Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Esab, Atom Arc 8018 (26-En - US-FactSheet - Main-01, 2016.10.26)

Caricato da

RodrigoDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Esab, Atom Arc 8018 (26-En - US-FactSheet - Main-01, 2016.10.26)

Caricato da

RodrigoCopyright:

Formati disponibili

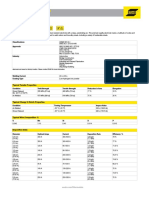

COVERED (STICK) ELECTRODES (SMAW)

LOW HYDROGEN/LOW ALLOY ELECTRODES

Atom Arc 8018

Atom Arc 8018 electrodes deposit 1% Ni weld metal. They are used primarily to weld high-tensile steels in the

70-80 ksi (483-552 MPa) tensile strength range, especially where notch toughness at temperatures as low as

-40°F (-40°C) is required.

Classifications: AWS A5.5:E8018-C3 H4R, ASME SFA 5.5

Approvals: QPL-22200/1 MIL-8018-C3, LR 4Y40M(H10), CWB CSA W48: E5518-C3,

ABS 3Y/AWS A5.5: E8018-C3

Industry or Segmentation: Pipeline, Bridge Construction, Power Generation, Ship/Barge Building, Mobile Equipment,

Petrochemical, Industrial and General Fabrication

Approvals are based on factory location. Please contact ESAB for more information.

Typical Tensile Properties

Condition Yield Strength Tensile Strength Elongation

As Welded 510 MPa (74 ksi) 585 MPa (85 ksi) 30 %

Stress Relieved 8 hr 621 °C (1150 °F) 485 MPa (70 ksi) 560 MPa (81 ksi) 30 %

Typical Charpy V-Notch Properties

Condition Testing Temperature Impact Value

As Welded -29 °C (-20 °F) 168 J (124 ft-lb)

As Welded -40 °C (-40 °F) 154 J (114 ft-lb)

Stress Relieved 8 hr 621 °C (1150 °F) -29 °C (-20 °F) 175 J (129 ft-lb)

Stress Relieved 8 hr 621 °C (1150 °F) -40 °C (-40 °F) 156 J (115 ft-lb)

Typical Weld Metal Analysis %

C Mn Si S P Ni Mo

0.046 1.11 0.33 0.009 0.011 0.97 0.13

Deposition Data

Diameter Optimal Amps Amps Deposition Rate Efficiency (%)

2.4 mm (3/32 in.) 90 A 70-100 A 0.8 kg/h (1.7 lb/h) 66.3 %

3.2 mm (1/8 in.) 120 A 90-160 A 1.2 kg/h (2.6 lb/h) 71.6 %

3.2 mm (1/8 in.) 140 A 90-160 A 1.2 kg/h (2.7 lb/h) 70.9 %

4.0 mm (5/32 in.) 170 A 130-220 A 1.7 kg/h (3.8 lb/h) 73.5 %

4.0 mm (5/32 in.) 140 A 130-220 A 1.1 kg/h (3.1 lb/h) 75 %

4.8 mm (3/16 in.) 200 A 200-300 A 2.2 kg/h (4.9 lb/h) 76.4 %

26-en_US-FactSheet_Main-01.pdf 10/26/16

4.8 mm (3/16 in.) 250 A 200-300 A 2.4 kg/h (5.4 lb/h) 74.6 %

esab.com

Potrebbero piacerti anche

- Monobloc ChairDocumento2 pagineMonobloc ChairJen gemudianoNessuna valutazione finora

- Esab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)Documento2 pagineEsab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)RodrigoNessuna valutazione finora

- Esab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)Documento2 pagineEsab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)RodrigoNessuna valutazione finora

- Start Up System and Seperator Logics - 660MW (DHI Make) BoilerDocumento44 pagineStart Up System and Seperator Logics - 660MW (DHI Make) BoilerHemendra VermaNessuna valutazione finora

- Electrodo Aws 7018-1 EsabDocumento1 paginaElectrodo Aws 7018-1 EsabHORACIONessuna valutazione finora

- Esab, Atom Arc 9018 (29-En - US-FactSheet - Main-01, 2016.10.26)Documento1 paginaEsab, Atom Arc 9018 (29-En - US-FactSheet - Main-01, 2016.10.26)RodrigoNessuna valutazione finora

- ESAB Filler Metal GuideDocumento1 paginaESAB Filler Metal GuidekapsarcNessuna valutazione finora

- Atom Arc 7018-1: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocumento2 pagineAtom Arc 7018-1: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesFranklin Aranda ChacónNessuna valutazione finora

- Atom Arc 8018Documento2 pagineAtom Arc 8018Jagan TnNessuna valutazione finora

- FICHADocumento2 pagineFICHAadmisecoinperuNessuna valutazione finora

- Dual Shield II 101 1.6 MMDocumento2 pagineDual Shield II 101 1.6 MMadanmeneses1Nessuna valutazione finora

- Dual Shiel Ii 101Documento2 pagineDual Shiel Ii 101Robin carcamoNessuna valutazione finora

- Coreweld 70: Metal-Cored Wires (Mcaw) Mild Steel WiresDocumento2 pagineCoreweld 70: Metal-Cored Wires (Mcaw) Mild Steel WiresJerald GuevarraNessuna valutazione finora

- Dual Shield II 101H4MDocumento2 pagineDual Shield II 101H4Madanmeneses1Nessuna valutazione finora

- Esab, Dual Shield II 110 (265-En - US-FactSheet - Main-01) (26.10.16)Documento2 pagineEsab, Dual Shield II 110 (265-En - US-FactSheet - Main-01) (26.10.16)RodrigoNessuna valutazione finora

- Esab, Dual Shield 810X Ni1 (248 en - US FactSheet - Main 01)Documento2 pagineEsab, Dual Shield 810X Ni1 (248 en - US FactSheet - Main 01)RodrigoNessuna valutazione finora

- Atom Arc 7018: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocumento2 pagineAtom Arc 7018: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesKrishna VachaNessuna valutazione finora

- Covered (Stick) Electrodes (SMAW)Documento5 pagineCovered (Stick) Electrodes (SMAW)Hanny Dewi SaragihNessuna valutazione finora

- Dual Shield 7100 Ultra: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresDocumento3 pagineDual Shield 7100 Ultra: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel Wiresadanmeneses1Nessuna valutazione finora

- Atom Arc 7018-B2L: Typical Tensile PropertiesDocumento1 paginaAtom Arc 7018-B2L: Typical Tensile PropertiesPubcrawlNessuna valutazione finora

- Dual Shield 710X: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresDocumento3 pagineDual Shield 710X: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresPhilippe TrudelNessuna valutazione finora

- Tech Data Sheet: Dual Shield T-115Documento3 pagineTech Data Sheet: Dual Shield T-115carlosNessuna valutazione finora

- 274 en - US FactSheet - Main 01Documento2 pagine274 en - US FactSheet - Main 01Luisa FernandaNessuna valutazione finora

- Dual Shield II 81-K2: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresDocumento2 pagineDual Shield II 81-K2: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresMOhammed PatelNessuna valutazione finora

- OK Autrod 2209: Typical Tensile PropertiesDocumento1 paginaOK Autrod 2209: Typical Tensile PropertiesjavadmohammadiNessuna valutazione finora

- Dual Shield 810X-NI1: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresDocumento2 pagineDual Shield 810X-NI1: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy Wiresadanmeneses1Nessuna valutazione finora

- Dual Shield II 70T-12H4: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresDocumento2 pagineDual Shield II 70T-12H4: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresPhilippe TrudelNessuna valutazione finora

- Esab, Coreshield 40 (275-En - US-FactSheet - Main-01) (26.10.16)Documento1 paginaEsab, Coreshield 40 (275-En - US-FactSheet - Main-01) (26.10.16)RodrigoNessuna valutazione finora

- Dual Shield 7100 Ultra: Typical Tensile PropertiesDocumento3 pagineDual Shield 7100 Ultra: Typical Tensile PropertiesDino Paul Castro HidalgoNessuna valutazione finora

- Dual Shield T-115: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresDocumento2 pagineDual Shield T-115: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresPEPITO GRILLO2Nessuna valutazione finora

- 278 en US FactSheet Main 01Documento1 pagina278 en US FactSheet Main 01Jorge Manuel GuillermoNessuna valutazione finora

- Tech Data Sheet: Dual Shield Ii 100-D1Documento3 pagineTech Data Sheet: Dual Shield Ii 100-D1carlosNessuna valutazione finora

- Atom Arc 8018: Features Typical Mechanical PropertiesDocumento2 pagineAtom Arc 8018: Features Typical Mechanical PropertiesFranklin Aranda ChacónNessuna valutazione finora

- Sureweld 6010: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesDocumento1 paginaSureweld 6010: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesGibbs PerNessuna valutazione finora

- Esab Welding RodDocumento1 paginaEsab Welding Rodv ictor manuel MunozNessuna valutazione finora

- Tech Data Sheet: DUAL SHIELD 8000-Ni2Documento3 pagineTech Data Sheet: DUAL SHIELD 8000-Ni2carlosNessuna valutazione finora

- MD250MW CAN DataSheet 1642812289Documento1 paginaMD250MW CAN DataSheet 1642812289masNessuna valutazione finora

- Dual Shield T-75: Typical Tensile PropertiesDocumento2 pagineDual Shield T-75: Typical Tensile PropertiescfloresNessuna valutazione finora

- ESB 255051815 SpecSheetDocumento2 pagineESB 255051815 SpecSheetanupmenon menonNessuna valutazione finora

- FabCO 811N1Documento2 pagineFabCO 811N1Sleyda MunozNessuna valutazione finora

- COR-1076C Coreweld Brochure 141118Documento28 pagineCOR-1076C Coreweld Brochure 141118Thanh TamNessuna valutazione finora

- Pipeweld 6010 Plus: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesDocumento1 paginaPipeweld 6010 Plus: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesRys Multiventas SacNessuna valutazione finora

- OK Tigrod 13.32Documento1 paginaOK Tigrod 13.32Paulo CorreiaNessuna valutazione finora

- Type 550X: Miniature I/P, E/P TransducerDocumento4 pagineType 550X: Miniature I/P, E/P TransducerDanang BagasNessuna valutazione finora

- Medidores AMERICAN METERSDocumento17 pagineMedidores AMERICAN METERSRaúl PalomoNessuna valutazione finora

- Pinnacle Alloys E8018 C3Documento2 paginePinnacle Alloys E8018 C3Sajeev SivanandanNessuna valutazione finora

- Pinnacle Alloys E7018 E7018 1Documento2 paginePinnacle Alloys E7018 E7018 1BerniIrleNessuna valutazione finora

- Exaton 383-16: Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocumento1 paginaExaton 383-16: Covered (Stick) Electrodes (Smaw) Stainless Steel Electrodessergio jose morales perazaNessuna valutazione finora

- Pinnacle Alloys E9018-M Code and Specification DataDocumento2 paginePinnacle Alloys E9018-M Code and Specification DataPutra Panca WardhanaNessuna valutazione finora

- m8083 sc86c14 Spec SheetDocumento2 paginem8083 sc86c14 Spec SheetJamal HabbasNessuna valutazione finora

- Hobart Maxal 1100Documento2 pagineHobart Maxal 1100jclenerNessuna valutazione finora

- Ficha Tecnica Esab Electrodos EspecialesDocumento1 paginaFicha Tecnica Esab Electrodos EspecialesStanley RamirezNessuna valutazione finora

- CSF-71T Technical Report EN - V2Documento7 pagineCSF-71T Technical Report EN - V2Miroslav ThôngNessuna valutazione finora

- RS 250 M Welding MachineDocumento1 paginaRS 250 M Welding MachineLucioNessuna valutazione finora

- OK Weartrode 30: Covered (Stick) Electrodes (Smaw) Hardfacing ElectrodesDocumento1 paginaOK Weartrode 30: Covered (Stick) Electrodes (Smaw) Hardfacing Electrodesraghubhaimantra4136Nessuna valutazione finora

- Pump SpecificationsDocumento2 paginePump Specificationsstranger252LavaNessuna valutazione finora

- Welding Generators MPMDocumento1 paginaWelding Generators MPMLucioNessuna valutazione finora

- Versaflow 80 C Plus: Product DataDocumento2 pagineVersaflow 80 C Plus: Product DataMuhammad victoryan nadezulNessuna valutazione finora

- Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocumento1 paginaTypical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationKukuh YuonoNessuna valutazione finora

- Fabcor 86 RDocumento2 pagineFabcor 86 RAnonymous fj4iRr1Nessuna valutazione finora

- Medidor de CaudalDocumento4 pagineMedidor de CaudalCarlos Rovello GandoNessuna valutazione finora

- SFTPreal10 Cat6A 6x4p Loom 650MHz AWG26Documento2 pagineSFTPreal10 Cat6A 6x4p Loom 650MHz AWG26Slobodan ĐenićNessuna valutazione finora

- Lincoln, Tech-Rod ® 99 (c141022)Documento2 pagineLincoln, Tech-Rod ® 99 (c141022)RodrigoNessuna valutazione finora

- Lincoln, TECHALLOY® 606 (c14107)Documento2 pagineLincoln, TECHALLOY® 606 (c14107)RodrigoNessuna valutazione finora

- Esab, OK Flux 10.71 (30.06.16), 420014-En - US-FactSheet - Main-01Documento2 pagineEsab, OK Flux 10.71 (30.06.16), 420014-En - US-FactSheet - Main-01RodrigoNessuna valutazione finora

- Esab, OK Autrod 12.10 (A345311)Documento1 paginaEsab, OK Autrod 12.10 (A345311)RodrigoNessuna valutazione finora

- Esab, OK Autrod 12.22 (1222252800)Documento1 paginaEsab, OK Autrod 12.22 (1222252800)RodrigoNessuna valutazione finora

- Esab, OK Flux 10.71 (30.06.16), 420014-En - US-FactSheet - Main-01Documento2 pagineEsab, OK Flux 10.71 (30.06.16), 420014-En - US-FactSheet - Main-01RodrigoNessuna valutazione finora

- Esab, Dual Shield II 110 (265-En - US-FactSheet - Main-01) (26.10.16)Documento2 pagineEsab, Dual Shield II 110 (265-En - US-FactSheet - Main-01) (26.10.16)RodrigoNessuna valutazione finora

- Esab, Coreshield 40 (275-En - US-FactSheet - Main-01) (26.10.16)Documento1 paginaEsab, Coreshield 40 (275-En - US-FactSheet - Main-01) (26.10.16)RodrigoNessuna valutazione finora

- Hobart, Hoballoy - 8018b2 (Aws E8018-B2 h4r)Documento2 pagineHobart, Hoballoy - 8018b2 (Aws E8018-B2 h4r)RodrigoNessuna valutazione finora

- Esab, Dual Shield 810X Ni1 (248 en - US FactSheet - Main 01)Documento2 pagineEsab, Dual Shield 810X Ni1 (248 en - US FactSheet - Main 01)RodrigoNessuna valutazione finora

- Esab, OK Tigrod NiCr-3 (21.06.16) (411170-En - US-FactSheet - Main-01)Documento1 paginaEsab, OK Tigrod NiCr-3 (21.06.16) (411170-En - US-FactSheet - Main-01)RodrigoNessuna valutazione finora

- Welding Strenx and Hardox V5 2015Documento16 pagineWelding Strenx and Hardox V5 2015Rodrigo100% (1)

- Hardox HiTuf 2016-01-14 264 371857150 enDocumento3 pagineHardox HiTuf 2016-01-14 264 371857150 enRodrigoNessuna valutazione finora

- Data Sheet 2006 Strenx 700 20170420 121 371857150 enDocumento2 pagineData Sheet 2006 Strenx 700 20170420 121 371857150 enRodrigoNessuna valutazione finora

- S 210Documento6 pagineS 210RodrigoNessuna valutazione finora

- UltraTech Powergrout NS2Documento2 pagineUltraTech Powergrout NS2Savalia HardikNessuna valutazione finora

- DAFZ RegulationsDocumento41 pagineDAFZ RegulationsRoger SchulpNessuna valutazione finora

- Sintex UPVC Windows PPTR1 (Compatibility Mode)Documento43 pagineSintex UPVC Windows PPTR1 (Compatibility Mode)Artegress GroupNessuna valutazione finora

- BOQ SampleDocumento72 pagineBOQ SampleLakmal Jayashantha100% (1)

- Lecture-10 Analysis and Design of Flate Plates and Flat SlabsDocumento64 pagineLecture-10 Analysis and Design of Flate Plates and Flat Slabskamra khanNessuna valutazione finora

- MSD CDocumento1 paginaMSD CbarrozomariakatrinaNessuna valutazione finora

- 3.syllabus (Solid State Physics) OptionalDocumento2 pagine3.syllabus (Solid State Physics) OptionalMuhammad Hasan RazaNessuna valutazione finora

- KLOCKE - Abrasive Machining of Advanced Aerospace Alloys and CompositesDocumento24 pagineKLOCKE - Abrasive Machining of Advanced Aerospace Alloys and CompositesLuis Fillipe Lopes TorresNessuna valutazione finora

- 13-04-2021 Load Combination ListDocumento1 pagina13-04-2021 Load Combination ListomkarNessuna valutazione finora

- 02 - Power PlugDocumento12 pagine02 - Power Plugzizou.rengokuNessuna valutazione finora

- Flow Measurement (Compatibility Mode)Documento11 pagineFlow Measurement (Compatibility Mode)NRNiloyNessuna valutazione finora

- Aashto - Catalog, Volume 2, 2018Documento24 pagineAashto - Catalog, Volume 2, 2018MiroslavNessuna valutazione finora

- Beam Design Detail Report: Material and Design DataDocumento10 pagineBeam Design Detail Report: Material and Design DataazwanNessuna valutazione finora

- Involute Gear Tooth Contact Stress AnalysisDocumento17 pagineInvolute Gear Tooth Contact Stress AnalysisCelsoNessuna valutazione finora

- Analisa Kabel Fire Alarm - KlarifikasiDocumento1 paginaAnalisa Kabel Fire Alarm - KlarifikasiDafam KalijudaNessuna valutazione finora

- Carrier - Company ProfileDocumento1 paginaCarrier - Company Profiledeboline mitraNessuna valutazione finora

- 5f72776f3e12c83107dc0f2e 56 ANSI Flange Access FittingDocumento8 pagine5f72776f3e12c83107dc0f2e 56 ANSI Flange Access Fittingiyandaseun8846Nessuna valutazione finora

- Structural Design of Drainage ChannelDocumento8 pagineStructural Design of Drainage ChannelMikaheel AdesanyaNessuna valutazione finora

- Permeability of Concrete - tcm45-346751Documento3 paginePermeability of Concrete - tcm45-346751abualamalNessuna valutazione finora

- Final Report Mauricio Schmidt MunizDocumento20 pagineFinal Report Mauricio Schmidt MunizIgnaas JimidarNessuna valutazione finora

- TDS Hipersite W7000Documento1 paginaTDS Hipersite W7000It WittayaNessuna valutazione finora

- 12326899Documento70 pagine12326899imranNessuna valutazione finora

- Anexo 3 Seleccion Equipos Volumen Variable de RefrigeranteDocumento41 pagineAnexo 3 Seleccion Equipos Volumen Variable de RefrigerantepabloabelgilsotoNessuna valutazione finora

- Advanced Cast Products - Ductile Iron Specs-ASTM 897, ASTM A536, SAE J434Documento27 pagineAdvanced Cast Products - Ductile Iron Specs-ASTM 897, ASTM A536, SAE J434George CharitouNessuna valutazione finora

- QCP KOC-VME 1221006120-PART 1 Rev 3Documento49 pagineQCP KOC-VME 1221006120-PART 1 Rev 3Alireza Golpesar100% (1)

- Hammerpoint Home Repair Estimator: ExteriorDocumento12 pagineHammerpoint Home Repair Estimator: ExteriorpauuxNessuna valutazione finora

- Brown White Minimalist Home Decoration PresentationDocumento110 pagineBrown White Minimalist Home Decoration PresentationMiMipan DRNessuna valutazione finora