Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Hobart, Hoballoy - 8018b2 (Aws E8018-B2 h4r)

Caricato da

RodrigoDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Hobart, Hoballoy - 8018b2 (Aws E8018-B2 h4r)

Caricato da

RodrigoCopyright:

Formati disponibili

HOBALLOY8018B2

AWS E8018-B2 H4R WELDING POSITIONS:

FEATURES: BENEFITS:

• Good arc characteristics • Stable, easy to control arc

• Low spatter level • Improves weld bead appearance, higher deposition

• Quick and easy slag removal • Reduces clean-up time

• Low moisture reabsorption • Prevents starting porosity

• Low smoke level • Welder safety and comfort

• Low hydrogen less than 4 ml/100 g • Resistant to hydrogen-induced cracking

APPLICATIONS:

• Boiler fabrication and maintenance

TYPE OF CURRENT: Direct Current Electrode Positive (DCEP) or AC

RECOMMENDED WELDING TECHNIQUES:

GENERAL: Electrode positive, work negative (DCEP) or AC

ARC LENGTH: Very short arc

FLAT: Angle electrode 10°-15° from 90°

VERTICAL-UP: Use weaving techniques

VERTICAL-DOWN: Not recommended

OVERHEAD: Use slight weaving motion within the puddle

STORAGE: After opening, store in holding oven (220°F to 350°F) until used.

RECONDITIONING If exposed to atmosphere for extended periods, reconditioned for one (1) hour at 600°F.

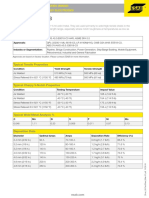

TYPICAL WELD METAL PROPERTIES* (Chem Pad):

Weld Metal Analysis (%) AWS Spec

Carbon (C) 0.08 0.12 max

Manganese (Mn) 0.69 0.90 max

Sulphur (S) 0.02 0.03 max

Phosphorus (P) 0.01 0.03 max

Silicon (Si) 0.66 0.80 max

Chromium (Cr) 1.34 1.00 - 1.50

Molybdenum (Mo) 0.51 0.40 - 0.65

TYPICAL MECHANICAL PROPERTIES* (SR):

Stress relieved 1 hour at 1275°F AWS Spec (minimum)

Tensile Strength 105,000 psi (723 MPa) 80,000 psi

Yield Strength 92,000 psi (634 MPa) 67,000 psi

Elongation % in 2” 21% 19%

TYPICAL CHARPY V-NOTCH IMPACT VALUES* (As Welded):

Not required

TYPICAL DIFFUSIBLE HYDROGEN:

Hydrogen Equipment AWS Spec

(GAS CHROMATOGRAPHY) 2.9 ml/100 g —

*The information contained or otherwise referenced herein is presented only as “typical” without guarantee or warranty, and Hobart Brothers Company

expressly disclaims any liability incurred from any reliance thereon. Typical data are those obtained when welded and tested in accordance with the AWS

A5.5 specification. Other tests and procedures may produce different results. No data is to be construed as a recommendation for any welding condition

or technique not controlled by Hobart Brothers Company.

Hobart Brothers Company 101 Trade Square East Troy, OH 45373

PH: (800) 424-1543 FX: 800-541-6607 www.hobartbrothers.com

HOBALLOY8018B2

Diameter Minimum Optimum* Maximum

Inches mm Type of Power Amps Amps Amps

3/32 2.4 DCEP or AC 70 100 110

1/8 3.2 DCEP or AC 90 135 160

5/32 4.0 DCEP or AC 130 170 220

3/16 4.8 DCEP or AC 200 250 300

*For out of position welding, reduce amperages shown by 15%.

TYPICAL DEPOSITION DATA (at optimum):

Diameter Deposition Rate

Inches mm Type of Power Amps lbs/hr

3/32 2.4 DCEP 100 2.47

1/8 3.2 DCEP 145 2.87

5/32 4.0 DCEP 190 3.84

3/16 4.8 DCEP 275 5.86

*Allowance made for 2” stub loss included.

• Maintaining a proper welding procedure - including pre-heat and interpass temperatures - may be critical

depending on the type and thickness of steel being welded.

STANDARD DIAMETERS AND PACKAGES: For a complete list of diameters and packaging,

please contact Hobart Brothers at (800) 424-1543, or (937) 332-5188 for International Customer Service.

Diameter Length 10-lb 50-lb

Inches mm Inches mm Can Can

3/32 2.4 14 355 S125432-033 S125432-035

1/8 3.2 14 355 S125444-033 S125444-035

5/32 4.0 14 355 — S125451-035

3/16 4.8 14 355 — S125458-035

CONFORMANCES AND APPROVALS:

• AWS A5.5, E8018-B2 H4R

• ASME SFA 5.5, F-4, A-3, E8018-B2

• ABS E8018-B2

CAUTION:

Consumers should be thoroughly familiar with the safety precautions on the warning label posted in each shipment and in the American National Standard

Z49.1, “Safety in Welding and Cutting,” published by the American Welding Society, 550 NW LeJune Road, Miami, FL 33126; OSHA Safety and Health

Standards 29 CFR 1910 is available from the U.S. Department of Labor, Washington, D.C. 20210

Material Safety Data Sheets on any Hobart Brothers Company product may be obtained from Hobart Customer Service or at www.hobartbrothers.com.

Because Hobart Brothers Company is constantly improving products, Hobart reserves the right to change design and/or

specifications without notice.

Hobart and Hoballoy are registered trademarks of Hobart Brothers Company, Troy, Ohio.

Revision Date: 131001 (Replaces 090605)

613-B, INDEX

Potrebbero piacerti anche

- AWS D1.1 - Bend PDFDocumento1 paginaAWS D1.1 - Bend PDFVIVEKNessuna valutazione finora

- A709a 709M-17 PDFDocumento8 pagineA709a 709M-17 PDFandresNessuna valutazione finora

- North American Standard For Cold-Formed Steel Framing - GeneralDocumento49 pagineNorth American Standard For Cold-Formed Steel Framing - GeneralNishan GajurelNessuna valutazione finora

- OPSS 906 - Nov12Documento20 pagineOPSS 906 - Nov12umerfr2Nessuna valutazione finora

- Standard For Steel Roof Deck: CSSBI 10M - 08 October 2008Documento8 pagineStandard For Steel Roof Deck: CSSBI 10M - 08 October 2008Anonymous P73cUg73LNessuna valutazione finora

- Standard Specification For Deformed and Plain Low-Alloy Steel Bars For Concrete ReinforcementDocumento7 pagineStandard Specification For Deformed and Plain Low-Alloy Steel Bars For Concrete ReinforcementJose Fernando Huayhua ApfataNessuna valutazione finora

- Interpretation and Classification of Non-Metallic Inclusions - MPC20160040-DL.000109386-1.Pdf0Documento10 pagineInterpretation and Classification of Non-Metallic Inclusions - MPC20160040-DL.000109386-1.Pdf0Nick pilipenkoNessuna valutazione finora

- Astm A1063A1063MDocumento11 pagineAstm A1063A1063Mارفع راسك فوق انت يمنيNessuna valutazione finora

- Seismic Design of Multi-Tiered Steel Braced Frames Including The Contribution From Gravity ColumnsDocumento21 pagineSeismic Design of Multi-Tiered Steel Braced Frames Including The Contribution From Gravity ColumnsDiego Matias Burgos FuentesNessuna valutazione finora

- Pre Stressing Wire GBDocumento6 paginePre Stressing Wire GBHayder AlsalihNessuna valutazione finora

- STD-INSP-0125 IGC Phases Practice - A - (ASTM A923) DUPLEXDocumento2 pagineSTD-INSP-0125 IGC Phases Practice - A - (ASTM A923) DUPLEXAkshay KalraNessuna valutazione finora

- Astm 666Documento7 pagineAstm 666JOSEPH REFUERZONessuna valutazione finora

- Ansi c80-6 2005Documento22 pagineAnsi c80-6 2005supervisor.electricistaNessuna valutazione finora

- Astm G 101Documento8 pagineAstm G 101El_Proesor100% (1)

- Ultimate Strength of Fillet Welded Connections Loaded in PlaneDocumento13 pagineUltimate Strength of Fillet Welded Connections Loaded in PlanePatrick PolujanNessuna valutazione finora

- Cast Carbon Steels in AWS D1.1 PDFDocumento3 pagineCast Carbon Steels in AWS D1.1 PDFIndra NainggolanNessuna valutazione finora

- Astm A242 1979Documento4 pagineAstm A242 1979bkprodhNessuna valutazione finora

- Chemical RraghavanDocumento60 pagineChemical RraghavanjoekaledaNessuna valutazione finora

- HDG Datasheet 4a - Specifying Hot Dip Galvanized SteelDocumento1 paginaHDG Datasheet 4a - Specifying Hot Dip Galvanized SteelCheah Hon KeongNessuna valutazione finora

- Astm A709 A709m-09Documento8 pagineAstm A709 A709m-09Tran Tien DungNessuna valutazione finora

- Astm A500 A500m-21Documento6 pagineAstm A500 A500m-21alvin duey100% (1)

- Steelwise: Are You Properly Specifying Materials?Documento9 pagineSteelwise: Are You Properly Specifying Materials?Muhammad AhsunNessuna valutazione finora

- AWS B2 1 1 008 2013 SWPS GTAW ofDocumento22 pagineAWS B2 1 1 008 2013 SWPS GTAW ofTuan Nguyen AnhNessuna valutazione finora

- K-Series Final 030911Documento54 pagineK-Series Final 030911Alvaro Alexis Mendoza PradaNessuna valutazione finora

- Steel Plates For Pressure Vessels, Produced by Thermo-Mechanical Control Process (TMCP)Documento10 pagineSteel Plates For Pressure Vessels, Produced by Thermo-Mechanical Control Process (TMCP)Sama UmateNessuna valutazione finora

- Deformed and Plain Low-Alloy Steel Bars For Concrete ReinforcementDocumento7 pagineDeformed and Plain Low-Alloy Steel Bars For Concrete ReinforcementSyed Mohammed ZakariaNessuna valutazione finora

- Sp17 - 97 ACI Design Handbook-Design of Structural Reinforced Concrete Elements in Accordance With The Strength Design Method of ACI 318-95Documento1 paginaSp17 - 97 ACI Design Handbook-Design of Structural Reinforced Concrete Elements in Accordance With The Strength Design Method of ACI 318-95curt volvoNessuna valutazione finora

- Asme Section II A-2 Sa-592 Sa-592mDocumento4 pagineAsme Section II A-2 Sa-592 Sa-592mAnonymous GhPzn1xNessuna valutazione finora

- A Journey Through Indian Reinforcing BarsDocumento5 pagineA Journey Through Indian Reinforcing BarssujupsNessuna valutazione finora

- Steel Castings, Welding, Qualifications of Procedures and PersonnelDocumento19 pagineSteel Castings, Welding, Qualifications of Procedures and PersonnelDavidNessuna valutazione finora

- Rolled Zinc: Standard Specification ForDocumento4 pagineRolled Zinc: Standard Specification ForCarlos HerreraNessuna valutazione finora

- 2 15P09 PDFDocumento88 pagine2 15P09 PDFMike2322Nessuna valutazione finora

- Astm A700 05 PDFDocumento41 pagineAstm A700 05 PDFirfanlarikhotmailcomNessuna valutazione finora

- Hot-Rolled Carbon, Low-Alloy, High-Strength Low-Alloy, and Alloy Steel Floor PlatesDocumento11 pagineHot-Rolled Carbon, Low-Alloy, High-Strength Low-Alloy, and Alloy Steel Floor PlatesNilton Santillan OrtegaNessuna valutazione finora

- A407-07 (2013) Standard Specification For Steel Wire, Cold-Drawn, For Coiled-Type SpringsDocumento3 pagineA407-07 (2013) Standard Specification For Steel Wire, Cold-Drawn, For Coiled-Type Springstjt4779Nessuna valutazione finora

- Astm A307 (2000)Documento7 pagineAstm A307 (2000)Marcelo Rodriguez FujimotoNessuna valutazione finora

- 011-Astm A 131 2008 Structural Steel For Ships PDFDocumento7 pagine011-Astm A 131 2008 Structural Steel For Ships PDFgraduateNessuna valutazione finora

- GBT 1228-2006 High Strength Bolts With Large Hexagon Head For Steel StructuresDocumento7 pagineGBT 1228-2006 High Strength Bolts With Large Hexagon Head For Steel Structures494328514Nessuna valutazione finora

- Outokumpu Forta Range Stainless Steel DatasheetDocumento16 pagineOutokumpu Forta Range Stainless Steel DatasheetNicola D'ettoleNessuna valutazione finora

- Astm A 307Documento6 pagineAstm A 307jeigocNessuna valutazione finora

- Transverse Rupture Strength of Metal Powder Specimens: Standard Test Method ForDocumento4 pagineTransverse Rupture Strength of Metal Powder Specimens: Standard Test Method FormaldopinNessuna valutazione finora

- Ansteel Product CatalogueDocumento13 pagineAnsteel Product Cataloguerashid isaarNessuna valutazione finora

- The Development of A New Design Procedure For Conventional Single-Plate Shear ConnectionsDocumento12 pagineThe Development of A New Design Procedure For Conventional Single-Plate Shear ConnectionsMiguelNessuna valutazione finora

- Dos A OilDocumento5 pagineDos A OilimranNessuna valutazione finora

- EN36 Case Hardening Steel: Shipping PolicyDocumento2 pagineEN36 Case Hardening Steel: Shipping PolicyMohit YadavNessuna valutazione finora

- Errata: Transportation OfficialsDocumento24 pagineErrata: Transportation OfficialsHector Enrique Reza ReyesNessuna valutazione finora

- Hmma 803-08Documento3 pagineHmma 803-08ahuguley79Nessuna valutazione finora

- TechnicalSplices PDFDocumento3 pagineTechnicalSplices PDFengineer_atulNessuna valutazione finora

- Star Core 6Documento2 pagineStar Core 6jmur10Nessuna valutazione finora

- Astm A1008 CRC Crs PDFDocumento9 pagineAstm A1008 CRC Crs PDFArul Edwin VijayNessuna valutazione finora

- Is 1852 PDFDocumento10 pagineIs 1852 PDFSIVANessuna valutazione finora

- Section - 05520 - Handrails and RailingsDocumento3 pagineSection - 05520 - Handrails and RailingsNana DelgadoNessuna valutazione finora

- ASTM B 69 Rolled ZN - 1998Documento4 pagineASTM B 69 Rolled ZN - 1998ecsuperalNessuna valutazione finora

- A255 10 PDFDocumento26 pagineA255 10 PDFwinky100% (2)

- High-Strength Steel Bolts, Classes 10.9 and 10.9.3, For Structural Steel Joints (Metric)Documento6 pagineHigh-Strength Steel Bolts, Classes 10.9 and 10.9.3, For Structural Steel Joints (Metric)Ngoc BuiNessuna valutazione finora

- Sampling Procedure For Impact Testing of Structural SteelDocumento5 pagineSampling Procedure For Impact Testing of Structural Steelrodrigo nuñezNessuna valutazione finora

- Astm A276-06Documento7 pagineAstm A276-06NadhiraNessuna valutazione finora

- Hoballoy 8018B2: AWS E8018-B2 H4R Elding OsitionsDocumento2 pagineHoballoy 8018B2: AWS E8018-B2 H4R Elding OsitionsJuanNessuna valutazione finora

- Pinnacle Alloys E8018 C3Documento2 paginePinnacle Alloys E8018 C3Sajeev SivanandanNessuna valutazione finora

- Lincoln, TECHALLOY® 606 (c14107)Documento2 pagineLincoln, TECHALLOY® 606 (c14107)RodrigoNessuna valutazione finora

- Beyond A1 Plus SB Unit 8 SML PDFDocumento11 pagineBeyond A1 Plus SB Unit 8 SML PDFAlex Rödriguez R50% (2)

- Lincoln, Superarc LA-90Documento2 pagineLincoln, Superarc LA-90RodrigoNessuna valutazione finora

- Unibraze Er80s-B2 (Tig)Documento1 paginaUnibraze Er80s-B2 (Tig)RodrigoNessuna valutazione finora

- Zeron 100 Brochure Rolled AlloysDocumento8 pagineZeron 100 Brochure Rolled AlloysRodrigoNessuna valutazione finora

- Lincoln, Tech-Rod ® 99 (c141022)Documento2 pagineLincoln, Tech-Rod ® 99 (c141022)RodrigoNessuna valutazione finora

- Espesificaciones de MaterialesDocumento2 pagineEspesificaciones de MaterialesDanyAlex GarciaNessuna valutazione finora

- Esab, OK Flux 10.71 (30.06.16), 420014-En - US-FactSheet - Main-01Documento2 pagineEsab, OK Flux 10.71 (30.06.16), 420014-En - US-FactSheet - Main-01RodrigoNessuna valutazione finora

- Dual Shield 7100 Ultra: Typical Tensile PropertiesDocumento3 pagineDual Shield 7100 Ultra: Typical Tensile PropertiesDino Paul Castro HidalgoNessuna valutazione finora

- Verticalshrouds Proteccion VerticalDocumento4 pagineVerticalshrouds Proteccion VerticalRodrigoNessuna valutazione finora

- Lincoln GMAW Welding GuideDocumento96 pagineLincoln GMAW Welding GuideМич БјукенонNessuna valutazione finora

- ABC 5edDocumento93 pagineABC 5edJuan Diego Garcia EsquenNessuna valutazione finora

- Essential Factors in Gas Shielded Metal Arc Welding GMAW - 5edDocumento33 pagineEssential Factors in Gas Shielded Metal Arc Welding GMAW - 5edCarlo MonsalveNessuna valutazione finora

- Steel Castings, Carbon, For General ApplicationDocumento4 pagineSteel Castings, Carbon, For General ApplicationJuan Carlos Chura QuispeNessuna valutazione finora

- 2015 KOBELCO Defect PDFDocumento25 pagine2015 KOBELCO Defect PDFayushNessuna valutazione finora

- Esab, OK Flux 10.71 (30.06.16), 420014-En - US-FactSheet - Main-01Documento2 pagineEsab, OK Flux 10.71 (30.06.16), 420014-En - US-FactSheet - Main-01RodrigoNessuna valutazione finora

- Esab, OK Autrod 12.10 (A345311)Documento1 paginaEsab, OK Autrod 12.10 (A345311)RodrigoNessuna valutazione finora

- Esab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)Documento2 pagineEsab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)RodrigoNessuna valutazione finora

- Esab, OK Autrod 12.22 (1222252800)Documento1 paginaEsab, OK Autrod 12.22 (1222252800)RodrigoNessuna valutazione finora

- Esab, Dual Shield 810X Ni1 (248 en - US FactSheet - Main 01)Documento2 pagineEsab, Dual Shield 810X Ni1 (248 en - US FactSheet - Main 01)RodrigoNessuna valutazione finora

- Esab, Dual Shield II 110 (265-En - US-FactSheet - Main-01) (26.10.16)Documento2 pagineEsab, Dual Shield II 110 (265-En - US-FactSheet - Main-01) (26.10.16)RodrigoNessuna valutazione finora

- Esab, OK Autrod 12.10 (A345311)Documento1 paginaEsab, OK Autrod 12.10 (A345311)RodrigoNessuna valutazione finora

- Dual Shield 7100 Ultra: Typical Tensile PropertiesDocumento3 pagineDual Shield 7100 Ultra: Typical Tensile PropertiesDino Paul Castro HidalgoNessuna valutazione finora

- Esab, OK Tigrod NiCr-3 (21.06.16) (411170-En - US-FactSheet - Main-01)Documento1 paginaEsab, OK Tigrod NiCr-3 (21.06.16) (411170-En - US-FactSheet - Main-01)RodrigoNessuna valutazione finora

- Fillet Weld DesignDocumento2 pagineFillet Weld Designsaj0205037Nessuna valutazione finora

- Esab, Coreshield 40 (275-En - US-FactSheet - Main-01) (26.10.16)Documento1 paginaEsab, Coreshield 40 (275-En - US-FactSheet - Main-01) (26.10.16)RodrigoNessuna valutazione finora

- Esab, Atom Arc 9018 (29-En - US-FactSheet - Main-01, 2016.10.26)Documento1 paginaEsab, Atom Arc 9018 (29-En - US-FactSheet - Main-01, 2016.10.26)RodrigoNessuna valutazione finora

- Esab, Atom Arc 8018 (26-En - US-FactSheet - Main-01, 2016.10.26)Documento1 paginaEsab, Atom Arc 8018 (26-En - US-FactSheet - Main-01, 2016.10.26)RodrigoNessuna valutazione finora

- Portafolio SoldDocumento1 paginaPortafolio SoldRodrigoNessuna valutazione finora

- Unit 3 Packet: The Mole Name WPHS ChemistryDocumento37 pagineUnit 3 Packet: The Mole Name WPHS ChemistryMichael TuroNessuna valutazione finora

- Export Zno To PDFDocumento2 pagineExport Zno To PDFTimNessuna valutazione finora

- EN9 Technical Data: Print Friendly Text Only Site MapDocumento1 paginaEN9 Technical Data: Print Friendly Text Only Site MapMari selvamNessuna valutazione finora

- Class 12 Diwali Assignment Inorganic ChemistryDocumento12 pagineClass 12 Diwali Assignment Inorganic ChemistryPrashantNessuna valutazione finora

- Cupola FurnaceDocumento13 pagineCupola FurnaceSumit Dhall100% (1)

- Notes On Wire Electrodes EN 440: Table 3Documento1 paginaNotes On Wire Electrodes EN 440: Table 3raduonoNessuna valutazione finora

- Physical Property Data-KoretskyDocumento8 paginePhysical Property Data-KoretskyLMVM927919Nessuna valutazione finora

- Aeroquip Fluid Compatibility InfoDocumento5 pagineAeroquip Fluid Compatibility Infos2000ratNessuna valutazione finora

- COA of Calcium D Pantothente - RevisedDocumento1 paginaCOA of Calcium D Pantothente - RevisedJose.SuarezNessuna valutazione finora

- Physico - Chemical Analysis of Rain Water Collected From 10 Selected Areas in Awka South, Anambra State, NigeriaDocumento18 paginePhysico - Chemical Analysis of Rain Water Collected From 10 Selected Areas in Awka South, Anambra State, NigeriaijsidonlineinfoNessuna valutazione finora

- 0620 Y16 SP 5Documento20 pagine0620 Y16 SP 5EzabyNessuna valutazione finora

- Chemistry Lesson - Nitric Acid Handwritten NotesDocumento7 pagineChemistry Lesson - Nitric Acid Handwritten NotesRushabh jainNessuna valutazione finora

- ACTIVITY NO. 11: The Atomic Number and The Synthesis of New Elements Name: Date: Year & Section: Score: Concept NotesDocumento3 pagineACTIVITY NO. 11: The Atomic Number and The Synthesis of New Elements Name: Date: Year & Section: Score: Concept NotesDexter DizonNessuna valutazione finora

- Reading Test 4Documento1 paginaReading Test 4Waleed AhmedNessuna valutazione finora

- Chapter 1 Chemical Reactions and EquationsDocumento12 pagineChapter 1 Chemical Reactions and EquationsPrabhuPalanichamyNessuna valutazione finora

- Assignment 1 Assignment 2 Assignment 3 Assignment 4 Assignment 5 Assignment 6Documento42 pagineAssignment 1 Assignment 2 Assignment 3 Assignment 4 Assignment 5 Assignment 6SamuelNessuna valutazione finora

- Tests - Mechanical Properties: Material Brand, Source, Tests Etc. Units RequirementDocumento2 pagineTests - Mechanical Properties: Material Brand, Source, Tests Etc. Units RequirementNandika MilindaNessuna valutazione finora

- Solubility TableDocumento1 paginaSolubility TableLiolah LiolahNessuna valutazione finora

- Cbse - Science: Board Paper - 2008Documento6 pagineCbse - Science: Board Paper - 2008Anupam KumarNessuna valutazione finora

- Chemical Reactions of A Penny in Hydrochloric AcidDocumento5 pagineChemical Reactions of A Penny in Hydrochloric AcidMatt Wedekind0% (1)

- B15 Lim, Carlo Martin, Perio Lim - Absolute Dating Inquiry ActivityDocumento3 pagineB15 Lim, Carlo Martin, Perio Lim - Absolute Dating Inquiry ActivityCarlo Martin LimNessuna valutazione finora

- Lecture 1, Dental Amalgam (Script)Documento9 pagineLecture 1, Dental Amalgam (Script)JustDen09Nessuna valutazione finora

- Certificate of Analysis: (Batch A) Certified Reference Material InformationDocumento4 pagineCertificate of Analysis: (Batch A) Certified Reference Material InformationrahulNessuna valutazione finora

- Atomic Radii of The ElementsDocumento6 pagineAtomic Radii of The ElementsYourMotherNessuna valutazione finora

- Heavy Metal PrecipitationDocumento8 pagineHeavy Metal PrecipitationSiti Mutia UtamiNessuna valutazione finora

- 56-1-3 (Chemistry)Documento16 pagine56-1-3 (Chemistry)avineshkushwaha47Nessuna valutazione finora

- SeamanshipDocumento40 pagineSeamanshipBatuhan AlgürNessuna valutazione finora

- 1 ElectrochemistryExercise PDFDocumento46 pagine1 ElectrochemistryExercise PDFDivyanshi TiwaryNessuna valutazione finora

- ASTM - G82 Corrosion Galvanica PDFDocumento7 pagineASTM - G82 Corrosion Galvanica PDFDanny Milton Silva VasquezNessuna valutazione finora

- Analitycal Methods AADocumento164 pagineAnalitycal Methods AAPaola Solange Cardozo CastilloNessuna valutazione finora