Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Vibrating Screen Data Sheet PDF

Caricato da

downloadDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Vibrating Screen Data Sheet PDF

Caricato da

downloadCopyright:

Formati disponibili

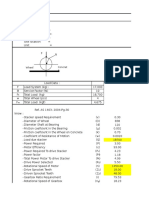

FMC Technologies, Inc.

Vibrating Screen

2730 Hwy 145 South

Saltillo, MS 38866

Data Sheet

P: 1.800.356.4899 P: 662.869.5711

F: 662.869.7405

Email: mhsol.info@fmcti.com

To assure correct recommendations, please furnish us with the following information:

1. Material Temperature

2. Capacity: Feed to screen TPH

Momentary Peak TPH

3. Size of largest pieces fed on screen

4. Weight per cu. Ft. (loose)

5. Characteristics of material:

(a) Bone dry (b) Wet (c) Granular

(d) Claylike (e) Sticky (f) Flaky

Give free moisture: % Normal % Maximum

6. Analysis of feed (Attach complete analysis; if this is impossible, give estimated or known percentage for each opening

at which separation is to be made; also for opening half the size of smallest separation).

% retained on sq. opening

% retained on sq. opening

% retained on sq. opening

% retained on sq. opening

% retained on sq. opening

6A. What is percent of half size material? (Half size is ½ the size you wish to screen at)

(Example: Screening at 1/4 ”, half size is 1/8”)

“)

7. Is screen to be used for (a) Scalping (b) Sizing (c) Dewatering

7A. Size separations required Number of decks

8. What is the maximum size piece permitted through:

(a) Top deck (b) Intermediate deck (c) Bottom deck

9. What percent of fines can be tolerated in the oversize? %

10. Power available: Motor RPM Voltage Phase Cycles

11. Method of feeding material to screen: Steady Irregular How fed

12. Space available for screen: Height Width Length

13. GPM for wet screening:

IMPORTANT NOTE: Make rough sketch on reverse side of this sheet showing headroom, floor space, and desired

location of screen in relation to elevators or bins.

Date Signed

Title

Company name and address

Contact Name:

Phone Number: Fax Number:

10211 02/17/10

Potrebbero piacerti anche

- Vibrating Screen Data SheetDocumento1 paginaVibrating Screen Data SheetAkhmad Audi HarvanNessuna valutazione finora

- Hydrocyclone Data SheetDocumento4 pagineHydrocyclone Data SheetHimmahSekarEagNessuna valutazione finora

- API 650 Tank Data SheetDocumento10 pagineAPI 650 Tank Data SheetDiego FlorNessuna valutazione finora

- 920 01 641 ImpellerOverview 08.03.2017 WebDocumento1 pagina920 01 641 ImpellerOverview 08.03.2017 Websaroat moongwattanaNessuna valutazione finora

- Furnace Hot Spot Repair Report Reformer Malaysia Jan 2017 PDFDocumento14 pagineFurnace Hot Spot Repair Report Reformer Malaysia Jan 2017 PDFRajabuddin AhmedNessuna valutazione finora

- Rotary ScrubberDocumento14 pagineRotary Scrubberkejriwal_itNessuna valutazione finora

- Technical Standard Specification - Mechanical Section 03 - Pumps, Compressors, Blowers, and CuttersDocumento51 pagineTechnical Standard Specification - Mechanical Section 03 - Pumps, Compressors, Blowers, and CuttersRenju RadhakrishnapillaiNessuna valutazione finora

- Asme Sec XDocumento1 paginaAsme Sec XSARSAN NDTNessuna valutazione finora

- Fan Calculation MooreDocumento8 pagineFan Calculation MooreArjun GirishNessuna valutazione finora

- P&IDDocumento1 paginaP&IDeuitimecNessuna valutazione finora

- SA-980-P-11449 - API 685 Submerged Pump PZ - Vert02Documento5 pagineSA-980-P-11449 - API 685 Submerged Pump PZ - Vert02altipatlarNessuna valutazione finora

- Apron Feeder Data SheetDocumento1 paginaApron Feeder Data SheetPat AuffretNessuna valutazione finora

- Internal Pressure Thickness Calculation As Per Code ASME B 31.3Documento1 paginaInternal Pressure Thickness Calculation As Per Code ASME B 31.3DikaAnindyajati100% (1)

- Feeco Rotary Kiln Design PaperDocumento16 pagineFeeco Rotary Kiln Design PaperRishabh KapoorNessuna valutazione finora

- Typical Specification For Steam Surface Condensers Appendix ADocumento5 pagineTypical Specification For Steam Surface Condensers Appendix Ahappale2002Nessuna valutazione finora

- Ds Screw ConveyorDocumento2 pagineDs Screw ConveyorGuntur NugrohoNessuna valutazione finora

- Iom 7541701 Modular Baghouse MBTDocumento44 pagineIom 7541701 Modular Baghouse MBTSantiago PENessuna valutazione finora

- 808 - Carbon Raschig Rings - E4 PDFDocumento1 pagina808 - Carbon Raschig Rings - E4 PDFNada Ibtihal YumnaNessuna valutazione finora

- 붙임 - 3-1. 천연가스용 볼밸브 표준규격Documento25 pagine붙임 - 3-1. 천연가스용 볼밸브 표준규격윤병택Nessuna valutazione finora

- Nozzle Loads On Static Equipment: Engineering Standard Specification FORDocumento4 pagineNozzle Loads On Static Equipment: Engineering Standard Specification FORHamid MansouriNessuna valutazione finora

- VESV1003 - Fabrication of Welded Vessels and Tanks To Be LinedDocumento6 pagineVESV1003 - Fabrication of Welded Vessels and Tanks To Be LinedMuhammad Farukh ManzoorNessuna valutazione finora

- Data Sheet For Rotary Calciner - TEPLDocumento2 pagineData Sheet For Rotary Calciner - TEPLpuneet gehlotNessuna valutazione finora

- Tank Bottom Replacement and Membrane Placement: Chevron Specification TAM-MN-1-ADocumento59 pagineTank Bottom Replacement and Membrane Placement: Chevron Specification TAM-MN-1-ABurak GülenNessuna valutazione finora

- Astm F952 12Documento6 pagineAstm F952 12Yasir NASSERALLAHNessuna valutazione finora

- DTS - Belt Bucket Elevator - DatasheetDocumento3 pagineDTS - Belt Bucket Elevator - DatasheetBRUNA NASCIMENTONessuna valutazione finora

- Hydrotest Procedure For PipingDocumento4 pagineHydrotest Procedure For Pipingsuria qaqcNessuna valutazione finora

- Boogie Stacker: Concret e WheelDocumento4 pagineBoogie Stacker: Concret e WheelWaris La Joi WakatobiNessuna valutazione finora

- ATEC Cyclone Datasheet EnglDocumento1 paginaATEC Cyclone Datasheet EnglDilnesa EjiguNessuna valutazione finora

- Silo Capacity CalculationDocumento1 paginaSilo Capacity Calculationlbc123Nessuna valutazione finora

- Sec.6 - Class C Heat ExchangerDocumento33 pagineSec.6 - Class C Heat ExchangerAgung Dewandaru MahatmantoNessuna valutazione finora

- Ramdas Osborne Ortt 1980 PDFDocumento10 pagineRamdas Osborne Ortt 1980 PDFSebastian PinzonNessuna valutazione finora

- Insulation & RefractoriesDocumento34 pagineInsulation & RefractoriesMVRNessuna valutazione finora

- Electric Heater Datasheet: Duty Bundle (@nom Voltage) Duty Heater (@nom Voltage)Documento3 pagineElectric Heater Datasheet: Duty Bundle (@nom Voltage) Duty Heater (@nom Voltage)SonNguyenNessuna valutazione finora

- Ahlstar End-Suction Single-Stage Centrifugal Pumps: Flow EquipmentDocumento28 pagineAhlstar End-Suction Single-Stage Centrifugal Pumps: Flow EquipmentARYAN_FATHONI_AMRINessuna valutazione finora

- Jigs BatacDocumento28 pagineJigs BatacZab Robledo RiveraNessuna valutazione finora

- Catalogo RescoDocumento2 pagineCatalogo RescopamelataboadalozanoNessuna valutazione finora

- Corrosion Above Ground Brochure EnglishDocumento6 pagineCorrosion Above Ground Brochure EnglishsyammohansNessuna valutazione finora

- Coupling Design and SelectionDocumento11 pagineCoupling Design and SelectionVivek RathodNessuna valutazione finora

- Dust Collector Installation ProcedureDocumento9 pagineDust Collector Installation Procedureadil shidiq100% (1)

- Steam Traps Solve Sticky Railcar Heating ProblemDocumento2 pagineSteam Traps Solve Sticky Railcar Heating ProblemAnonymous v5uipHNessuna valutazione finora

- HEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEDocumento8 pagineHEATING COIL Reff. Pressure Vessel Manual, Procedure 6-8 & ASMEhgagNessuna valutazione finora

- RS 1500 Sulphur GranulatorDocumento4 pagineRS 1500 Sulphur GranulatorvzgscribdNessuna valutazione finora

- Continuous Disc Dryer: Use and FunctionDocumento4 pagineContinuous Disc Dryer: Use and FunctionDouglas TondelloNessuna valutazione finora

- Mixer Data SheetDocumento2 pagineMixer Data SheetBenedick Jayson MartiNessuna valutazione finora

- A Regular ASME Design Checklist - Deconeq Engineering GroupDocumento3 pagineA Regular ASME Design Checklist - Deconeq Engineering GroupAmit SharmaNessuna valutazione finora

- Rhino Process Equipment: Product DescriptionDocumento2 pagineRhino Process Equipment: Product DescriptionMurli ramchandranNessuna valutazione finora

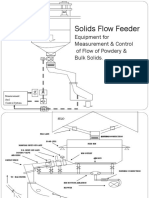

- SFFDocumento7 pagineSFFAbhishek DuttaNessuna valutazione finora

- People's Republic of China Industry Standard Welded Steel Pressure VesselDocumento78 paginePeople's Republic of China Industry Standard Welded Steel Pressure VesselmightsrightNessuna valutazione finora

- LTA and Dryer Cylinders - Applying Mandatory Appendix 32Documento2 pagineLTA and Dryer Cylinders - Applying Mandatory Appendix 32GTpianomanNessuna valutazione finora

- Agitator Spreadsheet DetailsDocumento7 pagineAgitator Spreadsheet DetailsAndrewNessuna valutazione finora

- Variable Design Point Method.Documento56 pagineVariable Design Point Method.jwochNessuna valutazione finora

- BHG - Transfer Chute Data SheetDocumento2 pagineBHG - Transfer Chute Data Sheetacas35Nessuna valutazione finora

- Molasses Tank 18092020Documento31 pagineMolasses Tank 18092020Keshav GopaulNessuna valutazione finora

- Wastecorp PlungerDocumento18 pagineWastecorp PlungerAlexander MedinaNessuna valutazione finora

- 1 Process VesselsDocumento4 pagine1 Process VesselsARIANA NICOLE RELIGIOSONessuna valutazione finora

- Wagon Loader SystemDocumento12 pagineWagon Loader Systemayaskant751001100% (1)

- Crane ds1Documento2 pagineCrane ds1Nurcahyo Djati WNessuna valutazione finora

- Cirebon CHS O&M Manual Ch1-SEC1Documento16 pagineCirebon CHS O&M Manual Ch1-SEC1seni cahyonoNessuna valutazione finora

- Lab No.1-Sieve AnalysisDocumento3 pagineLab No.1-Sieve AnalysisghazalNessuna valutazione finora

- Pre Board Part IDocumento6 paginePre Board Part IMeljun GementizaNessuna valutazione finora

- ReadmeDocumento1 paginaReadmeCroitoru Alexandru-CristianNessuna valutazione finora

- You Can Download Professional Powerpoint Diagrams For Free: Your Text HereDocumento1 paginaYou Can Download Professional Powerpoint Diagrams For Free: Your Text HeredownloadNessuna valutazione finora

- KIRDocumento13 pagineKIRdownloadNessuna valutazione finora

- Abs TrakDocumento3 pagineAbs TrakdownloadNessuna valutazione finora

- Krakatau SteelDocumento30 pagineKrakatau SteeldownloadNessuna valutazione finora

- Free PPT Templates: Insert The Title of Your Presentation HereDocumento61 pagineFree PPT Templates: Insert The Title of Your Presentation HeredownloadNessuna valutazione finora

- W7-323E Reheat FurnacesDocumento29 pagineW7-323E Reheat FurnacesMadan Mohan Katta100% (1)

- Power Guide 2015 (FinalL)Documento140 paginePower Guide 2015 (FinalL)downloadNessuna valutazione finora

- FF0017 01 Dark SpeedometerDocumento5 pagineFF0017 01 Dark SpeedometerdownloadNessuna valutazione finora

- Tandem Cold MillsDocumento56 pagineTandem Cold MillsdownloadNessuna valutazione finora

- References For Hot Strip MillsDocumento44 pagineReferences For Hot Strip MillsdownloadNessuna valutazione finora

- Con 234556Documento17 pagineCon 234556downloadNessuna valutazione finora

- Tandem Cold MillsDocumento56 pagineTandem Cold MillsdownloadNessuna valutazione finora

- Compact ColdMillsDocumento32 pagineCompact ColdMillsdownloadNessuna valutazione finora

- Sdgs Why-It-Matters Goal-14Documento2 pagineSdgs Why-It-Matters Goal-14api-335841488Nessuna valutazione finora

- Ring Opening Paten 1Documento13 pagineRing Opening Paten 1downloadNessuna valutazione finora

- 01 PackagingDocumento132 pagine01 PackagingdownloadNessuna valutazione finora

- GHG Emissions in The Production and Use of Ethanol From SugarcaneDocumento20 pagineGHG Emissions in The Production and Use of Ethanol From SugarcanedownloadNessuna valutazione finora

- Proj Desc 688 02dec2010Documento72 pagineProj Desc 688 02dec2010downloadNessuna valutazione finora

- U11 BK Kuye Design Nothom DevDocumento59 pagineU11 BK Kuye Design Nothom DevdownloadNessuna valutazione finora

- FF0125 01 Free Flat Infographic Elements Powerpoint 16x9Documento5 pagineFF0125 01 Free Flat Infographic Elements Powerpoint 16x9downloadNessuna valutazione finora

- FF0095 01 Free 3D Cone Chart Powerpoint 4x3Documento4 pagineFF0095 01 Free 3D Cone Chart Powerpoint 4x3downloadNessuna valutazione finora

- This Is Your Christmas PresentationDocumento26 pagineThis Is Your Christmas PresentationdownloadNessuna valutazione finora

- Complete PDD For CKT Compost PlantDocumento80 pagineComplete PDD For CKT Compost PlantdownloadNessuna valutazione finora

- Sustainable DevelopmentDocumento7 pagineSustainable DevelopmentMarvin Santos50% (2)

- Detailed Description of Kinetic and Reactor Modeling For Naphtha CA 2011 FueDocumento20 pagineDetailed Description of Kinetic and Reactor Modeling For Naphtha CA 2011 FuedownloadNessuna valutazione finora

- Optimal Design of A Radial Flow Membrane Reactor As A Nov 2013 InternationalDocumento20 pagineOptimal Design of A Radial Flow Membrane Reactor As A Nov 2013 Internationaldownload100% (1)

- Presentation Title: Subtitle Goes HereDocumento3 paginePresentation Title: Subtitle Goes HereDeVi K. NinGsihNessuna valutazione finora

- Rushton ImpellerDocumento20 pagineRushton ImpellerlindaNessuna valutazione finora

- TEKIM - Rotaty Drum FilterDocumento6 pagineTEKIM - Rotaty Drum FilterdownloadNessuna valutazione finora

- NAVISTEM B3000 Control Instruction ManualDocumento116 pagineNAVISTEM B3000 Control Instruction Manualdecaso000Nessuna valutazione finora

- Candy cdpn-2d522px Safety InstructionsDocumento38 pagineCandy cdpn-2d522px Safety Instructionsjdv1234Nessuna valutazione finora

- Modicon Momentum 171CCC98030Documento2 pagineModicon Momentum 171CCC98030m.a.hadiNessuna valutazione finora

- Fresadora B40pte B40e 2 PDFDocumento70 pagineFresadora B40pte B40e 2 PDFRaul Alanoca ColqueNessuna valutazione finora

- Working at HeightDocumento46 pagineWorking at HeightSubhi HSNessuna valutazione finora

- Normas para Transformadores - ABBDocumento10 pagineNormas para Transformadores - ABBluizwillcoxNessuna valutazione finora

- Reovib Mfs 168: Unique Selling PointDocumento8 pagineReovib Mfs 168: Unique Selling PointMarianNeaguNessuna valutazione finora

- A SectionDocumento102 pagineA Sectionmarc5278Nessuna valutazione finora

- Utilization Factor PDFDocumento4 pagineUtilization Factor PDFMuraryspotty33% (3)

- Application Specific Intelligent Power Modules - A Novel Approach To System Integration in Low Power DrivesDocumento15 pagineApplication Specific Intelligent Power Modules - A Novel Approach To System Integration in Low Power DriveschandooNessuna valutazione finora

- '14 Volt L Axle Noise and Failure at 44k - Driving in L - GM Volt ForumDocumento14 pagine'14 Volt L Axle Noise and Failure at 44k - Driving in L - GM Volt ForumOleksandr FominNessuna valutazione finora

- Simatic st80 STPC Chap02 English 2013Documento138 pagineSimatic st80 STPC Chap02 English 2013Eduardo Bueno LemesNessuna valutazione finora

- TMB Switchgear ProductsDocumento3 pagineTMB Switchgear Productskazem shakeriNessuna valutazione finora

- Dreame T20 Cordless Vacuum Cleaner User ManualsDocumento79 pagineDreame T20 Cordless Vacuum Cleaner User ManualsIgnacio SeisdedosNessuna valutazione finora

- Error CodesDocumento24 pagineError CodesGustavo Rodriguez89% (47)

- Anna University ME 9301 Design of Jigs. Fixtures and Press Tools Question PaperDocumento5 pagineAnna University ME 9301 Design of Jigs. Fixtures and Press Tools Question PaperMuruga AnanthNessuna valutazione finora

- Adani BessDocumento45 pagineAdani Bessdan_geplNessuna valutazione finora

- BuLED-50E-OSR LED Light Accessory To Replace MR16 Fitting For Osram ModularsDocumento3 pagineBuLED-50E-OSR LED Light Accessory To Replace MR16 Fitting For Osram ModularsleoNessuna valutazione finora

- Paradise Cable Catalouge PDFDocumento112 pagineParadise Cable Catalouge PDFtanzir40% (5)

- Receiving and Inspection: Installation, Operation and Maintenance ManualDocumento16 pagineReceiving and Inspection: Installation, Operation and Maintenance ManualIvy LeeNessuna valutazione finora

- Datasheet - HK Mb90m408apf 4289720Documento64 pagineDatasheet - HK Mb90m408apf 4289720Sebastian CorreaNessuna valutazione finora

- Dwell Calibration PDFDocumento16 pagineDwell Calibration PDFwillyhuaNessuna valutazione finora

- F200aet 2006Documento88 pagineF200aet 2006Ray Cepeda MenaNessuna valutazione finora

- Yamaha Manual Rx-V2092Documento88 pagineYamaha Manual Rx-V2092nigosanNessuna valutazione finora

- Manual Subwoofer Velodyne ImpactDocumento17 pagineManual Subwoofer Velodyne Impactmgibson2000Nessuna valutazione finora

- Babylock BL18 SMDocumento22 pagineBabylock BL18 SMDavid GarnerNessuna valutazione finora

- Preventive Maintenance Checklist - KR150Documento7 paginePreventive Maintenance Checklist - KR150Juan c sanchezNessuna valutazione finora

- RepymotDocumento4 pagineRepymotEngin UzunNessuna valutazione finora

- Planos Electrónicos Monitor Fetal Corometrics Modelo 170 SeriesDocumento88 paginePlanos Electrónicos Monitor Fetal Corometrics Modelo 170 Seriesviviana vargasNessuna valutazione finora

- Lesson 8: Cpus Used in Personal ComputersDocumento14 pagineLesson 8: Cpus Used in Personal ComputersahsanloverboyNessuna valutazione finora