muy Buenos 3110Documento17 pagineMuy Buenos 3110Jesus MorenoNessuna valutazione finora

- Self Reliant PotterDocumento116 pagineSelf Reliant PotterYaroslav MatviychukNessuna valutazione finora

- Glazes - For The Self-Reliant Potter: Appendix: Glaze RecipesDocumento21 pagineGlazes - For The Self-Reliant Potter: Appendix: Glaze RecipesgeertjepNessuna valutazione finora

- Utilization of Broken Glass Into Ceramics: QuartzDocumento7 pagineUtilization of Broken Glass Into Ceramics: QuartzJane Michelle EmanNessuna valutazione finora

- Ceramics Monthly (June 1959)Documento44 pagineCeramics Monthly (June 1959)Wade MacMorrighan100% (1)

- Chinese Ceramics Final DraftDocumento60 pagineChinese Ceramics Final DraftEliezer HabaNessuna valutazione finora

- Slips and GlazesDocumento3 pagineSlips and GlazesKelley_Eggert_800Nessuna valutazione finora

- Basic Info About Glaze FormulationsDocumento3 pagineBasic Info About Glaze FormulationsThongMaVanNessuna valutazione finora

- Advanced Ceramics SyllabusDocumento4 pagineAdvanced Ceramics Syllabusapi-285550989Nessuna valutazione finora

- The Sweet Life - Ceramics: Art & PerceptionDocumento4 pagineThe Sweet Life - Ceramics: Art & PerceptionBlair SchulmanNessuna valutazione finora

- CeramicsDocumento13 pagineCeramicsHitesh BhatiaNessuna valutazione finora

- Betty WoodmanDocumento22 pagineBetty WoodmanMargaret MillerNessuna valutazione finora

- Firing Temperatures: & Cone EquivalentsDocumento2 pagineFiring Temperatures: & Cone EquivalentsIcy45Nessuna valutazione finora

- Clay Packet GuideDocumento4 pagineClay Packet Guideapi-290985916100% (1)

- Everyday Electronics 1974 01Documento5 pagineEveryday Electronics 1974 01marcosscarato0% (1)

- William J. O'Brien Exhibition PosterDocumento2 pagineWilliam J. O'Brien Exhibition PosterThe Renaissance SocietyNessuna valutazione finora

- 15 Cone 10 RecipesDocumento10 pagine15 Cone 10 RecipesInga NowakNessuna valutazione finora

- Roman CupDocumento8 pagineRoman CupJiri Van denNessuna valutazione finora

- The Potter's Craft: A Practical Guide for the Studio and WorkshopDa EverandThe Potter's Craft: A Practical Guide for the Studio and WorkshopNessuna valutazione finora

- Ceramics VocabularyDocumento3 pagineCeramics Vocabularyhaana duggerNessuna valutazione finora

- Roger GrahamDocumento3 pagineRoger GrahamStefan Van CleemputNessuna valutazione finora

- Low Temperature Co-Fired Ceramics With Ultra-Low Sintering Temperature A ReviewDocumento20 pagineLow Temperature Co-Fired Ceramics With Ultra-Low Sintering Temperature A ReviewMeiliza HastutiNessuna valutazione finora

- Pottery Clays and ChemicalsDocumento16 paginePottery Clays and ChemicalsDave SmithNessuna valutazione finora

- Ceramic: Interior Design Assignment-IDocumento35 pagineCeramic: Interior Design Assignment-IkhizarNessuna valutazione finora

- Iridescent and Manganese Crystalline GlazesDocumento37 pagineIridescent and Manganese Crystalline Glazesvolkan100% (4)

- How To Design, Make, and Install and Murals: Ceramic TilesDocumento19 pagineHow To Design, Make, and Install and Murals: Ceramic TilesChanrathNessuna valutazione finora

- 407 Studio Process Sheet Ceramics 2Documento5 pagine407 Studio Process Sheet Ceramics 2api-583626725Nessuna valutazione finora

- ESmalte Rojos PDFDocumento7 pagineESmalte Rojos PDFtengocorazon100% (1)

- Electric KilnsDocumento16 pagineElectric KilnsMadalina Teler100% (1)

- Como Construir HornosDocumento8 pagineComo Construir Hornosfrencho rmzNessuna valutazione finora

- Glazed CeramicsDocumento7 pagineGlazed CeramicsPablo Cesar Reyes AmadorNessuna valutazione finora

- Mixing Slip, Plaster Mold Fabrication, Slip-CastingDocumento4 pagineMixing Slip, Plaster Mold Fabrication, Slip-CastingLauraNessuna valutazione finora

- Salt Glazed Clay SurfacesDocumento67 pagineSalt Glazed Clay SurfacesMilen SolakovNessuna valutazione finora

- Clay and Glaze MaterialsDocumento28 pagineClay and Glaze Materialsapi-26965779100% (2)

- Ceramic FritsDocumento2 pagineCeramic Fritslaklain100% (1)

- GLAZEDocumento5 pagineGLAZE2011 YCM English Docent CourseNessuna valutazione finora

- Introduction To CeramicsDocumento29 pagineIntroduction To CeramicsShrikrishna BirajdarNessuna valutazione finora

- Clay Culture - Blue Kashi Tiles - Ceramic Arts NetworkDocumento7 pagineClay Culture - Blue Kashi Tiles - Ceramic Arts NetworkcomsianNessuna valutazione finora

- Crystalline Glaze NotesDocumento5 pagineCrystalline Glaze NotesTim Carlson100% (1)

- Atmospheric FiringsDocumento15 pagineAtmospheric Firingspele kedioglu100% (1)

- Absorcion Agilent ManualDocumento64 pagineAbsorcion Agilent ManualRuben MartinezNessuna valutazione finora

- cadaily-RawMaterials 2Documento16 paginecadaily-RawMaterials 2shaky4u100% (1)

- Ceramic: For Other Uses, See - A Ceramic Is An, NonmetallicDocumento7 pagineCeramic: For Other Uses, See - A Ceramic Is An, Nonmetallicletter_ashish4444Nessuna valutazione finora

- Introduction To Glaze CalculationDocumento4 pagineIntroduction To Glaze CalculationThongMaVanNessuna valutazione finora

- Copper (II) OxideDocumento5 pagineCopper (II) OxideWill Aguilar MamaniNessuna valutazione finora

- BE. Heat Exchangers.Documento97 pagineBE. Heat Exchangers.Gannavarapu KrishnaNessuna valutazione finora

- Folded Plate StructureDocumento4 pagineFolded Plate StructureSonal Sharma50% (2)

- Chemical Reactions and Equations: Case Study Based Questions 10th ScienceDocumento6 pagineChemical Reactions and Equations: Case Study Based Questions 10th ScienceSath-HyaNessuna valutazione finora

- Din 580-Lifting Eye Bolts PDFDocumento1 paginaDin 580-Lifting Eye Bolts PDFAntohi CatalinNessuna valutazione finora

- Brochure Agro Green PDFDocumento16 pagineBrochure Agro Green PDFLuís Felipe MinelloNessuna valutazione finora

- Organic Chemistry ReviewerDocumento1 paginaOrganic Chemistry Reviewerniyah austeroNessuna valutazione finora

- Astm b117 1973 PDFDocumento10 pagineAstm b117 1973 PDFabthakurNessuna valutazione finora

- Lecture No. 1 Fundamentals of GeologyDocumento28 pagineLecture No. 1 Fundamentals of GeologyJovin ManarinNessuna valutazione finora

- En 13811Documento12 pagineEn 13811Dule JovanovicNessuna valutazione finora

- Ronnel AC Design Solution 2Documento36 pagineRonnel AC Design Solution 2Xype LanderNessuna valutazione finora

- GCSE Science 2011 Contents Guide Chemistry-1Documento12 pagineGCSE Science 2011 Contents Guide Chemistry-1airulyantiNessuna valutazione finora

- Gusset Plate Connection To Round HSS Tension MembersDocumento7 pagineGusset Plate Connection To Round HSS Tension Membersglav1309Nessuna valutazione finora

- Instituto Alemão de Normalização-Din 10149-2Documento15 pagineInstituto Alemão de Normalização-Din 10149-2Helder VieiraNessuna valutazione finora

- PPTDocumento11 paginePPTBHAVESH JOSHINessuna valutazione finora

- M/S Hitesh Steel Duplex Steel Division Maharashtra IndiaDocumento10 pagineM/S Hitesh Steel Duplex Steel Division Maharashtra IndiaM/S Hitesh SteelNessuna valutazione finora

- Rizal Technological University Pasig Senior High School: Title PageDocumento68 pagineRizal Technological University Pasig Senior High School: Title PageChristian KhalilNessuna valutazione finora

- 730 UlfmDocumento4 pagine730 UlfmTobias Alberto Gonzalez PeresNessuna valutazione finora

- 324-Chapter 1 Rock Bit Interactions PDFDocumento42 pagine324-Chapter 1 Rock Bit Interactions PDFBilge KaanNessuna valutazione finora

- Estado Del Arte de Las Resinas 2011Documento10 pagineEstado Del Arte de Las Resinas 2011kelly johanna quintero arevaloNessuna valutazione finora

- Flange Isolating Gasket Kits: To Order Please Specify The FollowingDocumento8 pagineFlange Isolating Gasket Kits: To Order Please Specify The Followingmoch ardiansyahNessuna valutazione finora

- H2safety 12568330130779 Phpapp01Documento80 pagineH2safety 12568330130779 Phpapp01Rommel AguillonNessuna valutazione finora

- What Is Sintering?Documento15 pagineWhat Is Sintering?Vu VoNessuna valutazione finora

- Physical Chemistry I (100 Items)Documento14 paginePhysical Chemistry I (100 Items)Mark Ryan Tripole67% (3)

- AAC Block ReportDocumento28 pagineAAC Block ReportKvvPrasad100% (4)

- MSDS-Etidronic AcidDocumento7 pagineMSDS-Etidronic Acidherbi naturalsNessuna valutazione finora

- 2.1 (131 Marks) : MarkschemeDocumento48 pagine2.1 (131 Marks) : MarkschemeSemwezi EnockNessuna valutazione finora

- Chemical Waste Log Book 2011 PDFDocumento15 pagineChemical Waste Log Book 2011 PDFVictor AniekanNessuna valutazione finora

- Algerian CondensateDocumento3 pagineAlgerian CondensateibrankNessuna valutazione finora

- 31-Material Planning & Procurement For Projects Vendor DevelopmentDocumento179 pagine31-Material Planning & Procurement For Projects Vendor DevelopmentBJ SwamyNessuna valutazione finora

- I. Read Each Question Carefully. Write The Letter of The Correct AnswerDocumento3 pagineI. Read Each Question Carefully. Write The Letter of The Correct AnswerAchmabNessuna valutazione finora