Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Full Cone Nozzle Spec Sheet

Caricato da

David Fernando Tirado ArizaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Full Cone Nozzle Spec Sheet

Caricato da

David Fernando Tirado ArizaCopyright:

Formati disponibili

WL

FULL CONE

Low Flow/Full Cone

DESIGN FEATURES SPRAY CHARACTERISTICS

• Advanced whirl plate design produces • Medium to coarse atomization

extremely uniform coverage Spray pattern: Full Cone. Square

• Male and female connections pattern available

Spray angles: 30°, 60°, 90°,

and 120° standard

Flow rates: 0.497 to 192 l/min

Metal

Full Cone 90° Full Cone 120° Female Metal Male Metal

Dimensions are approximate. Check with BETE for critical dimension applications.

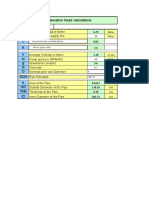

WL Flow Rates and Dimensions

Full Cone, 30°, 60°, 90° and 120° Spray Angles, BSP or NPT

Male or LITERS PER MINUTE @ BAR Approx. Dimensions for

Female

Pipe Nozzle K 0.7 1 2 3 5 10 15 20 Orifice Metal Only (mm) Wt. (g)

Size Number Factor bar bar bar bar bar bar bar bar Dia. (mm) A B C D Metal Plas.

WL 1/4 0.587 0.497 0.587 0.814 0.984 1.25 1.73 2.10 2.40 1.09

1/8 WL 1/2 1.17 0.993 1.17 1.63 1.97 2.50 3.47 4.19 4.80 1.40 22.2 28.6 11.1 14.3 28.4 7.1

WL 3/4 1.76 1.49 1.76 2.44 2.95 3.75 5.20 6.29 7.20 1.83

WL 1 2.35 1.99 2.35 3.25 3.94 5.01 6.93 8.39 9.60 2.08

1/4 27.0 34.9 14.2 17.5 42.5 10.6

WL 1 1/2 3.52 2.98 3.52 4.88 5.91 7.51 10.4 12.6 14.4 2.77

TO ORDER: specify pipe size, connection type, nozzle

WL 2 4.70 3.97 4.70 6.51 7.87 10.0 13.9 16.8 19.2 3.18

3/8 WL 3 7.05 5.96 7.05 9.76 11.8 15.0 20.8 25.2 28.8 3.96 31.8 38.1 17.5 22.2 56.7 14.2

WL 4 9.40 7.95 9.40 13.0 15.7 20.0 27.7 33.6 38.4 4.78

number, spray angle, and material.

WL 5 11.7 9.93 11.7 16.3 19.7 25.0 34.7 41.9 48.0 5.16

1/2 WL 6 14.1 11.9 14.1 19.5 23.6 30.0 41.6 50.3 57.6 5.56 38.1 50.8 22.2 28.6 85.1 28.4

WL 7 16.4 13.9 16.4 22.8 27.6 35.0 48.5 58.7 67.2 5.79

WL 8 18.8 15.9 18.8 26.0 31.5 40.0 55.5 67.1 76.8 5.94

3/4 WL 10 23.5 19.9 23.5 32.5 39.4 50.1 69.3 83.9 96.0 7.14 44.5 54.0 28.6 34.9 170 42.5

WL 12 28.2 23.8 28.2 39.0 47.2 60.1 83.2 101 115 7.92

WL 15 35.2 29.8 35.2 48.8 59.1 75.1 104 126 144 8.33

1 55.6 60.3 34.9 41.3 397 99.2

WL 20 47.0 39.7 47.0 65.1 78.7 100 139 168 192 9.53

Flow Rate ( l⁄min ) = K ( bar ) 0.47

Standard Materials: Brass, 303 Stainless Steel, 316 Stainless Steel, PVC, Polypropylene, and PTFE (1/8" PTFE and

Polypropylene not available in 120°).

Spray angle performance varies with pressure. Contact BETE for specific data on critical applications.

24 www.BETE.com

Potrebbero piacerti anche

- BETE WL-metricDocumento1 paginaBETE WL-metriccpvwqthcghoNessuna valutazione finora

- Low Flow Full Cone NozzlesDocumento1 paginaLow Flow Full Cone NozzlesDaniel RestrepoNessuna valutazione finora

- NF Flat Fan Pattern NozzleDocumento1 paginaNF Flat Fan Pattern NozzlehendrobamaNessuna valutazione finora

- BETE NF-metricDocumento1 paginaBETE NF-metricRavi Chaitanya VelamarthyNessuna valutazione finora

- Bete NDocumento1 paginaBete NRaúl PalomoNessuna valutazione finora

- BETE_NDocumento1 paginaBETE_NDenaibeliNessuna valutazione finora

- Superman PDFDocumento2 pagineSuperman PDFlehuyNessuna valutazione finora

- ANSI B16.5 Class 300 Welding Neck FlangesDocumento2 pagineANSI B16.5 Class 300 Welding Neck FlangeslehuyNessuna valutazione finora

- Extended Life Hollow Cone NozzlesDocumento2 pagineExtended Life Hollow Cone NozzlesAlfian JunaidiNessuna valutazione finora

- ANSI B16.5 Flange CatalogueDocumento14 pagineANSI B16.5 Flange Catalogue김명래Nessuna valutazione finora

- Wheatland ASTM A 53 Schedule 40 Pipe SpecsDocumento1 paginaWheatland ASTM A 53 Schedule 40 Pipe SpecsKelvin RojasNessuna valutazione finora

- Ball Valve - VictaulicDocumento4 pagineBall Valve - VictaulicMF CHOONGNessuna valutazione finora

- Bete NFDocumento1 paginaBete NFRavi Chaitanya VelamarthyNessuna valutazione finora

- Roofdek D32S: Ultimate Section Properties To EurocodeDocumento1 paginaRoofdek D32S: Ultimate Section Properties To EurocodeVolodymyr ShchurNessuna valutazione finora

- 11 - OrificeDocumento7 pagine11 - OrificeANDERSON NERESNessuna valutazione finora

- Standard Pipe Schedule 40 ASTM A 53 Grades A and BDocumento2 pagineStandard Pipe Schedule 40 ASTM A 53 Grades A and Btarek eidNessuna valutazione finora

- Standard Pipe Schedule 40 ASTM A 53 Grades A and BDocumento2 pagineStandard Pipe Schedule 40 ASTM A 53 Grades A and BAngel PintoNessuna valutazione finora

- Booms With A Strong Profile: Inboard EndDocumento2 pagineBooms With A Strong Profile: Inboard EndJoe SeraphinNessuna valutazione finora

- Bete NFDocumento1 paginaBete NFNicolás Garay GutiérrezNessuna valutazione finora

- Boquilla Bete - Modelo Sc.... 1Documento2 pagineBoquilla Bete - Modelo Sc.... 1FransSanchezReyesNessuna valutazione finora

- 2002 07 02 Duct Design Proforma ED1Documento3 pagine2002 07 02 Duct Design Proforma ED1Mohammed HaniNessuna valutazione finora

- AC Fans Static Calculation Final-1Documento20 pagineAC Fans Static Calculation Final-1Hendrias A.SNessuna valutazione finora

- Bete - MaxiPassDocumento2 pagineBete - MaxiPassdrewtwitchNessuna valutazione finora

- Hammer Lug Union SpecificationDocumento16 pagineHammer Lug Union Specificationashved505100% (1)

- FILLET WELD SOLUTIONSDocumento2 pagineFILLET WELD SOLUTIONSAli QureshiNessuna valutazione finora

- 7 - LWNDocumento8 pagine7 - LWNANDERSON NERESNessuna valutazione finora

- Pages From CatelogDocumento21 paginePages From CatelogMoAmen AtlamNessuna valutazione finora

- ANSI ASME B16.5 forged flange dimensionsDocumento8 pagineANSI ASME B16.5 forged flange dimensionsEdgar PereiraNessuna valutazione finora

- STEEL PIPE SPECIFICATIONS AND PRESSURE RATINGSDocumento5 pagineSTEEL PIPE SPECIFICATIONS AND PRESSURE RATINGSNéstor Ramírez PeñalozaNessuna valutazione finora

- FT Eslabon Maestro A342Documento1 paginaFT Eslabon Maestro A342fernando.solarNessuna valutazione finora

- MS Seamless Pipe ASTM A106Documento3 pagineMS Seamless Pipe ASTM A106imtz20130% (1)

- V-Cone Ficha TécnicaDocumento2 pagineV-Cone Ficha TécnicaIrving Uc Fernandez100% (1)

- 600/1000 V Xlpe Insulated and PVC Sheathed Cu / Xlpe / PVC (N2Xy) SNI IEC 60502-1: 2009 / IEC 60502-1Documento4 pagine600/1000 V Xlpe Insulated and PVC Sheathed Cu / Xlpe / PVC (N2Xy) SNI IEC 60502-1: 2009 / IEC 60502-1Rahmawan fiberhomeNessuna valutazione finora

- VBW12121 - 300PSI Wafer Butterfly ValveDocumento1 paginaVBW12121 - 300PSI Wafer Butterfly ValveErickNessuna valutazione finora

- Flange Weight ChartDocumento1 paginaFlange Weight Chartabhishek198327Nessuna valutazione finora

- ANSI Flange DimensnioDocumento3 pagineANSI Flange Dimensniohon choong chongNessuna valutazione finora

- Norma Ansib16.5 Clase 150 para Flanges WNDocumento2 pagineNorma Ansib16.5 Clase 150 para Flanges WNmaicon metalNessuna valutazione finora

- K-511-V, FLW SWTDocumento2 pagineK-511-V, FLW SWTamir shokrNessuna valutazione finora

- Maximum Free Passage: Wide Angle MetalDocumento1 paginaMaximum Free Passage: Wide Angle MetalAlfonso BlancoNessuna valutazione finora

- Flanges: ANSI/AWWA C115/A21.15Documento4 pagineFlanges: ANSI/AWWA C115/A21.15JAvier DelgadoNessuna valutazione finora

- SHOABA PROJECT DUCT PRESSURE DROP ANALYSISDocumento6 pagineSHOABA PROJECT DUCT PRESSURE DROP ANALYSISmohamedNessuna valutazione finora

- Data Sheet 29 - Fig Tc704 Conical (Witches Hat) StrainerDocumento1 paginaData Sheet 29 - Fig Tc704 Conical (Witches Hat) StrainerAnonymous 0OizFXUONessuna valutazione finora

- 2wt Arita Ci Bfly VLV Uni Flanged MalaysiaDocumento2 pagine2wt Arita Ci Bfly VLV Uni Flanged MalaysiaannaomarNessuna valutazione finora

- Long Weld NecksDocumento7 pagineLong Weld NecksEDEN GONZALEZNessuna valutazione finora

- N2XCY 1 X (1.5-800) MM 0.6/1 KVDocumento5 pagineN2XCY 1 X (1.5-800) MM 0.6/1 KVCombox BlackNessuna valutazione finora

- Ss Pipe Tube Schedule Pipes WeighDocumento2 pagineSs Pipe Tube Schedule Pipes WeighHimTex GlobalNessuna valutazione finora

- Electrical Brochure 201928Documento5 pagineElectrical Brochure 201928Karloff AutencioNessuna valutazione finora

- Lap Joint Stub End PDFDocumento2 pagineLap Joint Stub End PDFBowo Edhi WibowoNessuna valutazione finora

- MW Microwhirl Misting NozzleDocumento1 paginaMW Microwhirl Misting NozzleblondtumbalaNessuna valutazione finora

- Building DesignDocumento8 pagineBuilding Designshreejay maneNessuna valutazione finora

- Three Four Leg Chain SlingDocumento5 pagineThree Four Leg Chain SlingchristopherNessuna valutazione finora

- Class 600 Flanges: Ansi B 16.5 Forged FlangesDocumento1 paginaClass 600 Flanges: Ansi B 16.5 Forged FlangesPascual Jimenez aNessuna valutazione finora

- 5-Acceleration Head Calculation SheetDocumento2 pagine5-Acceleration Head Calculation SheetAhmed Ayman0% (1)

- Butterfly Valve DatasheetDocumento2 pagineButterfly Valve DatasheetKanthan DevanNessuna valutazione finora

- 501-453 Universal Cable GalndsDocumento1 pagina501-453 Universal Cable Galndsmeribout adelNessuna valutazione finora

- CANAN Steel Deck Catalogue - 2023Documento48 pagineCANAN Steel Deck Catalogue - 2023Clarice Lispector100% (1)

- ASTC RailingDocumento44 pagineASTC RailingSAGAR BARAVKARNessuna valutazione finora

- ANSI Orifice FlangesDocumento5 pagineANSI Orifice FlangesSefri SusantoNessuna valutazione finora

- Drilling Fluids Processing HandbookDa EverandDrilling Fluids Processing HandbookValutazione: 4.5 su 5 stelle4.5/5 (4)

- Porter's Five Forces TemplateDocumento3 paginePorter's Five Forces TemplateDavid Fernando Tirado ArizaNessuna valutazione finora

- Boquillas BETE - TF PDFDocumento2 pagineBoquillas BETE - TF PDFDavid Fernando Tirado ArizaNessuna valutazione finora

- NEW GENERATION NOZZLESDocumento2 pagineNEW GENERATION NOZZLESDavid Fernando Tirado ArizaNessuna valutazione finora

- Amberlite BD10DRY DatasheetDocumento1 paginaAmberlite BD10DRY DatasheetDavid Fernando Tirado ArizaNessuna valutazione finora

- McDonalds Marketing StrategyDocumento65 pagineMcDonalds Marketing StrategyMohamed Zahid محمد زاهد100% (2)

- Deterioration Fo Cane Juice - Sources and IndicatorsDocumento9 pagineDeterioration Fo Cane Juice - Sources and IndicatorsDavid Fernando Tirado ArizaNessuna valutazione finora

- Material Safety Data Sheet Konkreton XSDocumento9 pagineMaterial Safety Data Sheet Konkreton XSDaniel DaiaNessuna valutazione finora

- Air Pollution: by Bibhabasu MohantyDocumento54 pagineAir Pollution: by Bibhabasu MohantyJaned PerwiraNessuna valutazione finora

- Nursery Production GuideDocumento150 pagineNursery Production GuideArmin AdemovicNessuna valutazione finora

- 1 MergedDocumento8 pagine1 MergedNo NameNessuna valutazione finora

- BlowersDocumento65 pagineBlowersmartin.rubenNessuna valutazione finora

- Indowud Brochure Revised PDFDocumento10 pagineIndowud Brochure Revised PDFsurabhi narangNessuna valutazione finora

- 1584Documento6 pagine1584malsttarNessuna valutazione finora

- Composite MaterialsDocumento399 pagineComposite MaterialsCharlton S.Inao100% (1)

- WoW Gold Guide v2Documento20 pagineWoW Gold Guide v2ZontirNessuna valutazione finora

- Indian Oil's Petrochemical Initiatives at Paradip & Downstream OpportunitiesDocumento26 pagineIndian Oil's Petrochemical Initiatives at Paradip & Downstream Opportunitiesabhishek chowdhuryNessuna valutazione finora

- Final PG Sby 0024Documento3 pagineFinal PG Sby 0024Afwa Wildan RomadhonNessuna valutazione finora

- Final Product 7 Learning Cycles - 6th Grade MatterDocumento46 pagineFinal Product 7 Learning Cycles - 6th Grade Matterapi-310725472Nessuna valutazione finora

- Safety Data Sheet: Pt. Musim MasDocumento6 pagineSafety Data Sheet: Pt. Musim MasAydilover AydinousNessuna valutazione finora

- Importance of biochemistry for nursing studentsDocumento2 pagineImportance of biochemistry for nursing studentsKathrina CraveNessuna valutazione finora

- D 5117 - 96 - Rduxmtctukve PDFDocumento4 pagineD 5117 - 96 - Rduxmtctukve PDFchabibNessuna valutazione finora

- Maintain Your BRH 501 Demolition HammerDocumento46 pagineMaintain Your BRH 501 Demolition HammerRomán Arturo Guerrero Uc100% (3)

- Service Valve: With ISO-fitting For PE Pipe Both Ends No. 2600Documento2 pagineService Valve: With ISO-fitting For PE Pipe Both Ends No. 2600Wonmin JeongNessuna valutazione finora

- Experiment 4 (Hydrates)Documento3 pagineExperiment 4 (Hydrates)Zaharahni Md SehatNessuna valutazione finora

- Turning Wood Into Green BioproductsDocumento2 pagineTurning Wood Into Green BioproductsSam MurrayNessuna valutazione finora

- Advantage and Disadvantage of Using Nanoparticles in AgricultureDocumento13 pagineAdvantage and Disadvantage of Using Nanoparticles in AgricultureAmjadRashidNessuna valutazione finora

- Chemistry Lecture Planner - Prayas 2022 - Complete Lecture Planner - Early Dropper Batch JEE - Chemistry PlannerDocumento2 pagineChemistry Lecture Planner - Prayas 2022 - Complete Lecture Planner - Early Dropper Batch JEE - Chemistry PlannerPradeep Yadav100% (1)

- Datasheet PLASBLAK PE4637pdfDocumento2 pagineDatasheet PLASBLAK PE4637pdfGodesPow. Jose L. Godes: Entrenamiento con potenciaNessuna valutazione finora

- Clavijas y Recept HubellDocumento40 pagineClavijas y Recept HubellArturo Pérez LohmanNessuna valutazione finora

- Dust Collection ChecklistDocumento4 pagineDust Collection ChecklistbroedenNessuna valutazione finora

- LCP SpanlockDocumento8 pagineLCP SpanlockGarfieldNessuna valutazione finora

- Biology For QLD An Aust Perp 3E Units1!2!9780190310219 Sample Chapter 3 Low Res SecureDocumento38 pagineBiology For QLD An Aust Perp 3E Units1!2!9780190310219 Sample Chapter 3 Low Res SecureRocil Clyde LumbayNessuna valutazione finora

- 1.2.7 Aromatic Stripper - 4 PDFDocumento14 pagine1.2.7 Aromatic Stripper - 4 PDFMohamad IbrahimNessuna valutazione finora

- CH 13Documento69 pagineCH 13pwmvsi100% (2)

- Test 1 Biology F4Documento12 pagineTest 1 Biology F4Nurfatin JamaludinNessuna valutazione finora

- Objectives Identify The Two Main Classes of Vitamins. List Seven Minerals Your Body Needs inDocumento28 pagineObjectives Identify The Two Main Classes of Vitamins. List Seven Minerals Your Body Needs inyosysilalahiNessuna valutazione finora