Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Yang Hyundai Final 2232012l

Caricato da

AvinashRaiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Yang Hyundai Final 2232012l

Caricato da

AvinashRaiCopyright:

Formati disponibili

A Study on the Lateral Stiffness of the Passenger

Car Suspension

Moonho Yang

Hyundai Motor Company

Abstract: The vehicle handling performance is the main function of vehicle suspension systems for

vehicle to be stable during severe cornering and/or abrupt misused steering maneuver conditions.

It is essential to satisfy sufficient lateral stiffness of vehicle suspension system for the effective

vehicle handling performance as well as avoiding contact problem between brake rotor and other

adjacent parts. Accordingly, it is important to make prediction of lateral suspension stiffness with

accurate computational simulation model, so that the suspension designer can verify the handling

performance before conforming detail suspension parameters.

This paper shows that the lateral stiffness analysis result of vehicle suspension can be improved

with the accurate bearing stiffness model correlated with experimental vehicle test data and also,

shows which design parameters contribute to lateral stiffness of vehicle suspension.

Keywords: lateral Stiffness, bearing stiffness

1. Introduction

During severe cornering and/or abrupt misused steering maneuver conditions, the axle system can

be subjected to the excessive lateral force generated at the tires contact patch. This force results in

the hub & bearing deflections, which cause contact problem between brake rotor and other

adjacent parts(brake caliper torque member, lower control arm) and negatively effect vehicle

handling performance.

In this paper the accurate bearing stiffness model correlated with experimental test is reviewed.

2. Bearing FE model

Figure 1 shows a example of bearing model. The respective bearing balls are modeled using a

non-linear SPRINGA element. DCOUP3D element is used to represent the contact area of a

bearing ball.

Figure 2 shows a layout example of the axle system with 1’st generation bearing. In case of 1’st

generation bearing, SHRINK FIT and PRETENSION are used to represent interference fittings of

the bearings on the hub and on the knuckle by negative tolerance and the tightening nut

respectively. And SHRINK FIT is used to represent interference fitting by orbital forming of the

3’rd generation bearing. Figure 3 shows a layout example of the 3’rd generation bearing.

2012 SIMULIA Customer Conference 1

Figure 1. Bearing FE model

Figure 2. Axle system with 1’st generation bearing

Figure 3. 3’rd generation bearing

2 2012 SIMULIA Customer Conference

3. Axle system stiffness

3.1 Test and analysis of the axle system stiffness

Figure 4, 5 show the test device and FE model of the axle system to correlate the axle system

stiffness.

Figure 4. Axle system stiffness test

Figure 5. FE model for the axle system stiffness analysis

2012 SIMULIA Customer Conference 3

Figure 6. Test and analysis result of axle system stiffness

Figure 6 shows the test and analysis result of A-vehicle axle system stiffness. Compared to the test

data, the analysis result has good accuracy. The bearing defection to the axle system stiffness is

about 2 times more than the hub deflection. The non-linearity of knuckle deflection curve is due to

sliding between knuckle and bearing outer race.

3.2 Parameter study of the axle system stiffness

Using this bearing stiffness model, the axle stiffness analyses of several design variables are

conducted. Figure 7 show design variables.

Figure 7. design variables

4 2012 SIMULIA Customer Conference

Table 1. analysis result of design variables (at 0.6G load)

Ball distance Knuckle thickness Hub plate thickness Deflection angle

present present present 1.0

present + 2mm present present 0.959

present present + 1.5mm present 0.957

present present present - 2mm 1.045

Table 1 shows that ball distance, knuckle thickness and hub plate thickness play an important role

in the axle system stiffness.

4. Full suspension system stiffness

4.1 Test and analysis of the full suspension system stiffness

Figure 8, 9 show SPMD(suspension parameter measuring device) and the full FE model of the

suspension system including BIW and flexible tire FE model.

Figure 8. SPMD (suspension parameter measuring device)

Figure 9. full FE model of the suspension system

2012 SIMULIA Customer Conference 5

Table 2 shows the test and analysis result of the full suspension system stiffness. Compared to the

test data, the analysis result has good accuracy.

Table 2. Test and analysis result of the full suspension system stiffness

Aiding direction Opposing direction

Vehicle-B Test 1.0 1.0

Analysis 1.022 1.023

Vehicle-C Test 1.0 1.0

Analysis 0.969 0.974

Vehicle-E Test 1.0 1.0

Analysis 0.984 1.028

4.2 Lateral stiffness contribution of the full suspension system stiffness

Using vehicle-F, G model, the lateral stiffness contribution simulations of the suspension design

parameters are conducted. The contribution is the increase rate of the lateral stiffness when

components are substituted with rigid elements and bushes are substituted with ball joints. Figure

10 shows that lower/upper arm bushes and hub&bearing play a role in the lateral stiffness.

(a) vehicle-F (b) vehicle-G

Figure 10. An example of the lateral stiffness contribution in a RR suspension system

5. Conclusion

This paper shows that the lateral stiffness analysis result of vehicle suspension can be improved

with the accurate bearing stiffness model correlated with experimental test data and also, shows

which design parameters contribute to lateral stiffness of vehicle suspension.

6 2012 SIMULIA Customer Conference

6. References

1. Steven J. Weber, “Eliminating Caliper Piston Knock Back In High Performance Vehicles”,

SAE, 2006-01-3197.

2. Gianini C., “Formula One Car Wheel Bearings: an FE Approach”, ACC 2007

2012 SIMULIA Customer Conference 7

Potrebbero piacerti anche

- Simulation and Test Correlation of Wheel Impact TestDocumento8 pagineSimulation and Test Correlation of Wheel Impact Testesmaeel ghafariNessuna valutazione finora

- TRDTGRDGDocumento8 pagineTRDTGRDGNguyễn Văn ThườngNessuna valutazione finora

- Bushing Connector Application in Suspension ModelingDocumento10 pagineBushing Connector Application in Suspension ModelingAvinashRaiNessuna valutazione finora

- Stability Improvement of An ATV by Modifying Suspension ParametersDocumento5 pagineStability Improvement of An ATV by Modifying Suspension ParametersAndhdNessuna valutazione finora

- Application of Impact Analysis For Aluminum Wheel With Inflated Tire - (S. Ishikawa, Y. Sakai, N. Nosaka)Documento12 pagineApplication of Impact Analysis For Aluminum Wheel With Inflated Tire - (S. Ishikawa, Y. Sakai, N. Nosaka)pezz07Nessuna valutazione finora

- Book - Gears - IndiaDocumento12 pagineBook - Gears - IndiadesetekNessuna valutazione finora

- Analysis For Suspension Hardpoint of Formula SAE Car Based On Correlation TheoryDocumento6 pagineAnalysis For Suspension Hardpoint of Formula SAE Car Based On Correlation TheoryAJHAY BABU J KNessuna valutazione finora

- Constant Velocity Steering Joint (CSJ) : Kenta YAMAZAKIDocumento4 pagineConstant Velocity Steering Joint (CSJ) : Kenta YAMAZAKIerkushagraNessuna valutazione finora

- Y4592 PDFDocumento4 pagineY4592 PDFPrathamesh PatikNessuna valutazione finora

- Fatigue Analysis of An Automotive Stabilizer BarDocumento4 pagineFatigue Analysis of An Automotive Stabilizer BarAbhay KhotNessuna valutazione finora

- Baja Sae Design ReportDocumento14 pagineBaja Sae Design Reportlucky_agrawal45Nessuna valutazione finora

- Design of Formula SAE Suspension ComponentsDocumento13 pagineDesign of Formula SAE Suspension ComponentsYasser Rohom0% (1)

- Optimal Design of A Wheelchair Suspension Based On A Compliant MechanismDocumento5 pagineOptimal Design of A Wheelchair Suspension Based On A Compliant MechanismMikyas BelayNessuna valutazione finora

- Indiana UniversityDocumento64 pagineIndiana Universitymdasifkhan2013Nessuna valutazione finora

- Application of CAE To Aluminum Wheel Impact Test Analysis Using Dynamic ImplicitDocumento9 pagineApplication of CAE To Aluminum Wheel Impact Test Analysis Using Dynamic ImplicitCarlos EduardoNessuna valutazione finora

- Fsae Design Suspension Components PDFDocumento13 pagineFsae Design Suspension Components PDFKingsley AyascaNessuna valutazione finora

- Bisht-Awasthi2021 Chapter AnalysisOfE-GlassFiberWheelRimDocumento13 pagineBisht-Awasthi2021 Chapter AnalysisOfE-GlassFiberWheelRimLtat KøükøüNessuna valutazione finora

- Fatigue Strength Analysis On The Automobile Stabilizer BarDocumento5 pagineFatigue Strength Analysis On The Automobile Stabilizer BarSantiago UrgilesNessuna valutazione finora

- Calculation of The Tooth Root Load Carrying Capacity of Beveloid GearsDocumento10 pagineCalculation of The Tooth Root Load Carrying Capacity of Beveloid GearsdineshkshirsagarNessuna valutazione finora

- Design Optimization of Automotive Engine Mount System: July 2020Documento7 pagineDesign Optimization of Automotive Engine Mount System: July 2020dandavatevvNessuna valutazione finora

- Du Canyi, Zhu Baochai, Wang Hengbo, Mai Xingye and Qin TaixingDocumento6 pagineDu Canyi, Zhu Baochai, Wang Hengbo, Mai Xingye and Qin TaixingMaxime MARIOTTINessuna valutazione finora

- Suspension AnalysisDocumento11 pagineSuspension Analysisanmol6237Nessuna valutazione finora

- SAE Mini BAJA: Suspension and Steering: Project ProgressDocumento22 pagineSAE Mini BAJA: Suspension and Steering: Project ProgressVitoria ColliNessuna valutazione finora

- Chapter 8 RevaDocumento20 pagineChapter 8 RevaanildhakeNessuna valutazione finora

- Influence of Gear Geometry On Gearbox Noise Reduction - An Experimental InvestigationDocumento7 pagineInfluence of Gear Geometry On Gearbox Noise Reduction - An Experimental InvestigationsamanaveenNessuna valutazione finora

- 06 F2010 Report PDFDocumento14 pagine06 F2010 Report PDFPrabhat TiwariNessuna valutazione finora

- Simulation of Wheel Impact Test Using Nite Element MethodDocumento9 pagineSimulation of Wheel Impact Test Using Nite Element MethodKemal BalabanNessuna valutazione finora

- Effects of Compliance On Vehicle Handling Properties: Society Op Automotive Engineers, IncDocumento10 pagineEffects of Compliance On Vehicle Handling Properties: Society Op Automotive Engineers, IncantoNo1Nessuna valutazione finora

- Ford Develops An Innovative Suspension Design Using AdamsDocumento4 pagineFord Develops An Innovative Suspension Design Using Adamsspamail73887Nessuna valutazione finora

- NAFEMS Auto Unified CAE Analysis For A Leaf Spring TypeDocumento10 pagineNAFEMS Auto Unified CAE Analysis For A Leaf Spring TypeIndranil BhattacharyyaNessuna valutazione finora

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsDa EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNessuna valutazione finora

- Torque SteerDocumento7 pagineTorque SteerAyushNessuna valutazione finora

- Spur Gear Design Learn EngineeringDocumento4 pagineSpur Gear Design Learn EngineeringImran Sajid ShahidNessuna valutazione finora

- P 07400Documento11 pagineP 07400raviprasadrNessuna valutazione finora

- Comparison Lugner-TTI 2009Documento4 pagineComparison Lugner-TTI 2009DougMillikenNessuna valutazione finora

- PROJECT 6thDocumento67 paginePROJECT 6thl kumar saiNessuna valutazione finora

- InfluenceOfBearingAsymmetryOnStability LinkedDocumento28 pagineInfluenceOfBearingAsymmetryOnStability LinkedRotor IntrnlNessuna valutazione finora

- PW 200 Dy 2Documento9 paginePW 200 Dy 2marten_zitNessuna valutazione finora

- Suspension Systems and ComponentsDocumento90 pagineSuspension Systems and Componentsmaheshgarg81100% (2)

- Suspension Paper 5Documento6 pagineSuspension Paper 5Rainier EstradaNessuna valutazione finora

- Study Concerning The Ball Joint Functionality of A Vehicle Steering SystemDocumento6 pagineStudy Concerning The Ball Joint Functionality of A Vehicle Steering SystemnicusorbarNessuna valutazione finora

- Wheel BRG Stiffness CalDocumento8 pagineWheel BRG Stiffness Calmans2014Nessuna valutazione finora

- Methods To Determine Torsional Stiffness in A Semi-Trailer Chassis FrameDocumento9 pagineMethods To Determine Torsional Stiffness in A Semi-Trailer Chassis Frameognen88Nessuna valutazione finora

- Mechanical Testing: Common Modes of Gear FailureDocumento17 pagineMechanical Testing: Common Modes of Gear FailureTheerayootNessuna valutazione finora

- Lva1 App6892Documento9 pagineLva1 App6892ssaassaasssNessuna valutazione finora

- DESIGN AND ANALYSIS OF AL 7075 Steering Knuckle PDFDocumento7 pagineDESIGN AND ANALYSIS OF AL 7075 Steering Knuckle PDFsanjeev105Nessuna valutazione finora

- Design & Fabrication of Rear Outboard Wheel Assembly For An ATVDocumento5 pagineDesign & Fabrication of Rear Outboard Wheel Assembly For An ATVumeshNessuna valutazione finora

- A Novel Gear Test Rig With Adjustable PDFDocumento10 pagineA Novel Gear Test Rig With Adjustable PDFjgjNessuna valutazione finora

- F 2008 SC 005Documento8 pagineF 2008 SC 005kiran_wakchaureNessuna valutazione finora

- A Novel Gear Test Rig With Adjustable Shaft Compliance and Misalignments Part I: DesignDocumento10 pagineA Novel Gear Test Rig With Adjustable Shaft Compliance and Misalignments Part I: DesignjgjNessuna valutazione finora

- Gear Geometry For Reduced and Robust Transmission Error and Gearbox NoiseDocumento21 pagineGear Geometry For Reduced and Robust Transmission Error and Gearbox Noiseranim najibNessuna valutazione finora

- ARB DesignDocumento4 pagineARB Designtamilselvan33Nessuna valutazione finora

- Validation of Torsional Rigidity of Fsae Chassis: Devesh Anand, Anuj Gupta & Jeyanthi SubramanianDocumento8 pagineValidation of Torsional Rigidity of Fsae Chassis: Devesh Anand, Anuj Gupta & Jeyanthi SubramanianTJPRC PublicationsNessuna valutazione finora

- Chevy Differentials: How to Rebuild the 10- and 12-BoltDa EverandChevy Differentials: How to Rebuild the 10- and 12-BoltValutazione: 5 su 5 stelle5/5 (8)

- Performance-Based Gear Metrology: Kinematic - Transmission - Error Computation and DiagnosisDa EverandPerformance-Based Gear Metrology: Kinematic - Transmission - Error Computation and DiagnosisNessuna valutazione finora

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsDa EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsValutazione: 4 su 5 stelle4/5 (1)

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsDa EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNessuna valutazione finora

- 48 WordNet Tulu ShivakumarDocumento7 pagine48 WordNet Tulu ShivakumarAvinashRaiNessuna valutazione finora

- NoodleDocumento52 pagineNoodleAvinashRaiNessuna valutazione finora

- Spring Wind UpDocumento8 pagineSpring Wind UpAvinashRaiNessuna valutazione finora

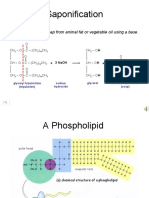

- Saponification: Process of Making Soap From Animal Fat or Vegetable Oil Using A BaseDocumento14 pagineSaponification: Process of Making Soap From Animal Fat or Vegetable Oil Using A BaseAvinashRaiNessuna valutazione finora

- 13 DigestionDocumento21 pagine13 Digestionapi-270511270Nessuna valutazione finora

- FatigueDocumento10 pagineFatigueAvinashRaiNessuna valutazione finora

- Cocoa World Production (2015/2016) : No. Country Production (1000 Ton/year)Documento80 pagineCocoa World Production (2015/2016) : No. Country Production (1000 Ton/year)AvinashRaiNessuna valutazione finora

- CasshewDocumento11 pagineCasshewAvinashRaiNessuna valutazione finora

- BharatanatyamDocumento4 pagineBharatanatyamAvinashRaiNessuna valutazione finora

- Pub Dance KathakDocumento58 paginePub Dance Kathakಜಗದೀಶ್ ಎ ಎಂNessuna valutazione finora

- Pub Dance KathakDocumento58 paginePub Dance Kathakಜಗದೀಶ್ ಎ ಎಂNessuna valutazione finora

- Yoga Is UsedDocumento42 pagineYoga Is UsedAvinashRaiNessuna valutazione finora

- Design and Failure Modes of Automotive Suspension SpringsDocumento20 pagineDesign and Failure Modes of Automotive Suspension SpringsheliselyayNessuna valutazione finora

- Customer ID Why Did You Purchase Hotstar Premium?Documento4 pagineCustomer ID Why Did You Purchase Hotstar Premium?AvinashRaiNessuna valutazione finora

- Vibration Study of A Vehicle Suspension Assembly WDocumento13 pagineVibration Study of A Vehicle Suspension Assembly WAvinashRaiNessuna valutazione finora

- FG IronDocumento23 pagineFG IronAvinashRaiNessuna valutazione finora

- Lateral Dynamics of Multiaxle Vehicles: Johannes StoerkleDocumento87 pagineLateral Dynamics of Multiaxle Vehicles: Johannes StoerkleAvinashRaiNessuna valutazione finora

- Design and Analysis of Independent Suspension System Using FEADocumento7 pagineDesign and Analysis of Independent Suspension System Using FEAAvinashRaiNessuna valutazione finora

- Lateral Dynamics of Multiaxle Vehicles: Johannes StoerkleDocumento87 pagineLateral Dynamics of Multiaxle Vehicles: Johannes StoerkleAvinashRaiNessuna valutazione finora

- AJSE December2009 Lowres PDFDocumento14 pagineAJSE December2009 Lowres PDFAvinashRaiNessuna valutazione finora

- Machine Design Ball Screw Vol 1 e BookDocumento22 pagineMachine Design Ball Screw Vol 1 e Bookविशाल पुडासैनीNessuna valutazione finora

- Is 210Documento16 pagineIs 210Debopriyo GhoshNessuna valutazione finora

- Dynamic Systems and Control: Associate Professor, Department of Engineering DesignDocumento1 paginaDynamic Systems and Control: Associate Professor, Department of Engineering DesignAvinashRaiNessuna valutazione finora

- Machine Design Ball Screw Vol 1 e BookDocumento22 pagineMachine Design Ball Screw Vol 1 e Bookविशाल पुडासैनीNessuna valutazione finora

- About Fifth Wheels: If You Want To Enhance The Efficiency of Your TractorDocumento17 pagineAbout Fifth Wheels: If You Want To Enhance The Efficiency of Your TractorAvinashRaiNessuna valutazione finora

- Bolted 1Documento47 pagineBolted 1Purna ChNessuna valutazione finora

- Absolute PDFDocumento1 paginaAbsolute PDFAvinashRaiNessuna valutazione finora

- Disclosure To Promote The Right To InformationDocumento25 pagineDisclosure To Promote The Right To InformationmggogsNessuna valutazione finora

- Three Wheeled Vehicle Eprintsrvr IIScDocumento30 pagineThree Wheeled Vehicle Eprintsrvr IIScSunilkumar ReddyNessuna valutazione finora

- Adams SolverDocumento138 pagineAdams Solveravegliante9314Nessuna valutazione finora

- Job Card-TPN 1010-B150Documento2 pagineJob Card-TPN 1010-B150Debasis Pattnaik DebaNessuna valutazione finora

- Physics II Problems PDFDocumento1 paginaPhysics II Problems PDFBOSS BOSS0% (1)

- CHS Module 4 - Install Computer Systems and NetworksDocumento72 pagineCHS Module 4 - Install Computer Systems and NetworksLawrence Cada Nofies96% (55)

- HVACDocumento15 pagineHVACariesNessuna valutazione finora

- JTY-GD-2151EIS Photoelectric JTWB-BCD-5151EIS Thermal Intrinsically Safe DetectorsDocumento2 pagineJTY-GD-2151EIS Photoelectric JTWB-BCD-5151EIS Thermal Intrinsically Safe DetectorsDauXuan HuynhNessuna valutazione finora

- L-33 (SM) (Ia&c) ( (Ee) Nptel)Documento18 pagineL-33 (SM) (Ia&c) ( (Ee) Nptel)Marvin BayanayNessuna valutazione finora

- Isuzu D Max Owners Manual Combined 17myDocumento698 pagineIsuzu D Max Owners Manual Combined 17myMauricio GonzalezNessuna valutazione finora

- Lightning and Surge Protection For Wind TurbinesDocumento12 pagineLightning and Surge Protection For Wind TurbinesJFREY1504Nessuna valutazione finora

- Questionnaire FinishedDocumento6 pagineQuestionnaire FinishedTamarah PaulaNessuna valutazione finora

- E7 TiempoDocumento12 pagineE7 TiempoJonatan Arango Gomez67% (3)

- 198508-1985 American Aircraft Falcon XPDocumento4 pagine198508-1985 American Aircraft Falcon XPfabianmeschiniNessuna valutazione finora

- Applications of MicroprocessorsDocumento10 pagineApplications of MicroprocessorsTECHNOLOGY UPDATESNessuna valutazione finora

- Schneider Pendant StationDocumento7 pagineSchneider Pendant StationNesil AbieraNessuna valutazione finora

- Subwoofer For TRIO Comparison03 XDDocumento4 pagineSubwoofer For TRIO Comparison03 XDStefan OtalasNessuna valutazione finora

- Samsung Concealed Heat Pump Ceiling CassetesDocumento3 pagineSamsung Concealed Heat Pump Ceiling Cassetese-ComfortUSANessuna valutazione finora

- IGS-NT 4.3.1 New Features ListDocumento33 pagineIGS-NT 4.3.1 New Features ListJo RoNessuna valutazione finora

- Air Starter Tank Sizing ToolDocumento6 pagineAir Starter Tank Sizing TooltstkupdhNessuna valutazione finora

- Everest EverestDocumento24 pagineEverest Everestabhi24shekNessuna valutazione finora

- LFE Desicant Dryer ManualDocumento12 pagineLFE Desicant Dryer ManualNaveen KumarNessuna valutazione finora

- Electrical Thumb Rules (Part 1)Documento3 pagineElectrical Thumb Rules (Part 1)Manish Tiwari100% (2)

- BDP PDFDocumento28 pagineBDP PDFjanolgo17Nessuna valutazione finora

- DK-26 Instruction Manual (Maintenance) PDFDocumento191 pagineDK-26 Instruction Manual (Maintenance) PDFFernando César Carbone86% (7)

- Watson Marlow 520S SpecificationsDocumento1 paginaWatson Marlow 520S SpecificationsXavier MilkeNessuna valutazione finora

- Panasonic+sa-Akx34ph Akx34pnDocumento126 paginePanasonic+sa-Akx34ph Akx34pnAndres Florentin Pizarro LazarteNessuna valutazione finora

- ME 462: Introduction To MEMS: Spring 2022Documento27 pagineME 462: Introduction To MEMS: Spring 2022eren onatNessuna valutazione finora

- Streetstar Brp215: Brp215 Led23/Nw 18W 220-240V Dw3 Mp1Documento2 pagineStreetstar Brp215: Brp215 Led23/Nw 18W 220-240V Dw3 Mp1Dewi SaraswatiNessuna valutazione finora

- 4 Botai Lighting Price ListDocumento33 pagine4 Botai Lighting Price ListImas MasripahNessuna valutazione finora

- Cof - Ree Ma P3 Me.m 090 11 PDFDocumento4 pagineCof - Ree Ma P3 Me.m 090 11 PDFvanbinhchNessuna valutazione finora

- Book 1Documento6 pagineBook 1nandini agrawalNessuna valutazione finora

- Question Paper Code:: Reg. No.Documento2 pagineQuestion Paper Code:: Reg. No.bala muruganNessuna valutazione finora