Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ABB Partner E

Caricato da

386Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ABB Partner E

Caricato da

386Copyright:

Formati disponibili

Hands-On

Maximizing

the user

benefits . . . The substation Laufenburg (EGL), Switzerland

. . . of IEC 61850 in substation automation systems

Based on the vast experience in substation automation (SA) and expertise in IEC 61850, ABB has fully imple-

mented the new standard in its portfolio. Through the combination with excellent system integration capa-

bilities, ABB can offer optimized solutions for new installations, modernization and migration projects.

Klaus-Peter Brand, members and is today strongly IEC 61850 work for them. The broad users to achieve operational

Petra Reinhardt, involved in the ongoing maintenance spectrum of well-coordinated equip- excellence.

Ivan De Mesmaeker and further development of the stan- ment, optimized solutions and compe-

dard. The expert IEC 61850 know- tent services offered minimizes pro- Conformant solutions

Competent partner ledge and verified interoperable sys- ject-to-production time and risks. ABB has proven solutions for new

Customers have long been seek- tems, products and tools as well as To ensure efficient management of installations, refurbishment as well as

ing a communication standard to comprehensive system integration IEC 61850 projects, ABB offers com- migration projects to meet users'

realize fully integrated substation capabilities make ABB a competent prehensive services throughout the availability and operational require-

automation systems. Placing the partner in IEC 61850-based projects. value chain, from specifying to com- ments and safeguard the investments

interests of its customers at the top The new standard is gaining missioning and from maintenance to throughout the lifecycle of a substa-

of its agenda, ABB has been commit- acceptance with utilities and suppliers system extension or upgrade. What is tion. These are based on a complete

ted to the elaboration and verification all around the globe. ABB supports more, we combine global experience portfolio of:

of the standard from the onset. Not customers in fully exploiting the bene- with local presence to offer compe- P station HMI and gateways, pro-

only has ABB been delegating up fits of IEC 61850. The combination of tent service within easy reach of our tection and control IEDs as well as

to thirteen of its renowned experts deep know-how and long experience customers worldwide. interfaces to the process and to

from the substation domain to the with an innovative portfolio assures Utility and industry customers all legacy products

IEC61850-related working groups of customers of getting state-of-the-art around the globe rely on us as their P comprehensive SA functionality

the Technical Committee TC57 and solutions for new stations, migration partner. To them we owe our mar- for today's and tomorrow's require-

provided the conveners for two out of and refurbishment projects at all volt- ket-leading position in substation ments

the three groups. It has also imple- age levels. From single IEDs, via sub- automation and protection. This is P powerful tool environment ensu-

mented and verified the validity of systems and system integration to our con-stant source of motivation ring efficient system design, com-

the standard in interoperability tests complete systems, customers can rely for further innovation and enhance- missioning and maintenance.

conducted together with other TC57 on ABB to make the advantages of ment of our portfolio to help the To verify the proper implementa-

tion of IEC 61850 throughout its port-

folio, ABB has established a System

Dr. Klaus-Peter Petra Reinhardt Ivan De

Brand is present- is working as Mesmaeker is

Verification Centre (SVC). Each and

ly working at the Marketing Com- presently work- every product, system component,

ABB University munication ing with with application and tool is tested in a

Switzerland as Manager with ABB Switzerland

instructor and ABB Switzerland Ltd. as Area

real-life system environment to prove

consultant. Since Ltd., Power Tech- Sales Manager its appropriate working and perform-

1995, he is a nology Systems, and Senior ance - functionally and interactively.

member of the working group of Baden/Switzerland after having gai- Technical Manager. He is also the

Complete protection and substation

IEC TC 57 defining the standard ned several years experience in sub- chairman of the Study Committee B5

IEC61850. He has been acting as edi- station automation and protection in (Protection and Substation Automati- automation systems are verified to

tor and co-editor for different parts Switzerland and South Africa where on) of CIGRÉ. ensure they fully meet the require-

thereof and is still engaged as an she has been working as sales ments in terms of communication,

expert and editor in the maintenance engineer and key account manager.

and extension of the standard. integration, functionality and per-

www.abb.com/substationautomation formance.

48 PRAXIS Profiline – IEC 61850 – Juli 2005

Hands-On

P ABB ensures a maximum level of transmission to distribution, and

product integration for enhanced require system integration of 3rd

performance and advanced functio- party IEDs resp. subsystems. The first

nality of the systems based on installations are already in service

excellent system integration ca- since December 2004.

pabilities as well as a complete

Example of a typical SA solution for a new transmission substation IEC61850-conformant product port- Specific benefits

folio. A common, easy-to-use for different types

Being a system integrator, ABB benefits in substation automation. engineering environment for the of projects

also offers to verify the compliance to Over and above the benefits gained complete range of applications over The projects mark ABB's capabi-

IEC 61850 of each and every compo- through the use of the standard the entire life cycle, guaranteeing lity to supply fully integrated, inter-

nent from other vendors that shall be such as higher flexibility, increased outstanding engineering and main- operable IEC 61850-based solu-

integrated into a system from ABB. efficiency and safeguarded invest- tenance productivity, supports this. tions. With respect to specific

A typical solution for a new trans- ments, ABB provides the following As a result, ABB can offer compre- project types, some key success fac-

mission substation with two voltage main features and benefits: hensive, high-quality service and tors and benefits are:

levels consists of a fully distributed P ABB designs optimized solutions support for systems and products P The efficient handling of bulk

arrangement of the station level with scalable system architectures that is responsive and customer- contracts with large volumes and

equipment. Its main components for any type, size and topology of oriented. critical time schedules profits from

being station HMI, gateway for the substation, based on the use of P ABB offers systems with all sub- highly qualified project manage-

communication to the remote control interoperable devices, the free allo- station functions supported by ment and strong support of power-

centre and time master are completely cation of functions and exploitation IEC61850, from the switchgear to ful engineering tools using the stan-

independent functional units. To of the functional capabilities of pro- the NCC gateway. The systems are dardized SCL.

ensure highest performance and avail- ducts. In combination with ABB's future-proof and open for further P Contracts involving comprehen-

ability, the solution supports more well proven applications, this not op-timization possibilities like usage sive homologation of e.g. a large

than one LAN for the communication only allows customers' availability of e.g. IEC 61850-conformant non- variety of typical feeder solutions

to the bay level devices and allows and performance requirements to conventional instrument transfor- are supported by a deep understan-

the separation of e.g. the transmission be fully met, but also to accommo- mers. As IEC 61850 is earmarked to ding of the customer requirements

and the medium voltage level de- date user-specific operational philo- even become the standard for com- and a comprehensive know-how of

vices. The fully distributed approach at sophies and to enhance safety and munication beyond the substation, IEC 61850 allowing customized pro-

station and bay level and the use of efficiency of system operation. e.g. between the substation and files without loosing interoperability.

high-quality substation-graded devices P ABB ensures proficient project remote control centers for telecon- P Refurbishment projects may be

guarantee very long lifetime and mini- execution in every phase, i.e. system trol or to power stations, ABB's very complex because of the large

mal loss in case of component failure. design, engineering, testing, commis- systems leave the door open for fur- variety of scenarios and goals. These

sioning and maintenance through ther integration. are characterized by the need for par-

Features and benefits efficient and reliable project manage- The importance of the numerous allel operation of existing and new

The consistent and systematic ment. This is supported by a powerful benefits varies with the specific pro- components even if only for a limited

use of the features of IEC 61850 tool environment that is based on ject conditions. Building on a very period of time. Apart from full system

enables ABB to maximize the user the strongly formal Substation Confi- deep know-how of the standard, integration capabilities, they need

guration description long experience in the substation future-proof migration scenarios

Language (SCL) and and SA domain as well as excellent considering also the benefits of

the use of the object- capabilities in system integration, IEC61850.

oriented data model ABB is able to maximize the advan- Through its experience, expertise

with its semantics. It tages for the customer in any type and efficient project management,

warrants user-under- of IEC 61850-based project. ABB is able to realize the different

standable and consi- contract types with full benefits for the

stent data in a high- First projects users. Whilst the advantages for new

quality system. The IEC 61850-conformant products installations are well known already,

reusability and portabi- as well as complete projects have those applying to refurbishments may

lity of the engineering been offered for some time now. be hidden by the mixture of existing

data makes the system ABB has been awarded several and new parts or by the stepwise pro-

easy to extend both by turnkey contracts for IEC 61850- cedure. The following refurbishment

size and functionality based solutions already. The projects project highlights some of these

and even supports range from bulk contracts with high aspects.

system refurbishment volumes and tight time schedules

thus optimally suppor- via sizeable contracts requiring Retrofit of EGL's 380kV

ting life cycle manage- stringent homologation of large Laufenburg substation

ment and safe-guar- numbers of typical feeders to chal- The Swiss utility Elektrizitäts-

ding customer's lenging retrofit projects. They span Gesellschaft Laufenburg AG (EGL)

The new 380 kV hybrid switchgear investments. the full range of voltage levels, from owns and operates an important part

PRAXIS Profiline – IEC 61850 – Juli 2005 49

Hands-On

bushings for connection to the existing P Bay-wise refurbishment to avoid

air insulated switchgear (AIS) busbar service interruption

(Figure ). Apart from needing mini- P Stepwise upgrade of the bay data

mum space, the encapsulated solution in the gateway both to station and

offers immunity to the environmental NCC level was achieved by preconfi-

conditions. It was fully tested and guring and pre-testing the system data

installed in minimal time. To perform using the SCL-based tool to ensure

the refurbishment without service data consistency

interruption, it was done bay by bay, P The hardwired station interlocking

i.e. in three months' time intervals. The used may be replaced later by a topo-

new switchgear offers simplified main- logy-based software solution using the

tenance, as replacement of a complete serial communication, once the overall

pole can be performed in less than 24 refurbishment has been completed

hours. The first refurbished bay is in P A protection engineers workplace

service since December 2004. for monitoring, disturbance record

handling and evaluation was connec-

The new SA system configuration

The solution for ted to the IEC 61850-conformant

substation automation Ethernet ring from the beginning

of the Swiss 380/220kV grid. The tomorrows' requirements in terms of During the stepwise refurbishment, P Sequential connection of the refur-

380kV Laufenburg substation, built in efficient operation, high functionality new control and protection IEDs (Intel- bished bays to the existing station

1967, is a key node in the European and open integration. The special ligent Electronic Devices) from ABB level (operators' workstation) via a

interconnected power system. Its con- problem of varying life cycles of bay were installed and provide all the gateway converting both data and

figuration is a triple busbar system and station level equipment had to be functions needed for the bay. ABB's services between IEC61850 and

with by-pass busbar and several lon- addressed and the latter be kept. The tool environment ensured efficient IEC60870-5-101.

gitudinal sections. After almost 40 customers' philosophy called for the integration of a main 2 protection This solution may easily be applied

years in operation the primary and integration of 3rd party main 2 protec- device from a third party featuring an to the remaining bays in future and is

secondary equipment of 7 out of 17 tion. A sustainable migration strategy IEC 61850 interface. also open for the later replacement of

feeders has to be replaced in several should ensure smooth transition to the An IEC 61850-conformant Ether- the existing station level by an IEC

steps over a two-year period. new technology; it should allow selec- net ring was used to realize the serial 61850-conformant one. The open

tive refurbishment of components to communication between the bays and communcation as per IEC61850 intro-

Requirements suit operational and economic needs from the bays to the existing station duced in the refurbishment of the sec-

and Goals of the as well as freedom of choice in suppli- level (station bus). The latter con- ondary system allows extensions of

Refurbishment ers for various parts and stages of the nection was made via an ABB gate- the substation as well as the integra-

Reliable overall refurbishment of project and future extensions. way converting from IEC61850 to tion of new functionality.

five line bays, one transformer feeder IEC60870-5-101. A GPS receiver was The outlined migration scenario

as well as one bus-coupler had to be The solution for connected to the Ethernet ring for proved to be successful and can be

performed without service interruption the switchgear time synchronization of all connected used for other substations as well.

and within a highly critical time span. New 380 kV switchgear had to be devices. Moreover, a protection

A future-proof retrofit concept was installed in the limited space given. For expert's workplace is available for Conclusion

required for the switchgear as well as the retrofit, a compact hybrid solution monitoring and evaluation of the dis- In addition to the expertise and

for the automation and protection from ABB is combining gas insulated turbance records. innovation to create optimized substa-

system so that they meet today's' and switchgear (GIS) modules with silicon The stepwise procedure applied tion automation solutions for new

equally to the switchgear and the sub- stations, ABB also has the experience

station automation and protection to successfully handle challenging re-

equipment. Any interruption-free refur- furbishment projects. By combining its

bishment, whether it involves the long experience and comprehensive

pri-mary and secondary side or only expertise both in substation automa-

the secondary part, requires a step- tion and in IEC61850 with its portfo-

wise approach. In Laufenburg the lio of fully conformant solutions, ABB

three months' time intervals were maximizes the benefits of the new

dictated by the replacement of the global standard for its customers.

switchgear. ABB also has comprehensive

expertise in current and voltage meas-

Summarized uring and has already gained first

migration scenario practical experiences with IEC61850-

In close cooperation with a compe- conformant, non-conventional instru-

tent supplier, EGL sustainably achieved ment transformers. These further

its project goals through a future-proof enhance the benefits of

The migration of bay control and protection refurbishment and migration concept: IEC61850-based solutions.

50 PRAXIS Profiline – IEC 61850 – Juli 2005

Potrebbero piacerti anche

- Testing IEC-61850 Sampled Values-Based Transformer Differential Protection SchemeDocumento19 pagineTesting IEC-61850 Sampled Values-Based Transformer Differential Protection Scheme386Nessuna valutazione finora

- Electrical Engineering Fundamental QuestionsDocumento5 pagineElectrical Engineering Fundamental Questions386Nessuna valutazione finora

- Easy Capacity Test App Note FINAL PDFDocumento4 pagineEasy Capacity Test App Note FINAL PDF386Nessuna valutazione finora

- AC-Induced 20corrosion 20and 20interactions 20with 20cathodic 20protectionDocumento8 pagineAC-Induced 20corrosion 20and 20interactions 20with 20cathodic 20protection386Nessuna valutazione finora

- Ppe Sample QuestionsDocumento3 paginePpe Sample QuestionsRUMMNessuna valutazione finora

- ClearanceDocumento42 pagineClearanceVijaya RekhaNessuna valutazione finora

- PPE 2011 Apr Q ADocumento16 paginePPE 2011 Apr Q AbaybarsNessuna valutazione finora

- Overlaoding Capability of Dry Tpe TransformersDocumento3 pagineOverlaoding Capability of Dry Tpe Transformers386Nessuna valutazione finora

- Ethics exam questions (CanadaDocumento10 pagineEthics exam questions (Canada386Nessuna valutazione finora

- Jpe 8-4-6 PDFDocumento13 pagineJpe 8-4-6 PDF386Nessuna valutazione finora

- Seoul MetroDocumento1 paginaSeoul Metro386Nessuna valutazione finora

- PCC 3201Documento9 paginePCC 3201386Nessuna valutazione finora

- Nerc Prot CoordDocumento47 pagineNerc Prot Coord386100% (1)

- Cathodic Protection Cuts Corrosion Costs - Print This PageDocumento5 pagineCathodic Protection Cuts Corrosion Costs - Print This Page386Nessuna valutazione finora

- Substation LayoutDocumento58 pagineSubstation Layout38692% (26)

- CIGRE Vol1Documento141 pagineCIGRE Vol1reinscNessuna valutazione finora

- 12 SwitchyardErectionRev07Documento91 pagine12 SwitchyardErectionRev07Rajesh Sirigirisetty SNessuna valutazione finora

- Gen Excitation SysDocumento22 pagineGen Excitation Sys386Nessuna valutazione finora

- Neplan Transmission ModuleDocumento45 pagineNeplan Transmission Module386Nessuna valutazione finora

- Kohlerpower@83474 Gen Set Motor Starting FinalDocumento9 pagineKohlerpower@83474 Gen Set Motor Starting Finalcyong7788Nessuna valutazione finora

- Arc Flash AnalysisDocumento2 pagineArc Flash Analysis386Nessuna valutazione finora

- Arc Flash Study The Six Steps PDFDocumento7 pagineArc Flash Study The Six Steps PDFCarlos Lino Rojas AgüeroNessuna valutazione finora

- Siemens Gis DataDocumento16 pagineSiemens Gis DataDilip ARNessuna valutazione finora

- Etap SimulationDocumento40 pagineEtap Simulation38650% (4)

- VT Guard-Ironing Out ResonanceDocumento5 pagineVT Guard-Ironing Out Resonance386Nessuna valutazione finora

- Transmission System RequirementDocumento17 pagineTransmission System RequirementAmit PatodiaNessuna valutazione finora

- Arc Flash Study The Six Steps PDFDocumento7 pagineArc Flash Study The Six Steps PDFCarlos Lino Rojas AgüeroNessuna valutazione finora

- ETAP Report For GCB SizingDocumento1 paginaETAP Report For GCB Sizing386Nessuna valutazione finora

- Installation Testing Troubleshooting Starters Overload RelaysDocumento34 pagineInstallation Testing Troubleshooting Starters Overload RelaysGogula Gunasekhar100% (1)

- Drehmo Ex-Proof enDocumento28 pagineDrehmo Ex-Proof en386100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- 16 Samss 502Documento25 pagine16 Samss 502paul reyesNessuna valutazione finora

- CG Power Systems Canada Eng EnglishDocumento6 pagineCG Power Systems Canada Eng EnglishpitambervermaNessuna valutazione finora

- Is 5039Documento18 pagineIs 5039VivekKajlaNessuna valutazione finora

- Tansient Recovery Voltage Investigation in The Application of 15kV Circuit Breaker FailureDocumento6 pagineTansient Recovery Voltage Investigation in The Application of 15kV Circuit Breaker FailureNoor Hasnizam HanafiNessuna valutazione finora

- Substation Primary Design StandardDocumento93 pagineSubstation Primary Design StandardPaulNessuna valutazione finora

- 7TH LPDocumento8 pagine7TH LPSeema MotagiNessuna valutazione finora

- Schneider MV Design Guide Switchgear DefinitionDocumento21 pagineSchneider MV Design Guide Switchgear DefinitionAdemEfeNessuna valutazione finora

- Kocos Op - Actas p6 Ii - EngDocumento24 pagineKocos Op - Actas p6 Ii - EngRoger Edgard Gomez BonifacioNessuna valutazione finora

- Eskom Kks Coding StandardDocumento37 pagineEskom Kks Coding StandardRizky NoviansyahNessuna valutazione finora

- Myremotecare: Introduction and Customer BenefitsDocumento44 pagineMyremotecare: Introduction and Customer Benefitsمحمد مNessuna valutazione finora

- NFPA 70E Compliance Solutions (NFPA 2021 Edition) BrochureDocumento12 pagineNFPA 70E Compliance Solutions (NFPA 2021 Edition) BrochureTarek Badr100% (3)

- The Most Reliable Busbar Trunking System: Canalis and IEC 61439-1&6Documento8 pagineThe Most Reliable Busbar Trunking System: Canalis and IEC 61439-1&6Tanveer ShahriarNessuna valutazione finora

- MV Switchgear Application GuideDocumento36 pagineMV Switchgear Application GuidemherbakNessuna valutazione finora

- Lowvoltage LV10-2 Complete English 2011Documento500 pagineLowvoltage LV10-2 Complete English 2011cachiletNessuna valutazione finora

- TemBreak 2 16-I61EU PDFDocumento435 pagineTemBreak 2 16-I61EU PDFafsdfNessuna valutazione finora

- SecoGear Cat Final2Documento22 pagineSecoGear Cat Final2Eulalio HortaNessuna valutazione finora

- Very Fast Transient Overvoltages (VFTO) in Gas-Insulated UHV SubstationsDocumento32 pagineVery Fast Transient Overvoltages (VFTO) in Gas-Insulated UHV Substationsjigyesh29Nessuna valutazione finora

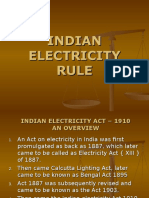

- Indian Electricity RuleDocumento75 pagineIndian Electricity RuleKiran Varghese KNessuna valutazione finora

- February 26, 2013: TESP10701R0/KSBDocumento119 pagineFebruary 26, 2013: TESP10701R0/KSBsrinivasaphanikiran100% (1)

- Info Iec61439-2 (Ed3.0) enDocumento6 pagineInfo Iec61439-2 (Ed3.0) enjueunNessuna valutazione finora

- Maintenance Testing Specifications For Electrical Power DistributionDocumento15 pagineMaintenance Testing Specifications For Electrical Power DistributionalanNessuna valutazione finora

- Esp Pricelist 2Documento76 pagineEsp Pricelist 2Manisankar DhabalNessuna valutazione finora

- Siemens Make Vacum Circuit BreakerDocumento3 pagineSiemens Make Vacum Circuit BreakersriyanuNessuna valutazione finora

- Siemens Technical FlyerDocumento2 pagineSiemens Technical FlyerThiagoPinheiroNessuna valutazione finora

- Gas-Insulated Switchgear: Type ZX1.2Documento14 pagineGas-Insulated Switchgear: Type ZX1.2xinying liuNessuna valutazione finora

- EDS 05-0001 - 132kV Grid and Primary System Protection and Control SchemesDocumento19 pagineEDS 05-0001 - 132kV Grid and Primary System Protection and Control SchemesVishwas KaleNessuna valutazione finora

- 056-022 Switchgear ControlDocumento4 pagine056-022 Switchgear ControlSon Do100% (1)

- Company Profile of SR POWER ENGINEERINGDocumento8 pagineCompany Profile of SR POWER ENGINEERINGAzad RahmanNessuna valutazione finora

- 2015 - Catalog - ABB Cable Accessories 12-42 KV - English - CSE-A FamilyDocumento12 pagine2015 - Catalog - ABB Cable Accessories 12-42 KV - English - CSE-A FamilyAnonymous oKr1c2WNessuna valutazione finora

- TRANSCO Specification For Cable & AccessoriesDocumento34 pagineTRANSCO Specification For Cable & AccessoriesAbhinav Sinha100% (2)