Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bolted and Welded

Caricato da

jvdummyCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Bolted and Welded

Caricato da

jvdummyCopyright:

Formati disponibili

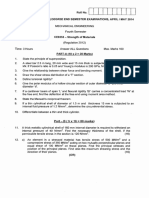

STEEL DESIGN (ASD, NSCP 2001)

Bolted and Riveted Connections Combined Tension and Shear Welded Connections

Possible Causes of Failure For shear: 𝒇𝒗 =

𝑹

𝑹=

𝑷 T = thickness of throat

𝑨𝒃 𝒏 𝑵

1. Due to Axial (ft ≤ Ft) t = thickness of plate

N = total no. of fastener

a.) Gross Area z = thickness of weld

𝑹 𝑅

𝒇𝒕 =

𝑨𝒈

For tension: 𝑓𝑡 =

𝐴𝑏 𝒇𝒗 ≤ 𝑭𝒗

𝐹𝑡 = 0.6𝐹𝑦

b.) Net Area a.) For Plate Fv = 0.3Fu

𝑅 𝑀𝑐𝐴

𝑓𝑡 = 𝑅= 𝑃

𝐴𝑒 (𝐼)(𝑁) 𝑓𝑣 =

𝐴𝑒

𝐴𝑒 = 𝑈𝐴𝑛 A = area of plate

𝐴𝑛 = 𝐴𝑔 − 𝐷𝑡𝑁 I = Inertia of plate 𝐴𝑒 = 𝑇𝐿𝑒

𝐴𝑛 ≤ 0.85𝐴𝑔 N = No. of fasteners

𝐹𝑡 = 0.5𝐹𝑢 𝐿𝑒 = 𝐿1 + 𝐿2 + 𝐿3 … ≥ 4𝑧

𝑃 (ñ) b.) For Fastener

𝑅=

𝑇𝑜𝑡𝑎𝑙 𝑛𝑜. 𝑜𝑓 𝑓𝑎𝑠𝑡𝑒𝑛𝑒𝑟

𝑀𝑐 𝑀𝑐 𝑃 = 𝑃1 + 𝑃2 + 𝑃3 …

𝑅= 2 = ∑ 𝑥2 + 𝑦2

U = reduction coefficient ∑𝑑 Case 1. Equal legs (most cases)

N = number of hole in plane failure M = Pe

Ag = Gross area c = distance from the c.g. 𝑇 = 𝑧𝑐𝑜𝑠45

An = net area e = eccentricity

Ae = effective area Case 2. Unequal Legs

Note: Higher governs

ñ = No. of resisting fastener

𝑇 = 𝑧1 𝑧2 /(√𝑧1 ² + 𝑧2 ²)

P = Reaction/force applied Eccentric Shear

D = d + 1.6mm Combined Shear and Tension

d = dia. of fastener 𝑹𝒕𝒐𝒕𝒂𝒍

𝒇𝒗𝒎𝒂𝒙 =

For Staggered Connections: 𝑨𝒃 𝒇≤𝑭

∑ 𝑺𝟐

𝐀𝐧 = 𝐀𝐠 − 𝐃𝐭𝐍 + (𝒕) 𝑹𝒅𝒙 =

𝑷𝒙

𝑹𝒅𝒚 =

𝑷𝒚

F = 0.3Fu

𝟒𝐠 𝑵 𝑵

N = no. of holes in plane failure 𝑻ӯ ̅

𝑻𝒙

𝑅𝑡𝑜𝑡𝑎𝑙

S = horizontal spacing between two fasteners 𝑹𝒕𝒙 = ∑ 𝑹𝒕𝒚 = ∑ 𝑓=

𝒙2 +𝒚2 𝒙2 +𝒚2 𝑧𝑐𝑜𝑠45

g = vertical spacing between two fasteners

t = thickness of plate 𝑅𝑡𝑜𝑡𝑎𝑙 = √𝑅𝑣 2 + 𝑅𝑡 2

𝑹𝒕𝒐𝒕𝒂𝒍 = √(𝑹𝒅𝒚 + 𝑹𝒕𝒚 )² + (𝑹𝒅𝒙 + 𝑹𝒕𝒙 )²

Note: Always consider the longest path 𝑷

2. Due to Shear (fv ≤ Fv) 𝑹𝒗 = (in terms of line load N/mm)

𝑳𝒆

𝑹 T = Pe

𝒇𝒗 = 𝑴

𝑨𝒃 𝒏 𝑹𝒕 =

Rdx or Rdy = Direct shear 𝑺

Fv = Allowable shear stress for fasteners

Ab = Area of fastener Rtx or Rty = torsional shear M = Pe

n = No. of shear plane (single – 1, double – 2)

𝑃 ӯ = vert.distance from the most stressed fastener S = section modulus

𝑅=

𝑡𝑜𝑡𝑎𝑙 𝑛𝑜. 𝑜𝑓 𝑓𝑎𝑠𝑡𝑒𝑛𝑒𝑟

𝒙̅ = hor. distance from the most stressed fastener S = d²/6

3. Due to Bearing (fp ≤ Fp)

𝑹 x = hor. distance from centroid to each fastener S = bd

𝒇𝒑 =

𝑨𝒄

𝑃 y = vert. distance from centroid to each fastener

𝑅=

𝑡𝑜𝑡𝑎𝑙 𝑛𝑜. 𝑜𝑓 𝑓𝑎𝑠𝑡𝑒𝑛𝑒𝑟

Ac = dt P = working load/actual load S = (4bd+d²)/6

Fp = 1.2Fu E = eccentricity S = πr²

A = Area of contact

d = diameter of fastener Note: Always consider the orientation of load

t = thickness of plate

4. Due to Block Shear 𝑅𝑑 𝑃

𝑃 = 0.3𝐹𝑢𝐴𝑣 + 0.5𝐹𝑢𝐴𝑡 Due to Direct Shear: 𝑓𝑑 = : 𝑅𝑑 =

𝑧𝑐𝑜𝑠45 𝐿𝑒

Av = Area at plane of failure parallel to working load 𝑅𝑡 𝑇𝑦 𝑇𝑥

At = Area at plane perpendicular to working load Due to Torsional Shear: 𝑓𝑡 = : 𝑅𝑡𝑥 = 𝐿2

: 𝑅𝑡𝑦 = 𝐿2

𝑧𝑐𝑜𝑠45 ∑ +𝑥.𝑔.2 +𝑦.𝑔.2 ∑ +𝑥.𝑔.2 +𝑦.𝑔.2

For Angles: 12 12

Wg = H + B – t

Wg = Gross width: t = thickness of angle 𝑅𝑡 = √𝑅𝑡𝑥 ² + 𝑅𝑡𝑦 ² : Due to Combined: 𝑅𝑡𝑜𝑡𝑎𝑙 = √𝑅𝑡𝑥 ² +(𝑅𝑡𝑦 + 𝑅𝑑 )²

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Thermodynamics NotesDocumento41 pagineThermodynamics NotesAbel NetoNessuna valutazione finora

- Ems ch9 NTDocumento19 pagineEms ch9 NTPurna YalamanchiliNessuna valutazione finora

- Practice Paper Xi Physics 2023-24Documento3 paginePractice Paper Xi Physics 2023-24Siddhi PatilNessuna valutazione finora

- Momentum Equation in Cylindrical Coordinate: Appendix BDocumento8 pagineMomentum Equation in Cylindrical Coordinate: Appendix BAbdul Rauf AttariNessuna valutazione finora

- 1a.rectilinear MotionDocumento5 pagine1a.rectilinear MotionAtulNessuna valutazione finora

- Hydrostatic Force On Plane SurfacesDocumento3 pagineHydrostatic Force On Plane SurfaceskarthikNessuna valutazione finora

- Lab 5Documento10 pagineLab 5Tayyab ZafarNessuna valutazione finora

- 2directional Drilling3Documento6 pagine2directional Drilling3Hugh He0% (1)

- Hydraulics and Hydrology: Class 2 Hydrostatic Forces On Plane SurfacesDocumento5 pagineHydraulics and Hydrology: Class 2 Hydrostatic Forces On Plane SurfacesLiza KimNessuna valutazione finora

- 2-Col Bent On Bored PilesDocumento29 pagine2-Col Bent On Bored PilesHenry DiyokeNessuna valutazione finora

- PROBLEM 13.14: SolutionDocumento1 paginaPROBLEM 13.14: SolutionNattamon PetchkeawNessuna valutazione finora

- Lab 4 ThermoDocumento16 pagineLab 4 ThermoNur HidayahNessuna valutazione finora

- Dynamic Characteristics of VehicleDocumento26 pagineDynamic Characteristics of VehiclesurabhiNessuna valutazione finora

- 36-Unsteady State Heat Conduction Lumped Heat Capacity Analysis - 14-Aug-2019Material - I - 14-Aug-2019 - TRANSIENT - HEAT - CONDUCTION PDFDocumento9 pagine36-Unsteady State Heat Conduction Lumped Heat Capacity Analysis - 14-Aug-2019Material - I - 14-Aug-2019 - TRANSIENT - HEAT - CONDUCTION PDFsiva yandraNessuna valutazione finora

- Thermodynamics Student Copy 1676700490372Documento20 pagineThermodynamics Student Copy 1676700490372Shahroz Nomani100% (1)

- Phypharm FinalsDocumento11 paginePhypharm FinalsLyka MarceloNessuna valutazione finora

- MC-10 Propeller (Inc. M Nut, Cal. of Prop. Fit - Inpe. Record)Documento69 pagineMC-10 Propeller (Inc. M Nut, Cal. of Prop. Fit - Inpe. Record)Ruban FernandesNessuna valutazione finora

- Design: Ductile of SteelDocumento14 pagineDesign: Ductile of SteelVineeth PvNessuna valutazione finora

- PM TB Solutions C05Documento6 paginePM TB Solutions C05Vishwajeet Ujhoodha82% (11)

- Ce8353 SomDocumento2 pagineCe8353 Somsrinithims78Nessuna valutazione finora

- Models Mems Fluid Structure InteractionDocumento16 pagineModels Mems Fluid Structure InteractionhahaerNessuna valutazione finora

- Waves - CombineDocumento60 pagineWaves - CombineHilman RazakNessuna valutazione finora

- 60 CuM-H @17.8 M - FYBROCDocumento1 pagina60 CuM-H @17.8 M - FYBROCWael WaelNessuna valutazione finora

- Cours3 Velocity TrianglesDocumento47 pagineCours3 Velocity TrianglespfylNessuna valutazione finora

- Length Power Dynamic Viscosity Heat FluxDocumento9 pagineLength Power Dynamic Viscosity Heat FluxAnubhav KhandelwalNessuna valutazione finora

- Honeycomb Beam & Panel Calculations XLV1 - 2Documento29 pagineHoneycomb Beam & Panel Calculations XLV1 - 2Krishant Krishant Krishant0% (1)

- Cruise Flight: 1 Equations of MotionDocumento3 pagineCruise Flight: 1 Equations of MotionSyafiq KamilNessuna valutazione finora

- FAILUREDocumento20 pagineFAILUREMarcharlie PadillaNessuna valutazione finora

- Deadman Stability Check PDFDocumento2 pagineDeadman Stability Check PDFANV D100% (1)

- Students Test Mechanical EnggDocumento9 pagineStudents Test Mechanical EnggArnel CdsNessuna valutazione finora