Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bohler Dcms T-MC

Caricato da

Flaviu-Andrei AstalisTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Bohler Dcms T-MC

Caricato da

Flaviu-Andrei AstalisCopyright:

Formati disponibili

BOHLER PCMS T-MC

bohler welding

by v o e sta lp ire

M etal cored w ire, seam less, cre e p re sista n t

Classifications

EN ISO 17634-A EN ISO 17634-B AWS A5.36 AWS A5.36M

T CrM ol M M21 1 T55T15-1M21-1CM- E80T15-M21PY-B2-H4 E550T15-M21PY-B2-H4

H5 H5

Characteristics and typical fields of application

Seamless, Cr-Mo alloyed, metalcored wire for single- or multilayer welding of creep resistant steels

up to 500°C with A r-C 0 2shielding gas.

Features include: high yield, good weldability, excellent bead appearance, very low spatter losses.

Wire with very low amount of diffusible hydrogen (< 3ml/100g) that reduces the risk of cracks.

Base materials

1.7335 13CrMo4-5, 1.7262 15CrMo5, 1.7728 16CrMoV4, 1.7218 25CrMo4, 1.7225 42CrMo4,

1.7258 24CrMo5, 1.7354 G22CrMo5-4, 1.7357 G17CrMo5-5

ASTM A 182 Gr. F12; A 193 Gr. B7; A 213 Gr. T12; A 217 Gr. WC6; A 234 Gr. W P 11;

A335 Cr. P11, P12; A 336 Gr. F11, F12; A 426 Gr. CP12

Typical analysis of aH-weid metal (wt.-%)

Gas C Si Mn Cr Mo

wt-% M21 0.06 0.40 1.10 1.20 0.50

Mechanical properties of all-weld metal

Condition Yield strength Tensile strength Elongation Impact work

Rpo^ Rm A (L0=5d0) ISO-V KV J

MPa MPa % +20°C -10°C -20°C

a 520 (>470) 620 (550-690) 22 (>20) 110 (>47) 90 80

a annealed 690°C / 60min - shielding gas M21

Operating data

Polarity: Shielding gas: 0 (mm)

L

M - DC ( + ) (EN ISO 14175) M21 1.0

1.2

/ \ i r. 1.4

1.6

Welding with standard GMAW power source possible

Approvals

TUV, DB, CE

AII information provided is based upon careful investigation and intensive research. 09/2015

However, v/e do not assum e a n y liabiiiîy fo r correctness and information is subject to change without notice. VAvw .voestalpine.com /w elding

Potrebbero piacerti anche

- Aws D15.2 PDFDocumento62 pagineAws D15.2 PDFStarla Hill100% (2)

- Uraian Analisa Harga SatuanDocumento6 pagineUraian Analisa Harga Satuandwi istNessuna valutazione finora

- Form RFIDocumento1 paginaForm RFIJosep SuryaNessuna valutazione finora

- Estimation of MagDocumento6 pagineEstimation of MagDeepak ShrivastavNessuna valutazione finora

- Metric Grease Fittings - Metric Zerk Fittings - Metric Grease FittingsDocumento6 pagineMetric Grease Fittings - Metric Zerk Fittings - Metric Grease FittingsUdayan BasuNessuna valutazione finora

- Data Sheet PR 6201Documento4 pagineData Sheet PR 6201Zarra FaktNessuna valutazione finora

- Format BBSDocumento8 pagineFormat BBSArmida ShareNessuna valutazione finora

- Form Deffect ListDocumento2 pagineForm Deffect ListWahyu Rohmad DiantoNessuna valutazione finora

- Kabel MetalDocumento2 pagineKabel Metalsri haryadiNessuna valutazione finora

- Welded Wire Mesh 50 X 50 X 1 6mm MSDSDocumento3 pagineWelded Wire Mesh 50 X 50 X 1 6mm MSDSMounir BoutaghaneNessuna valutazione finora

- Davidi Int - Company Profile Sept 2014 - PotraitDocumento28 pagineDavidi Int - Company Profile Sept 2014 - PotraitChaidir TransmissionNessuna valutazione finora

- Lighting Solutions Lighting Solutions: AmorisDocumento51 pagineLighting Solutions Lighting Solutions: AmorisjohanNessuna valutazione finora

- Rencana Keselamatan Kesehatan Kerja & Lingkungan: ProyekDocumento15 pagineRencana Keselamatan Kesehatan Kerja & Lingkungan: ProyekSilvester LamanepaNessuna valutazione finora

- MU-Weber General Presentation New (Key Account)Documento97 pagineMU-Weber General Presentation New (Key Account)syahrulNessuna valutazione finora

- Socla Katalog CZ - 3Documento28 pagineSocla Katalog CZ - 3Anugrah Prihantoro Amd TNessuna valutazione finora

- PT Inter World Steel MillsDocumento20 paginePT Inter World Steel Millssugiarto budiNessuna valutazione finora

- BaskomDocumento8 pagineBaskomKrisnandha RahardianNessuna valutazione finora

- Rencana Pembangunan Bendungan Cibeet Kabupaten Bogor: NorthDocumento1 paginaRencana Pembangunan Bendungan Cibeet Kabupaten Bogor: NorthEdi AriyantoNessuna valutazione finora

- Invoice: Mr. Edy Jl. Jakarta Blok CF No 8 SamarindaDocumento1 paginaInvoice: Mr. Edy Jl. Jakarta Blok CF No 8 Samarindaone borneo100% (1)

- Colour Card Multi-PoxDocumento4 pagineColour Card Multi-PoxGunawan MuhamadNessuna valutazione finora

- Break Down Quotation Asti-A Rev. 03Documento2 pagineBreak Down Quotation Asti-A Rev. 03Kholer Burgman67% (3)

- SPINDO Catalogue New PDFDocumento56 pagineSPINDO Catalogue New PDFTitus Deus PrizfelixNessuna valutazione finora

- Standard Non-Inverter CS/CU-YN18WKJ: Air Conditioners Single SplitDocumento1 paginaStandard Non-Inverter CS/CU-YN18WKJ: Air Conditioners Single SplitBoy KailimangNessuna valutazione finora

- RAB & Spek IGMDocumento2 pagineRAB & Spek IGMfatwa1985Nessuna valutazione finora

- Daikin VRV FXMQ Medium Static Concealed Ducted Indoor Unit BrochureDocumento1 paginaDaikin VRV FXMQ Medium Static Concealed Ducted Indoor Unit BrochureChuy Cantú100% (1)

- Brosur Lampu PJU SHT 30WDocumento1 paginaBrosur Lampu PJU SHT 30WRahmat HidayatNessuna valutazione finora

- Brosur+Len+200+Wp 24V+MonocrystallineDocumento2 pagineBrosur+Len+200+Wp 24V+Monocrystallineeric_agustianNessuna valutazione finora

- Daily Report, Selasa 21 Januari 2020 PDFDocumento2 pagineDaily Report, Selasa 21 Januari 2020 PDFAndika AndikaNessuna valutazione finora

- Reel No672 - 36mm X 1500m 35x7 (Wa) Galv RHLL KW Mill & GL CertDocumento3 pagineReel No672 - 36mm X 1500m 35x7 (Wa) Galv RHLL KW Mill & GL CertNg Thiam YongNessuna valutazione finora

- 1 Site Plan Komplek SATPAS OKI by Iskandar Ilyas Semendawai 085267069867Documento1 pagina1 Site Plan Komplek SATPAS OKI by Iskandar Ilyas Semendawai 085267069867Arsitek Iskandar Ilyas SemendawaiNessuna valutazione finora

- Project: RDMP-JO-Building PKG 1 Title: Bar Bending Schedule A B C D Dia. Length (M) QTY Unit Weight (KG/M) Total Length (M) Total Weight (KG)Documento2 pagineProject: RDMP-JO-Building PKG 1 Title: Bar Bending Schedule A B C D Dia. Length (M) QTY Unit Weight (KG/M) Total Length (M) Total Weight (KG)hendra efendiNessuna valutazione finora

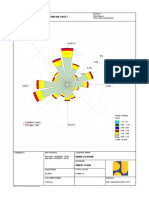

- Windrose - Dry Season (Apr-Oct)Documento1 paginaWindrose - Dry Season (Apr-Oct)Edi AriyantoNessuna valutazione finora

- Penetrant Test Report - ContohDocumento2 paginePenetrant Test Report - ContohSmksore PasNessuna valutazione finora

- Katalog TSP PT PDFDocumento24 pagineKatalog TSP PT PDFdeniNessuna valutazione finora

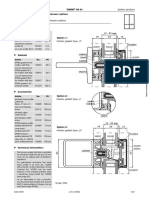

- Seal Weld Activ 8Documento23 pagineSeal Weld Activ 8Mostafa NabilNessuna valutazione finora

- CV. Batu Penjuru - Doc Penaw Kolang Paket 1 Bag2Documento10 pagineCV. Batu Penjuru - Doc Penaw Kolang Paket 1 Bag2Sudarma SibagariangNessuna valutazione finora

- Jotamastic 80: Technical Data SheetDocumento14 pagineJotamastic 80: Technical Data SheetCv RONATAMA GUSLHANNessuna valutazione finora

- Rab PacingDocumento1 paginaRab PacingRosyadNessuna valutazione finora

- Drawing List For ConstructionDocumento3 pagineDrawing List For Constructionkere_hore007Nessuna valutazione finora

- 3'' K Ill W ATE RLI NE: 4'' C VC Li NEDocumento2 pagine3'' K Ill W ATE RLI NE: 4'' C VC Li NEArdy Chidy ArismanNessuna valutazione finora

- Belawan Port SituationDocumento5 pagineBelawan Port SituationAde YudiarsyahNessuna valutazione finora

- Extract Pages From Tower Triangle 20 M - Revisi 1Documento2 pagineExtract Pages From Tower Triangle 20 M - Revisi 1Sholahuddin DiinNessuna valutazione finora

- 01.01.02.01 Spesifikasi-Soilfelt LSDocumento2 pagine01.01.02.01 Spesifikasi-Soilfelt LSjogja raya100% (1)

- Katalog SevenDocumento19 pagineKatalog SevenAn ZizNessuna valutazione finora

- Visio-Pondasi Jembatan Timbang 100 Ton (16m)Documento17 pagineVisio-Pondasi Jembatan Timbang 100 Ton (16m)Lalu Aditiya MardinatalNessuna valutazione finora

- H D I y LDocumento7 pagineH D I y LCoklatabis CokicokiNessuna valutazione finora

- Draft Justek V.O 07 Partial Taking OverDocumento14 pagineDraft Justek V.O 07 Partial Taking OverFahmi PratamaNessuna valutazione finora

- SPHC, SPHDDocumento2 pagineSPHC, SPHDMihai Condeescu100% (1)

- Datasheet For Overcurrent Protection Devices ACB 2000A 50 Ka MVS20N3MF2ADocumento12 pagineDatasheet For Overcurrent Protection Devices ACB 2000A 50 Ka MVS20N3MF2AAli Mahdy ArrosikhNessuna valutazione finora

- Test Certificate: Hex Bolt, Nut & Plain WasherDocumento1 paginaTest Certificate: Hex Bolt, Nut & Plain WasherQC Konart steelNessuna valutazione finora

- SKT TKG Las - RudolfDocumento4 pagineSKT TKG Las - RudolfRifalMkNessuna valutazione finora

- Aliva 264Documento2 pagineAliva 264Bambang SupriyantoNessuna valutazione finora

- Weekly Report JAS EPC SP WKSAI 13 - 20 Januari 2023 PT. Odira (ANSI, API & Crude Oil Pump)Documento10 pagineWeekly Report JAS EPC SP WKSAI 13 - 20 Januari 2023 PT. Odira (ANSI, API & Crude Oil Pump)Andy ArdianNessuna valutazione finora

- Rencana Anggaran Biaya (Rab)Documento4 pagineRencana Anggaran Biaya (Rab)D'wansaGrazzanoNessuna valutazione finora

- DayeDocumento2 pagineDayeJosip JurčićNessuna valutazione finora

- 017 - Test Report of Quality TGL 25 Sept 2023 - BIOSOLAR B35Documento1 pagina017 - Test Report of Quality TGL 25 Sept 2023 - BIOSOLAR B35moehammadsaliem7Nessuna valutazione finora

- Spesifikasi Mobil Derek Dutro 130 HD PDFDocumento3 pagineSpesifikasi Mobil Derek Dutro 130 HD PDFKenny ELtorNessuna valutazione finora

- Drilling Log: Soil or Rock Material DescriptionDocumento1 paginaDrilling Log: Soil or Rock Material DescriptionYosep AlianduNessuna valutazione finora

- Acg080 PDFDocumento1 paginaAcg080 PDFSonia Liset Mamani HuamaniNessuna valutazione finora

- Extrana Product CatalogDocumento78 pagineExtrana Product CatalogBaswara SadewaNessuna valutazione finora

- Draft Material RequestDocumento3 pagineDraft Material Requestbang awiNessuna valutazione finora

- Boehler NiCu1 Ti T-FD - CWDocumento1 paginaBoehler NiCu1 Ti T-FD - CWbrayanNessuna valutazione finora

- S51 - S62Documento12 pagineS51 - S62Flaviu-Andrei AstalisNessuna valutazione finora

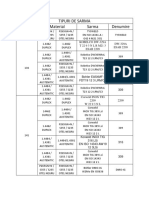

- Tipuri de Sarma Procedeu Material Sarma DenumireDocumento1 paginaTipuri de Sarma Procedeu Material Sarma DenumireFlaviu-Andrei AstalisNessuna valutazione finora

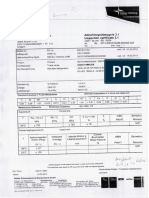

- Inspection Certificate Welding Wire TysweldDocumento1 paginaInspection Certificate Welding Wire TysweldFlaviu-Andrei AstalisNessuna valutazione finora

- Inspection Certificate Welding Wire - Union NiMoCrDocumento1 paginaInspection Certificate Welding Wire - Union NiMoCrFlaviu-Andrei AstalisNessuna valutazione finora

- Antorchas BINZEL AlphaDocumento20 pagineAntorchas BINZEL AlphaBrian HernandezNessuna valutazione finora

- Datasheet-Sandvik-188mn-En-V2017-10-17 10 - 15 Version 1Documento3 pagineDatasheet-Sandvik-188mn-En-V2017-10-17 10 - 15 Version 1szystNessuna valutazione finora

- A Case Study of Shock Absorber Production PlantDocumento39 pagineA Case Study of Shock Absorber Production PlantHarsha VardhanNessuna valutazione finora

- Cam Operated HammerDocumento52 pagineCam Operated HammerSRL MECHNessuna valutazione finora

- GE8261-Engineering Practices Lab - MECH PDFDocumento74 pagineGE8261-Engineering Practices Lab - MECH PDFMohamed BasheerNessuna valutazione finora

- LB Aw NM SPT CMT enDocumento54 pagineLB Aw NM SPT CMT envulduovlakNessuna valutazione finora

- Diesel Engine Driven Welder - Manual Processes: CC DCDocumento8 pagineDiesel Engine Driven Welder - Manual Processes: CC DCabdelbassetNessuna valutazione finora

- T-SS-SA-1166 - 120414 - Welding Process Control Procedure (SG2425-CST-007) Rev.0Documento110 pagineT-SS-SA-1166 - 120414 - Welding Process Control Procedure (SG2425-CST-007) Rev.0Akansha SharmaNessuna valutazione finora

- HandbookDocumento446 pagineHandbookudaafNessuna valutazione finora

- Guide For Welding Iron Castings: ANSI/AWS D11.2-89 (R2006) An American National StandardDocumento8 pagineGuide For Welding Iron Castings: ANSI/AWS D11.2-89 (R2006) An American National StandardCyperTCNessuna valutazione finora

- 5488ef42-7434-49ca-b03a-e2994ef8e657Documento62 pagine5488ef42-7434-49ca-b03a-e2994ef8e657Mujahid Ahmed FadelNessuna valutazione finora

- Mig WeldingDocumento14 pagineMig WeldingVijay KumarNessuna valutazione finora

- Chapter 11 - Surfacing and Shape Welding PDFDocumento15 pagineChapter 11 - Surfacing and Shape Welding PDFCarlos GarcíaNessuna valutazione finora

- Lab 4 Welding (Smaw) (FKM Penang)Documento4 pagineLab 4 Welding (Smaw) (FKM Penang)Ilman FaiqNessuna valutazione finora

- Nixon 1986Documento13 pagineNixon 1986Abhay SinghNessuna valutazione finora

- Merit S-6: Lincoln Electric China Gmaw Solid WireDocumento2 pagineMerit S-6: Lincoln Electric China Gmaw Solid Wirelovaldes62Nessuna valutazione finora

- Ijett V50P205Documento8 pagineIjett V50P205Ronald AranhaNessuna valutazione finora

- F 03 01 09 Brosur Welding Inspector Rev.22-14Documento1 paginaF 03 01 09 Brosur Welding Inspector Rev.22-14Garry MorhanNessuna valutazione finora

- Study of Microstructure and Mechanical Properties of Aluminum Alloy Welded by MIG and TIG Welding ProcessesDocumento9 pagineStudy of Microstructure and Mechanical Properties of Aluminum Alloy Welded by MIG and TIG Welding ProcessesDieter Huaman ToscanoNessuna valutazione finora

- Welding Safety Checklist Sample ReportDocumento8 pagineWelding Safety Checklist Sample ReportMusbah SahlNessuna valutazione finora

- Stainless Steel Piping Fabrication-EGDocumento8 pagineStainless Steel Piping Fabrication-EGYusufNessuna valutazione finora

- D1.8 Seismic Supplement Welding Manual - LincolnDocumento48 pagineD1.8 Seismic Supplement Welding Manual - LincolnElías MartínezNessuna valutazione finora

- FCAW Consumables - Part 4 - TWIDocumento6 pagineFCAW Consumables - Part 4 - TWIJlkKumarNessuna valutazione finora

- Appendix 1 Part 4 Radiographic Interpreter 5th Edition February 2016 PDFDocumento6 pagineAppendix 1 Part 4 Radiographic Interpreter 5th Edition February 2016 PDFRizwan NazirNessuna valutazione finora

- StockDocumento12 pagineStockeileenkohNessuna valutazione finora

- Metals and How To Weld Nickel Alloys Like Inconel 718Documento39 pagineMetals and How To Weld Nickel Alloys Like Inconel 718Erick Hogan100% (1)

- SSAB Welding Hardox Wear Plate 103 enDocumento20 pagineSSAB Welding Hardox Wear Plate 103 enimupathanNessuna valutazione finora

- Welding of Aerospace AlloysDocumento46 pagineWelding of Aerospace Alloyscreativechand100% (1)