Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Qatro Manual RP Sobreintensidad Ge (Sin Fecha)

Caricato da

Héctor DiazDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Qatro Manual RP Sobreintensidad Ge (Sin Fecha)

Caricato da

Héctor DiazCopyright:

Formati disponibili

QATRO - BASE DE DATOS - TÉCNICA EXTERNA 1 DE 16

INSTRUCTIONS GEH-1753J

TIME-OVERCURRENT RELA YS

TYPES

IAC51A IAC52A

IAC51B IAC52 B

IAC51R

GENERAL _ ELECTRIC

QATRO BD-TE-T&F-GE-AT-C-002 (sin fecha)

QATRO - BASE DE DATOS - TÉCNICA EXTERNA 2 DE 16

GEH-1753 Time Overcurrent Relays Type IAe

TOP PIVOT _ _ _ _ _ _ _ _~ . ; - - - - - TAP

BLOCK

TAPPLUG ------~~¡f~~..~~~~?-~----~~~;=:

SEAL-IN UNIT

HOLDING COIL

'----"_ _.....-!!!!!~"*I_TIME DIAL

SEAL-IN

TARGET-------~~

SEAL-IN UNir

STATIONARY

CONTACT, LEFT

SEAL -IN UNIT

STATlONARY

CONTACT, RIGHT

SEAL-IN

MOVING

CONTACT

ASSEMBLY-- - DISK

DRAG

~-#-MAGNET

A - (8006996) Front View

DISK

ANO

SHAFT

LDWER

JEWEL SCREW-

~~~~:: ........ ~~""""-

B - (8006997) Rear Vie,"

Figure 1. The 1nduction lnit for Type lAG Relayso

QATRO BD-TE-T&F-GE-AT-C-002 (sin fecha)

QATRO - BASE DE DATOS - TÉCNICA EXTERNA 3 DE 16

TIME-OVERCURRENT RELAYS

TYPE IAC

INTRODUCTION

Contact Instantaneous AC Trip Induction Outline & Internal

Type Circuits Unit Unit Unit Panel Drilling Connection

IAC51A(-)A One Na No Qne Fig. 18 Fig. 11

IAC51B(- )A Qne Yes No Qne Fig. 18 Fig. 12

IAC51R(- )A Qne Yes Yes Qne Fig. 18 Fig. 13

IAC52A(-)A Two No No Qne Fig. 18 Fig. 14

IAC52B(- )A Two Yes No Qne Fig. 18 Fig. 15

The Type IAC relays comprise a group of relays permits instantaneous tripping for extremely high

that are employed to protect against overcurrent on currents, or an induction unit with an a-c tripping

single-phase and polyphase circuits. The various unit for use where d-c power is unavailable or a-c

relays in this IAC group are identified by model tripping is preferred. Since practically aH IAC

numbers, and the relays differ in the number of relays are composed of various combinations of the

circuits they close, the length of time delay and aboye - that is, the induction unit, the instantaneous

features that are determined by the characteristics unit and the a-c tripping unit - they are for con-

of the protected circuito venience, described separately in the following text.

The aboye table indicates the units comprising each

These relays consist of an induction unit or an type and also lists the internal connections and out-

induction unit with an instantaneous unit which Une and panel drilling diagrams.

INDUCTION UNIT

INTRODUCTION APPLICATIO N

The induction unit is the máin unit in all IAC

The induction unit is the basic unit in aH IAC relays, supplying the inverse time delay character-

relays. Fig. 1 shows the induction unit mounted in istics of the relay and sounding an alarm or tripping

the cradle. These units are of the induction-disk the breakers for overload currents which cause it

construction type. The disk is actuated by a current to close its contacts.

operating coil on a laminated U-magneto The disk

shaft carries the moving contact which completes OPERATING CHARACTERISTICS

the alarm or trip circuit when it touches the station-

ary contact or contacts. The disk shaft is restrained The induction unit may have one or two circuit-

by a spiral spring to give the proper contact-closing closing contacts which close as the current increases

current and its motion is retarded by a permanent to the pick-up value as set on the tap block. The

magnet acting on the disk to give the correct tilne time delay in closing the contacts is determined by

delay. the setting of the time dial (Fig. 1). The time-current

characteristics are shown in Fig. 2.

There is a seal-in unit mounted on the front

to the left of the shaft. This unit has its coil in

series and its contacts in parallel with the main RATINGS

contacts such that when the main contacts close the The induction element is designed to use any

seal-in unit picks up and seals in. When the one of three operating coils, each having a different

seal-in unit picks up, it raises a target into view combination of taps as follows: 4, 5~ 6, 8, 10, 12

which ratches up and rernains exposed until released and 16 amperes; 1.5, 2.0, 2.5, 3.0, 4.0, 5.0 and 6.0

by pressing a button beneath the lower left corner amperes; 0.5, 0.6, 0.8, 1.0, 1.2, 1.5 and 2.0 am-

of the cover. peres.

Tilese instructians do nat purpart ta caver all details ar variatians in equipment nar ta pravide far

every possihle contingency to be met in cannectian with installatian, aperatian ar maintenance. Shauld

furtlJer informatian he desired ar shauld particular prablems arise which are not cave red sufficiently far

the purchaser's purposes, the matter shauld be referred ta the General Electric Company.

Tu the extent required the products described herein meet applicable ANSI, IEEE' and NEMA standards;

but JlO SclC!J assurance is gi ven wi th respect ta local codes and ardinances because they vary greatly.

QATRO BD-TE-T&F-GE-AT-C-002 (sin fecha)

QATRO - BASE DE DATOS - TÉCNICA EXTERNA 4 DE 16

GEH-1753 Time Overcurrent Relays Type lAC

20

10

~

1\ \

S

7

• \\1\.

\\. I\.'\.

I

1\, 1\.'\ l"'-.

~ 11

\\ 1\.'-, _"'-. :"-

'\ '\ '\ "-

Z

o

~

!Il

4

3

\.

,

\ '\. '\ 1\. "-

"'-. '\

'" "-"- ."

"" 1'-..

2;í \ ~ 1"'- "-

r-- .......

1'-.. i" f'... 1'--.

~ r--~ l'----

\. "-1"- r-- .....

i' f'...

2 "- '"f'-.

~ r-.::

........

\ "- f'- ['-,1'-

f'.... 1'--1'- r-- t-

r-...... r-

1-", 10 f--

l" ............. r-

~ 1"t'- f'-. 1'-- 1'1'-

~ r-.

r-...... r- t"'-t-- 9

r-.. t- 1-

r- r- I'-t"'- 8

f" I"-r--. 1'--1' t--. r-..

1

.S

"'\. "- r--- -...... 7

r::--, " r- f--

f--

.S

......

1"-

1'-.

~"

--- t"'-t-- I~ rn f--

f--

-

.1

.1 "- ¡-..... ..............

--- 1"- 1"-4

IV CJI

.-

e f--

I\. 1'-

.11

1- "- '" l"

.............

--.

1'---"

r-

3 Q)

1--

f--

.4

" "- r-- r- 1....... (I) f--

1--

.3

....... 1-,.... 1"-2 - 1--

.2

r--",

r---. r- ---- -- r-- r- r-r-

I

O

e

.- 1--

1--

r--- t-- r--

Q)

.-t-E f--

~

r-I"-

.1

JII

.DI

.07

.01

.05

.04

.03

.02

.01

.5 .1 .1 .8 .8 1 2 3 4 11 • 1 • • 10 20 30 40 50 80 7080 DO!

MULTlPLES OF RELAY TAP SETTING

Fig.2. (088880269 [3) Time-current Curves of Type lAC Relays with lnverse-time Characteristics

QATRO BD-TE-T&F-GE-AT-C-002 (sin fecha)

QATRO - BASE DE DATOS - TÉCNICA EXTERNA 5 DE 16

Time Overcurrent Relays Type YAC GEH-1753

The current-closing rating of the contacts is BURDENS

30 amperes for voltages not exceeding 250 volts.

The current-carrying ratings are affected by the Burdens for the standard coils are given in the

selection of the tap on the target and seal-in coil following tableo These are calculated burdens at

as indicated in the following table: five amperes based on burden of minimum tapo

DUAL RATED Volt-ampere burdens for the lowest tap on any

0.2/2.0 0.6/2.0 of the three coils can be determined for any value

of current, up to 20 times tap setting, from Fig. 3.

0.2 2.0 0.6 2.0

Carry 30 amps for (sec) 0.05 2.2 0.5 3.5

Coi! Volt- Imp.

Carry 10 amps for (sec) 0.45 20 5.0 30

Amperes Freq. Tap

Amps Ohms

PF

Carry continuous1y (amp) 0.37 2.3 1.2 2.6

Minimum operating (amp) 0.2 2.0 0.6 2.0

Minimum dropout (amp) 0.05 0.5 0.15 0.5 4-16 60 4.0 8.8 0.35 0.29

DC resistance (ohms) 8.3 0.24 0.78 0.18 50 4.0 8.0 0.32 0.31

60 hertz impedance (oh'TIs) 50 0.65 6.2 0.65 25 4.0 7.5 0.30 0.36

50 hertz impedance (ohms) 42 0.54 5.1 0.54

1.5-6.0 60 1.5 59.0 2.36 0.26

If the tripping current exceeds 30 amperes, an 50 1.5 52.0 2.08 0.28

auxiliar y relay should be used, the connections being 25 1.5 48.0 1.92 0.34

such that the tripping current does not pass through 0.5-2.0 60 0.5 530.0 21.2 0.26

the contacts or the target and seal-in coils of the 50 0.5 470.0 18.8 0.28

protective relay. 25 0.5 430.0 17.2 0.34

48

45 I

/ TAP

RANGE

4. / .5-2.0

J9

/

}ti ,

/ 60

.....

JJ -- /

/ / 'i '" 50

30 / /' /'

~

o V / V

l 27

T

A

24 I V ~/L

"

E

~V/V

21

V

18

¿ /

15

/;V ./

25"'] RANGE

,-

HP

12 I~ L

V 60~ 1. 5-6. o

V f-;::: ~ ::-- 50", ANPS.

9 11 V ~

::::::::: ~ ~

~ ::::- ] TAP

ti

J ~~

~

---::::: """"'" 60"'jRANGE

25", 4-16

50ft .• NPS.

o ~

o 4 ti B 10 12 14 16 lB 20

MULTIPLES OF MINIMUM TAP SETIING

SATURATION CuRVES AT VARIOUS FREQUENCIES

FOR 3 TAP RAHGES OF THE TYPE IAeS1A RELAY

LOWEST TAP USEO IN AlL CASES

Fig. 3. (K-6306891-1) Saturation Curves for Lowest laps ',f the Induction Unit

of Type lAC Relays \oJith Inverse-time C:haractcrislics.

QATRO BD-TE-T&F-GE-AT-C-002 (sin fecha)

QATRO - BASE DE DATOS - TÉCNICA EXTERNA 6 DE 16

GEH-1753 Time Overcurrent Relays Type IAC

I"J~rRIP

BUS

W

ll::2 ll=l

DEVICE FUNCTION NUMBERS FOR USE 28

lli

52

t t

WITH ALL EXTERNAL DIAGRAMS

L

#

ll.::l

50 Instantaneous Unit

I-J

51 Overcurrent, Relay, Type IAC

51N - Ground Overcurrent Relay, Type lAC

52 Power Circuit Breaker

SI Seal-in Unit, with Target

Fig. 4 (K-6375667-2) External Connections aE Three

TC Trip CoU Type IAC5lA Relays used Eor Phase-to-Phase and

Ground Overcurrent Partectian oE a 3-Phase Circuito

A Auxiliary contact, closed when breaker

closes.

A-C Bus

A-e BUS

1

.li

!

d ~ ~+~

¡ ¡

" rRIPPI~G .~

M.l I

t- ~ ~ -~ }l::1..

~ACTOR-

l

;

-L

-=- ~ t;T 1 1

Fil" 5 (K6375668-l) External Connections oE Three Fig. 6 (K-6375669-6) External Connections oE Three

Type IAC51A Relays used in Conjunction with Tripping Type IAC5lR Relays used for 3-Phase Circuit Protection.

Reactors for Protection oE aTThree-Phase Circuito

QATRO BD-TE-T&F-GE-AT-C-002 (sin fecha)

QATRO - BASE DE DATOS - TÉCNICA EXTERNA 7 DE 16

Time Overcurrent Relays Type IAC GEH-1753

INSTANTANEOUS UNIT

INTRODUCTION mounted beside the adjustable pole piece. Time-

current characteristics are shown in Fig. 10.

The instantaneous unit is a small instantaneous

hinge-type unit which may be mounted on the right RATINGS

front side of the induction unit (See Fig. 7). Its

contacts are normally connected in parallel with The instantaneous unit is designed to use either

the contacts oí the main unit. Its coil is connected of two coils having pickup ranges of 10 to 40, and

in series with the operating coil of the main unit. 20 to 80 amperes respectively. The current-closing

rating oí the contacts is 30 amperes íor voltages

When the current reaches apredetermined value, not exceeding 250 volts.

the instantaneous unit operates, closing the contact

[ircuit and raising its target into view. The target BURDENS

latches in the exposed position until released by

pressing the button beneath the lower left-hand Burden data on the instantaneous unit coils are

corner oí the relay cover. given in the following table:

APPLICATION Coil Freq. Amp. Volt Imp. PF

Amp Ohms

The instantaneous unit is used on certain IAC

relay models to provide instantaneous tripping for 10-40 60 5 0.95

current exceeding a predetermined value. 0.83 0.033

50 5 0.80 0.032 0.95

25 5 0.65 0.027 0.98

OPERATING CHARACTERISTICS 20-80 60 5 0.21 0.008 0.95

The instantaneous element operates over a 4 to 50 5 0.20 0.008 0.95

1 range and has its calibration stamped on a scale 25 5 0.15 0.007 0.98

~..-'_~_,,---=*CAl.IIlAATIOH

j;;;;;¡¡í;;;;;;~~r:::~~;;;;;.;;.~e:~ Pl.ATE

ADJUSTABloE

POlo! PIEC!

OPEAATIIIG

COI lo

SHORTING

_ TARO!T COIL ---+-+--1:

STATIONARY

CONTACTS M Al N -~~_.'--f---J

COIL

.. -=

• -

; .

Fig. 7. (8006998) Type lAe Relay with an Fig. 8. (8007060) Type IAe Relay with an

Instantaneous Unit. A-e Tripping Unit.

QATRO BD-TE-T&F-GE-AT-C-002 (sin fecha)

QATRO - BASE DE DATOS - TÉCNICA EXTERNA 8 DE 16

GEH-1753 Time Overcurrent Relays Type IAC

A-e TRIPPING UNll

INTRODUCTION

The a-e tripping unit is a Type REA relay unit

designed to energize a circuit breaker trip eoilfrom 16S1 BREAKER

its assoe iated current transformer upon the operation TRIP COIL

of the main unit of the IAe relay. It transíers the

current from the secondary oí the eurrent trans-

íormer into the trip coil and removes the current

from the trip coil when the breaker trips. CURRENT AC THIP UNIT

L

TRANS NORIJALLV

CLOSto

The tripping unit is mounted on the rear oí the oc;:;----+------<~

,----------;-:::1 CONl ACTS

frame opposite the tapped operating coil of the

induction unit (see Fig. 8). The operation oí this

unit is illustrated in Fig. 9. The secondary current

circulates through the induction unit current coil Al:. TRIP UN~T

and the main coil oí the REA auxiliary tripping unit, SHORTlhG

returning through the REA eontacts to the current COIL

transformer. Normally, most of the flux generated

by the main REA coil passes through the upper limb

oí the magnetic structure and holds the armature

firmly against this limbo When the contacts oí the

induction unit close, the shorting coil oí the REA is o

short-circuited and current flows in this coil by

transíormer action, causing a redistribution oí flux 1--_ _- ' ,..._-+_r=~~~r-:::::::¡:::J AC TRII" UN IT

MAIN COIL

which actuates the armature and the REA contacts.

The opening oí the REA contacts causes the secondary

current to flow through the trip coil which trips the

breaker.

Fig o 9 (K-6154766-2) Diagram lllustrating Operatioü

of Type IAC Relays having an A-C Tripping Unit.

0.030

OPERATI NG TIME

0.025 RANGE FOR N4Y

PI CKUP SETIING

•

~

el)

I

0.0-20

&.U

::1

..- O.Ol~

Q..

:;)

u

:.le

0.010

eL

0.005

O

O 1 2 4 6 7 b 10

NULTIPLES Of PICK-UP

Fig. 10 (6306872 [5]) Time-current Characteristics of Original Instantaneous Unit

QATRO BD-TE-T&F-GE-AT-C-002 (sin fecha)

QATRO - BASE DE DATOS - TÉCNICA EXTERNA 9 DE 16

Time Overcurrent Relays Type IAC GEH-1753

APPLICATION which has contacts rated 200 amperes, can be used

in conjunction with IAC overcurrent relays. The

The a-c tripping unit is used in Type IAC relays REAllB is not mounted inside the IAC case.

where a relíable direct-current tripping source is

not available and it i8 necessary to trip the breaker BURDENS

from the current-transformer secondary.

Burdens of the REA unit are given in the

RATINGS íollowing table:

The a-c tripping unít has a contínuous ratíng of Impedance Volt-

five amperes but wiU operate on a minimum current Frequency Amp PF

in Ohms Amperes

of 3.5 amperes. They should be used wíth three-

ampere trip coUs. The contacts of these uníts wíll 60 5 0.49 0.80 12.2

transfer current transformer secondary current up 50 5 0.33 0.85 8.4

to 100 amperes. For applícatíons where the second- 25 5 0.23 0.62 5.8

ary current exceeds 100 amperes, the REAllB relay,

RECEIVING, HANDLING AND STORAGE

These relays, when not included as a part of a packing the relay in order that none of the parts are

control panel, will be shipped in cartons designed injured or the adjustments disturbed.

to ~rotect them against damage. Immediately upon

receipt of the relay, an examination should be made If the relays are not to be installed immediately,

for any damage sustained during shipment. If they should be stored in their original cartons in a

injury or damage resulting írom rough handling is place that is free írom moisture, dust, and metall1c

evident, a claim should be filed at once with the chips. Foreign matter collected on the outside oí

transportation company and the nearest Sales Office the case may find its way inside when the cover is

of the General Electric Company notüied promptly. removed and cause trouble in the operation oí the

Reasonable care should be exercised in un- relay.

INDUCTION

UNIT

D

INDUCTION INSTANT

SEAL-IN ~ UNIT ""'- I UNIT

UNIT '"

l

1

1 f1

2 6

I NTERNAL CONNECTIONS (FRONT VIEW)O=SHORT FINGER

2

6

SHORT FINGER

Fig. 11. (K-6209658-10) Interna1 Connections fo: Fig. 12. (K-6209661 [11) Interna1 Connections for

the Type IAC51A Re1ay (Front View). the Type IAC51B Relay (Front View)

QATRO BD-TE-T&F-GE-AT-C-002 (sin fecha)

QATRO - BASE DE DATOS - TÉCNICA EXTERNA 10 DE 16

GEH-1753 Time Overcurrent Relays Type IAe

INDUCTION

1Jf'i:-:-

SEAL-IN

iJ t; : A-e íRIP

I - UN I T

NU

SN INSTANT.

T: Ut.1:

AT

N

T

1

1~ 1f1 ~ 1~ 1

2 4 6 8 10

Fig. 13 (K-6209294-3) Internal Connections for the Type IAC51R Relay (Front View)

INOUCTION

INOUCTION

UNIT

SI

SEAL-IN

UNIT

2

6

SHORT FINGER

Fig. 14 (K-6209662 [5]) Internal Connections for the Type IAC52A Relay (Front View)

10

QATRO BD-TE-T&F-GE-AT-C-002 (sin fecha)

QATRO - BASE DE DATOS - TÉCNICA EXTERNA 11 DE 16

Time Overcurrent Relays Type IAC GEH-1753

TO TIMER

----

"STOP"

Te INDICATING LIGHT

WHEN CHECKING PICKUP

OF MAIN UN I T

SEAL-IN

UNIT

INSTANT.

UNIT

- - --

¿

r---

------

-

ro INDICATING LlGHT WHEt

CHECKING PICKUP OF

INSTANTANEOUS UN IT

INDUCTION o

2 3 4 5

UN /T

o o o o

6 7 8 9 10

xLA13 TEST PLUG

INSTANT. VARIABLE RESISTOR

UN IT

.r

TO TIMER

r1'

"STAflT"

TO ACCURATELY REPRODUCE

RELAY CHARACTER I STI es

ALL TESTS SHOULD BE

r,tAOE WI TH RELAY I N CASE.

2 10

MIN. RECQI.t.4ENDED VOLTS,

120 AT RATED FREQUENCY

• * SHORT FINGER

Fig. 15 (K-6209663 [8]> Internal Connections for Fig. 16 (K-6154399-7) Testing Connections for

the Type IAC52B Relay (Front View) Type IAC Relays such as Type IAC51A

INSTALLATION

LOCATION circuits and other circuits with shorting bars that

the auxiliary brush be bent high enough to engage

The location should be clean and dry, free from the connecting plug or test plug before the main

dust and excessive vibration, and well lighted to brushes do. This will prevent CT secondary cir-

facilitate inspection and testing. cuits from being opened.

MOUNTING

The relay should be mounted on a vertical

surface. The outline and panel diagrams are shown

in Figs. 20 and 21. CONNECTING PLUG MAIN BRUSH CONNECTING BLOCK

CONNECTIONS

Internal connection diagrams for the various

relay types are shown in Fig. 11 to 17 inclusive.

Typical wiring diagrams are given in Fig. 4 to 6

inclusive.

One of the mounting studs or screws should be

permanently grounded by a conductor not less than

No. 12 B&S gage copper wire or its equivalente

INSPICTION

NOTE: AFTER ENGAGING AUXllIARY BRUSH, CONNECTING PLUG

At the time of installation, the relay should be TRAVELS 1/4 INCH BEFORE ENGAGING THE MAIN BRUSH ON

inspected for tarnished contacts, loose screws, or

~HE TERMINAL BLOCK.

other imperfections. If any trouble is found, it

should be corrected in the manner described under

MAINTENANCE.

CAUTION:

Fig. 17 (8025039) Cross Section of Drawout Case

Every circuit in the drawout case has an auxi- Showing Position of Auxiliary Brush.

liary brush. It is especially important on current

11

QATRO BD-TE-T&F-GE-AT-C-002 (sin fecha)

QATRO - BASE DE DATOS - TÉCNICA EXTERNA 12 DE 16

GEH-1753 Time Overcurrent Relays Type IAC

ADJUSTMENTS

TARGET AND SEAL-IN UNIT The primary adjustment for the time of opera-

tion of the unit is made by means of the time dial.

For trip coils operating on currents ranging However, further adjustment is obtained by moving

from 0.2 up to 2.0 amperes at the minimum control the permanent magnet along its supporting shelf;

voltage, set the target and seal-in tap screw in the moving the magnet toward the disk shaft decreases

0.2-ampere tapo the time, while moving it away increases the time.

For trip coils operating on currents ranging If selee:tive action of two or more relays is

from 2 to 30 amperes at the minimum control volt- required, determine the maximum possible short-

age, place the tap plug in the 2-ampere tapo circuit current of the Une and then choose a time

The tap screw is the screw ho 1.ding the right- value for each relay that dlifers sufficiently to in-

hand stationary contact of the seal-in unit. To sure the proper sequence in the operatio~ of the

change the tap setting, first remove the connecting several circuit breakers. Allowance must }\le made

plug. Then, take a screw from the left-hand station- for the time involved in opening each break~r after

ary contact and place it in the desired tapo Next, the relay contacts close. For this reason, unless

remove the screw from the other tap, and place it the circuit time of operation is known with accuracy,

in the left-hand contacto This procedure is neces- there should be a düference of about 0.5 second (at

sary to prevent the right-hand stationary contact the maximum current) between relays whose opera-

tion is to be selective.

írom getting out of adjustment. Screws should not

be in both taps at the same time.

EXAMPLE OF SETTING

INDUCTION UNIT The time and current settings of the overcurrent

unit can be made easily and quickly. Each time value

shown in Fig. 2 indicates the time required íor the

CURRENT SETTING contacts to close with a particular time-dial setting

The tap plug must not be removed without first when the current is a prescribed number oí times

withdrawing the connecting plug. the current-tap setting. In order to secure any of

the particular time-current settings shown in Fig. 2,

The current at which the contacts operate may insert the removable plug in the proper tap re-

be changed by changing the position of the tap plug ceptacle and adjust the time-dial to the proper

in the tap block at the top of the relay. Screw the position. The íollowing example illustrates the

tap plug firmly into the tap marked for the desired procedure in making a relay setting.

current (below which the unit is not to operate).

When changing the current setting of the unit, Assume a Type IAC relay is used in a circuit

where the circuit breaker should trip on a sustained

remove the connecting plug to short circuit the cur- current of approximately 450 amperes; also, the

rent transformer secondary circuito Next, screw breaker should trip in 1.9 secon<;is on a short-circuit

the tap plug into tap marked for the desired current current of 3750 amperes. Assume further that

and then replace the connecting plug. current transformers of 60/1 ratio are used.

The pickup of the unit for any current tap is

adjusted by means oí a spring-adjusting ringo The The current tap setting is íound by dividing the

ring may be turned by inserting a screw driver in minimum primary tripping current by the current

the notches around the edge. By turning the ring, transformer ratio. In this case, 450 divided by 60

the operating current of the unit may be brought equals 7.5 amps. Since there is no 7.5-amp tap, the

into agreement with the tap setting employed, ti for 8-amp. tap is used. To find the proper time-dial

sorne reason, this adjustment has been disturbed. setting to give 1.9 seconds time delay at 3750 am-

This adjustment also permits any desired setting peres, divide 3750 by the transíormer ratio. This

intermediate between the various tap settings to be gives 62.5 amperes secondary current which is 7.8

obtained. The unit is adjusted at the factory to close times the 8-ampere setting. By reíerring to the

its contacts from any time-dial position at a mini- time current curves (Fig. 2), it will be seen that 7.8

mum current within five percent oí the tap-plug times the minimum operating current gives 1.9

setting. The unit resets at 90 per cent of the mini- seconds time delay when the relay is set sl1ghtly

mum closing value. aboye the No. 6 time-dial setting.

TIME SETTING

The aboye results should be checked by ¡neans

The setting of the time dial determines the oí an accurate timing device. Slight readjustment

length of time the unit requires to close its contacts oí the dial can be made until the desired time is

when the current reaches a predetermined value. obtained. .

The contacts are just closed when the dial is set on

O. When the dial is set on 10, the disk must travel Aid in making the proper selection oí relay

the maximum amount to close thc contacts and there- settings may be obtained on application to the nearest

fore thi.s setting gives the maximum time setting. Sales Office of the General Electric Company.

12

QATRO BD-TE-T&F-GE-AT-C-002 (sin fecha)

QATRO - BASE DE DATOS - TÉCNICA EXTERNA 13 DE 16

Time Overcurrent Relays Type IAe GEH-1753

CONTACTADJUSTMENT l. CONTACT ADJUSTMENT

With the untt de-energized, the movable contact

The contacta should have approximately 1/32 should He against the stationary contact with enough

inch wipe. That is the stationary contact should be tension to always insure a good closed circuito The

deflected about l;:b inch when the disk completes movable contact brush should be free of any kinks.

its travel. The contact wipe is adjusted by turning Also this contact brush should not touch the com-

the screws in the contact brush which regulates the pound bushing supported from the top of the arma-

position oí the brush, in relation to the brush stop. ture. The brass backing strip should be adjusted to

For relays with two circuit-closing contacts, the allowa 1/16-i.nch contact gap wtth the contacts open.

tips should be in the same vertical plane. The compound bushing support should be adjusted to

allow the back of the movable contact to just touch

the brass backing strip when the armature operates

When the time dial ls moved to a position where to open the contacts. The outer edge of the com-

the contacts just close, the time-dial scale should pound bushing should be approximately 1/32 - inch

indicate zero. If this is found incorrect, and the from the innar edge of the stationary contact sup-

brushes are correctly adjusted, regulate the dial to porting post.

read zero. This is done by changing the posttion of

the arm attached to the shaft which rs located below 2. ARMA TURE ADJUSTMENT

the time dial. Loosen the screw which clamps the Loosen the two screws which hold the armature-

arm to the shaft and turn the arm, relative to the assembly bracket to the bottom of the frame. Slide

shaft, until the contacts just make at the zero time- the bracket in or out, whichever is necessary, until

dial setting. the armature just touches the pole face of the upper

coreo In this position, the armature should be about

1/32 inch from the pole face of the lower coreo

INSTANTANEOUS UNIT Next, sUde the bracket in until the armature leaf

spring as sumes a vertical posttion and is spaced

Select the current above which is desired to clear of both armature and the vertical tip of the

have the instantaneous unit operate and set the ad- bracket. With this setting, the armature should be

justable pole plece so that the top of hexagon head flush against the pole face of both cores, and should

is even with the desired calibration on the scale. put enough pressure on the armature to always re-

To raige or lower the pole piece loosen the locknut turn ií.. flush against the pole face of the lcwer core

and turn it up or down and then tighten in position. after each operation of the unit. This alignment is

important as a slight gap between armature andpole

The contacts should be adjusted to make at face of the lower core after the unit operates may

about the same time and to have approximately 1/8" cause contacts to open momentarily, dropping the

wipe. This adjustment can be made by loosening relay target when the circuit breaker is reclosed.

the screws holding the stationary contacts and moving Under these conditions, the momentary opening of

the contacts up or down as required. the contacts is due to the shock of the armature

being pulled in against the pole face when the lower

A-e TRIPPING UNIT coil is energized. Excessive pressure on the arma-

ture, caused by the bracket being pushed in too far,

The a-c tripping unit should not require any will result in too high a pickup or chattering of the

attention other than occasional cleaning of the con- movable contact during operation of the unit. Tighten

tacta. However, ü the adjustment should be lost, the bracket screws securely after the proper ad-

it may be restored as follows: justment has been obtained.

OPERATION

Before the relay is put into service it should be The pickup current should be checked on one or

given a check to determine that factory adjustments more of the taps and the time should be checked for

have not been disturbed. The time-dial will be set one or more dial settings.

at zero before the relay leaves the factory. It is

necessary to change this setting in order to open the Recommended test connections for the above

relay contacts. test are shown in Fig. 18.

MAINTENANCE

The relaya are adjuated at the factory and it ia exploring its surface with the point of a fine needle.

adviaable not to disturb the adjustments. If, for any If it is necessary to replace the jewel a new pivot

reason, they have been disturbed, the followingpoints should be screwed into the bottom of the shaft at

should be observed in restoring them: the shaft at the same time. The jewel should be

turned up until the disk is centered in the air gapa,

DISK AND BEARINGS after which it should be locked in this position by

the set screw provided for this purpose.

The lower jewel may be tested for cracks by

13

QATRO BD-TE-T&F-GE-AT-C-002 (sin fecha)

QATRO - BASE DE DATOS - TÉCNICA EXTERNA 14 DE 16

GEH-1753 Time Overcurrent Relays Type !Al:

CONTACT CLEANING and deterioration of the contacts. Abrasive paper or

cloth may leave minute particles of insulating

For cleaning fine silver contacts, a flexible abrasive material in the contacts and thus prevent

burnishing tool should be used, This consists of a closing.

flexible strip of metal with an etched roughened

surface, resembling in effect a superfine file. The The burnishing tool described aboye can be

polishing action is so delicate that no scratches are obtained froro the factory.

left, yet corroded material will be removed rapidly

and thoroughly. The flexibility of the tool insures

the cleaning of the actual points of contacto PERIODIC TESTING

Fine silver contacts should not be cleaned with An operation test and inspection of the relay at

knives, files, or abrasive paper or cloth. Knives least once every six months are recommended. Test

or files may leave scratches which increase arcing connections are shown in Fig. 18.

RENEWAL PARTS

It is recommended that sufficient quantities of pany, specify quantity required, name ofpartwanted,

renewal parts be carried in stock to enable the and give complete nameplate data. If possible,

prompt replacement of any that are worn, broken, give the General Electric Company requisition

or damaged. number on which the relay was furnished.

When ordering renewal parts, address the For a recommended parts list refer to Parts

nearest Sales Office of the General Electric Com- Bulletin number GEF-3883.

MI SEI94IC AAlB)'IMSTMTMBUS.m

~ERATING TIME

.025

, ,.(Ji!(}

,.. \ "-

OPEIlATI N& TI ME

1---

8o: 1\ ~,

RANGE FOR »IV

V- PI C1WP SETT I MCi

.0 10

'~

~'--

I

--

.00 5 "-

-'--

r--...

1

1

I

1

3 5 7 8 9 10

1.5 2

J<lUL TI PlES OF PICKUP

Fig. 19 (0208A8695 (l. J) Time-Current Characteristics for the "Hi-G" Unit

Since the last edition, Figures 12 and 14 ha ve been revised.

14

QATRO BD-TE-T&F-GE-AT-C-002 (sin fecha)

QATRO - BASE DE DATOS - TÉCNICA EXTERNA 15 DE 16

Time Overcurrent Relaye Type IAC GEH-1753

SENI-FlUSH--PANEL l O C H I O N _

IITG. SURFACE

"'TG.

~G'_._6_~ ___ o~~

1 'f=,==:::;~====::::1!

1 ( _ _ _ _ _ __ _

fe--1B STUDS FOR

¡ SURFACE "'Tt..

t.¡

II

l, f 1- --#'--J....jL.. ,~

._-.-=::::3

;~~~:;;;:::=~I~

11 ¡---

10-32 x 3/8

T

NTG.

----

:::Y---- "''''

(\'\0

.-

... 0

11<'"

~~

S7

SCREW

STUD HU"'BER I NG STUD NU"'BER I HG

--··- r

<ROHT VlfW FRONT VI EW

F I G.-A F IG.-B

._---

:mro-

A

r HUN.E..!.G._.

¡

1

..BEE.RR. I N.G. .

_ A

).

A

A

__ -

1 ...2..YfE......

RE lAY __

I AC51A

_~c51B ~

I AC51C

I AC52A

___-

B

B IAC51R

B IAC52B I

, 1 3 5 1 1 3 5 7 9

¡OOO 1

1°0000

~9_Q----" ",-00000 2 4 6 8 10 VIEW SHOWIHG ASSE"'BlY OF

HARDWARE FOR SURFACE "'TG.

ON STEE l PAN E LS.

OUTLINE

~ DRlll

~ DR III

2 HOlES 3 DRlll

~

5 HO lE S

/ • '" "OC""

-¡1~-'lL

r

!

~ 1 íh _ II<~

" --y- "'-~ !;~

"'.L. .' . 9~r- 2~,.

~I 1-8

~1j1 ¡ B'

f--- 2~ --L... 25

PANEL RllllNG L--....!. 5!' 8

SENI-fl SH MTG. 4

FIG.A&B PANEL DR Il LI HG

FOR FIG.B

SURf .CE "TO. - FROH VI r.

"ig. 18 (237C707-1) Outline and Panel Drilling for the Type IAC51A, IAC51B, IAC51R, IAC52A and IAC52B Relays

15

QATRO BD-TE-T&F-GE-AT-C-002 (sin fecha)

QATRO - BASE DE DATOS - TÉCNICA EXTERNA 16 DE 16

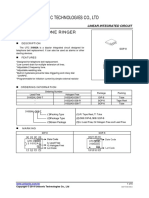

å *( 3RZHU 0DQDJHPHQW

215 Anderson Avenue

Markham, Ontario

Canada L6E 1B3

Tel: (905) 294-6222

Fax: (905) 201-2098

www.ge.com/indsys/pm

QATRO BD-TE-T&F-GE-AT-C-002 (sin fecha)

Potrebbero piacerti anche

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsDa EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsValutazione: 3 su 5 stelle3/5 (2)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Nessuna valutazione finora

- 110 Waveform Generator Projects for the Home ConstructorDa Everand110 Waveform Generator Projects for the Home ConstructorValutazione: 4 su 5 stelle4/5 (1)

- Megasquirt2 Setting Up-3.4Documento117 pagineMegasquirt2 Setting Up-3.4cheomanoftroyNessuna valutazione finora

- Office FurnitureDocumento98 pagineOffice FurniturekidycaNessuna valutazione finora

- IO Wiring DiagramsDocumento172 pagineIO Wiring DiagramsNikola MilosevicNessuna valutazione finora

- Condensate Drain Calculation Lab AHU PDFDocumento1 paginaCondensate Drain Calculation Lab AHU PDFAri RizaldiNessuna valutazione finora

- Trane - CentraVac StarterDocumento28 pagineTrane - CentraVac StarterSam Wang Chern PengNessuna valutazione finora

- List of Instruments & EquipmentsDocumento1 paginaList of Instruments & EquipmentsRAHUL SINGHNessuna valutazione finora

- Project On Ac Voltage Controller Using TriacDocumento33 pagineProject On Ac Voltage Controller Using Triackatul830486% (7)

- Design and Implementation of Liquid Level Detector Using Ultrasonic SensorDocumento6 pagineDesign and Implementation of Liquid Level Detector Using Ultrasonic SensorInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Ge Iac Rela ManualDocumento16 pagineGe Iac Rela ManualArivazhagan AdhikesavanNessuna valutazione finora

- Metal Detector Robot Project ReportDocumento27 pagineMetal Detector Robot Project Reportniraj adhikari100% (1)

- Digrama de Moto Cat 3126aDocumento2 pagineDigrama de Moto Cat 3126aDaniel LopezNessuna valutazione finora

- AS3842Documento14 pagineAS3842alex castroNessuna valutazione finora

- SQ416V-SQ420V-SQ420W-SQ625W-SQ416Q-SQ420Q - Wiring Manual PDFDocumento153 pagineSQ416V-SQ420V-SQ420W-SQ625W-SQ416Q-SQ420Q - Wiring Manual PDFDaniel BarrientosNessuna valutazione finora

- CD4060 Timer Circuit 1 Minute To 2 HoursDocumento9 pagineCD4060 Timer Circuit 1 Minute To 2 HoursBabu Variath100% (1)

- Interview QuesDocumento12 pagineInterview Quesvlsi_asicNessuna valutazione finora

- Manual Relé GEDocumento16 pagineManual Relé GEPablo Briceño NavarroNessuna valutazione finora

- Time Overcurrent Relays: General ElectricDocumento16 pagineTime Overcurrent Relays: General ElectricalfredohdnNessuna valutazione finora

- IAC 77 Type RelayDocumento36 pagineIAC 77 Type RelayJoe JohnsonNessuna valutazione finora

- Manual Serviço Hitachi Rak Tem EsquemaDocumento72 pagineManual Serviço Hitachi Rak Tem EsquemaFlabio OliveiraNessuna valutazione finora

- D D D D D D D D D: Description/ordering InformationDocumento7 pagineD D D D D D D D D: Description/ordering InformationViola Safa Nur AnnisaNessuna valutazione finora

- Panasonic tx-pf42-g30Documento117 paginePanasonic tx-pf42-g30zarkoNessuna valutazione finora

- JVC PCV 77 Service Manual PDFDocumento36 pagineJVC PCV 77 Service Manual PDFSilvio CoutoNessuna valutazione finora

- AKAI 14CNT11BB (BS), 21CTU01BC Service Manual PDFDocumento12 pagineAKAI 14CNT11BB (BS), 21CTU01BC Service Manual PDFAouadi AbdellazizNessuna valutazione finora

- Panasonic SC Hm700 SC Hm800Documento82 paginePanasonic SC Hm700 SC Hm800Jorch Ramirez Estrada100% (3)

- THL 32 SV 6 KDocumento60 pagineTHL 32 SV 6 KSiva KumarNessuna valutazione finora

- Capitulo 6. Generadores de FuncionesDocumento90 pagineCapitulo 6. Generadores de FuncionesjemimaNessuna valutazione finora

- 29TC658Documento30 pagine29TC658acuarelitobasuraNessuna valutazione finora

- Gek 91718Documento14 pagineGek 91718mauricio suarezNessuna valutazione finora

- TXP 42 GT 30 eDocumento142 pagineTXP 42 GT 30 eluis pintoNessuna valutazione finora

- Panasonic TX-p42vt30e, TX-p42vt30j Chasis Gpf14d-EDocumento145 paginePanasonic TX-p42vt30e, TX-p42vt30j Chasis Gpf14d-EClaudelino ToffolettiNessuna valutazione finora

- KALLEY K-TV2xPFDocumento17 pagineKALLEY K-TV2xPFNelson David BarrerraNessuna valutazione finora

- Icr Uv Geh-1783jDocumento16 pagineIcr Uv Geh-1783jGiovani ScarpatiNessuna valutazione finora

- VSX-D906S Service Manual, VSX-07TX, VSX-09TX (OCR)Documento84 pagineVSX-D906S Service Manual, VSX-07TX, VSX-09TX (OCR)evolutgNessuna valutazione finora

- Panasonic Th-48ax670t Th-55ax670t SM 1Documento106 paginePanasonic Th-48ax670t Th-55ax670t SM 1KNessuna valutazione finora

- Philco Pm1414 Chasis La5-ADocumento26 paginePhilco Pm1414 Chasis La5-Abinsakluis1808Nessuna valutazione finora

- RC820 (2E RELAY) Instruction Manual: ToshibaDocumento25 pagineRC820 (2E RELAY) Instruction Manual: Toshibaiam_sutat5147Nessuna valutazione finora

- SERVICE MANUAL Colour Television: Model No. PS2114Documento28 pagineSERVICE MANUAL Colour Television: Model No. PS2114AmirNessuna valutazione finora

- Current Mode Controller: FeaturesDocumento20 pagineCurrent Mode Controller: FeaturesJune SendaydiegoNessuna valutazione finora

- Lab 3Documento4 pagineLab 3Liu WenNessuna valutazione finora

- Hitachi 12k InverterDocumento74 pagineHitachi 12k InverterDaio AlvaresNessuna valutazione finora

- TH-P50X50D TH-P50X50G TH-P50X50K TH-P50X50M TH-P50X50P TH-P50X50S TH-P50X50V TH-P50X50ZDocumento92 pagineTH-P50X50D TH-P50X50G TH-P50X50K TH-P50X50M TH-P50X50P TH-P50X50S TH-P50X50V TH-P50X50ZSuchat LuangampornkulNessuna valutazione finora

- D D D D D D: A78L00 Series Positive-Voltage RegulatorsDocumento14 pagineD D D D D D: A78L00 Series Positive-Voltage RegulatorsbaixadocNessuna valutazione finora

- Icom Ux14 enDocumento10 pagineIcom Ux14 enWildWestNessuna valutazione finora

- Ge Iav52Documento38 pagineGe Iav52MFOBLLLLLLLNessuna valutazione finora

- Panasonic TX p42x20b, P42x20e, p42x20l, P42x25e, P42x25es, Pf42x20 Chassis Gph13deDocumento120 paginePanasonic TX p42x20b, P42x20e, p42x20l, P42x25e, P42x25es, Pf42x20 Chassis Gph13deMarek LeskoNessuna valutazione finora

- MP65, 125, 150 Service Manual PDFDocumento140 pagineMP65, 125, 150 Service Manual PDFShovan AdhikaryNessuna valutazione finora

- CPA - A330 - AMM - FSN - 752 - 01-Oct-2022 - 36-11-55-000-804-A - Removal of The Bleed Valve Control SolenoidDocumento6 pagineCPA - A330 - AMM - FSN - 752 - 01-Oct-2022 - 36-11-55-000-804-A - Removal of The Bleed Valve Control SolenoidMARCO CHANNessuna valutazione finora

- Videocon - Chassis Nano3 CST - Nano4 CSTDocumento29 pagineVideocon - Chassis Nano3 CST - Nano4 CSTchanchaldatta0% (1)

- B3865VDocumento32 pagineB3865Vrazaabbas.oistNessuna valutazione finora

- SB-WA500PP: Wireless Subwoofer UnitDocumento41 pagineSB-WA500PP: Wireless Subwoofer UnitMarceloNessuna valutazione finora

- Toshiba Chassis-Tac9350 Cf27c30Documento16 pagineToshiba Chassis-Tac9350 Cf27c30Roberto Jimenez RojasNessuna valutazione finora

- CTV 21d TXT Mega PH Tda9351 SMDocumento37 pagineCTV 21d TXT Mega PH Tda9351 SMMersija CelikNessuna valutazione finora

- Student PS LAB MANUAL 21-22Documento29 pagineStudent PS LAB MANUAL 21-2219-L-0219 SainadhNessuna valutazione finora

- Model SK 6150 6155Documento14 pagineModel SK 6150 6155Abdalhakeem AlturkyNessuna valutazione finora

- TX-P46G30E TX-P46G30J: Plasma TelevisionDocumento116 pagineTX-P46G30E TX-P46G30J: Plasma TelevisionJohnNessuna valutazione finora

- S-816 Series: External Transistor Type Cmos Voltage RegulatorDocumento24 pagineS-816 Series: External Transistor Type Cmos Voltage RegulatorTuto JhakornNessuna valutazione finora

- PJCDocumento7 paginePJCgneafNessuna valutazione finora

- Panasonic Th-L47et5d Chassis La35 Led TVDocumento75 paginePanasonic Th-L47et5d Chassis La35 Led TVsunny100% (1)

- TN 203 0.6 PDFDocumento19 pagineTN 203 0.6 PDFAhmed58seribegawanNessuna valutazione finora

- Aywa NSX-F959Documento49 pagineAywa NSX-F959CasteloencantadoNessuna valutazione finora

- Pioneer Cld-A100 SMDocumento84 paginePioneer Cld-A100 SMJorgeNessuna valutazione finora

- Panasonic th-p50st30d G K M P S T VDocumento134 paginePanasonic th-p50st30d G K M P S T VDrazen HajlingNessuna valutazione finora

- Unisonic Technologies Co., LTD: Telephone Tone RingerDocumento5 pagineUnisonic Technologies Co., LTD: Telephone Tone Ringerzero cloudNessuna valutazione finora

- ParkeDocumento2 pagineParkeSergio GomezNessuna valutazione finora

- Abb High Voltage Bushing Wells For Pad Mounted Distribution Transformers R5Documento9 pagineAbb High Voltage Bushing Wells For Pad Mounted Distribution Transformers R5Eko SusantoNessuna valutazione finora

- A17.6 Rope Replacement Criteria FinalDocumento2 pagineA17.6 Rope Replacement Criteria FinalGunnie PandherNessuna valutazione finora

- LED Tubes Ballast Compatibility SheetDocumento7 pagineLED Tubes Ballast Compatibility SheetDiego García MedinaNessuna valutazione finora

- MS 1525 (New)Documento73 pagineMS 1525 (New)nikpedie89100% (1)

- TMS320F2806Documento140 pagineTMS320F2806ankurmalviyaNessuna valutazione finora

- AIZ Glass InsulatorsDocumento16 pagineAIZ Glass InsulatorsrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrNessuna valutazione finora

- 150Khz, 3A PWM Buck DC/DC Converter Features General DescriptionDocumento12 pagine150Khz, 3A PWM Buck DC/DC Converter Features General Descriptionpaulmx13Nessuna valutazione finora

- PW-552TBL Part List CartonsealerDocumento52 paginePW-552TBL Part List CartonsealerTeguh HariyadiNessuna valutazione finora

- Altec AC18-70B SpecsDocumento4 pagineAltec AC18-70B SpecsJulioCRXNessuna valutazione finora

- 6FX2001-2CC50 Datasheet enDocumento1 pagina6FX2001-2CC50 Datasheet enbuva034Nessuna valutazione finora

- Date:16.07 Project Name: Zelco-SL TYPE - TOWER - 3M LEG EXTENSION Revision. 0Documento10 pagineDate:16.07 Project Name: Zelco-SL TYPE - TOWER - 3M LEG EXTENSION Revision. 0alifbaharunNessuna valutazione finora

- TTR100 1 DS Us V01Documento6 pagineTTR100 1 DS Us V01andyNessuna valutazione finora

- Chapter 10 Rev 3 Rod ChangingDocumento13 pagineChapter 10 Rev 3 Rod ChangingAnonymous 340A7vnwV1Nessuna valutazione finora

- Industrial Control Transformers (Machine Tool) - 9070T500D1Documento4 pagineIndustrial Control Transformers (Machine Tool) - 9070T500D1Luis Eduardo Vargas NeriNessuna valutazione finora

- Ed Saex2 3ph 400 60 s2 15 enDocumento3 pagineEd Saex2 3ph 400 60 s2 15 enGilberto PimentaNessuna valutazione finora

- CPR1817 30Documento20 pagineCPR1817 30Jamie MiddletonNessuna valutazione finora

- Sumitomo Md200Documento72 pagineSumitomo Md200javier vallejo100% (1)

- Spare Parts Side Door ElevatorDocumento9 pagineSpare Parts Side Door ElevatorAnthony WaaliaNessuna valutazione finora

- List of MIPS Architecture Processors - WikipediaDocumento6 pagineList of MIPS Architecture Processors - WikipediaTechnical NoviceNessuna valutazione finora