Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Part 3. Piping Design - Chapter 4. Steam Piping: Example 5 Illustrates The Three Concepts Mentioned

Caricato da

Karthikeyan Sankarrajan0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

25 visualizzazioni1 paginaThis document discusses the design of steam piping systems. It covers calculating the warm-up load, radiation load, and total condensate load on a steam trap. The warm-up load is based on pipe length, temperature difference, and time. The radiation load depends on pipe length, temperature difference, and insulation properties. The total load is the sum of the warm-up and half the radiation loads. Trap selection requires considering this total load along with pressure differential and a safety factor, usually 2-8 times the load, to ensure adequate condensate removal. An example calculates loads and selects a trap with a 3 times safety factor for a steam main.

Descrizione originale:

Steam piping

Titolo originale

Steam Piping

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document discusses the design of steam piping systems. It covers calculating the warm-up load, radiation load, and total condensate load on a steam trap. The warm-up load is based on pipe length, temperature difference, and time. The radiation load depends on pipe length, temperature difference, and insulation properties. The total load is the sum of the warm-up and half the radiation loads. Trap selection requires considering this total load along with pressure differential and a safety factor, usually 2-8 times the load, to ensure adequate condensate removal. An example calculates loads and selects a trap with a 3 times safety factor for a steam main.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

25 visualizzazioni1 paginaPart 3. Piping Design - Chapter 4. Steam Piping: Example 5 Illustrates The Three Concepts Mentioned

Caricato da

Karthikeyan SankarrajanThis document discusses the design of steam piping systems. It covers calculating the warm-up load, radiation load, and total condensate load on a steam trap. The warm-up load is based on pipe length, temperature difference, and time. The radiation load depends on pipe length, temperature difference, and insulation properties. The total load is the sum of the warm-up and half the radiation loads. Trap selection requires considering this total load along with pressure differential and a safety factor, usually 2-8 times the load, to ensure adequate condensate removal. An example calculates loads and selects a trap with a 3 times safety factor for a steam main.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

Part 3. Piping Design | Chapter 4.

Steam Piping

The radiation load builds up as the warm – up load Given:

drops off under normal operating conditions. The peak Steam main – 10 in. diam steel pipe, 50 ft long

occurs at the mid – point of the warm – up cycle. Steam pressure – 5 psig ( 227 F )

Therefore, one – half of the radiation load Is added to Room temperature – 70 F db ( steam main in space )

warm – up load to determine the amount of condensate Warm – up time – 15 minutes

that the trap handles. Steam trap to drip main into vacuum return line

(2 in. vacuum gage design)

Pressure Differential Find:

The pressure differential across the trap is determined 1. Warm – up load.

at design conditions. If a vacuum exists on the discharge 2. Radiation load.

side of the trap, the vacuum is added to the inlet side 3. Total condensate load.

pressure to determine the differential. 4. Specifications for steam trap at end of supply main.

Safety Factor Solution:

Good design practice dictates the use of safety 1. The warm – up load is determined from the following

factors in steam trap selection. Safety factors from 2 to 1 to equation:

as high as 8 to 1 may be required, and for the following

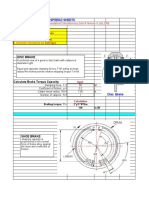

reasons: C1 = W x (tfh–l xti)Tx .114

1. The steam pressure at the trap inlet or the back

pressure at the trap discharge the steam trap Where: W = 40.48 lb / ft x 50 ft ( Table 2 )

capacity. tf = 227 F

2. If the trap is sized for normal operating load, ti = 70 F

condensate may back up into the steam lines or hl = 960 Btu/ lb ( from steam tables)

apparatus during start – up or warm – up T = .25 hr

operation. C1 = 2024 x ( 227 – 70 ) x .114

3. It the steam trap is selected to discharge a full 960 x .25

and continuous steam of water, the air could not = 150 lb / hr of condensate

vented from the steam. 2. The radiation load is calculated by using the following

equation: L x K x (tf – ti)

C2 =

The following guide is used to determine the safety hl

factor: Where: L = 50 ft

K = 6.41 Btu / (hr) (linear foot)

( deg F diff between pipe and air)

from Table 54 , Part I

tf = 227 F

ti = 70 F

hI = 960 Btu / lb ( from steam tables)

C2 = 50 x 6.41 x (227 – 70)

960

= 52 lb / hr of condensate

When the steam trap is to be used in a high pressure 3. The total condensate load for steam trap selection is

system, determine whether or not the system is to operate equal to the warm – up load plus one half the radiation

under low pressure conditions at certain intervals such as load.

night time or weekends. If this condition is likely to occur, Total condensate load = C1 + ( 1/2 x C2)

then an additional safety factor should be considered to = 150+(1/2 x 52)

account for the lower pressure drop available during night = 176 lb / hr

time operation. 4. Steam trap selection is dependent on three factors:

Example 5 illustrates the three concepts mentioned condensate handled, safety factor applied to total

previously in trap selection – condensate handled, condensate load, and pressure differential across the

pressure differential and safety factor. steam trap. The safety factor for a steam trap at the end

of the main is 3 to 1 from the table on this page.

Example 5 – Steam Trap Selection for Dripping Supply Main to Applying the 3 to 1 safety factor to the total condensate

Return Line

Potrebbero piacerti anche

- Finned TubeDocumento4 pagineFinned Tubeknife2008Nessuna valutazione finora

- Application Guide: Air Systems - Energy SeriesDocumento12 pagineApplication Guide: Air Systems - Energy SeriesJojolasNessuna valutazione finora

- Circulation of BoilerDocumento5 pagineCirculation of BoilerMuralikrishna ArigondaNessuna valutazione finora

- Repjwhc1.doc - Measurement-Condenser-Losses-Due-Fouling-And-Those-Due-Air-Ingressrepjwhc1Documento15 pagineRepjwhc1.doc - Measurement-Condenser-Losses-Due-Fouling-And-Those-Due-Air-Ingressrepjwhc1Ashish MahtoNessuna valutazione finora

- Steam Mains Trap Design GuideDocumento37 pagineSteam Mains Trap Design GuideTrina Ritchell AquinoNessuna valutazione finora

- Heat Transfer and Heat - ExchangersDocumento6 pagineHeat Transfer and Heat - Exchangershoang vu ngocNessuna valutazione finora

- Estimation of Over-All Heat TransferDocumento10 pagineEstimation of Over-All Heat TransferAllan Troy SalazarNessuna valutazione finora

- Thermal Design of Shell and Tube Heat ExchangersDocumento5 pagineThermal Design of Shell and Tube Heat ExchangersmohamedNessuna valutazione finora

- Week 5 & 6Documento10 pagineWeek 5 & 6Mariel MirafloresNessuna valutazione finora

- Design of LPG Refigeration System: 1. Copper TubesDocumento20 pagineDesign of LPG Refigeration System: 1. Copper TubesJeevan Landge PatilNessuna valutazione finora

- 6159b9a3-a853-4554-bf38-b5a65964ffceDocumento39 pagine6159b9a3-a853-4554-bf38-b5a65964ffceUsman AliNessuna valutazione finora

- Artigo HotDocumento8 pagineArtigo Hotluiz.henriqueNessuna valutazione finora

- Refrigeration and AirconditioningDocumento107 pagineRefrigeration and Airconditioningadrian paul relayosaNessuna valutazione finora

- An Optimized Configuration for the TriplDocumento7 pagineAn Optimized Configuration for the TriplQuốc Nguyễn MinhNessuna valutazione finora

- CheGuide ‐ Jacketed Vessel Heat Transfer (Half Pipe Coil)Documento4 pagineCheGuide ‐ Jacketed Vessel Heat Transfer (Half Pipe Coil)AzhaNessuna valutazione finora

- Solutions Problem Set 3 PDFDocumento18 pagineSolutions Problem Set 3 PDFOsama SyedNessuna valutazione finora

- Steam Generation Thermodynamics: Efficiency Improvements Can Quickly Be Identified With Back-Of-The-Envelope CalculationsDocumento4 pagineSteam Generation Thermodynamics: Efficiency Improvements Can Quickly Be Identified With Back-Of-The-Envelope CalculationsDaniel Puello RodeloNessuna valutazione finora

- Improve Steam Generator Efficiency with ThermodynamicsDocumento4 pagineImprove Steam Generator Efficiency with ThermodynamicsBramJanssen76Nessuna valutazione finora

- Finned Tube Heat ExchangerDocumento6 pagineFinned Tube Heat ExchangerShailesh DeshmukhNessuna valutazione finora

- Bemco Inc Discusses Air Flow Calculations for Temperature Uniformity in Environmental ChambersDocumento12 pagineBemco Inc Discusses Air Flow Calculations for Temperature Uniformity in Environmental ChambersKrishna ChaitanyaNessuna valutazione finora

- Air Change Load - Vapor Compression NotesDocumento9 pagineAir Change Load - Vapor Compression NotesRai OlinoNessuna valutazione finora

- 5.3.1 General: 5.3 PenstockDocumento8 pagine5.3.1 General: 5.3 PenstocklijalemNessuna valutazione finora

- Lab Manual Convection Radiation (EDocFind - Com)Documento10 pagineLab Manual Convection Radiation (EDocFind - Com)Hilmi ÖlmezNessuna valutazione finora

- Heat Transfer Analysis Of: Compact Heat Exchangers Using Standard CurvesDocumento4 pagineHeat Transfer Analysis Of: Compact Heat Exchangers Using Standard CurvesfbahsiNessuna valutazione finora

- EE2355 Design of Electrical Machines NotesDocumento24 pagineEE2355 Design of Electrical Machines Notesmadhes14Nessuna valutazione finora

- Department of Mechanical Engineering: Heat TransferDocumento31 pagineDepartment of Mechanical Engineering: Heat TransferarulmuruguNessuna valutazione finora

- PSV Scenario and CalculationDocumento35 paginePSV Scenario and CalculationBaba Johneh0% (1)

- Mech 330: Applied Thermodynamics Ii: WM HH WM HHDocumento10 pagineMech 330: Applied Thermodynamics Ii: WM HH WM HHYosua WijayaNessuna valutazione finora

- Chapter 17Documento36 pagineChapter 17Nayoga MandaNessuna valutazione finora

- SI8 Errata 99Documento19 pagineSI8 Errata 99Vigilancia ViajerosNessuna valutazione finora

- Vertical ConderDocumento9 pagineVertical Condermanoj kumarNessuna valutazione finora

- Free and Forced ConvetionDocumento11 pagineFree and Forced Convetionعبدالملك جمالNessuna valutazione finora

- Heat Exchanger PerformanceDocumento31 pagineHeat Exchanger PerformanceFA AyNessuna valutazione finora

- Boosting Efficiency in Gas TurbinesDocumento24 pagineBoosting Efficiency in Gas TurbinesMUmairWaheedNessuna valutazione finora

- 5 09b e Adcamat Apst ppt14 Pump Traps Understanding Stall ConditionDocumento4 pagine5 09b e Adcamat Apst ppt14 Pump Traps Understanding Stall ConditionIan B. YtomNessuna valutazione finora

- Heat Transfer From Pin-Fin Apparatus. Extended Surfaces of Fins Are Used To Increase The Heat Transfer Rate From ADocumento22 pagineHeat Transfer From Pin-Fin Apparatus. Extended Surfaces of Fins Are Used To Increase The Heat Transfer Rate From AAlen SajuNessuna valutazione finora

- TEST ON A PIN - FIN APPATATUS BY FORCED CONVECTION - Pin Fin New-2Documento5 pagineTEST ON A PIN - FIN APPATATUS BY FORCED CONVECTION - Pin Fin New-2Jady chess24Nessuna valutazione finora

- Heat Pump DiagramDocumento17 pagineHeat Pump DiagramAhmed SabryNessuna valutazione finora

- Experiment No 7 Pin Fin ApparatusDocumento5 pagineExperiment No 7 Pin Fin Apparatusgaur123450% (2)

- Condenser: CH 1407-Chemical Process Equipment Design and Drawing / Compiled By, R.ARUL KAMALAKUMARDocumento8 pagineCondenser: CH 1407-Chemical Process Equipment Design and Drawing / Compiled By, R.ARUL KAMALAKUMARarulrakkNessuna valutazione finora

- Calculating Maximum Tube Metal TemperaturesDocumento12 pagineCalculating Maximum Tube Metal Temperaturesck19654840Nessuna valutazione finora

- Calculation of Radiant Section TemperaturesDocumento8 pagineCalculation of Radiant Section TemperaturesmedobasNessuna valutazione finora

- 5.optimum Thermal Design of MicrochannelDocumento7 pagine5.optimum Thermal Design of MicrochannelAnkit LonareNessuna valutazione finora

- Dual-duct constant-volume system analysis hot and cold air flowsDocumento3 pagineDual-duct constant-volume system analysis hot and cold air flowsZaid Tariq AlabiryNessuna valutazione finora

- Estimating Heat Sink Thermal ResistanceDocumento6 pagineEstimating Heat Sink Thermal ResistanceRAHUL VEERNessuna valutazione finora

- Simulacion Aero Enfriador PDFDocumento40 pagineSimulacion Aero Enfriador PDFNicandroGonzalesNessuna valutazione finora

- Lab 2Documento17 pagineLab 2Callum BiggsNessuna valutazione finora

- Horizontal Shell-and-Tube Condenser CapacityDocumento4 pagineHorizontal Shell-and-Tube Condenser Capacitykero_the_heroNessuna valutazione finora

- Processes 09 00111Documento15 pagineProcesses 09 00111Eng-MustafaHathalAl-SaraiNessuna valutazione finora

- Lab Heat PumpDocumento9 pagineLab Heat PumpShahran IezzatNessuna valutazione finora

- Xample Ransient Flow of A Ewtonian Liquid Through A Cylindrical PipeDocumento8 pagineXample Ransient Flow of A Ewtonian Liquid Through A Cylindrical Pipewoongs73Nessuna valutazione finora

- CASTEL Selection Criteria For Safety ValveDocumento9 pagineCASTEL Selection Criteria For Safety ValvelorenzoNessuna valutazione finora

- Department of Mechanical Engineering. Mce315 Design Studies 1 Report On ExperimentDocumento9 pagineDepartment of Mechanical Engineering. Mce315 Design Studies 1 Report On ExperimentBukky EmmanuelNessuna valutazione finora

- Predict storage-tank heat transfer preciselyDocumento57 paginePredict storage-tank heat transfer preciselyMilan Djumic100% (2)

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"Da EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"Nessuna valutazione finora

- Machines DesignDocumento7 pagineMachines DesignKarthikeyan SankarrajanNessuna valutazione finora

- Led Bollard Light: Item Code: EL-S-BOL-LEDDocumento1 paginaLed Bollard Light: Item Code: EL-S-BOL-LEDKarthikeyan SankarrajanNessuna valutazione finora

- Stress DesignDocumento11 pagineStress DesignKarthikeyan SankarrajanNessuna valutazione finora

- Shaft DesignDocumento13 pagineShaft DesignKarthikeyan SankarrajanNessuna valutazione finora

- IPC Loading UnitsDocumento3 pagineIPC Loading UnitsTaqui Mubeen67% (3)

- Health Facility GuidelinesDocumento51 pagineHealth Facility GuidelinesAshok Kumar Pillai100% (1)

- Refrigerant Dehumidification Technology: Technical Bulletin 1Documento12 pagineRefrigerant Dehumidification Technology: Technical Bulletin 1Karthikeyan SankarrajanNessuna valutazione finora

- Brake DesignDocumento2 pagineBrake DesignKarthikeyan SankarrajanNessuna valutazione finora

- Seasonal Energy Efficien..Documento6 pagineSeasonal Energy Efficien..Karthikeyan SankarrajanNessuna valutazione finora

- Method statement for testing and commissioningDocumento1 paginaMethod statement for testing and commissioningKarthikeyan SankarrajanNessuna valutazione finora

- Smacna Duct Fitting Loss TableDocumento2 pagineSmacna Duct Fitting Loss TableKarthikeyan Sankarrajan75% (4)

- Sewerage CalculatorDocumento5 pagineSewerage CalculatorKarthikeyan SankarrajanNessuna valutazione finora

- Air Flow Velocity in DuctsDocumento2 pagineAir Flow Velocity in DuctsKarthikeyan SankarrajanNessuna valutazione finora

- SMACNA - HVAC-Systems-Duct-Design1990 260Documento1 paginaSMACNA - HVAC-Systems-Duct-Design1990 260Karthikeyan Sankarrajan100% (1)

- Water Regulations Advisory Scheme Ltd. (Wras) Material ApprovalDocumento2 pagineWater Regulations Advisory Scheme Ltd. (Wras) Material ApprovalKarthikeyan SankarrajanNessuna valutazione finora

- F.A.Q. Picv: General Valve QuestionsDocumento9 pagineF.A.Q. Picv: General Valve QuestionsKarthikeyan SankarrajanNessuna valutazione finora

- Grease Trap TypesDocumento1 paginaGrease Trap TypesKarthikeyan SankarrajanNessuna valutazione finora

- Led Top Pole Light: Item Code: LL-POLETOP-LEDDocumento1 paginaLed Top Pole Light: Item Code: LL-POLETOP-LEDKarthikeyan SankarrajanNessuna valutazione finora

- For Underground Installation: Grease SeparatorsDocumento1 paginaFor Underground Installation: Grease SeparatorsKarthikeyan SankarrajanNessuna valutazione finora

- Lux LevelDocumento1 paginaLux LevelKarthikeyan SankarrajanNessuna valutazione finora

- Typical Kv valve sizing chartDocumento1 paginaTypical Kv valve sizing chartKarthikeyan SankarrajanNessuna valutazione finora

- 00 HVAC CalcDocumento52 pagine00 HVAC Calcibson045001256Nessuna valutazione finora

- Fittings - K ValueDocumento2 pagineFittings - K ValueKarthikeyan SankarrajanNessuna valutazione finora

- Underground coalescence separatorDocumento1 paginaUnderground coalescence separatorKarthikeyan SankarrajanNessuna valutazione finora

- Part 11. Air-Water System - Chapter 1. Induction Unit SystemDocumento1 paginaPart 11. Air-Water System - Chapter 1. Induction Unit SystemKarthikeyan SankarrajanNessuna valutazione finora

- Part 10. All-Air Systems - Chapter 4. Dual-Duct System: Table 1 Summarizes The Cooling Load Requirements of 2)Documento1 paginaPart 10. All-Air Systems - Chapter 4. Dual-Duct System: Table 1 Summarizes The Cooling Load Requirements of 2)Karthikeyan SankarrajanNessuna valutazione finora

- Air Duct Design Friction Loss ChartDocumento1 paginaAir Duct Design Friction Loss ChartKarthikeyan SankarrajanNessuna valutazione finora

- Halton: - High Heat and High Grease Emissions? Not To Worry With Mist On Demand!Documento4 pagineHalton: - High Heat and High Grease Emissions? Not To Worry With Mist On Demand!Karthikeyan SankarrajanNessuna valutazione finora

- Recommended Duct VelocitiesDocumento1 paginaRecommended Duct VelocitiesKarthikeyan Sankarrajan100% (1)

- NTi Audio AppNote XL2 Noise CurvesDocumento13 pagineNTi Audio AppNote XL2 Noise CurvesdjossNessuna valutazione finora

- How To Install Windows XP From Pen Drive Step by Step GuideDocumento3 pagineHow To Install Windows XP From Pen Drive Step by Step GuideJithendra Kumar MNessuna valutazione finora

- Administrations whose CoCs are accepted for CECDocumento1 paginaAdministrations whose CoCs are accepted for CECGonçalo CruzeiroNessuna valutazione finora

- Practical Finite Element Simulations With SOLIDWORKS 2022Documento465 paginePractical Finite Element Simulations With SOLIDWORKS 2022knbgamageNessuna valutazione finora

- New ALS MADRASAH COMBINEDDocumento6 pagineNew ALS MADRASAH COMBINEDJane BaysaNessuna valutazione finora

- Jeremy Hughes ReviewDocumento5 pagineJeremy Hughes ReviewgracecavNessuna valutazione finora

- Canterburytales-No Fear PrologueDocumento10 pagineCanterburytales-No Fear Prologueapi-261452312Nessuna valutazione finora

- Nutritional support through feeding tubesDocumento76 pagineNutritional support through feeding tubesKryzza LeizellNessuna valutazione finora

- WBC Study Reveals God's NatureDocumento11 pagineWBC Study Reveals God's NatureSherwin Castillo DelgadoNessuna valutazione finora

- 1 - Gear Seminar ManualDocumento125 pagine1 - Gear Seminar Manualgustool7100% (1)

- Activity 2Documento5 pagineActivity 2Kier VillegasNessuna valutazione finora

- Biotox Gold 2.0-2021 Relaunch ReviewDocumento6 pagineBiotox Gold 2.0-2021 Relaunch ReviewChinthaka AbeygunawardanaNessuna valutazione finora

- EINC ChecklistDocumento3 pagineEINC ChecklistMARK JEFTE BRIONESNessuna valutazione finora

- Psalms Magick of The Old Testament PDFDocumento129 paginePsalms Magick of The Old Testament PDFirrrs100% (1)

- C++ NotesDocumento129 pagineC++ NotesNikhil Kant Saxena100% (4)

- Nataraja Stotram - A Hymn Without 'CharaNa' and 'ShRi~NgaDocumento8 pagineNataraja Stotram - A Hymn Without 'CharaNa' and 'ShRi~NgaSiva Krishna100% (1)

- The Daily Tar Heel For September 18, 2012Documento8 pagineThe Daily Tar Heel For September 18, 2012The Daily Tar HeelNessuna valutazione finora

- Sample Interview Questions for Motivation, Communication, TeamsDocumento6 pagineSample Interview Questions for Motivation, Communication, TeamsSahibzada Muhammad MubeenNessuna valutazione finora

- Arts9 q4 Mod1 Theatricalforms v5Documento30 pagineArts9 q4 Mod1 Theatricalforms v5Harold RicafortNessuna valutazione finora

- Surface Coating ProcessesDocumento7 pagineSurface Coating ProcessesSailabala ChoudhuryNessuna valutazione finora

- Teaching Support Untuk Managemen HRDocumento102 pagineTeaching Support Untuk Managemen HRFernando FmchpNessuna valutazione finora

- Grade 4 DLL Quarter 2 Week 2 Sir Bien CruzDocumento47 pagineGrade 4 DLL Quarter 2 Week 2 Sir Bien CruzRonel Fillomena0% (1)

- Leica CS10 CS15 GSSensors QG v3.0.1 en PDFDocumento16 pagineLeica CS10 CS15 GSSensors QG v3.0.1 en PDFMohammad Saiful AzamNessuna valutazione finora

- Transport in Plants: Test Yourself 9.1 (Page 178)Documento3 pagineTransport in Plants: Test Yourself 9.1 (Page 178)lee100% (3)

- Automotive E-Coat Paint Process Simulation Using FEADocumento20 pagineAutomotive E-Coat Paint Process Simulation Using FEAflowh_100% (1)

- GBM Auction Versus English Auction A Large-Scale Empirical Study - E. Bessire, K. Elhadji Tchiambou (October 2021)Documento18 pagineGBM Auction Versus English Auction A Large-Scale Empirical Study - E. Bessire, K. Elhadji Tchiambou (October 2021)Guillaume GonnaudNessuna valutazione finora

- ANAPHYDocumento23 pagineANAPHYYu, Denise Kyla BernadetteNessuna valutazione finora

- SomDocumento191 pagineSomVivek GosaviNessuna valutazione finora

- Oreilly Design For Voice InterfacesDocumento37 pagineOreilly Design For Voice InterfacesHarmony JordenNessuna valutazione finora

- B2PLUS UNIT 6 Test Answer Key HighDocumento2 pagineB2PLUS UNIT 6 Test Answer Key HighАндрій НікітінNessuna valutazione finora

- Health Information SystemDocumento11 pagineHealth Information SystemVineeta Jose100% (1)