Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Hydril 513™

Caricato da

renatoCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Hydril 513™

Caricato da

renatoCopyright:

Formati disponibili

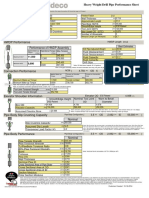

Hydril 513™ Efficiency and Torque Values

PIPE CONNECTION

Size OD & Weight Wall Efficiency Make-up Torque Yield Torque (Maximum Torque)

(Nominal) Thickness Bending/ Compression Minimum Target K-55 N-80/ T-95/ C-110/ Q-125

C-90

Tension L-80 HC-95 P-110

Inches Lbs/Ft Inches % % Ft-Lbs Ft-Lbs Ft-Lbs Ft-Lbs Ft-Lbs Ft-Lbs Ft-Lbs Ft-Lbs

4.500 11.60 0.250 61.9 71.2 2800 3400 8600 11500 12700 13300 15000 17000

4.500 12.60 0.271 62.8 71.7 3000 3600 8600 11500 12700 13200 15000 17000

4.500 13.50 0.290 59.7 72.6 3900 4700 12000 16000 18000 19000 21000 24000

4.500 15.10 0.337 63.1 74.1 5100 6200 14000 18000 20000 21000 24000 26000

4.500 16.60 0.375 64.7 76.6 6000 7200 16000 21000 23000 24000 27000 30000

4.500 17.00 0.380 64.6 76.6 6100 7400 16000 21000 23000 24000 27000 30000

4.500 18.80 0.430 62.9 73.5 6800 8200 16000 21000 23000 24000 27000 30000

4.500 21.50 0.500 62.9 72.0 6700 8100 13500 17000 19000 20000 22000 24000

5.000 15.00 0.296 60.1 72.4 4700 5700 15000 20000 22000 23000 26000 29000

5.000 18.00 0.362 63.7 73.7 6500 7800 17000 23000 25000 26000 29000 33000

5.000 21.40 0.437 62.5 72.8 8200 9900 20000 26000 29000 30000 34000 38000

5.000 23.20 0.478 62.6 71.7 7700 9300 17000 22000 24000 25000 28000 31000

5.000 24.10 0.500 61.8 70.7 8000 9600 17000 22000 24000 25000 28000 31000

5.000 26.70 0.562 64.2 72.1 11000 13200 22000 28000 30000 31000 35000 39000

5.500 17.00 0.304 62.8 74.4 5100 6200 18000 24000 26000 28000 31000 35000

5.500 20.00 0.361 63.8 73.9 7000 8400 20000 27000 30000 31000 35000 39000

5.500 23.00 0.415 63.5 74.1 8400 10100 23000 31000 34000 36000 41000 45000

5.500 26.00 0.476 63.5 72.8 8200 9900 20000 26000 28000 29000 33000 37000

7.000 26.00 0.362 62.4 72.3 7900 9500 31000 42000 47000 49000 56000 63000

7.000 29.00 0.408 61.5 75.8 7900 9500 26000 35000 39000 41000 46000 52000

7.000 32.00 0.453 63.7 76.7 10700 12900 34000 46000 51000 53000 61000 68000

7.000 35.00 0.498 61.8 73.6 11700 14100 34000 46000 51000 54000 61000 68000

7.000 38.00 0.540 62.9 75.4 14900 18000 43000 59000 65000 68000 77000 86000

7.625 29.70 0.375 60.0 75.2 9000 10800 38000 53000 59000 62000 70000 79000

7.625 33.70 0.430 59.8 73.4 8700 10500 31000 42000 46000 48000 55000 62000

7.625 39.00 0.500 62.0 73.8 12500 15000 40000 54000 60000 63000 72000 80000

7.625 42.80 0.562 65.5 77.4 17000 21000 51000 69000 76000 80000 91000 102000

7.625 45.30 0.595 62.1 73.4 18000 22000 52000 70000 77000 81000 91000 102000

7.750 46.10 0.595 60.8 72.2 18000 21000 53000 72000 79000 83000 94000 106000

8.625 40.00 0.450 58.9 73.2 10100 12200 55000 78000 86000 91000 104000 118000

9.375 39.00 0.400 58.9 73.2 10100 11600 52000 76000 85000 90000 104000 118000

9.625 47.00 0.472 61.7 74.3 14000 17000 61000 84000 94000 98000 112000 126000

9.625 53.50 0.545 60.5 72.9 18000 22000 78000 108000 120000 126000 144000 163000

9.625 58.40 0.595 62.9 74.3 21000 26000 78000 108000 120000 126000 144000 161000

9.875 62.80 0.625 62.6 73.4 22000 27000 82000 114000 126000 132000 151000 170000

9.875 65.10 0.650 60.4 70.8 22000 27000 82000 114000 126000 132000 151000 170000

10.750 55.50 0.495 60.9 73.2 18000 22000 75000 105000 117000 123000 141000 159000

10.750 60.70 0.545 66.4 79.0 23000 28000 98000 136000 151000 158000 181000 204000

10.750

11.750

11.750

65.70

60.00

65.00

0.595

0.489

0.534

61.1

65.7

60.4

72.7

78.1

71.8

25000

20000

22000

30000

24000

26000

98000

89000

89000

136000

125000

125000

151000

139000

139000

158000

146000

146000

181000

168000

168000

204000

189000

189000

Hydril 513™

11.875

12.750

71.80

88.00

0.582

0.672

61.8

62.7

74.5

73.0

30000

37000

36000

44400

124000

133000

174000

186000

195000

207000

205000

218000

235000

249000

266000

281000

Integral Casing Connection

13.375 68.00 0.480 63.5 75.9 24000 29000 115000 162000 181000 190000 218000 246000 BULLETIN 9902-C (REPLACES 9902-B)

13.375 72.00 0.514 62.1 73.7 26000 31000 115000 162000 181000 190000 218000 246000

13.625 88.20 0.625 60.1 74.5 42000 50000 205000 288000 321000 338000 388000 438000

14.000 99.60 0.700 66.0 75.8 44000 53000 160000 223000 249000 261000 299000 337000

14.000 104.20 0.734 63.1 72.5 46000 55000 161000 224000 249000 262000 300000 338000

14.000 112.60 0.797 62.6 74.1 48000 58000 195000 271000 302000 317000 363000 409000

14.000 113.00 0.800 64.3 75.8 48000 58000 195000 271000 302000 317000 363000 409000

16.000 95.00 0.566 63.6 76.7 44000 53000 225000 319000 357000 376000 433000 490000

16.000 96.00 0.575 62.6 75.5 45000 54000 225000 319000 357000 376000 433000 490000

16.000 102.90 0.625 62.8 73.9 47000 56000 207000 293000 327000 344000 395000 447000

16.000 109.00 0.656 62.6 73.2 48000 58000 207000 292000 326000 343000 395000 446000

The minimum and target make-up torque values apply to all grades and alloys of steel.

Many factors influence torque application. To ensure that minimum torque is attained, a field target torque (optimum torque) 15% over minimum is recommended.

An appropriate safety factor should be applied to these yield torque values.

HYDRIL HYDRIL INTERNATIONAL TUBULAR SALES

Houston, Texas Aberdeen, Scotland

Telephone: 281.985.3412 Telephone: +44.1224.299.554

Fax: 281.985.3376 Fax: +44.1224.299.578 R E D E F I N I N G R E L I A B I L I T Y T M

E-mail: tubularsales@hydril.com www.hydril.com E-mail: hits@hydril.com

Hydril 513™ Casing Features Hydril 513™ Performance Data

Combining the Benefits of a Metal Seal with the Superior Compression PIPE CONNECTION HYDRIL 513 TENSILE CAPACITY MINIMUM PARTING LOAD

Size OD & Weight Critical

and Torque Capabilities of the Wedge Thread™ (Nominal) Plain End Wall ID

Drift

Pin ID Make-up Threads

Section

K-55/ C-90/

T-95 HC-95 C-110 P-110 Q-125

Weight Thickness (Nominal) (Bored) Loss per Inch L-80 N-80

Area

Inches Lbs/Ft Lbs/Ft Inches Inches Inches Inches Inches Sq In 1000 Lbs 1000 Lbs 1000 Lbs 1000 Lbs 1000 Lbs 1000 Lbs 1000 Lbs

4.500 11.60 11.36 0.250 4.000 3.875 3.918 3.43 4.09 2.066 196 207 217 227 248 258 279

4.500 12.60 12.25 0.271 3.958 3.833 3.876 3.43 4.09 2.261 215 226 237 249 271 283 305

4.500 13.50 13.05 0.290 3.920 3.795 3.838 3.73 3.68 2.290 218 229 240 252 275 286 309

4.500 15.10 15.00 0.337 3.826 3.701 3.744 4.30 3.36 2.781 264 278 292 306 334 348 375

4.500 16.60 16.54 0.375 3.750 3.625 3.668 4.37 3.29 3.144 299 314 330 346 377 393 424

4.500 17.00 16.74 0.380 3.740 3.615 3.658 4.37 3.29 3.177 302 318 334 349 381 397 429

4.500 18.80 18.71 0.430 3.640 3.515 3.558 4.37 3.29 3.458 329 346 363 380 415 432 467

4.500 21.50 21.38 0.500 3.500 3.375 3.418 4.00 3.06 3.952 375 395 415 435 474 494 534

Pipe body OD connection facili- PIN Field proven structural capability

5.000 15.00 14.88 0.296 4.408 4.283 4.327 3.75 3.68 2.629 250 263 276 289 315 329 355

tates running and circulating and is provided with tension and bend-

5.000 18.00 17.95 0.362 4.276 4.151 4.194 4.32 3.36 3.360 319 336 353 370 403 420 454

eliminates downhole coupling face ing strengths of 60 - 65%. The high

5.000 21.40 21.32 0.437 4.126 4.001 4.045 4.39 3.29 3.915 372 392 411 431 470 489 529

hang-up. The boxes are machined strength of the dovetail Wedge

5.000 23.20 23.11 0.478 4.044 3.919 3.963 4.02 3.06 4.251 404 425 446 468 510 531 574

onto as-received pipe ends. Thread provides superior perfor-

5.000 24.10 24.05 0.500 4.000 3.875 3.919 4.02 3.06 4.369 415 437 459 481 524 546 590

mance in combined torsion, bend- 5.000 26.70 26.66 0.562 3.876 3.751 3.795 4.66 3.06 5.031 478 503 528 553 604 629 679

Superior torque strength permits ing, and tension or compression.

5.500 17.00 16.89 0.304 4.892 4.767 4.813 3.78 3.68 3.116 296 312 327 343 374 390 421

rotating into place and rotating

5.500 20.00 19.83 0.361 4.778 4.653 4.698 4.35 3.36 3.718 353 372 390 409 446 465 502

during cementing in deviated Excellent for use in slim-hole

5.500 23.00 22.56 0.415 4.670 4.545 4.590 4.42 3.29 4.210 400 421 442 463 505 526 568

holes without fear of structural fail- applications. Hydril 513 pro-

5.500 26.00 25.56 0.476 4.548 4.423 4.468* 4.05 3.06 4.771 453 477 501 525 573 596 644

ure. The load and stab flanks of motes savings by permitting use

7.000 26.00 25.69 0.362 6.276 6.151 6.199 4.36 3.36 4.711 448 471 495 518 565 589 636

the Wedge Thread provide a pos- of smaller protection casing

7.000 29.00 28.75 0.408 6.184 6.059 6.093 4.07 3.06 5.196 494 520 546 572 624 650 701

itive torque stop virtually eliminat- strings.

7.000 32.00 31.70 0.453 6.094 6.000 6.034* 4.70 3.06 5.935 564 594 623 653 712 742 801

ing pin end ID restrictions caused

7.000 35.00 34.61 0.498 6.004 5.879 5.913 4.65 3.06 6.286 597 629 660 691 754 786 849

by over-torque. Stabbing resistance of the pin 7.000 38.00 37.29 0.540 5.920 5.795 5.829* 5.46 2.75 6.893 655 689 724 758 827 862 931

end face is maintained with the

7.625 29.70 29.06 0.375 6.875 6.750 6.800 4.42 3.29 5.125 487 513 538 564 615 641 692

Versatility for multiple applica- swaged, stress relieved, and

7.625 33.70 33.07 0.430 6.765 6.640 6.675 4.06 3.06 5.813 552 581 610 639 698 727 785

tions. Hydril 513 provides excel- bored ID. Pins are end-drifted

7.625 39.00 38.08 0.500 6.625 6.500 6.535 4.69 3.06 6.939 659 694 729 763 833 867 937

lent sealing and structural perfor- after manufacture at the pipe body

7.625 42.80 42.43 0.562 6.501 6.376 6.411 5.51 2.75 8.168 776 817 858 898 980 1021 1103

mance while maintaining a pipe drift diameter.

7.625 45.30 44.71 0.595 6.435 6.310 6.345* 5.51 2.75 8.161 775 816 857 898 979 1020 1102

body OD. Its many uses include

7.750 46.10 45.51 0.595 6.560 6.500 6.535* 5.49 2.75 8.131 772 813 854 894 976 1016 1098

production liners, drilling liners, lin- 100% internal pressure rated

ers for horizontal and extended metal-to-metal seal maintains 8.625 40.00 39.33 0.450 7.725 7.625 7.665 4.73 3.06 7.154 680 715 751 787 858 894 966

reach wells and liners that must be gas-sealing capability under high 9.375 39.00 38.34 0.400 8.575 8.500 8.540* 4.47 3.29 6.643 631 664 698 731 797 830 897

drilled into place. axial and bending loads. The shal- 9.625 47.00 46.18 0.472 8.681 8.525 8.566 4.75 3.06 8.374 796 837 879 921 1005 1047 1130

low angle chamfer on the bored ID 9.625 53.50 52.90 0.545 8.535 8.500 8.541* 5.56 2.75 9.405 893 941 988 1035 1129 1176 1270

Excellent compression rating of the pin promotes uniform stress 9.625 58.40 57.44 0.595 8.435 8.279 8.320* 5.56 2.75 10.617 1009 1062 1115 1168 1274 1327 1433

provided by the reverse angle stab under the seal around the full

9.875 62.80 61.80 0.625 8.625 8.500 8.541* 5.56 2.75 11.369 1080 1137 1194 1251 1364 1421 1535

flank of the dovetail threads circumference of the connection. 9.875 65.10 64.04 0.650 8.575 8.500 8.541* 5.56 2.75 11.369 1080 1137 1194 1251 1364 1421 1535

makes the Hydril 513 suitable for

10.750 55.50 54.26 0.495 9.760 9.625 9.665 4.75 3.06 9.712 923 971 1020 1068 1165 1214 1311

all liner applications. Compression Pin ID bevel eliminates downhole

10.750 60.70 59.45 0.545 9.660 9.504 9.546 5.56 2.75 11.602 1102 1160 1218 1276 1392 1450 1566

strength exceeds tension. tool hang-ups and promotes tool

10.750 65.70 64.59 0.595 9.560 9.500 9.542* 5.56 2.75 11.598 1102 1160 1218 1276 1392 1450 1566

passage through the connection.

100% pipe body collapse 11.750 60.00 58.87 0.489 10.772 10.625 10.666* 4.79 3.06 11.366 1080 1137 1193 1250 1364 1421 1534

11.750 65.00 64.03 0.534 10.682 10.625 10.666* 4.79 3.06 11.365 1080 1137 1193 1250 1364 1421 1534

strength is created with the lubri- Patented Seal Saver protects the

cant seal of the dovetail threads. pin seal from handling damage 11.875 71.80 70.26 0.582 10.711 10.625 10.665* 5.87 2.65 12.760 1212 1276 1340 1404 1531 1595 1723

and acts as a stiffener to improve 12.750 88.00 86.76 0.672 11.406 11.250 11.291 5.69 2.75 15.987 1519 1599 1679 1759 1918 1998 2158

metal seal functioning. 13.375 68.00 66.17 0.480 12.415 12.259 12.303 4.94 3.06 12.348 1173 1235 1297 1358 1482 1544 1667

13.375 72.00 70.67 0.514 12.347 12.250 12.294* 4.94 3.06 12.897 1225 1290 1354 1419 1548 1612 1741

Interchangeable with Hydril 523™. 13.625 88.20 86.86 0.625 12.375 12.250 12.295* 6.44 2.35 15.341 1457 1534 1611 1688 1841 1918 2071

14.000 99.60 99.52 0.700 12.600 12.412 12.456 5.79 2.75 19.304 1834 1930 2027 2123 2316 2413 2606

U.S. and foreign patents apply.

14.000 104.20 104.09 0.734 12.532 12.344 12.388 5.79 2.75 19.302 1834 1930 2027 2123 2316 2413 2606

14.000 112.60 112.49 0.797 12.406 12.250 12.293* 6.62 2.06 20.694 1966 2069 2173 2276 2483 2587 2794

14.000 113.00 112.89 0.800 12.400 12.250 12.293* 6.62 2.06 21.332 2027 2133 2240 2347 2560 2667 2880

16.000 95.00 93.38 0.566 14.868 14.750 14.793 6.02 2.65 17.454 1658 1745 1833 1920 2094 2182 2356

16.000 96.00 94.81 0.575 14.850 14.750 14.793 6.02 2.65 17.443 1657 1744 1832 1919 2093 2180 2355

16.000 102.90 102.72 0.625 14.750 14.562 14.605 5.86 2.75 18.959 1801 1896 1991 2085 2275 2370 2559

16.000 109.00 107.60 0.656 14.688 14.600 14.643* 5.86 2.75 19.795 1881 1980 2078 2177 2375 2474 2672

Tensile strength calculated on K-55/L-80 = 95 ksi, N-80/C-90 = 100 ksi, T-95 = 105 ksi, HC-95 = 110 ksi, C-110 = 120ksi, P-110 = 125 ksi, Q-125 = 135 ksi ultimate.

* For this item bore will pass popular drift size.

] Interchangeable where bracketed.

Hydril 513 is interchangeable with Hydril 523 in a given size and weight.

BOX

©2006 Hydril Company LP All Rights Reserved

Hydril 513™ Casing Features Hydril 513™ Performance Data

Combining the Benefits of a Metal Seal with the Superior Compression PIPE CONNECTION HYDRIL 513 TENSILE CAPACITY MINIMUM PARTING LOAD

Size OD & Weight Critical

and Torque Capabilities of the Wedge Thread™ (Nominal) Plain End Wall ID

Drift

Pin ID Make-up Threads

Section

K-55/ C-90/

T-95 HC-95 C-110 P-110 Q-125

Weight Thickness (Nominal) (Bored) Loss per Inch L-80 N-80

Area

Inches Lbs/Ft Lbs/Ft Inches Inches Inches Inches Inches Sq In 1000 Lbs 1000 Lbs 1000 Lbs 1000 Lbs 1000 Lbs 1000 Lbs 1000 Lbs

4.500 11.60 11.36 0.250 4.000 3.875 3.918 3.43 4.09 2.066 196 207 217 227 248 258 279

4.500 12.60 12.25 0.271 3.958 3.833 3.876 3.43 4.09 2.261 215 226 237 249 271 283 305

4.500 13.50 13.05 0.290 3.920 3.795 3.838 3.73 3.68 2.290 218 229 240 252 275 286 309

4.500 15.10 15.00 0.337 3.826 3.701 3.744 4.30 3.36 2.781 264 278 292 306 334 348 375

4.500 16.60 16.54 0.375 3.750 3.625 3.668 4.37 3.29 3.144 299 314 330 346 377 393 424

4.500 17.00 16.74 0.380 3.740 3.615 3.658 4.37 3.29 3.177 302 318 334 349 381 397 429

4.500 18.80 18.71 0.430 3.640 3.515 3.558 4.37 3.29 3.458 329 346 363 380 415 432 467

4.500 21.50 21.38 0.500 3.500 3.375 3.418 4.00 3.06 3.952 375 395 415 435 474 494 534

Pipe body OD connection facili- PIN Field proven structural capability

5.000 15.00 14.88 0.296 4.408 4.283 4.327 3.75 3.68 2.629 250 263 276 289 315 329 355

tates running and circulating and is provided with tension and bend-

5.000 18.00 17.95 0.362 4.276 4.151 4.194 4.32 3.36 3.360 319 336 353 370 403 420 454

eliminates downhole coupling face ing strengths of 60 - 65%. The high

5.000 21.40 21.32 0.437 4.126 4.001 4.045 4.39 3.29 3.915 372 392 411 431 470 489 529

hang-up. The boxes are machined strength of the dovetail Wedge

5.000 23.20 23.11 0.478 4.044 3.919 3.963 4.02 3.06 4.251 404 425 446 468 510 531 574

onto as-received pipe ends. Thread provides superior perfor-

5.000 24.10 24.05 0.500 4.000 3.875 3.919 4.02 3.06 4.369 415 437 459 481 524 546 590

mance in combined torsion, bend- 5.000 26.70 26.66 0.562 3.876 3.751 3.795 4.66 3.06 5.031 478 503 528 553 604 629 679

Superior torque strength permits ing, and tension or compression.

5.500 17.00 16.89 0.304 4.892 4.767 4.813 3.78 3.68 3.116 296 312 327 343 374 390 421

rotating into place and rotating

5.500 20.00 19.83 0.361 4.778 4.653 4.698 4.35 3.36 3.718 353 372 390 409 446 465 502

during cementing in deviated Excellent for use in slim-hole

5.500 23.00 22.56 0.415 4.670 4.545 4.590 4.42 3.29 4.210 400 421 442 463 505 526 568

holes without fear of structural fail- applications. Hydril 513 pro-

5.500 26.00 25.56 0.476 4.548 4.423 4.468* 4.05 3.06 4.771 453 477 501 525 573 596 644

ure. The load and stab flanks of motes savings by permitting use

7.000 26.00 25.69 0.362 6.276 6.151 6.199 4.36 3.36 4.711 448 471 495 518 565 589 636

the Wedge Thread provide a pos- of smaller protection casing

7.000 29.00 28.75 0.408 6.184 6.059 6.093 4.07 3.06 5.196 494 520 546 572 624 650 701

itive torque stop virtually eliminat- strings.

7.000 32.00 31.70 0.453 6.094 6.000 6.034* 4.70 3.06 5.935 564 594 623 653 712 742 801

ing pin end ID restrictions caused

7.000 35.00 34.61 0.498 6.004 5.879 5.913 4.65 3.06 6.286 597 629 660 691 754 786 849

by over-torque. Stabbing resistance of the pin 7.000 38.00 37.29 0.540 5.920 5.795 5.829* 5.46 2.75 6.893 655 689 724 758 827 862 931

end face is maintained with the

7.625 29.70 29.06 0.375 6.875 6.750 6.800 4.42 3.29 5.125 487 513 538 564 615 641 692

Versatility for multiple applica- swaged, stress relieved, and

7.625 33.70 33.07 0.430 6.765 6.640 6.675 4.06 3.06 5.813 552 581 610 639 698 727 785

tions. Hydril 513 provides excel- bored ID. Pins are end-drifted

7.625 39.00 38.08 0.500 6.625 6.500 6.535 4.69 3.06 6.939 659 694 729 763 833 867 937

lent sealing and structural perfor- after manufacture at the pipe body

7.625 42.80 42.43 0.562 6.501 6.376 6.411 5.51 2.75 8.168 776 817 858 898 980 1021 1103

mance while maintaining a pipe drift diameter.

7.625 45.30 44.71 0.595 6.435 6.310 6.345* 5.51 2.75 8.161 775 816 857 898 979 1020 1102

body OD. Its many uses include

7.750 46.10 45.51 0.595 6.560 6.500 6.535* 5.49 2.75 8.131 772 813 854 894 976 1016 1098

production liners, drilling liners, lin- 100% internal pressure rated

ers for horizontal and extended metal-to-metal seal maintains 8.625 40.00 39.33 0.450 7.725 7.625 7.665 4.73 3.06 7.154 680 715 751 787 858 894 966

reach wells and liners that must be gas-sealing capability under high 9.375 39.00 38.34 0.400 8.575 8.500 8.540* 4.47 3.29 6.643 631 664 698 731 797 830 897

drilled into place. axial and bending loads. The shal- 9.625 47.00 46.18 0.472 8.681 8.525 8.566 4.75 3.06 8.374 796 837 879 921 1005 1047 1130

low angle chamfer on the bored ID 9.625 53.50 52.90 0.545 8.535 8.500 8.541* 5.56 2.75 9.405 893 941 988 1035 1129 1176 1270

Excellent compression rating of the pin promotes uniform stress 9.625 58.40 57.44 0.595 8.435 8.279 8.320* 5.56 2.75 10.617 1009 1062 1115 1168 1274 1327 1433

provided by the reverse angle stab under the seal around the full

9.875 62.80 61.80 0.625 8.625 8.500 8.541* 5.56 2.75 11.369 1080 1137 1194 1251 1364 1421 1535

flank of the dovetail threads circumference of the connection. 9.875 65.10 64.04 0.650 8.575 8.500 8.541* 5.56 2.75 11.369 1080 1137 1194 1251 1364 1421 1535

makes the Hydril 513 suitable for

10.750 55.50 54.26 0.495 9.760 9.625 9.665 4.75 3.06 9.712 923 971 1020 1068 1165 1214 1311

all liner applications. Compression Pin ID bevel eliminates downhole

10.750 60.70 59.45 0.545 9.660 9.504 9.546 5.56 2.75 11.602 1102 1160 1218 1276 1392 1450 1566

strength exceeds tension. tool hang-ups and promotes tool

10.750 65.70 64.59 0.595 9.560 9.500 9.542* 5.56 2.75 11.598 1102 1160 1218 1276 1392 1450 1566

passage through the connection.

100% pipe body collapse 11.750 60.00 58.87 0.489 10.772 10.625 10.666* 4.79 3.06 11.366 1080 1137 1193 1250 1364 1421 1534

11.750 65.00 64.03 0.534 10.682 10.625 10.666* 4.79 3.06 11.365 1080 1137 1193 1250 1364 1421 1534

strength is created with the lubri- Patented Seal Saver protects the

cant seal of the dovetail threads. pin seal from handling damage 11.875 71.80 70.26 0.582 10.711 10.625 10.665* 5.87 2.65 12.760 1212 1276 1340 1404 1531 1595 1723

and acts as a stiffener to improve 12.750 88.00 86.76 0.672 11.406 11.250 11.291 5.69 2.75 15.987 1519 1599 1679 1759 1918 1998 2158

metal seal functioning. 13.375 68.00 66.17 0.480 12.415 12.259 12.303 4.94 3.06 12.348 1173 1235 1297 1358 1482 1544 1667

13.375 72.00 70.67 0.514 12.347 12.250 12.294* 4.94 3.06 12.897 1225 1290 1354 1419 1548 1612 1741

Interchangeable with Hydril 523™. 13.625 88.20 86.86 0.625 12.375 12.250 12.295* 6.44 2.35 15.341 1457 1534 1611 1688 1841 1918 2071

14.000 99.60 99.52 0.700 12.600 12.412 12.456 5.79 2.75 19.304 1834 1930 2027 2123 2316 2413 2606

U.S. and foreign patents apply.

14.000 104.20 104.09 0.734 12.532 12.344 12.388 5.79 2.75 19.302 1834 1930 2027 2123 2316 2413 2606

14.000 112.60 112.49 0.797 12.406 12.250 12.293* 6.62 2.06 20.694 1966 2069 2173 2276 2483 2587 2794

14.000 113.00 112.89 0.800 12.400 12.250 12.293* 6.62 2.06 21.332 2027 2133 2240 2347 2560 2667 2880

16.000 95.00 93.38 0.566 14.868 14.750 14.793 6.02 2.65 17.454 1658 1745 1833 1920 2094 2182 2356

16.000 96.00 94.81 0.575 14.850 14.750 14.793 6.02 2.65 17.443 1657 1744 1832 1919 2093 2180 2355

16.000 102.90 102.72 0.625 14.750 14.562 14.605 5.86 2.75 18.959 1801 1896 1991 2085 2275 2370 2559

16.000 109.00 107.60 0.656 14.688 14.600 14.643* 5.86 2.75 19.795 1881 1980 2078 2177 2375 2474 2672

Tensile strength calculated on K-55/L-80 = 95 ksi, N-80/C-90 = 100 ksi, T-95 = 105 ksi, HC-95 = 110 ksi, C-110 = 120ksi, P-110 = 125 ksi, Q-125 = 135 ksi ultimate.

* For this item bore will pass popular drift size.

] Interchangeable where bracketed.

Hydril 513 is interchangeable with Hydril 523 in a given size and weight.

BOX

©2006 Hydril Company LP All Rights Reserved

Hydril 513™ Efficiency and Torque Values

PIPE CONNECTION

Size OD & Weight Wall Efficiency Make-up Torque Yield Torque (Maximum Torque)

(Nominal) Thickness Bending/ Compression Minimum Target K-55 N-80/ T-95/ C-110/ Q-125

C-90

Tension L-80 HC-95 P-110

Inches Lbs/Ft Inches % % Ft-Lbs Ft-Lbs Ft-Lbs Ft-Lbs Ft-Lbs Ft-Lbs Ft-Lbs Ft-Lbs

4.500 11.60 0.250 61.9 71.2 2800 3400 8600 11500 12700 13300 15000 17000

4.500 12.60 0.271 62.8 71.7 3000 3600 8600 11500 12700 13200 15000 17000

4.500 13.50 0.290 59.7 72.6 3900 4700 12000 16000 18000 19000 21000 24000

4.500 15.10 0.337 63.1 74.1 5100 6200 14000 18000 20000 21000 24000 26000

4.500 16.60 0.375 64.7 76.6 6000 7200 16000 21000 23000 24000 27000 30000

4.500 17.00 0.380 64.6 76.6 6100 7400 16000 21000 23000 24000 27000 30000

4.500 18.80 0.430 62.9 73.5 6800 8200 16000 21000 23000 24000 27000 30000

4.500 21.50 0.500 62.9 72.0 6700 8100 13500 17000 19000 20000 22000 24000

5.000 15.00 0.296 60.1 72.4 4700 5700 15000 20000 22000 23000 26000 29000

5.000 18.00 0.362 63.7 73.7 6500 7800 17000 23000 25000 26000 29000 33000

5.000 21.40 0.437 62.5 72.8 8200 9900 20000 26000 29000 30000 34000 38000

5.000 23.20 0.478 62.6 71.7 7700 9300 17000 22000 24000 25000 28000 31000

5.000 24.10 0.500 61.8 70.7 8000 9600 17000 22000 24000 25000 28000 31000

5.000 26.70 0.562 64.2 72.1 11000 13200 22000 28000 30000 31000 35000 39000

5.500 17.00 0.304 62.8 74.4 5100 6200 18000 24000 26000 28000 31000 35000

5.500 20.00 0.361 63.8 73.9 7000 8400 20000 27000 30000 31000 35000 39000

5.500 23.00 0.415 63.5 74.1 8400 10100 23000 31000 34000 36000 41000 45000

5.500 26.00 0.476 63.5 72.8 8200 9900 20000 26000 28000 29000 33000 37000

7.000 26.00 0.362 62.4 72.3 7900 9500 31000 42000 47000 49000 56000 63000

7.000 29.00 0.408 61.5 75.8 7900 9500 26000 35000 39000 41000 46000 52000

7.000 32.00 0.453 63.7 76.7 10700 12900 34000 46000 51000 53000 61000 68000

7.000 35.00 0.498 61.8 73.6 11700 14100 34000 46000 51000 54000 61000 68000

7.000 38.00 0.540 62.9 75.4 14900 18000 43000 59000 65000 68000 77000 86000

7.625 29.70 0.375 60.0 75.2 9000 10800 38000 53000 59000 62000 70000 79000

7.625 33.70 0.430 59.8 73.4 8700 10500 31000 42000 46000 48000 55000 62000

7.625 39.00 0.500 62.0 73.8 12500 15000 40000 54000 60000 63000 72000 80000

7.625 42.80 0.562 65.5 77.4 17000 21000 51000 69000 76000 80000 91000 102000

7.625 45.30 0.595 62.1 73.4 18000 22000 52000 70000 77000 81000 91000 102000

7.750 46.10 0.595 60.8 72.2 18000 21000 53000 72000 79000 83000 94000 106000

8.625 40.00 0.450 58.9 73.2 10100 12200 55000 78000 86000 91000 104000 118000

9.375 39.00 0.400 58.9 73.2 10100 11600 52000 76000 85000 90000 104000 118000

9.625 47.00 0.472 61.7 74.3 14000 17000 61000 84000 94000 98000 112000 126000

9.625 53.50 0.545 60.5 72.9 18000 22000 78000 108000 120000 126000 144000 163000

9.625 58.40 0.595 62.9 74.3 21000 26000 78000 108000 120000 126000 144000 161000

9.875 62.80 0.625 62.6 73.4 22000 27000 82000 114000 126000 132000 151000 170000

9.875 65.10 0.650 60.4 70.8 22000 27000 82000 114000 126000 132000 151000 170000

10.750 55.50 0.495 60.9 73.2 18000 22000 75000 105000 117000 123000 141000 159000

10.750 60.70 0.545 66.4 79.0 23000 28000 98000 136000 151000 158000 181000 204000

10.750

11.750

11.750

65.70

60.00

65.00

0.595

0.489

0.534

61.1

65.7

60.4

72.7

78.1

71.8

25000

20000

22000

30000

24000

26000

98000

89000

89000

136000

125000

125000

151000

139000

139000

158000

146000

146000

181000

168000

168000

204000

189000

189000

Hydril 513™

11.875

12.750

71.80

88.00

0.582

0.672

61.8

62.7

74.5

73.0

30000

37000

36000

44400

124000

133000

174000

186000

195000

207000

205000

218000

235000

249000

266000

281000

Integral Casing Connection

13.375 68.00 0.480 63.5 75.9 24000 29000 115000 162000 181000 190000 218000 246000 BULLETIN 9902-C (REPLACES 9902-B)

13.375 72.00 0.514 62.1 73.7 26000 31000 115000 162000 181000 190000 218000 246000

13.625 88.20 0.625 60.1 74.5 42000 50000 205000 288000 321000 338000 388000 438000

14.000 99.60 0.700 66.0 75.8 44000 53000 160000 223000 249000 261000 299000 337000

14.000 104.20 0.734 63.1 72.5 46000 55000 161000 224000 249000 262000 300000 338000

14.000 112.60 0.797 62.6 74.1 48000 58000 195000 271000 302000 317000 363000 409000

14.000 113.00 0.800 64.3 75.8 48000 58000 195000 271000 302000 317000 363000 409000

16.000 95.00 0.566 63.6 76.7 44000 53000 225000 319000 357000 376000 433000 490000

16.000 96.00 0.575 62.6 75.5 45000 54000 225000 319000 357000 376000 433000 490000

16.000 102.90 0.625 62.8 73.9 47000 56000 207000 293000 327000 344000 395000 447000

16.000 109.00 0.656 62.6 73.2 48000 58000 207000 292000 326000 343000 395000 446000

The minimum and target make-up torque values apply to all grades and alloys of steel.

Many factors influence torque application. To ensure that minimum torque is attained, a field target torque (optimum torque) 15% over minimum is recommended.

An appropriate safety factor should be applied to these yield torque values.

HYDRIL HYDRIL INTERNATIONAL TUBULAR SALES

Houston, Texas Aberdeen, Scotland

Telephone: 281.985.3412 Telephone: +44.1224.299.554

Fax: 281.985.3376 Fax: +44.1224.299.578 R E D E F I N I N G R E L I A B I L I T Y T M

E-mail: tubularsales@hydril.com www.hydril.com E-mail: hits@hydril.com

Potrebbero piacerti anche

- Fundamentals and Applications of Bionic Drilling FluidsDa EverandFundamentals and Applications of Bionic Drilling FluidsNessuna valutazione finora

- Hydril 533Documento4 pagineHydril 533Fernando OlaveoNessuna valutazione finora

- Hydril 523™ PDFDocumento4 pagineHydril 523™ PDFrenatoNessuna valutazione finora

- Hydril Mac IIDocumento4 pagineHydril Mac IIFabian Romero BecerraNessuna valutazione finora

- Hydril 563™ B PDFDocumento4 pagineHydril 563™ B PDFrenatoNessuna valutazione finora

- Hydril 523 Integral Casing Connection: Hydril 523 Efficiency and Torque ValuesDocumento4 pagineHydril 523 Integral Casing Connection: Hydril 523 Efficiency and Torque ValuestheislandboyNessuna valutazione finora

- Manual Manual Power TongDocumento13 pagineManual Manual Power TongJAVIER EDUARDO MANTILLA BUITRAGONessuna valutazione finora

- Drill CollarDocumento1 paginaDrill CollarGuillermo Rangel AvalosNessuna valutazione finora

- TenarisHydril Wedge523 521 Running GuidelinesDocumento16 pagineTenarisHydril Wedge523 521 Running GuidelinesJuan RuizNessuna valutazione finora

- Junk Subs (JUNK BASKET)Documento1 paginaJunk Subs (JUNK BASKET)mosli_Nessuna valutazione finora

- 20-1718 Rig Tongs AOTDocumento10 pagine20-1718 Rig Tongs AOTRahul M.R100% (1)

- Drill Pipe Performance DataDocumento35 pagineDrill Pipe Performance DatasnatajNessuna valutazione finora

- AOT Brochure-Safety Clamp Type C PDFDocumento1 paginaAOT Brochure-Safety Clamp Type C PDFtedongsalekoNessuna valutazione finora

- Drilling SpoolDocumento2 pagineDrilling SpoolCarlos Sarmiento CalderónNessuna valutazione finora

- Wellhead Equipment CatalogDocumento29 pagineWellhead Equipment CatalogDewy PambayunNessuna valutazione finora

- Side Entry Subs (Welded) - Oil Rig Drill String Accessories - Downhole Oil Tools, IncDocumento2 pagineSide Entry Subs (Welded) - Oil Rig Drill String Accessories - Downhole Oil Tools, Inccaballero_tigreNessuna valutazione finora

- Tablas Tuberia XTDocumento35 pagineTablas Tuberia XTArcadio Bahena100% (1)

- Drilling Hole Opener WebDocumento2 pagineDrilling Hole Opener WebBehrangNessuna valutazione finora

- Drilco Spiral Drill Collar PsDocumento1 paginaDrilco Spiral Drill Collar Psyojan35Nessuna valutazione finora

- Botil Model BTCN Mechanical Set PackerDocumento2 pagineBotil Model BTCN Mechanical Set PackerReivaj JavierNessuna valutazione finora

- BOP Drawing Template BaseDocumento39 pagineBOP Drawing Template BaseSergio Ali TerrazasNessuna valutazione finora

- 10 Appendix Casing Size TableDocumento16 pagine10 Appendix Casing Size TableDen MartinNessuna valutazione finora

- FPI Freepoint IndicatorDocumento1 paginaFPI Freepoint IndicatorBayu CiptoajiNessuna valutazione finora

- Maintenance Steps of Mud Gas SeparatorDocumento1 paginaMaintenance Steps of Mud Gas SeparatorNumbWong100% (1)

- Slip Type ElevatorDocumento15 pagineSlip Type ElevatorJohn Jairo Simanca100% (1)

- Annexure-1 - Sub Surface Testing of Liner Hanger, Tie Back Packer & SISO Anchor Seal Assembly PDFDocumento7 pagineAnnexure-1 - Sub Surface Testing of Liner Hanger, Tie Back Packer & SISO Anchor Seal Assembly PDFMehdi NorouziNessuna valutazione finora

- CF Diverter BrochureDocumento2 pagineCF Diverter BrochureRobertok1234Nessuna valutazione finora

- IV-0794-20 CROSS OVER Pin-Box 05807HDocumento1 paginaIV-0794-20 CROSS OVER Pin-Box 05807Hivan dario benavides bonillaNessuna valutazione finora

- Gryphon Product OverviewDocumento51 pagineGryphon Product OverviewTaras ByloNessuna valutazione finora

- Series 150 Overshot Make Up Torques PDFDocumento8 pagineSeries 150 Overshot Make Up Torques PDFRazvan RaduNessuna valutazione finora

- Iv-0017-21 Overshot Standard X42093Documento1 paginaIv-0017-21 Overshot Standard X42093ivan dario benavides bonillaNessuna valutazione finora

- Cameron - DL-Annular BopDocumento1 paginaCameron - DL-Annular BopAnonymous 48jYxR1CNessuna valutazione finora

- RP Insp Rep 01Documento8 pagineRP Insp Rep 01advantage025Nessuna valutazione finora

- STRG CapacitiesDocumento1 paginaSTRG Capacitiesislam atifNessuna valutazione finora

- Basic of Drillpipe Tensile Capacity and Its Calculation PDFDocumento5 pagineBasic of Drillpipe Tensile Capacity and Its Calculation PDFMokr AchourNessuna valutazione finora

- Slip Type Elevator - YT - HYT - YC - HYC Slip Type Elevator For Drilling or Work-Over OperationDocumento1 paginaSlip Type Elevator - YT - HYT - YC - HYC Slip Type Elevator For Drilling or Work-Over OperationHanyNessuna valutazione finora

- Drill Pipe Spec's SheetDocumento10 pagineDrill Pipe Spec's SheetAhmed BakrNessuna valutazione finora

- Drill Pipe Spec SheetDocumento2 pagineDrill Pipe Spec SheetVijay KotiNessuna valutazione finora

- BHA FishingDocumento104 pagineBHA FishingDiego Armando HerreraNessuna valutazione finora

- 4in DP 14# IU S135T XTF39 (5.00 x2.5625)Documento7 pagine4in DP 14# IU S135T XTF39 (5.00 x2.5625)Pavin PiromNessuna valutazione finora

- Hammer Unions PDFDocumento7 pagineHammer Unions PDFflasher_for_nokiaNessuna valutazione finora

- Rotary Shouldered Connections BMCPDocumento37 pagineRotary Shouldered Connections BMCPOGIS MKNessuna valutazione finora

- VFP - Vam Eis - en PDFDocumento30 pagineVFP - Vam Eis - en PDFZed ZedNessuna valutazione finora

- Tenaris Running Manual 01Documento20 pagineTenaris Running Manual 01advantage025Nessuna valutazione finora

- Drillstar CatalogueDocumento16 pagineDrillstar CatalogueDon BraithwaiteNessuna valutazione finora

- Tool Joint Data Assembly Data: Drill Pipe Data TablesDocumento5 pagineTool Joint Data Assembly Data: Drill Pipe Data TablesSefa AslanhanNessuna valutazione finora

- DRT Motor Manual 6-16-10Documento55 pagineDRT Motor Manual 6-16-10sumsolcaggNessuna valutazione finora

- API Box Boreback Stress Relief With Truncated Threads Can Cause Premature Connection Fatigue Failure, Gerdes, 2010Documento8 pagineAPI Box Boreback Stress Relief With Truncated Threads Can Cause Premature Connection Fatigue Failure, Gerdes, 2010Ryan Fenyves100% (1)

- Octg Division: Date:19/02/2016 Reference: MD-15-XXX Rev 0Documento2 pagineOctg Division: Date:19/02/2016 Reference: MD-15-XXX Rev 0Jenny100% (1)

- HeavyWeight 3.5 25.58lbs NC-38Documento3 pagineHeavyWeight 3.5 25.58lbs NC-38Инженер Луис А. ГарсиаNessuna valutazione finora

- TenarisHydril Wedge 563 RunningGuidelinesDocumento16 pagineTenarisHydril Wedge 563 RunningGuidelinesDario JaimesNessuna valutazione finora

- 2-36, TMC Jar, OpDocumento15 pagine2-36, TMC Jar, OpAli HosseiniNessuna valutazione finora

- Griffith Drilling JarDocumento1 paginaGriffith Drilling JarFakhrurrozi ArbianNessuna valutazione finora

- 50000805Documento138 pagine50000805HayLenLeeNessuna valutazione finora

- Mud Gas Separator InfoDocumento2 pagineMud Gas Separator InfoHIPAPNessuna valutazione finora

- Rotating Control Device: SperrydrillingservicesDocumento4 pagineRotating Control Device: SperrydrillingservicesSlim.B100% (1)

- Hydril 521™Documento4 pagineHydril 521™renatoNessuna valutazione finora

- Use This Chart Only When All Outriggers Are Fully Extended: Rated Load On OutriggersDocumento1 paginaUse This Chart Only When All Outriggers Are Fully Extended: Rated Load On OutriggersYeison UribeNessuna valutazione finora

- Table A-1 Asphalt Institute's Equivalent Axle Load Factors: Axle Load (LB) Single Axle Tandem Axles Tridem AxlesDocumento8 pagineTable A-1 Asphalt Institute's Equivalent Axle Load Factors: Axle Load (LB) Single Axle Tandem Axles Tridem AxlesEdgar Limo SaavedraNessuna valutazione finora

- EIC4 Workbook AKDocumento13 pagineEIC4 Workbook AKrenato100% (3)

- Drilling Mud and Cement Slurry (1982)Documento118 pagineDrilling Mud and Cement Slurry (1982)renatoNessuna valutazione finora

- Ebook 2019Documento128 pagineEbook 2019renatoNessuna valutazione finora

- Casing Data SheetDocumento19 pagineCasing Data Sheetdursosono50% (2)

- Textbook DetDocumento12 pagineTextbook DetrenatoNessuna valutazione finora

- Ebook 2020Documento96 pagineEbook 2020renato0% (2)

- English in Common 6 Unit 9 Test: Answer Key: Permission Granted To Reproduce For Classroom UseDocumento1 paginaEnglish in Common 6 Unit 9 Test: Answer Key: Permission Granted To Reproduce For Classroom UserenatoNessuna valutazione finora

- English in Common 4 Review Test 1 Units 1-5: Answer Key: Permission Granted To Reproduce For Classroom UseDocumento1 paginaEnglish in Common 4 Review Test 1 Units 1-5: Answer Key: Permission Granted To Reproduce For Classroom UserenatoNessuna valutazione finora

- EIC4 Review Test1 AKDocumento4 pagineEIC4 Review Test1 AKrenatoNessuna valutazione finora

- English in Common 4 Review Test 1 Units 1-5: Audioscript: Track 40Documento1 paginaEnglish in Common 4 Review Test 1 Units 1-5: Audioscript: Track 40renatoNessuna valutazione finora

- EIC4 Review Test1Documento4 pagineEIC4 Review Test1renatoNessuna valutazione finora

- AcknowledgmentsDocumento2 pagineAcknowledgmentsrenatoNessuna valutazione finora

- English in Common 4 Review Test 2 Units 6-10: Answer Key: Permission Granted To Reproduce For Classroom UseDocumento1 paginaEnglish in Common 4 Review Test 2 Units 6-10: Answer Key: Permission Granted To Reproduce For Classroom UserenatoNessuna valutazione finora

- Los Verb Pattenrs Más Importantes Del Inglés NewDocumento1 paginaLos Verb Pattenrs Más Importantes Del Inglés NewYuraimig RiveroNessuna valutazione finora

- Front Matter PDFDocumento2 pagineFront Matter PDFrenatoNessuna valutazione finora

- 31 - Temperature in WellsDocumento7 pagine31 - Temperature in WellsAgus AlexandriNessuna valutazione finora

- EIC6 Final TestDocumento3 pagineEIC6 Final TestrenatoNessuna valutazione finora

- Monte Carlo With Applications To Finance in RDocumento73 pagineMonte Carlo With Applications To Finance in RMadMinarch100% (2)

- Monte Carlo Simulation in Engineering PDFDocumento98 pagineMonte Carlo Simulation in Engineering PDFrenatoNessuna valutazione finora

- Tapa IndiceDocumento3 pagineTapa IndicerenatoNessuna valutazione finora

- Organizational Learning: Why Become An Organization That Learns? Learning Organizational ChecklistDocumento2 pagineOrganizational Learning: Why Become An Organization That Learns? Learning Organizational ChecklistrenatoNessuna valutazione finora

- Frontmatter 2018 PDFDocumento2 pagineFrontmatter 2018 PDFrenatoNessuna valutazione finora

- AcknowledgmentsDocumento2 pagineAcknowledgmentsrenatoNessuna valutazione finora

- PetroBowl Set IDocumento47 paginePetroBowl Set IrenatoNessuna valutazione finora

- 501solved ProblemsDocumento14 pagine501solved Problemsrenato0% (5)

- Foreword PDFDocumento1 paginaForeword PDFrenatoNessuna valutazione finora

- IntroductionDocumento5 pagineIntroductionrenato100% (1)

- 501solved ProblemsDocumento14 pagine501solved Problemsrenato0% (5)

- DrillingDocumento1 paginaDrillingrenatoNessuna valutazione finora

- 501solved ProblemsDocumento14 pagine501solved Problemsrenato0% (5)

- Panduit Electrical CatalogDocumento1.040 paginePanduit Electrical CatalognumnummoNessuna valutazione finora

- Netapp Cabling and Hardware BasicsDocumento14 pagineNetapp Cabling and Hardware BasicsAnup AbhishekNessuna valutazione finora

- BemlDocumento46 pagineBemlrushabhNessuna valutazione finora

- CM6 Combined 2013Documento154 pagineCM6 Combined 2013مسعد مرزوقىNessuna valutazione finora

- ASWipLL HW Installation Guide-V07-460Documento322 pagineASWipLL HW Installation Guide-V07-460Fernando MartinNessuna valutazione finora

- 802 OM 4-InspDocumento12 pagine802 OM 4-InspGabriel vieiraNessuna valutazione finora

- Singapore - GCCM Talk SlidesDocumento115 pagineSingapore - GCCM Talk SlidesChimhuee ChuaNessuna valutazione finora

- Transmission and DistributionDocumento10 pagineTransmission and Distributionprabhjot singh186% (21)

- MB Biostar P4SDP 3 PDFDocumento12 pagineMB Biostar P4SDP 3 PDFEustahije BrzicNessuna valutazione finora

- DataDocumento194 pagineDataddlaluNessuna valutazione finora

- Mubeen Ahmad: Mobile: +92-3085235851Documento3 pagineMubeen Ahmad: Mobile: +92-3085235851engr.zubair34Nessuna valutazione finora

- IBM Whitepaper OSIMMDocumento22 pagineIBM Whitepaper OSIMMKlaus DoernerNessuna valutazione finora

- KP Sharma Estimate PDFDocumento3 pagineKP Sharma Estimate PDFSudip GhimireNessuna valutazione finora

- Enzymes and Effects of PHDocumento4 pagineEnzymes and Effects of PHSeph Cordova50% (2)

- Powershell Import Update Users Groups From CSV FileDocumento2 paginePowershell Import Update Users Groups From CSV FilecrakchakibNessuna valutazione finora

- Bucher LRV Hydraulic ValveDocumento90 pagineBucher LRV Hydraulic Valvedean_lockey0% (1)

- Positector Calibration ProcedureDocumento6 paginePositector Calibration ProcedureluigimasterNessuna valutazione finora

- Ii.7.2 Alat Kedokteran 2 PDFDocumento153 pagineIi.7.2 Alat Kedokteran 2 PDFAguesBudi S TalawangNessuna valutazione finora

- Vibration Diagnosis and CorrectionDocumento54 pagineVibration Diagnosis and Correctionbhanuka2009Nessuna valutazione finora

- SJ-20121112095141-003-LTE (V3.10.10) Alarm Handling (FDD) PDFDocumento338 pagineSJ-20121112095141-003-LTE (V3.10.10) Alarm Handling (FDD) PDFRahul SharmaNessuna valutazione finora

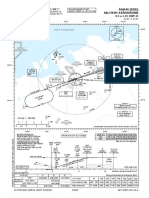

- I/G/O I/G/O A/M/I: Instrument Approach Chart - IcaoDocumento1 paginaI/G/O I/G/O A/M/I: Instrument Approach Chart - IcaoMIkołaj MorzeNessuna valutazione finora

- Wave Load Calculation in Transitional Water (Prototype)Documento1 paginaWave Load Calculation in Transitional Water (Prototype)pradewoNessuna valutazione finora

- Building A Model Steam Engine From Scratch Chapter 1, 150 121Documento19 pagineBuilding A Model Steam Engine From Scratch Chapter 1, 150 121Liam Clink100% (2)

- MTK 1023-Material and ConsumableDocumento13 pagineMTK 1023-Material and ConsumableGraceLamNessuna valutazione finora

- SET-1: Answer To The Interview QuestionsDocumento9 pagineSET-1: Answer To The Interview QuestionsÆshok IncreĐible KingNessuna valutazione finora

- Mastering Bitcoin PDFDocumento282 pagineMastering Bitcoin PDFdoanminhNessuna valutazione finora

- PayrollBatchLoader v4Documento158 paginePayrollBatchLoader v4MaheshNessuna valutazione finora

- Structural MembersDocumento37 pagineStructural Membersmario gadianoNessuna valutazione finora

- Craftsman 73754 ManualDocumento24 pagineCraftsman 73754 Manualjkchromy945Nessuna valutazione finora

- Us 8466302Documento11 pagineUs 8466302Widya Isti AriantiNessuna valutazione finora