Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Thrust Position, Differential Expansion, and Rod Position Monitor Specifications

Caricato da

Tu Pham0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

26 visualizzazioni1 paginao

Titolo originale

Csi 6210

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoo

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

26 visualizzazioni1 paginaThrust Position, Differential Expansion, and Rod Position Monitor Specifications

Caricato da

Tu Phamo

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

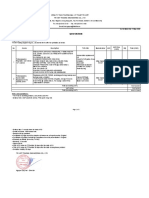

Specifications Sheet

July 2012 CSI 6500 Machinery Health™ Monitor

Thrust Position, Differential Expansion,

and Rod Position Monitor Specifications

The A6210 monitor operates in 3 target on the shaft. If the case and

distinct modes: thrust position, shaft grow at approximately the same

differential expansion, or rod rate, then the differential expansion

position. remains close to the desired value

The Thrust Position mode of zero. The differential expansion

accurately monitors thrust position and measurement mode supports

reliably provides machinery protection tandem/complementary or cone/

by comparing the measured axial shaft ramp modes.

position against alarm set-points – Finally, the A6210 monitor can be

driving alarms and relay outputs. configured for average rod drop mode

Shaft thrust monitoring is one of – used to monitor rider band wear in

the most critical measurements on reciprocating compressors. Over time,

turbomachinery. Sudden and small rider bands wear in horizontal

axial movements should be detected reciprocating compressors due to

the force of gravity acting on the n Two-channel, 3U size, 1-slot plug

in 40 msecs or less to minimize or

horizontally-oriented piston in the in module decreases cabinet space

avoid rotor to case contact.

compressor cylinder. If the rider band requirements in half from traditional

Redundant sensors and voting logic

wears beyond spec, the piston can four-channel 6U size cards

are recommended. Thrust bearing

temperature measurement is highly contact the cylinder wall and cause n API 670 and API 618 compliant hot

recommended as a complement incremental machine damage and swappable module

to thrust position monitoring. possible failure.

n Front and rear buffered and

Shaft thrust monitoring consists By mounting at least one displacement proportional outputs, 0/4-20 mA

of one to three displacement probe to measure the piston rod output, 0-10 V output

sensors mounted in the axial position, you will receive notification

n Self-checking facilities include

direction parallel to the shaft at when the piston drops – an indication

monitoring hardware, power input,

the shaft-end or thrust collar. of rider band wear. You can then set

hardware temperature, simplifies

The displacement sensor is a shutdown protection thresholds for

and cable

non-contact sensor that measures automatic trip. The average rod

drop parameter can be factored to n Built-in software linearization easing

shaft position.

represent the actual rider band wear, sensor adjustment after installation

For extremely critical safety or with no factor applied, rod drop will n Use with displacement sensor 6422,

applications, the A6250 monitor represent the actual movement of the 6423, 6424 and 6425 and driver

provides triple-redundant thrust piston rod. CON xxx

protection built on the SIL 3-rated

overspeed system platform. The CSI 6500 includes easy integration

to the DeltaV and Ovation process

The A6210 monitor can also be automation systems, including pre-

configured for differential expansion configured DeltaV Graphic Dynamos

measurements. As both the case and Ovation Graphic Marcros to speed

and rotor grow due to changes in operator graphic development. AMS

thermal conditions at turbine start-up, Suite provides maintenance personnel

differential expansion delivers a advanced predictive and performance

measure of the relative difference diagnostic tools to confidently and

between mounted displacement accurately determine machine

sensors on the case and the sensor malfunctions early.

www.assetweb.com/mhm

Potrebbero piacerti anche

- ADS R Man en 4 21Documento20 pagineADS R Man en 4 21rammu200173% (11)

- S&S Make: RRM For 6000 RPMDocumento16 pagineS&S Make: RRM For 6000 RPMABVSAI100% (1)

- Yaw Damper Installation GuideDocumento12 pagineYaw Damper Installation GuideJamal AlshaweshNessuna valutazione finora

- RAS Rot2ProgDocumento12 pagineRAS Rot2ProgAlen JefryNessuna valutazione finora

- Dresser-Rand: Service ManualDocumento1 paginaDresser-Rand: Service ManualTu PhamNessuna valutazione finora

- Berger Paints - Ar-19-20 PDFDocumento302 pagineBerger Paints - Ar-19-20 PDFSahil Garg100% (1)

- RA 9184 & RA 3019 NotesDocumento5 pagineRA 9184 & RA 3019 Notesleng_evenNessuna valutazione finora

- Data MiningDocumento721 pagineData MiningAuly Natijatul AinNessuna valutazione finora

- Oven MondelezDocumento16 pagineOven MondelezMahmood EijazNessuna valutazione finora

- Part-1 Radial Vibration: Common Point GroundingDocumento6 paginePart-1 Radial Vibration: Common Point GroundingAshok KumarNessuna valutazione finora

- Field Application Note: TSI - Differential/Rotor Expansion DiffexpDocumento4 pagineField Application Note: TSI - Differential/Rotor Expansion DiffexpPranav BhattNessuna valutazione finora

- Subtleties in Rotor Thrust Position MeasurementsDocumento5 pagineSubtleties in Rotor Thrust Position MeasurementsOualid LamraouiNessuna valutazione finora

- Sureshot MP Tech Sheet 1 PDFDocumento2 pagineSureshot MP Tech Sheet 1 PDFmartonoNessuna valutazione finora

- Differential/Rotor Expansion: Last Updated: 06/24/2017Documento6 pagineDifferential/Rotor Expansion: Last Updated: 06/24/2017Aditya PrajasNessuna valutazione finora

- Catálogo GefranDocumento20 pagineCatálogo GefranRobsonNunesDalColNessuna valutazione finora

- WXR-250A Weather Radar SystemDocumento36 pagineWXR-250A Weather Radar SystemEka Krisnanta100% (4)

- Local ProbesDocumento87 pagineLocal Probessujiv_sujiv1278Nessuna valutazione finora

- Rotary Motion Sensor Manual CI 6538Documento34 pagineRotary Motion Sensor Manual CI 6538scrusnNessuna valutazione finora

- Straight Differential Expansion - DMXDocumento4 pagineStraight Differential Expansion - DMXJurun_BidanshiNessuna valutazione finora

- Eccentricity Measurement in STGDocumento7 pagineEccentricity Measurement in STGKarthick Velayutham100% (1)

- Brosur Item 1Documento28 pagineBrosur Item 1Mohd SetiawanNessuna valutazione finora

- Displacement TransducersDocumento20 pagineDisplacement Transducerstibi7hac7Nessuna valutazione finora

- Catalogue For TFM-FR-TZ-TX-B PDFDocumento15 pagineCatalogue For TFM-FR-TZ-TX-B PDFGuru Vaga50% (2)

- SIPART PS2 Electropneumatic Positioners: Sipart Ps2, Sipart Ps2 Pa, Sipart Ps2 Eex D and Sipart Ps2 Eex D PaDocumento16 pagineSIPART PS2 Electropneumatic Positioners: Sipart Ps2, Sipart Ps2 Pa, Sipart Ps2 Eex D and Sipart Ps2 Eex D PaLovelySinghNessuna valutazione finora

- Msdac Frauscher ACS2000Documento12 pagineMsdac Frauscher ACS2000Pooja SinghNessuna valutazione finora

- Argenia Solar Wireless Digital Axle Counter 0318Documento8 pagineArgenia Solar Wireless Digital Axle Counter 0318ahmadNessuna valutazione finora

- Bendix Ws-20 Antilock Wheel Speed Sensor: DescriptionDocumento4 pagineBendix Ws-20 Antilock Wheel Speed Sensor: DescriptionPablo NuñezNessuna valutazione finora

- Greer RCI510 Operators W450273ADocumento33 pagineGreer RCI510 Operators W450273AAndres Florentin Pizarro LazarteNessuna valutazione finora

- SIEMENS CatalougeDocumento21 pagineSIEMENS CatalougekaicyemNessuna valutazione finora

- 670-675 enDocumento32 pagine670-675 enWalter EguizabalNessuna valutazione finora

- Sentry AeDocumento4 pagineSentry AeVictor NoschangNessuna valutazione finora

- Pneumatic Positioner Type 3766: Mounting and Operating Instructions EB 8355-1 ENDocumento56 paginePneumatic Positioner Type 3766: Mounting and Operating Instructions EB 8355-1 ENSrinivasa MuralidharaNessuna valutazione finora

- Eddy Probe Systems PDFDocumento44 pagineEddy Probe Systems PDFVanessa Pajares LanciatoNessuna valutazione finora

- M Series SPEX MonochromatorDocumento20 pagineM Series SPEX Monochromatorstre0539100% (1)

- ARCA Fly ARCAPRO GBDocumento6 pagineARCA Fly ARCAPRO GBcvfNessuna valutazione finora

- T83843en 3730-3Documento12 pagineT83843en 3730-3aespinosa_rNessuna valutazione finora

- Strain Measurement in A Shaft Subjected To TorqueDocumento4 pagineStrain Measurement in A Shaft Subjected To TorqueRajarajan NMNessuna valutazione finora

- Straight Differential Expansion Measurements With The VM600: Turbine Supervisory InstrumentationDocumento4 pagineStraight Differential Expansion Measurements With The VM600: Turbine Supervisory InstrumentationFaisal ImranNessuna valutazione finora

- Torque SensorDocumento6 pagineTorque SensorBayu Ari MurtiNessuna valutazione finora

- GMD Joint TrackingDocumento36 pagineGMD Joint TrackingEhab Attia SelimNessuna valutazione finora

- Method Statement For Modifications in Low Power Circuit Breaker Ds-206S For New Compressor SystemsDocumento8 pagineMethod Statement For Modifications in Low Power Circuit Breaker Ds-206S For New Compressor SystemsJohn Philip BuntalesNessuna valutazione finora

- Brochure VC-6000 CM Engl.Documento8 pagineBrochure VC-6000 CM Engl.Amith MenonNessuna valutazione finora

- Masoneilan 12300 Series: Level Transmitter / ControllerDocumento12 pagineMasoneilan 12300 Series: Level Transmitter / ControllerA-selam Ibra100% (1)

- IL01209005EDocumento20 pagineIL01209005EJames LclNessuna valutazione finora

- Custody Transfer SystemDocumento8 pagineCustody Transfer SystempriyoNessuna valutazione finora

- Protection Relay ANSI StandardsDocumento7 pagineProtection Relay ANSI StandardskondareddyNessuna valutazione finora

- Lifting TrainingDocumento9 pagineLifting TrainingMohamed OmarNessuna valutazione finora

- Visco Pro 2000Documento63 pagineVisco Pro 2000Luz Stella Calixto GomezNessuna valutazione finora

- 2 - HydroFORM - Mechanical Setup R2Documento17 pagine2 - HydroFORM - Mechanical Setup R2carlosNessuna valutazione finora

- Gas Turbine Monitoring System: Meggitt Sensing SystemsDocumento2 pagineGas Turbine Monitoring System: Meggitt Sensing SystemsBrickvilleNessuna valutazione finora

- MODULE 4 - Environmental SensorsDocumento26 pagineMODULE 4 - Environmental Sensorsgavin.vedder1980Nessuna valutazione finora

- Spas348c en DacaDocumento114 pagineSpas348c en Dacablack_engNessuna valutazione finora

- Bwear CeDocumento4 pagineBwear CeMic UtuNessuna valutazione finora

- TD594BDocumento1 paginaTD594Briyadh bsisoNessuna valutazione finora

- Eddy Probes SystemsDocumento55 pagineEddy Probes SystemsRoberto Galina OrtizNessuna valutazione finora

- Wild Presentation - 09052020Documento46 pagineWild Presentation - 09052020Dasari RamamohanaNessuna valutazione finora

- Accelerometer:-: Musical InstrumentDocumento14 pagineAccelerometer:-: Musical InstrumentJyotirekha PatiNessuna valutazione finora

- Model Mx25 1'' Oval Gear Flowmeter: Instruction ManualDocumento20 pagineModel Mx25 1'' Oval Gear Flowmeter: Instruction ManualRómulo Zevallos GutiérrezNessuna valutazione finora

- Serv7106 V09N02 TXTDocumento44 pagineServ7106 V09N02 TXTmario saavedra tarazonaNessuna valutazione finora

- Hydro Turbine Vibration MonitoringDocumento8 pagineHydro Turbine Vibration MonitoringreddyloginNessuna valutazione finora

- Probador de Fase y Rotación de MotorDocumento32 pagineProbador de Fase y Rotación de Motornatsumyortiz02Nessuna valutazione finora

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Nessuna valutazione finora

- Flight Test Instrumentation: Proceedings of the Third International Symposium 1964Da EverandFlight Test Instrumentation: Proceedings of the Third International Symposium 1964M. A. PerryNessuna valutazione finora

- Tri Viet PDFDocumento2 pagineTri Viet PDFTu PhamNessuna valutazione finora

- Basket Strainers: ApplicationsDocumento15 pagineBasket Strainers: ApplicationsTu PhamNessuna valutazione finora

- Parts List: UylinulkDocumento19 pagineParts List: UylinulkTu PhamNessuna valutazione finora

- Pressure Vessels Design and EngineeringDocumento1 paginaPressure Vessels Design and EngineeringTu PhamNessuna valutazione finora

- USA INDUSTRIES, INC. - Manufacturer & Supplier: Piping Products For Isolation & TestingDocumento1 paginaUSA INDUSTRIES, INC. - Manufacturer & Supplier: Piping Products For Isolation & TestingTu PhamNessuna valutazione finora

- Valve Specifications: (Đính kèm YCMS số /YCMS/2020/DVK.CK.77)Documento1 paginaValve Specifications: (Đính kèm YCMS số /YCMS/2020/DVK.CK.77)Tu PhamNessuna valutazione finora

- Ut PDFDocumento1 paginaUt PDFTu PhamNessuna valutazione finora

- Data Sheet: 26 - Fig Tc704 Conical (Witches Hat) Strainer: Kaysafe Engineering LTDDocumento1 paginaData Sheet: 26 - Fig Tc704 Conical (Witches Hat) Strainer: Kaysafe Engineering LTDTu PhamNessuna valutazione finora

- Valve Specifications: (Đính kèm YCMS số /YCMS/2020/DVK.CK.77)Documento2 pagineValve Specifications: (Đính kèm YCMS số /YCMS/2020/DVK.CK.77)Tu PhamNessuna valutazione finora

- Pressure Vessels Design and EngineeringDocumento1 paginaPressure Vessels Design and EngineeringTu PhamNessuna valutazione finora

- T1553 60Documento8 pagineT1553 60Tu PhamNessuna valutazione finora

- 5.checklist Kiem Tra - Lap - Rev 1Documento3 pagine5.checklist Kiem Tra - Lap - Rev 1Tu PhamNessuna valutazione finora

- Cocktail Kingdom: Trim Holding Mesh To Flat Stamped HandleDocumento1 paginaCocktail Kingdom: Trim Holding Mesh To Flat Stamped HandleTu PhamNessuna valutazione finora

- PDCV - 1120 Outlet PressureDocumento1 paginaPDCV - 1120 Outlet PressureTu PhamNessuna valutazione finora

- 5.checklist Thao - Rev 1Documento3 pagine5.checklist Thao - Rev 1Tu PhamNessuna valutazione finora

- 2843-DVK-XCK-xem Xet Phe Duyet QT Kiem Tra, Khac Phuc Loi Nhiet Do EC-1101-22112019Documento2 pagine2843-DVK-XCK-xem Xet Phe Duyet QT Kiem Tra, Khac Phuc Loi Nhiet Do EC-1101-22112019Tu PhamNessuna valutazione finora

- 3 International Commercial Sale of GoodsDocumento31 pagine3 International Commercial Sale of GoodsPranav GhabrooNessuna valutazione finora

- Temporary Strainers: Model 92Documento1 paginaTemporary Strainers: Model 92Tu PhamNessuna valutazione finora

- Success With English Everywhere: For Advanced LearnersDocumento44 pagineSuccess With English Everywhere: For Advanced LearnersguifmdsNessuna valutazione finora

- New Process DataDocumento2 pagineNew Process DataTu PhamNessuna valutazione finora

- CSI 6500 Machinery Health Monitor: Online Machinery Monitoring Product Data SheetDocumento12 pagineCSI 6500 Machinery Health Monitor: Online Machinery Monitoring Product Data SheetTu PhamNessuna valutazione finora

- Uporedna Tabela Addinol-Ovih UljaDocumento4 pagineUporedna Tabela Addinol-Ovih UljaasimpeksNessuna valutazione finora

- Notes On Mass and Energy Balances For Membranes 2007 PDFDocumento83 pagineNotes On Mass and Energy Balances For Membranes 2007 PDFM TNessuna valutazione finora

- Shear Wall Design PDFDocumento9 pagineShear Wall Design PDFjk.dasgupta100% (2)

- Risk, Return & Capital BudgetingDocumento18 pagineRisk, Return & Capital BudgetingMuhammad Akmal HussainNessuna valutazione finora

- Psychological Attitude Towards SafetyDocumento17 paginePsychological Attitude Towards SafetyAMOL RASTOGI 19BCM0012Nessuna valutazione finora

- Course Syllabus: Ecommerce & Internet MarketingDocumento23 pagineCourse Syllabus: Ecommerce & Internet MarketingMady RamosNessuna valutazione finora

- Kudla Vs PolandDocumento4 pagineKudla Vs PolandTony TopacioNessuna valutazione finora

- LS Series Hand Crimping ToolsDocumento4 pagineLS Series Hand Crimping ToolsbaolifengNessuna valutazione finora

- Techgig Open Round CompetitionDocumento6 pagineTechgig Open Round CompetitionAnil Kumar GodishalaNessuna valutazione finora

- TreeSize Professional - Folder Contents of - CDocumento1 paginaTreeSize Professional - Folder Contents of - CHenrique GilNessuna valutazione finora

- Supply DemandProblems With Solutions, Part 1Documento16 pagineSupply DemandProblems With Solutions, Part 1deviNessuna valutazione finora

- Mio Digiwalker c220/c220sDocumento32 pagineMio Digiwalker c220/c220sTNessuna valutazione finora

- 4 FAR EAST BANK & TRUST COMPANY V DIAZ REALTY INCDocumento3 pagine4 FAR EAST BANK & TRUST COMPANY V DIAZ REALTY INCDanielleNessuna valutazione finora

- Assignment Business EnvironmentDocumento9 pagineAssignment Business EnvironmentVikram MayuriNessuna valutazione finora

- Hospital Management System DatabaseDocumento18 pagineHospital Management System DatabasesamdhathriNessuna valutazione finora

- NumaConcert ManualDocumento96 pagineNumaConcert ManualPippo GuarneraNessuna valutazione finora

- Document 20Documento3 pagineDocument 20api-586815209Nessuna valutazione finora

- SMPLEDocumento2 pagineSMPLEKla AlvarezNessuna valutazione finora

- 2 Players The One With Steam BaronsDocumento1 pagina2 Players The One With Steam BaronsBrad RoseNessuna valutazione finora

- Analysis and Design of Foundation of ROB at LC-9 Between Naroda and Dabhoda Station On Ahmedabad-Himmatnagar RoadDocumento10 pagineAnalysis and Design of Foundation of ROB at LC-9 Between Naroda and Dabhoda Station On Ahmedabad-Himmatnagar RoadmahakNessuna valutazione finora

- Learning Activity Sheet Science 10 Second Quarter - Week 8Documento4 pagineLearning Activity Sheet Science 10 Second Quarter - Week 8Eller Jansen AnciroNessuna valutazione finora

- Step Recovery DiodesDocumento3 pagineStep Recovery DiodesfahkingmoronNessuna valutazione finora

- New York State - NclexDocumento5 pagineNew York State - NclexBia KriaNessuna valutazione finora

- T53 L 13 Turboshaft EngineDocumento2 pagineT53 L 13 Turboshaft EngineEagle1968Nessuna valutazione finora

- O-CNN: Octree-Based Convolutional Neural Networks For 3D Shape AnalysisDocumento11 pagineO-CNN: Octree-Based Convolutional Neural Networks For 3D Shape AnalysisJose Angel Duarte MartinezNessuna valutazione finora

- 3.2.3 Practice - Taking The PSAT (Practice)Documento5 pagine3.2.3 Practice - Taking The PSAT (Practice)wrighemm200Nessuna valutazione finora

- Personal Information: Witec Smaranda 11, A3 Bis, Blvd. Chisinau, Bucharest, Romania 0040722597553Documento6 paginePersonal Information: Witec Smaranda 11, A3 Bis, Blvd. Chisinau, Bucharest, Romania 0040722597553MirelaRoșcaNessuna valutazione finora