Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Table 5 - Service Factor, A.C. Induction Motors: Part 8. Auxiliary Equipment - Chapter 2. Motors and Motor Controls

Caricato da

Karthikeyan Sankarrajan0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

23 visualizzazioni1 paginaThis document discusses motor insulation classes and factors that can cause motor overheating such as:

1. Different insulation classes have different temperature limits and are used for different motor applications. Class A insulation is commonly used for air conditioning and refrigeration motors.

2. External factors beyond load can cause overheating, including poor ventilation, debris blocking heat dissipation, high ambient temperatures, voltage unbalance, and variations in voltage or frequency from rated values.

3. Operating a motor continuously at its service factor overload rating will increase its temperature rise and shorten the life of its insulation. Each 10°C increase in temperature rise halves the life of the insulation.

Descrizione originale:

Motor Classification

Titolo originale

Motor Classification

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document discusses motor insulation classes and factors that can cause motor overheating such as:

1. Different insulation classes have different temperature limits and are used for different motor applications. Class A insulation is commonly used for air conditioning and refrigeration motors.

2. External factors beyond load can cause overheating, including poor ventilation, debris blocking heat dissipation, high ambient temperatures, voltage unbalance, and variations in voltage or frequency from rated values.

3. Operating a motor continuously at its service factor overload rating will increase its temperature rise and shorten the life of its insulation. Each 10°C increase in temperature rise halves the life of the insulation.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

23 visualizzazioni1 paginaTable 5 - Service Factor, A.C. Induction Motors: Part 8. Auxiliary Equipment - Chapter 2. Motors and Motor Controls

Caricato da

Karthikeyan SankarrajanThis document discusses motor insulation classes and factors that can cause motor overheating such as:

1. Different insulation classes have different temperature limits and are used for different motor applications. Class A insulation is commonly used for air conditioning and refrigeration motors.

2. External factors beyond load can cause overheating, including poor ventilation, debris blocking heat dissipation, high ambient temperatures, voltage unbalance, and variations in voltage or frequency from rated values.

3. Operating a motor continuously at its service factor overload rating will increase its temperature rise and shorten the life of its insulation. Each 10°C increase in temperature rise halves the life of the insulation.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

Part 8. Auxiliary Equipment | Chapter 2.

Motors And Motor Controls

For open motors applied in the tropics or similar

2. Ambient environment temperature, normally 40 environments, special insulation must be provided

C (104 F). because the motors may be exposed to excessive

3. Hot-spot temperature allowance, ranging from ambient temperatures and humidity.

5-15 C (usually 10 C).

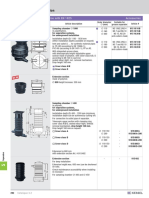

4. Service factor, normally 15 C. TABLE 5 – SERVICE FACTOR, A.C. INDUCTION

5. Allowable design motor temperature rise. MOTORS

TABLE 4 – CLASSIFICATION OF MOTOR- Motor Horsepower Service Factor

INSULATING MATERIALS 1

/8 and below 1.40

1

/6 , 1/4, 1/3 1.35

Open or 1

/2 , 3/4, 1 1.25

Dripproof Limiting 1 1/2, 2 1.20

Insulation Description Guarded Safe 3 and larger 1.15

Class Motor Hot Spot

Temp Rise Temp Service Factor

(C) (C) Standard open type motors of NEMA Design A, B

O Cotton, silk, paper and similar 40† 90(194 F) and C (also Design F) carry a service factor, an

organic materials neither im- allowable continuous overload above the rated name-

pregnated with insulating plate horsepower, without causing a dangerous

compounds* nor immersed in a temperature rise because of overload. Table 5 lists the

liquid dielectric. service factors for fractional and integral horsepower

A Same materials as in Class O 40 105(221 F) induction motors.

but impregnated or immersed in Service factors apply only when the voltage and

liquid dielectric*; also enamel frequency are held at the rated value. When a motor is

coated on conductors. operated continuously overloaded, the motor naturally

B Mica, glass fiber asbestos and 70 130(266 F) has a higher temperature rise and, therefore may have

other inorganic or organic an efficiency, power factor and speed different than the

materials in built-up form using rated load. The locked-rotor torque, current and

suitable binders. breakdown torque remain the same. It must be

C Entirely of mica, porcelain, remembered that the temperature rise caused by

glass, quartz or similar inorganic operating a motor at a continuous service factor

materials. overload shortens the life of insulation and therefore the

F Same as Class B, using 90† 155(311 F) life of the motor. As a rule each temperature rise of 10 C

modified organic binders. halves the life of the insulation.

H Same as Class B, using silicone 110 180(356 F)

resin binders. EXTERNAL OVERHEATING OF MOTOR

*An insulation is considered to be impregnated when a suitable The temperature rise previously discussed is the

substance replaces the air between its fibers. result of current flow occasioned by the load applied at

the rated voltage and frequency. However there are

†Approximate temperature rise. other considerations under which motor overheating

may result:

Motors used in air conditioning and refrigeration 1. Obstruction to heat dissipation due to

systems normally use Class A insulation that permits a improper ventilation.

40 C temperature rise for the windings. With present 2. Obstruction to heat dissipation due to physical

standards the life of the motor winding is approximately debris inside or outside the motor.

35,000 hours when operated at rated temperature and 3. Rise in ambient temperature above 40 C (104

subjected to normal dielectric and mechanical stresses F).

and humidity. 4. Unbalance in voltage.

5. Voltage and/or frequency variation from rated.

Potrebbero piacerti anche

- 130403-23 73 10-Air Handling Unit DX Coil Rev-01Documento4 pagine130403-23 73 10-Air Handling Unit DX Coil Rev-01Adil ShahNessuna valutazione finora

- Data Sheet 30HP MVN-90 03TR, TCV 1 PUMPSETDocumento3 pagineData Sheet 30HP MVN-90 03TR, TCV 1 PUMPSETAnggara PangestuNessuna valutazione finora

- CWLPCH2Documento36 pagineCWLPCH2adesa2014Nessuna valutazione finora

- Intellect Air Systems - Daikin Input Data: Latitude AltitudeDocumento1 paginaIntellect Air Systems - Daikin Input Data: Latitude AltitudeaneeshNessuna valutazione finora

- Ducting VelocitiesDocumento2 pagineDucting Velocitiesanwar2masNessuna valutazione finora

- CT PresentationDocumento22 pagineCT PresentationJithin DasNessuna valutazione finora

- SRL Diagnostics: Types of Cooling Tower - Cooling Tower Basic CalculationsDocumento13 pagineSRL Diagnostics: Types of Cooling Tower - Cooling Tower Basic CalculationssumitNessuna valutazione finora

- Cooling Tower Efficiency CalculationsDocumento3 pagineCooling Tower Efficiency CalculationsPramod SharmaNessuna valutazione finora

- EAU S1 - Fan SelectionDocumento1 paginaEAU S1 - Fan SelectionMohsin ShaikhNessuna valutazione finora

- Fise Tehnice Ue VRF FujitsuDocumento10 pagineFise Tehnice Ue VRF FujitsuMihaela CimpeanuNessuna valutazione finora

- Met 2Documento225 pagineMet 2Pranav kant100% (1)

- HvacDocumento34 pagineHvacDilshad AhemadNessuna valutazione finora

- Carrier 38LH D13 1PD UpdateDocumento13 pagineCarrier 38LH D13 1PD Updatesunil kumarNessuna valutazione finora

- 22 KW Motor DatasheetDocumento2 pagine22 KW Motor DatasheetJohn ShermanNessuna valutazione finora

- Detailed of Power Calculation of RBS and Other EquipmentDocumento7 pagineDetailed of Power Calculation of RBS and Other EquipmentWasisNessuna valutazione finora

- Daikin VRV SheetDocumento6 pagineDaikin VRV SheetSridhar ReddyNessuna valutazione finora

- Fans, Blowers and CompressorsDocumento29 pagineFans, Blowers and CompressorsMohammed.abudi1996Nessuna valutazione finora

- Primary Heat Load 1stDocumento27 paginePrimary Heat Load 1stRishabh SinghNessuna valutazione finora

- Heat Load ApolloDocumento22 pagineHeat Load ApolloBabla SwainNessuna valutazione finora

- AHU Costing - 06.07.2019Documento10 pagineAHU Costing - 06.07.2019Mohsin ShaikhNessuna valutazione finora

- Chiller Ton CalculationDocumento3 pagineChiller Ton CalculationGovinda Raj100% (1)

- HVAC, PHE & FF Eqpt - Elect LoadDocumento13 pagineHVAC, PHE & FF Eqpt - Elect LoadSaurabh DwivediNessuna valutazione finora

- AHU Specification - SaiverDocumento4 pagineAHU Specification - SaiverRyan Au YongNessuna valutazione finora

- Electrical Thumb Rules (Part-2)Documento2 pagineElectrical Thumb Rules (Part-2)Electrical RadicalNessuna valutazione finora

- Ac BoqDocumento200 pagineAc BoqYogeshNessuna valutazione finora

- Air Changes Per HourDocumento4 pagineAir Changes Per HourKg Chit ZawNessuna valutazione finora

- Ahu Matrix For OrderDocumento2 pagineAhu Matrix For OrderOanh NguyenNessuna valutazione finora

- AHU Coil SelectionDocumento7 pagineAHU Coil SelectiondheerajdorlikarNessuna valutazione finora

- Airtech 1710-02811 Dt. 14.10.2017 With ThyristorDocumento3 pagineAirtech 1710-02811 Dt. 14.10.2017 With ThyristorMohsin ShaikhNessuna valutazione finora

- 1-4b HVACDocumento28 pagine1-4b HVACMadhu SagheeNessuna valutazione finora

- Coil Selection For 38 TR Ahu r0 18.12.2006Documento2 pagineCoil Selection For 38 TR Ahu r0 18.12.2006Mohsin ShaikhNessuna valutazione finora

- Measure Motor Efficiency To Understand VFDDocumento5 pagineMeasure Motor Efficiency To Understand VFDGeorge MarkasNessuna valutazione finora

- HVAC Formulas by AEMEPDocumento9 pagineHVAC Formulas by AEMEPZen LohNessuna valutazione finora

- Electrical Diagnostic Check ListDocumento1 paginaElectrical Diagnostic Check ListSergiSerranoNessuna valutazione finora

- Coil Selection ReportDocumento1 paginaCoil Selection ReportMohsin Shaikh100% (1)

- What Is The Basis For Fan SelectionDocumento3 pagineWhat Is The Basis For Fan SelectionsmcsamindaNessuna valutazione finora

- AHU SizingDocumento8 pagineAHU Sizingmohammad hamdanNessuna valutazione finora

- BOQ HVAC-Ginger ManesarDocumento4 pagineBOQ HVAC-Ginger Manesarmascotengineers100% (1)

- Air Flow in Ducts: Now That You Can Size Equipment, The Next Task Would Be To Design The Air Distribution SystemDocumento22 pagineAir Flow in Ducts: Now That You Can Size Equipment, The Next Task Would Be To Design The Air Distribution SystemMukti WibowoNessuna valutazione finora

- Deep Submersible Hayward MotorsDocumento33 pagineDeep Submersible Hayward MotorsKasinathan MuniandiNessuna valutazione finora

- Sample For Heat Load CalculationDocumento6 pagineSample For Heat Load CalculationKannan VivekNessuna valutazione finora

- Ahu-1, 1500CFMDocumento1 paginaAhu-1, 1500CFMChandra SekharNessuna valutazione finora

- Branch Leaflet TECS-WDocumento12 pagineBranch Leaflet TECS-WAlfin khoeril UmamNessuna valutazione finora

- Star-Delta Starter: Electrical Notes & ArticlesDocumento25 pagineStar-Delta Starter: Electrical Notes & Articlesprabhanshu241991100% (1)

- 750 TR Chiller Load LineDocumento2 pagine750 TR Chiller Load Linecalvin.bloodaxe4478Nessuna valutazione finora

- Air WashersDocumento7 pagineAir WashersimshubhamlackNessuna valutazione finora

- HVAC System: Air Handling UnitDocumento11 pagineHVAC System: Air Handling UnitmohamednavaviNessuna valutazione finora

- Equip SCH Rev 3.0Documento26 pagineEquip SCH Rev 3.0Weain DionNessuna valutazione finora

- Shubharambh Banquets HL - All Halls 26-5-2017Documento5 pagineShubharambh Banquets HL - All Halls 26-5-2017calvin.bloodaxe4478Nessuna valutazione finora

- Pumpsandpumpingsystems 150309110148 Conversion Gate01Documento58 paginePumpsandpumpingsystems 150309110148 Conversion Gate01AltairNessuna valutazione finora

- Revised Bill of Quantities - Gas Pipeline Work For Nitrogen, LPG, Compressed Air & SteamDocumento6 pagineRevised Bill of Quantities - Gas Pipeline Work For Nitrogen, LPG, Compressed Air & Steamsk luko100% (1)

- Design CalculationsDocumento5 pagineDesign CalculationsDar AkhtNessuna valutazione finora

- Pembril: Constant Filling Fluid CouplingsDocumento2 paginePembril: Constant Filling Fluid CouplingsMUHAMMAD INDRAWAN100% (1)

- Multi Unit Conversion NEWDocumento38 pagineMulti Unit Conversion NEWehtesham314Nessuna valutazione finora

- AR 4.5 Building Services - IiDocumento32 pagineAR 4.5 Building Services - IiAlisha RaffiNessuna valutazione finora

- Schneider Electric LT6 Protection Intelligence Combined Catalog 9110CT9702Documento24 pagineSchneider Electric LT6 Protection Intelligence Combined Catalog 9110CT9702Igidio PedroNessuna valutazione finora

- Motor Temperature Ratings: DefinitionsDocumento4 pagineMotor Temperature Ratings: DefinitionstekhakkoNessuna valutazione finora

- Motor Winding Temperature ClassDocumento2 pagineMotor Winding Temperature ClassDeepak JoyNessuna valutazione finora

- Letter01!01!02 - Insulation - Defining Class Temperature RatingsDocumento1 paginaLetter01!01!02 - Insulation - Defining Class Temperature Ratingslbk50Nessuna valutazione finora

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesDa EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNessuna valutazione finora

- Shaft DesignDocumento13 pagineShaft DesignKarthikeyan SankarrajanNessuna valutazione finora

- Seasonal Energy Efficien..Documento6 pagineSeasonal Energy Efficien..Karthikeyan SankarrajanNessuna valutazione finora

- SMACNA - HVAC-Systems-Duct-Design1990 260Documento1 paginaSMACNA - HVAC-Systems-Duct-Design1990 260Karthikeyan Sankarrajan100% (1)

- Machines DesignDocumento7 pagineMachines DesignKarthikeyan SankarrajanNessuna valutazione finora

- Stress DesignDocumento11 pagineStress DesignKarthikeyan SankarrajanNessuna valutazione finora

- Smacna Duct Fitting Loss TableDocumento2 pagineSmacna Duct Fitting Loss TableKarthikeyan Sankarrajan75% (4)

- F.A.Q. Picv: General Valve QuestionsDocumento9 pagineF.A.Q. Picv: General Valve QuestionsKarthikeyan SankarrajanNessuna valutazione finora

- Grease Trap TypesDocumento1 paginaGrease Trap TypesKarthikeyan SankarrajanNessuna valutazione finora

- Fittings - K ValueDocumento2 pagineFittings - K ValueKarthikeyan SankarrajanNessuna valutazione finora

- Sewerage CalculatorDocumento5 pagineSewerage CalculatorKarthikeyan SankarrajanNessuna valutazione finora

- Impeller DesignDocumento1 paginaImpeller DesignKarthikeyan SankarrajanNessuna valutazione finora

- 1.2 JP - MTD STMT - 151104 - L1Documento1 pagina1.2 JP - MTD STMT - 151104 - L1Karthikeyan SankarrajanNessuna valutazione finora

- Led Bollard Light: Item Code: EL-S-BOL-LEDDocumento1 paginaLed Bollard Light: Item Code: EL-S-BOL-LEDKarthikeyan SankarrajanNessuna valutazione finora

- For Underground Installation: Grease SeparatorsDocumento1 paginaFor Underground Installation: Grease SeparatorsKarthikeyan SankarrajanNessuna valutazione finora

- Typical VALVES - K VALUEDocumento1 paginaTypical VALVES - K VALUEKarthikeyan SankarrajanNessuna valutazione finora

- Recommended Duct VelocitiesDocumento1 paginaRecommended Duct VelocitiesKarthikeyan Sankarrajan100% (1)

- Part 11. Air-Water System - Chapter 1. Induction Unit SystemDocumento1 paginaPart 11. Air-Water System - Chapter 1. Induction Unit SystemKarthikeyan SankarrajanNessuna valutazione finora

- Lux LevelDocumento1 paginaLux LevelKarthikeyan SankarrajanNessuna valutazione finora

- For Underground Installation: Coalescence SeparatorDocumento1 paginaFor Underground Installation: Coalescence SeparatorKarthikeyan SankarrajanNessuna valutazione finora

- Halton: - High Heat and High Grease Emissions? Not To Worry With Mist On Demand!Documento4 pagineHalton: - High Heat and High Grease Emissions? Not To Worry With Mist On Demand!Karthikeyan SankarrajanNessuna valutazione finora

- Part 2. Air Distribution - Chapter 2. Air Duct Design: Chart 7 - Frection Loss For Round DuctDocumento1 paginaPart 2. Air Distribution - Chapter 2. Air Duct Design: Chart 7 - Frection Loss For Round DuctKarthikeyan SankarrajanNessuna valutazione finora

- Part 10. All-Air Systems - Chapter 4. Dual-Duct System: Table 1 Summarizes The Cooling Load Requirements of 2)Documento1 paginaPart 10. All-Air Systems - Chapter 4. Dual-Duct System: Table 1 Summarizes The Cooling Load Requirements of 2)Karthikeyan SankarrajanNessuna valutazione finora

- Part 7. Refrigeration Equipment - Chapter 4. Combination Absorption-Centrifugal SystemDocumento1 paginaPart 7. Refrigeration Equipment - Chapter 4. Combination Absorption-Centrifugal SystemKarthikeyan SankarrajanNessuna valutazione finora

- Brine SelectionDocumento1 paginaBrine SelectionKarthikeyan SankarrajanNessuna valutazione finora

- Part 1. Load Estimating - Chapter 8. Applied PsychrometricsDocumento1 paginaPart 1. Load Estimating - Chapter 8. Applied PsychrometricsKarthikeyan SankarrajanNessuna valutazione finora

- Part 3. Piping Design - Chapter 4. Steam Piping: Example 5 Illustrates The Three Concepts MentionedDocumento1 paginaPart 3. Piping Design - Chapter 4. Steam Piping: Example 5 Illustrates The Three Concepts MentionedKarthikeyan SankarrajanNessuna valutazione finora

- Part 7. Refrigeration Equipment - Chapter 1. Reciprocating Refrigeration MachineDocumento1 paginaPart 7. Refrigeration Equipment - Chapter 1. Reciprocating Refrigeration MachineKarthikeyan SankarrajanNessuna valutazione finora

- Part 12. Water and DX System - Chapter 1. Fan-Coil Unit SystemDocumento1 paginaPart 12. Water and DX System - Chapter 1. Fan-Coil Unit SystemKarthikeyan SankarrajanNessuna valutazione finora

- Part 2. Air Distribution - Chapter 2. Air Duct Design: Chart 10 - L/Q RatioDocumento1 paginaPart 2. Air Distribution - Chapter 2. Air Duct Design: Chart 10 - L/Q RatioKarthikeyan SankarrajanNessuna valutazione finora

- Part 7. Refrigeration Equipment - Chapter 1. Reciprocating Refrigeration MachineDocumento1 paginaPart 7. Refrigeration Equipment - Chapter 1. Reciprocating Refrigeration MachineKarthikeyan SankarrajanNessuna valutazione finora

- Experimental Investigation of Electronic and Magnetic Properties of LaAlO3-SrTiO3 InterfacesDocumento204 pagineExperimental Investigation of Electronic and Magnetic Properties of LaAlO3-SrTiO3 InterfacestophensenNessuna valutazione finora

- Sintering of Ceramics - New Emerging TechniquesDocumento624 pagineSintering of Ceramics - New Emerging TechniquesJosé Ramírez100% (3)

- D 5282 - 98 - Rduyodi - PDFDocumento3 pagineD 5282 - 98 - Rduyodi - PDFjayakumarNessuna valutazione finora

- ElectrostaticsDocumento52 pagineElectrostaticsR Rrajesh KoomarrNessuna valutazione finora

- Sidorkin, Domain Structure in Ferroelectrics and RelatedDocumento247 pagineSidorkin, Domain Structure in Ferroelectrics and RelatedZomatoswiggy100% (2)

- 5TE ManualDocumento38 pagine5TE ManualJose Luis Alcazar RomeroNessuna valutazione finora

- Course Structure of BE Electrical Engineering BranchDocumento56 pagineCourse Structure of BE Electrical Engineering BranchAnjishnu MahantaNessuna valutazione finora

- FERROELECTROMAGNETSDocumento109 pagineFERROELECTROMAGNETSAamerNessuna valutazione finora

- Design of Capacitive Voltage Divider For Measuring Ultrafast VoltagesDocumento8 pagineDesign of Capacitive Voltage Divider For Measuring Ultrafast VoltagesMIKS DARKNessuna valutazione finora

- Mid Exam OnlineDocumento2 pagineMid Exam OnlineShakeel Ahmad KasuriNessuna valutazione finora

- Chapter:-Capacitance - 3 Time: Hrs 2: Lecture Planning & FlowDocumento34 pagineChapter:-Capacitance - 3 Time: Hrs 2: Lecture Planning & Flow33-Siddharth NairNessuna valutazione finora

- Questions & Answers On Capacitors: 1. Define CapacitorDocumento4 pagineQuestions & Answers On Capacitors: 1. Define CapacitorTanmay HazraNessuna valutazione finora

- IISc Bangalore Course WorkDocumento12 pagineIISc Bangalore Course WorkPowerranger2.0Nessuna valutazione finora

- Class 6-7 ElectrostaticsDocumento10 pagineClass 6-7 ElectrostaticsChandraKiranNessuna valutazione finora

- Ferroelectrics Go BananasDocumento3 pagineFerroelectrics Go BananasAnastasiosPaterasNessuna valutazione finora

- Electronics Basic Questions ObjectiveDocumento82 pagineElectronics Basic Questions ObjectiveKrishan Gupta100% (3)

- Sustamid PA6GOLDocumento1 paginaSustamid PA6GOLPatrick BaridonNessuna valutazione finora

- Rotating Machines Testing and Monitoring Brochure ENU PDFDocumento28 pagineRotating Machines Testing and Monitoring Brochure ENU PDFmunggangNessuna valutazione finora

- Piezoelectric Accelerometers and Vibration Pre AmplifiersDocumento160 paginePiezoelectric Accelerometers and Vibration Pre Amplifiersavoid11Nessuna valutazione finora

- Improvement of Reliability and Dielectric Breakdown Strength of NB Doped Lead Zirconate Titanate Films Via Microstructure Control of SeedDocumento7 pagineImprovement of Reliability and Dielectric Breakdown Strength of NB Doped Lead Zirconate Titanate Films Via Microstructure Control of Seedcbs78Nessuna valutazione finora

- MEGGERDocumento2 pagineMEGGERHMBPNessuna valutazione finora

- Det1013 - Electrical Technology: Capacitors & CapacitanceDocumento47 pagineDet1013 - Electrical Technology: Capacitors & CapacitanceSuhaila SharifNessuna valutazione finora

- What Are Microwaves?Documento20 pagineWhat Are Microwaves?Anup DalalNessuna valutazione finora

- IES2013 EEE Objective Paper 1Documento20 pagineIES2013 EEE Objective Paper 1Srinivas DalliNessuna valutazione finora

- RTHS: A Low-Cost High-Performance Real-Time Hardware Sorter, Using A Multidimensional Sorting AlgorithmDocumento13 pagineRTHS: A Low-Cost High-Performance Real-Time Hardware Sorter, Using A Multidimensional Sorting AlgorithmasddsdsaNessuna valutazione finora

- Capacitor 2 Worksheet BDocumento11 pagineCapacitor 2 Worksheet BLiza Macalinao MangalimanNessuna valutazione finora

- s00396 023 05120 2Documento19 pagines00396 023 05120 2halikonhdNessuna valutazione finora

- Unit Two - Electrical Circuit ParametersDocumento21 pagineUnit Two - Electrical Circuit ParametersSena MekoninNessuna valutazione finora

- Underground Cables M 16 1Documento167 pagineUnderground Cables M 16 1Shivam MùnjãlNessuna valutazione finora

- Interconnect I - Class 21: Prerequisite Reading - Chapter 4Documento32 pagineInterconnect I - Class 21: Prerequisite Reading - Chapter 4spyeagleNessuna valutazione finora