Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Finite Element Analysis of Steam Boiler Used in Power Plants

Caricato da

Arkay KumarTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Finite Element Analysis of Steam Boiler Used in Power Plants

Caricato da

Arkay KumarCopyright:

Formati disponibili

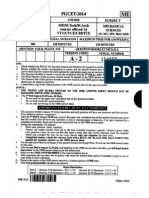

SSRG International Journal of Mechanical Engineering (SSRG-IJME) – volume 1 Issue 6 October 2014

Finite Element Analysis of Steam Boiler Used In Power Plants

1

M. Suri Babu, 2 Dr.B.Subbaratnam

1

M.Tech student, 2Professor, Dept of Mechanical Engineering, Kits, Markapur, A.P, India

ABSTRACT PROBLEM DEFINITION AND

A boiler or steam generator is a METHODOLOGY

closed vessel used to generate steam by The objective of this project is to

applying heat energy to water.During the make a 3D model of the steam boilerand

process of generating steam, the steam study the structural and thermal behaviour

boiler is subjected to huge thermal and of the steam boilerby performing the finite

structural loads.To obtain efficient element analysis.3D modelling software

operation of the power plant, it is (UNIGRAPHICS NX) was used for

necessary to design a structure to designing and analysis software (ANSYS)

withstand these thermal and structural was used for structural and thermal

loads. Using CAD and CAE softwares is analysis.

the advanced methodology of designing

The methodology followed in the project

these structures before constructing a

is as follows:

prototype.In this project finite element

analysis of the steam boiler was carried out Create a 3D model of the steam

to validate the design for actual working boilerassembly using NX-CAD

conditions. The main tasks involved in the software.

project are performing the 3D modelling of Convert the surface model into

the boiler and finite element analysis. In parasolid file and import the model

this project, design optimization of the into ANSYS to do analysis.

boiler is also done based on the results Perform thermal analysis on the steam

obtained from the thermal and structural boilerassemblyfor thermal loads.

analysis. NX-CAD software is used for Perform static analysis on the existing

design and 3D modelling. ANSYS model of the steam boilerassemblyfor

software is used for doing finite element pressure loads and thermal loads to

analysis. find deflections and stress, optimized if

enquired.

ISSN: 2348 – 8360 www.internationaljournalssrg.org Page 28

SSRG International Journal of Mechanical Engineering (SSRG-IJME) – volume 1 Issue 6 October 2014

Based on the above results, design software.Steam boiler assemblywas

changes are implemented to reduce the converted to surface model for analysis.

stresses and deflections.

Develop modified model of the steam

boilerassemblyusing NX-CAD

software, and import it to ANSYS

software.

Perform thermal analysis on the

modified steam boilerassemblyfor

thermal loads. Fig. 3D model of steam boiler assembly

Perform static analysis on the modified (surface model)

steam boilerassemblyfor pressure loads

and thermal loads to find deflections

and stress, optimized if required. FINITE ELEMENT ANALYSIS OF

Perform Modal analysis to find natural STEAM BOILER

frequencies on the existing model of

the steam boilerassembly. COUPLED-FIELD ANALYSES:

From the modal analysis results, the Material Properties of Steel IS: 2062-

natural frequencies, mode shapes and 1999:

their mass participations of the steam Young’s modulus = 200Gpa

boilerare plotted and checked if any Yield Strength = 250 Mpa

natural frequencies are present in the Tensile Strength = 410 Mpa

operating range of the steam boilerand Thermal conductivity) = 16

critical frequencies are identified. Density, (kg/m3) = 7850

From the harmonic analysis results, the Poisson’s ratio, v = 0.3

operating frequencies are cheeked with Thermal expansion= 1.3*10 6

the critical frequencies and

documented the deflections and

Boundary conditions:

stresses values of critical frequencies.

In structural analysis of steam boiler

3D MODELING OF STEAM BOILER assembly, we have to apply structural and

The 3D model of the steam boiler thermal loads. Temperature distribution is

assemblywas developed using NX- CAD applied as Thermal loads on steam boiler

ISSN: 2348 – 8360 www.internationaljournalssrg.org Page 29

SSRG International Journal of Mechanical Engineering (SSRG-IJME) – volume 1 Issue 6 October 2014

assembly obtained from the thermal

analysis performed earlier.

Von Mises stress:

Support base plates are arrested in

all Dof,

Pressure load 1716164Pa is applied

inside of the boiler shell.

Temperature distribution (373K) is

obtained from thermal analysis is

applied as temperature on the

boiler structure.

Fig. Von Mises stress of steam boiler

assembly

From the above results it is observed

that:

Fig. applied structural and thermal

boundary conditions on steam boiler Total temperature distribution is

assembly 373k on steam boiler assembly.

The Max Deflection and Max

RESULTS

VonMises Stress observed 1.6mm

Nodal temperature: and 430Mpa on the steam boiler

assembly for operating loading

conditions respectivly. And the

Yield strength of the materials steel

is 250Mpa.

Hence according to the Maximum

Yield Stress Theory, the VonMises

stress is higher than the yield

strength of the material. Hence the

design of steam boiler assembly is

Fig. Temperature distribution on steam

not safe for the above operating

boiler assembly

loads.

ISSN: 2348 – 8360 www.internationaljournalssrg.org Page 30

SSRG International Journal of Mechanical Engineering (SSRG-IJME) – volume 1 Issue 6 October 2014

To overcome these high stresses and Density, (kg/m3) = 7850

deflections, design modification of steam Poisson’s ratio, v = 0.3

boiler assembly is required. From the Thermal expansion= 1.3*10 6

above results, it is observed that the high Boundary conditions:

stresses are at boiler shell regions. To

In structural analysis of modified steam

reduce the stresses on the boiler shell

boiler assembly, we have to apply

region, thickness of shell body is

structural and thermal loads.

increased.

Support base plates are arrested in

3D MODELING OF MODIFIED

all Dof,

STEAM BOILER

Pressure load 1716164Pa is applied

To reduce the stresses on the boiler shell

inside of the modified boiler shell.

region, thickness of shell body is

Temperature distribution (373K) is

increased.

obtained from thermal analysis is

applied as temperature on the

modified steam boiler.

Fig. 3D model of modified steam boiler

Fig. applied structural and thermal

boundary conditions on modified steam

FINITE ELEMENT ANALYSIS OF boiler assembly

MODIFIED STEAM BOILER

RESULTS

COUPLED-FIELD ANALYSES

Nodal temperature:

Material Properties of Steel IS: 2062-

1999:

Young’s modulus = 200Gpa

Yield Strength = 250 Mpa

Tensile Strength = 410 Mpa

Thermal conductivity) = 16

ISSN: 2348 – 8360 www.internationaljournalssrg.org Page 31

SSRG International Journal of Mechanical Engineering (SSRG-IJME) – volume 1 Issue 6 October 2014

Hence according to the Maximum

Yield Stress Theory, the VonMises

stress is less than the yield strength

of the material. Hence the design of

steam boiler assembly is safe for

the above operating loads.

Then the modified steam boiler assembly

Fig. Temperature distribution on modified is analyzed for dynamic loading

steam boiler assembly conditions. To check the structure response

for resonance condition,

Von Mises stress:

MODAL ANALYSIS OF MODIFIED

STEAM BOILER:

Modal analysis is performed on modified

steam boiler assembly to calculate the

natural frequencies in the operating range

of 0-150 Hz.

From the modal analysis,

Fig. Von Mises stress of modified steam The total weight of the Modified steam

boiler assembly boiler is 44.8tons

From the above results it is observed It is observed that the maximum

that: mass participation of 20.7tone is

observed in X-dir for the frequency

Total temperature distribution is of 28.7Hz.

373k on steam boiler assembly. It is observed that the maximum

The Max Deflection 2.1mm mass participation of 4.7tone and

andMax VonMises Stress 176Mpa 6.3tone are observed in Y-dir for

observed on the modified steam the frequency of 57.6Hz and

boiler assembly for operating 65.9Hz.

loading conditions. And the Yield It is observed that the maximum

strength of the materials steel is mass participation of 6.9tone,

250Mpa 4.2tone and 4.9tone are observed in

ISSN: 2348 – 8360 www.internationaljournalssrg.org Page 32

SSRG International Journal of Mechanical Engineering (SSRG-IJME) – volume 1 Issue 6 October 2014

Z-dir for the frequency of 57.6Hz, 1. Max. Von Mises stress of frequency @

65.9Hz and 97.5Hz. 30Hz

To check the structure response at the

mentioned frequency due to the operating

loads, harmonic analysis is carried out on

the modified steam boiler assembly.

HARMONIC ANALYSIS OF

MODIFIED STEAM BOILER:

Harmonic analysis was carried out

on the Modified steam boiler to determine Fig. Von Mises stress of Modified steam

the deflections and stress of a structure in boiler

the frequency range of 0 -150 Hz. The

total number of sub steps defined for the 2. Max. Von Mises stress of frequency @

analysis is 15. 60Hz

Amplitude vsforcing frequency:

Harmonic response on steam boiler:

Fig. Von Mises stress of Modified steam

boiler

3. Max. Von Mises stress of frequency @

Fig. harmonic response on steam boiler in 100Hz

linear scale

ISSN: 2348 – 8360 www.internationaljournalssrg.org Page 33

SSRG International Journal of Mechanical Engineering (SSRG-IJME) – volume 1 Issue 6 October 2014

2 60 6.1 232

3 70 1.3 103

4 100 4.4 221

From the above results it is

observed that the critical frequencies

30Hz, 60Hz, 70Hz, and 100Hz are having

Fig. Von Mises stress of Modified steam stresses of 89MPa, 232MPa, 103MPa, and

boiler 221MPa respectively. The yield strength of

4. Max. Von Mises stress of frequency the material used for Modified steam

@ 100Hz boiler is 250MPa.

According to the VonMises Stress

Theory, the VonMises stress of Modified

steam boiler at frequencies 30Hz, 60Hz,

70Hz, and 100Hz are less than the yield

strength of the material.

Hence the design of Modified

steam boiler is safe for the above operating

Fig. Von Mises stress of Modified steam loading conditions.

boiler

From the Harmonic analysis,

CONCLUSION

The deflections and stresses at the nearest

In the present project a Modified steam

natural frequency in the operation range of

boiler has been designed and optimized for

0-150 Hz are plotted in the below table.

structural and thermal analysis.

Table. deflections and von mises stress

The Modified steam boiler was studied for

for critical frequencies

3 different cases:

VON MISES Couple field Analysis

Def.

S.no FRQ.(Hz) STRESS Modal analysis

(mm)

(MPa) Harmonic Analysis

1 30 0.7 89

ISSN: 2348 – 8360 www.internationaljournalssrg.org Page 34

SSRG International Journal of Mechanical Engineering (SSRG-IJME) – volume 1 Issue 6 October 2014

From the above analysis it is concluded 8. Lou Roussinos, P. E., “Boiler Design and

that that the Modified steam boiler has Efficiency” [online], Available:

stresses and deflections within the design http://www.forestprod.org/drying06williamson

.pd f, Accessed: September 1, 2010.

limits of the material used. The deflections

9. Murdock, K. L., “3ds max 9 Bible, Wiley

and stresses obtained in the harmonic

Publishing Inc. Indianapolis, Indiana, 2007.

analysis are also under the design limits.

10. Nagpal, G. R., 1998, Power Plant

Therefore it is concluded that the Modified Engineering, Khanna, Delhi.

steam boiler is safe under the given 11. Steam Pressure Reduction: Opportunities

operating conditions. and Issues by U.S Deportment of energy,

REFERENCES 12. Rapid Start up Analysis of a Natural

1. Steam Boiler Room Questions & Answers, Circulation HRSG Boiler with a Vertical

Third Edition by Stephen M.Elonka andAlex Steam Separator Design by M.J. Albrecht,

Higgins W.A. Arnold, R. Jain and J.G. DeVitto,

2. Steam Boiler Operation by James J.Jackson, 13.Technological investigations and efficiency

Prentice-Hall Inc, New Jersey, 1980. analysis of a steam heat exchange condenser:

3. Boilers by Carl D. Shields, McGraw Hill 14. conceptual design of a hybrid steam

Book Company, U.S, 1961. condenser by R K Kapooria and S kumar,

4. Industrial Heat Generation and Distribution 15. Developmental design of a laboratory fire-

-NIFES Training Manual Issued For CEC – tube Steam boiler by I. O. OHIJEAGBON,

India Energy Bus Project

5. Practical Boiler Water Treatment by

Leo.I.Pincus, McGraw Hill Inc, New York,

1962.Modeling, simulating and optimizing

boiler heating surfaces and evaporator circuits

by Kim Sørensen ,Thomas Condra and Niels

Houbak,

6. Ganapathy, V., “Steam Plant Calculations

Manual”,2nd Edition, Marcel Dekker Inc.,

1994.

7. Kitto, J. B. and Stultz, S. C., “Steam:

ItsGeneration and Use”, 41st Edition, The

Babcock

and Wilcox Company, Barberton, Ohio,

U.S.A, 2005.

ISSN: 2348 – 8360 www.internationaljournalssrg.org Page 35

Potrebbero piacerti anche

- 723ijarse PDFDocumento19 pagine723ijarse PDFMahsaNessuna valutazione finora

- (Final) Research Journal Exhaust ManifoldDocumento10 pagine(Final) Research Journal Exhaust ManifoldJustine Zcin MataacNessuna valutazione finora

- International Journal of Pure and Applied Mathematics No. 14 2017, 379-385Documento8 pagineInternational Journal of Pure and Applied Mathematics No. 14 2017, 379-385Vijay VijayNessuna valutazione finora

- 1 s2.0 S0360544219305808 MainDocumento15 pagine1 s2.0 S0360544219305808 MainHugo CostaNessuna valutazione finora

- Post DNB Heat Transfer Experiments For PWR Fuel AssembliesDocumento10 paginePost DNB Heat Transfer Experiments For PWR Fuel AssembliesThales FigueiredoNessuna valutazione finora

- CFD Analysis and Visualization of The Two Phase Flow in A Thermosyphon For A Passive Heat Removal System of A Nuclear Power PlantDocumento4 pagineCFD Analysis and Visualization of The Two Phase Flow in A Thermosyphon For A Passive Heat Removal System of A Nuclear Power PlantRomy RizkyNessuna valutazione finora

- Structural and Thermal Analysis of An Exhaust Manifold of A Multi Cylinder Engine IJERTCONV3IS10016 PDFDocumento4 pagineStructural and Thermal Analysis of An Exhaust Manifold of A Multi Cylinder Engine IJERTCONV3IS10016 PDFKarthikNessuna valutazione finora

- Energy of A Pair of Friction Steel-BronzeDocumento4 pagineEnergy of A Pair of Friction Steel-BronzecarlosNessuna valutazione finora

- Development of Computer Program For Combustion Analysis in Pulverized Coal-Fired BoilersDocumento5 pagineDevelopment of Computer Program For Combustion Analysis in Pulverized Coal-Fired BoilersJayanath Nuwan SameeraNessuna valutazione finora

- Optimization and Design Analysis of SteaDocumento6 pagineOptimization and Design Analysis of SteaMahad KhanNessuna valutazione finora

- Simulation of The Firebox ofDocumento6 pagineSimulation of The Firebox ofAli DarvishiNessuna valutazione finora

- 09 Vapor Power CyclesDocumento34 pagine09 Vapor Power CyclesGergely Aaron GyebrovszkiNessuna valutazione finora

- Of Steam Turbine-Generators: I Method For Predicting The PerformanceDocumento40 pagineOf Steam Turbine-Generators: I Method For Predicting The PerformancenckpourlasNessuna valutazione finora

- Structural and Thermal Analysis of A Boiler Using Finite Element AnalysisDocumento5 pagineStructural and Thermal Analysis of A Boiler Using Finite Element AnalysismohanNessuna valutazione finora

- Internal Combustion Engine Heat Release Calculation Using Single Zone and CFD 3D Numerical ModelsDocumento12 pagineInternal Combustion Engine Heat Release Calculation Using Single Zone and CFD 3D Numerical ModelsPinsteritNessuna valutazione finora

- Thermal Analysis On Power Amplifier UsedDocumento7 pagineThermal Analysis On Power Amplifier UsediiphlabsNessuna valutazione finora

- Boiler Firing Control Design Using Model Predictive TechniquesDocumento6 pagineBoiler Firing Control Design Using Model Predictive TechniquesAqmal FANessuna valutazione finora

- Management of Hot Spots in Refractory Lined High Temperature EquipmentDocumento8 pagineManagement of Hot Spots in Refractory Lined High Temperature EquipmentALEJANDRO FIGUEROANessuna valutazione finora

- The Electric Arc Furnace Off-Gasses Modeling Using CFDDocumento8 pagineThe Electric Arc Furnace Off-Gasses Modeling Using CFDmehdihaNessuna valutazione finora

- Mme 2014022616072971Documento7 pagineMme 2014022616072971조기현Nessuna valutazione finora

- CFD Modeling of Real Scale Slab Reheating FurnaceDocumento7 pagineCFD Modeling of Real Scale Slab Reheating FurnaceFernando AraujoNessuna valutazione finora

- Application of CFD in Thermal Power Plants PDFDocumento4 pagineApplication of CFD in Thermal Power Plants PDFSylvesterNessuna valutazione finora

- Research PaperDocumento9 pagineResearch Paperirfan ashrafNessuna valutazione finora

- UTA MTL - White PaperDocumento4 pagineUTA MTL - White PaperAditya Krishna GaneshramNessuna valutazione finora

- Analyzing, Controlling, and OptimizingDocumento15 pagineAnalyzing, Controlling, and OptimizingLy PhamNessuna valutazione finora

- CFD Study of Fluid Flow and Temperature DistributiDocumento5 pagineCFD Study of Fluid Flow and Temperature DistributiДенис ЛяпуновNessuna valutazione finora

- Raghuram 2017 IOP Conf. Ser. Mater. Sci. Eng. 225 012043Documento7 pagineRaghuram 2017 IOP Conf. Ser. Mater. Sci. Eng. 225 012043wahyuNessuna valutazione finora

- Revresearch Journal Exhaust ManifoldDocumento12 pagineRevresearch Journal Exhaust ManifoldJandelle MarcosNessuna valutazione finora

- Structural and Thermal Analysis On Gas Turbine Blade Using Solid WorksDocumento4 pagineStructural and Thermal Analysis On Gas Turbine Blade Using Solid WorksSeth Ferrara100% (1)

- Combined Brayton and Steam Rankine Cycle: Paper TopicDocumento3 pagineCombined Brayton and Steam Rankine Cycle: Paper TopicAtharva ChodankarNessuna valutazione finora

- ANN Springer SmrekarDocumento17 pagineANN Springer SmrekarNauman KhitranNessuna valutazione finora

- Design and Analysis of Axial Flow Turbine With Computer SoftwareDocumento8 pagineDesign and Analysis of Axial Flow Turbine With Computer SoftwareMusab muaz sarıNessuna valutazione finora

- Design and Analysis of Axial Flow Turbine With Computer SoftwareDocumento8 pagineDesign and Analysis of Axial Flow Turbine With Computer SoftwareAlekhya TNessuna valutazione finora

- Chandak 2015 IOP Conf. Ser. Mater. Sci. Eng. 88 012033Documento9 pagineChandak 2015 IOP Conf. Ser. Mater. Sci. Eng. 88 012033luis900000Nessuna valutazione finora

- Topsoe High Flux Steam Reform - AshxDocumento6 pagineTopsoe High Flux Steam Reform - AshxAgam HanasichulaNessuna valutazione finora

- Experimental and Numerical Methodology For The Aero-Thermal Analysis of ADocumento11 pagineExperimental and Numerical Methodology For The Aero-Thermal Analysis of AMohamed Ould MoussaNessuna valutazione finora

- Simulation of Heat Treatment and Materials With The Use of The Abaqus SoftwareDocumento8 pagineSimulation of Heat Treatment and Materials With The Use of The Abaqus Softwaremanashree02Nessuna valutazione finora

- Mas2012 181Documento6 pagineMas2012 181akinkanalangNessuna valutazione finora

- Irjet V7i5952Documento5 pagineIrjet V7i5952ds8123395Nessuna valutazione finora

- Thermodynamic Performance of Molten Salt Heat StorDocumento6 pagineThermodynamic Performance of Molten Salt Heat Stormxc2425Nessuna valutazione finora

- Design of A Heater For Natural Gas Stations AssistDocumento7 pagineDesign of A Heater For Natural Gas Stations AssistsidNessuna valutazione finora

- Performance Increase of Steam Turbine Condensers by CFD AnalysisDocumento10 paginePerformance Increase of Steam Turbine Condensers by CFD AnalysisAbdullah RobbaniNessuna valutazione finora

- Kit Rattana 2021Documento17 pagineKit Rattana 2021Sơn TiếnNessuna valutazione finora

- Improving The Energy Efficiency of NPP: S.E. Shcheklein, O.L. Tashlykov, A.M. DubininDocumento7 pagineImproving The Energy Efficiency of NPP: S.E. Shcheklein, O.L. Tashlykov, A.M. DubininJorge EspinosaNessuna valutazione finora

- Heat Recovery Steam GeneratorDocumento21 pagineHeat Recovery Steam GeneratorAbdullah AhmedNessuna valutazione finora

- Ferritic Stainless Steels For High-Temperature Applications: Stabilization of The Microstructure by Solid State Precipitation of MX CarbonitridesDocumento10 pagineFerritic Stainless Steels For High-Temperature Applications: Stabilization of The Microstructure by Solid State Precipitation of MX CarbonitridesVenkatesh PandianNessuna valutazione finora

- Tan Diesel Internal CombustionDocumento62 pagineTan Diesel Internal CombustionBryan Ray TanNessuna valutazione finora

- Thermal Modelling of Induction MachinesDocumento7 pagineThermal Modelling of Induction MachinesRohan ChandrashekarNessuna valutazione finora

- Thermal Design-Tm - 17Documento10 pagineThermal Design-Tm - 17VilasNessuna valutazione finora

- Amm 241-244 2139Documento5 pagineAmm 241-244 2139Alok SinghNessuna valutazione finora

- The Analysis of Heat Transfer in Automotive Turbochargers: Nick BainesDocumento8 pagineThe Analysis of Heat Transfer in Automotive Turbochargers: Nick BainesMuhtasim FuadNessuna valutazione finora

- Temperature Analysis Using ABAQUS: Technical NoteDocumento13 pagineTemperature Analysis Using ABAQUS: Technical NotevinayNessuna valutazione finora

- Designing Optimum Heat SinksDocumento8 pagineDesigning Optimum Heat SinksRameshNessuna valutazione finora

- Heatsink EfficiencyDocumento6 pagineHeatsink EfficiencyHarryNessuna valutazione finora

- Design and Simulation Analysis of Physical Heat Dissipation - 2023 - Results inDocumento7 pagineDesign and Simulation Analysis of Physical Heat Dissipation - 2023 - Results inronaldquezada038Nessuna valutazione finora

- Modeling and Analysis of Steam Turbine Blade-Ijaerdv05i0451562n PDFDocumento11 pagineModeling and Analysis of Steam Turbine Blade-Ijaerdv05i0451562n PDFGuruvenu KamanuruNessuna valutazione finora

- A Review On Analysis of Low Pressure StaDocumento3 pagineA Review On Analysis of Low Pressure StapoojaNessuna valutazione finora

- Development of Steam Injection For Ruston TB5000 and Tornado EnginesDocumento7 pagineDevelopment of Steam Injection For Ruston TB5000 and Tornado EnginesalirezaNessuna valutazione finora

- 6) A Process Model For Friction Stir Welding of Age Hardening Aluminum AlloysDocumento12 pagine6) A Process Model For Friction Stir Welding of Age Hardening Aluminum AlloysMuhammad Umer Farooq AwanNessuna valutazione finora

- Conjugate Heat TransferDocumento29 pagineConjugate Heat TransferK Srinivasa SagarNessuna valutazione finora

- Mechanical 2014Documento32 pagineMechanical 2014Arkay KumarNessuna valutazione finora

- Axiom - Teach Me Session - Presentation Techniques - 1 April 2014Documento53 pagineAxiom - Teach Me Session - Presentation Techniques - 1 April 2014Arkay KumarNessuna valutazione finora

- Presentation Techniques 101 Checklist - 9th April 2014Documento1 paginaPresentation Techniques 101 Checklist - 9th April 2014Arkay KumarNessuna valutazione finora

- Struct - Element - Types Shell 63 and The RestDocumento5 pagineStruct - Element - Types Shell 63 and The RestshobziNessuna valutazione finora

- What Is CurrentDocumento4 pagineWhat Is CurrentsosputaNessuna valutazione finora

- ANSYS Quick StartDocumento25 pagineANSYS Quick Startapi-3833671100% (1)

- Pipingflexibilityanalysis PDFDocumento762 paginePipingflexibilityanalysis PDFhirenkumar patel100% (1)

- Failure Theories, Static LoadsDocumento15 pagineFailure Theories, Static LoadsJoseph Xavier Francisco RibeiroNessuna valutazione finora

- Hechmer 1991Documento7 pagineHechmer 1991rahulNessuna valutazione finora

- Finite Element Analysis of Beam-To-Column Joints IDocumento15 pagineFinite Element Analysis of Beam-To-Column Joints IJhonatan Romero CastilloNessuna valutazione finora

- Von Mises' Yield Criterion and Nonlinearly Hardening Rotating ShaftsDocumento17 pagineVon Mises' Yield Criterion and Nonlinearly Hardening Rotating ShaftsAnonymous UoHUagNessuna valutazione finora

- Da 2 - Efa PDFDocumento4 pagineDa 2 - Efa PDFAnish ChakrabartiNessuna valutazione finora

- Structural Performance Analysis of SAE Supra ChassisDocumento14 pagineStructural Performance Analysis of SAE Supra ChassisAjay bhosaleNessuna valutazione finora

- Tresca Vs Von Mises 1626508549Documento8 pagineTresca Vs Von Mises 1626508549Sodsai LamtharnNessuna valutazione finora

- Cement and Concrete Composites: F.P. Bos, P.J. Kruger, S.S. Lucas, G.P.A.G. Van ZijlDocumento18 pagineCement and Concrete Composites: F.P. Bos, P.J. Kruger, S.S. Lucas, G.P.A.G. Van ZijlKhalid EL ABBAOUINessuna valutazione finora

- Composites Science and Technology: S. Fliegener, J. Hohe, P. GumbschDocumento11 pagineComposites Science and Technology: S. Fliegener, J. Hohe, P. GumbschThắngNguyễnNessuna valutazione finora

- Spe 17927 PaDocumento6 pagineSpe 17927 PaAlejandro MonroyNessuna valutazione finora

- Stress Analysis of Gun Barrel Subjected To Dynamic Pressure: H. Babaei, M. Malakzadeh, H. AsgariDocumento10 pagineStress Analysis of Gun Barrel Subjected To Dynamic Pressure: H. Babaei, M. Malakzadeh, H. AsgariAmilcarRafaelVitriagoNessuna valutazione finora

- Lecture 4C Failure Theory of Isotropic Materials From PopovDocumento13 pagineLecture 4C Failure Theory of Isotropic Materials From PopovJoshua KarthikNessuna valutazione finora

- pvp2000 Vol399Documento4 paginepvp2000 Vol399Bogdan GabrielNessuna valutazione finora

- Plastic Deformation-State of Stress, Yield Criteria Rule, and Hardening RulesDocumento19 paginePlastic Deformation-State of Stress, Yield Criteria Rule, and Hardening RulesJosé CunhaNessuna valutazione finora

- A Deep Learning Framework For Solution and Discovery in Solid MechanicsDocumento24 pagineA Deep Learning Framework For Solution and Discovery in Solid MechanicseliwzNessuna valutazione finora

- Chapter 5 - 2Documento19 pagineChapter 5 - 2advait deshmukhNessuna valutazione finora

- Zona PanelDocumento7 pagineZona PanelrobertNessuna valutazione finora

- Anchor Stiffness FormulaDocumento24 pagineAnchor Stiffness FormulaAhsan SattarNessuna valutazione finora

- Solved Problems in SEC by Mark Guimba PDFDocumento138 pagineSolved Problems in SEC by Mark Guimba PDFRayyanNessuna valutazione finora

- 08 Plasticity 07 Associated Flow RulesDocumento4 pagine08 Plasticity 07 Associated Flow RulesHareen CherukuruNessuna valutazione finora

- DMM PPT 1Documento66 pagineDMM PPT 1Umar KhalakNessuna valutazione finora

- Machine Design Lec. 4&5 Failure TheoriesDocumento18 pagineMachine Design Lec. 4&5 Failure TheoriesAbd El-Razek AhmedNessuna valutazione finora

- Solution Manual 3rd Ed Metal FormingDocumento11 pagineSolution Manual 3rd Ed Metal FormingmehrceNessuna valutazione finora

- Static FailureDocumento10 pagineStatic FailureQ_TNessuna valutazione finora

- Von Mises Yeild CreationDocumento5 pagineVon Mises Yeild CreationSuraj KolteNessuna valutazione finora

- ASME PTB-5-2013 Cont 0101Documento10 pagineASME PTB-5-2013 Cont 0101pouya_ms0% (2)

- UNIT-I Introduction To Design Process (Bhaskar)Documento64 pagineUNIT-I Introduction To Design Process (Bhaskar)Harshal A ShahNessuna valutazione finora

- Lecture 1Documento54 pagineLecture 1nofal AdreesNessuna valutazione finora