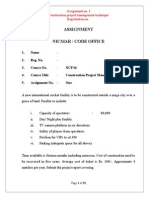

Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Connections - Art, Science, and Information in The Quest For Economy and Safety

Caricato da

Srinivasan NarasimhanTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Connections - Art, Science, and Information in The Quest For Economy and Safety

Caricato da

Srinivasan NarasimhanCopyright:

Formati disponibili

Connections: Art, Science, and Information

in the Quest for Economy and Safely

DR. WILLIAM A. THORNTON

INTRODUCTION Load (UDL): For moment connections, the notes might say

Connections are an extremely important part of the final use stiffeners and doublers as required, and design for the

configuration of a steel structure. Many, if not most, collapses strength of the beams. For bracing connections, a typical

are caused by inadequate connections. The constructed cost detail might be shown with a statement to design for all

of a steel frame is heavily dependent on the connections used, eccentricities. It is the primary purpose of this paper to show

both the type of connection and how they are configured. Yet, by anecdotal examples, i.e., "war stories," that this approach

connections are often an afterthought. Commercially avail- to connections can be both uneconomical and unsafe. A

able software will pretty much automatically design the mem- secondary purpose is to give the motivation behind a new

bers of the frame, but there is no commercially available method of bracing design called the Uniform Force Method.

software that will do the same for the connections. In fact, the Examples will be given of shear connections, bracing connec-

frame design software chooses "optimal" members, usually tions, and moment connections.

least weight, with no regard whatsoever as to how these

members will impact on the connections. SHEAR CONNECTIONS

The emphasis in engineering schools is similar to that of Shear connections are a subject where information is the primary

commercially available design software, i.e., it is on the quantity lacking on most jobs. These connections have been

design of members. Very little work is done on connections heavily studied over the years, and other than questions regard-

at the undergraduate level and probably also at the graduate ing ductility and robustness, are well understood.

level. Connections are considered by many professors as Shear connections are the most common connection on all

essentially trivial in a mathematical sense. Very sophisticated jobs. Ideally, the engineer should give the shear for every

and mathematically elegant solutions can be prescribed for beam end. While this may appear to be a lot of extra work, it

member and frame design; e.g., lateral torsional buckling of is not as difficult as it first seems since the loads are known

members, and the direct stiffness method for frames. Connec- from sizing the beams. Why not put them on the drawing? (In

tions, on the other hand, are thought to be designed by no more addition to helping the fabricator, having the loads used in the

sophisticated analysis than counting bolts and determining original design right on the drawing is very handy for future

weld lengths. This is not true except for the simplest connec- renovations.) If the loads are shown for every beam end, there

tions. While there are essentially only three types of members is very little room for error, and the connections will be as

in a structural frame (beams, columns, and beam-columns), economical as possible.

there is an almost infinite variety of connections depending However, instead of actual loads, most jobs these days have

on frame geometry. For this reason, connection design is one or more of the statements regarding shear connections:

actually more interesting than member design, because this

great variety often requires the designer to rely on intuition • Item 1. All shear connections shall contain the maximum

and art as well as science. possible number of rows of bolts;

As mentioned above, connections are often an after- • Item 2. Design all shear connections for one-half UDL;

thought. In many engineering offices, once the frame is • Item 3. Design all shear connections for the shear capac-

designed and "on paper," the drawings are ready to be "re- ity of the beam;

leased for construction." Connections are handled by a series • Item 4. Minimum design loads for standard rolled shapes,

of typical details and general notes which refer to AISC unless noted otherwise:

manuals. Typical notes for shear connections might make

reference to full depth connections or the Uniform Design W8 C8 . . 10 kips W21 65 kips

W10C10 15 kips W24 75 kips

W12C12 25 kips W27 90 kips

W14C15 35 kips W30 125 kips

Dr. William A. Thornton is chief engineer, Cives Steel Co. and

W16 . . . 45 kips W33 140 kips

president, Cives Engineering Corp., Roswell, GA.

W18 . . . 55 kips W36 175 kips

132 ENGINEERING JOURNAL / FOURTH QUARTER /1995

Item 3

Let's consider each of these.

Item 3 requires the connection to develop the shear capacity

of the beam, but this is impossible with the usual shear

Iteml

connections (single clips, double clips, shear end plate, shear

Item 1 requires "full depth" connections. tab) unless the beam is haunched or web doublers are used.

The fabricator assumes the engineer has reviewed his Also, since most beams are coped, just what is the "shear

design and the capacity of these connections will exceed the capacity" of the beam? Is it the uncoped capacity (35.4 kips

actual loads in all cases. But in many cases, these will be for the W 10x22 shown previously) or should the capacity of

uneconomical, as with long span beams. In other cases, they what is left be used?

may be unsafe. It's clear that Item 3 is ambiguous, which can lead to errors

Suppose a beam has a large cope, as when connecting a affecting safety as well as result in ridiculous designs. In

small beam to a large one (see Figure 1). This may greatly Figure 6, the W 10x22 of Figure 4 has end connections good

reduce the capacity of the full depth connection because of for 35.4 kips, which means the W10x22 is capable of support-

the reduced beam section. Has the engineer considered this, ing 35.4 tons! Obviously, these W10x22s are just intended to

or has he reviewed his drawings by checking the actual load reduce the unbraced length or provide decking support. If a

against the capacity of a full depth connection on an uncoped real load of 35.4 tons must be carried, a short W 18x35 with

beam? It is very likely that he has done the latter. As a second five rows of bolts would be cheaper and safer.

example, consider steel at different elevations.

Figure 2 shows a "full depth" connection for the upset

Item 4

W 18x35. The capacity of this "full depth" connection is 20k

whereas a true full depth connection for the W 18x35 (Figure While at first glance, Item 4 appears to be innocuous, try to

3) is 49k. Will the engineer realize this if he specifies "use the develop 15k in the W 10x22 shown previously. Figure 7

maximum possible number of rows"? results.

Item 2 Single Angles and UDL

If in-fill beams frame near the ends of a main beam, the UDL The uniform design load UDL is a great crutch of the engineer

method can be unsafe. If beams are short, it will be uneco- because it allows him to issue design drawings without put-

nomic. Figure 4 shows a floor framing plan. All beam shear ting the beam reactions on the drawings. Instead, often the

connections are contractually required to be designed for fabricator is told to design the beam end connections for

one-half UDL. The three W10x22s framing between the one-half UDL, or some other percentage to account for com-

W36xl70 and the W36x230 are 3-ft. long. The one-half UDL posite design, unless greater reactions are shown. Unless

reaction is 61.8k! Of course, this is ridiculous—but the fab- concentrated loads are located very near the beam ends, UDL

ricator is contractually obliged to supply it if the engineer reactions are generally very conservative. Because the reac-

insists, and we have done jobs where the engineer did just tions are too large, extremely strong connections, such as

that. Figure 5 shows the resulting connection. Note that the double framing angles, will often be required.

shear capacity of a W10x22 is only 35.4 kips, so designing Single angles, because the bolts are in single shear, will

for 61.8 kips is doubly ridiculous and leads to a discussion of have about half the strength of double clips for the same

Item 3. number of rows of bolts. But if actual reactions are given, it

W18 x 35

CARRYING DEAM

\

-jr—

jjr#]

1J

r IN-FILL BEAM

COPE 7% X 7%

1-

"Hr## I

"Hr I

nr#l

CAPACITY = 20 KIPS

BOLTS A325N >U 0

W30 x 173

Fig. 1. Usual beam to beam connection top of

steel at common elevation. Fig. 2. "Full depth " connection for upset beam.

ENGINEERING JOURNAL/FOURTH QUARTER/ 1995 133

will almost always be found that a single angle connection ft.x200 ft. with 25-ft. bays and 200 beams per floor with single

will work, perhaps with a couple of extra rows of bolts. angles, there is a savings of 200 x 30 x 25 = $150,000.

Figure 8 is part of an industrial building with dead load of Returning to Figure 8, suppose Beam 1 is subjected to the

140 psf and live load of 250 psf. Beam 1, of Figure 8 is shown same load of 82 kips total, but 32 of the 82 is a concentrated

in Figure 9. The total load on Beam 1 is 82 kips and the actual load located at mid-span, such as from a vessel. Figure 11

reactions are thus 41 kips. The one-half UDL reaction is 45 shows the actual reaction of the beam, now a W24x76, is still

kips, which is pretty close. Now look at the connections. The 41 kips, while the one-half UDL reaction is 56 kips—which

minimum double clip connection on this coped beam has four is 37 percent greater than the actual reaction. This means

rows and is good for 81 kips, almost twice the actual reaction. while a five row single angle connection is okay for the actual

Many designers routinely require "full depth" connections, reaction, a six row connection with a capacity of 66 kips

i.e. six rows. The six row double dip connection is good for would be required for the one-half UDL reaction. Figure 12

166 kips, almost three times the actual reaction. However, a shows the disparity between actual and one-half UDL reac-

five row single angle is good for 52 kips, which is okay for tions for Beam 2. Again, single angles are sufficient.

the actual and the one-half UDL reactions.

BRACING CONNECTIONS

As this example illustrates, single angles will work even in

heavy industrial applications, and they are much less expen- Bracing connections are subject where the art and science of

sive than double clips, especially for erection. In Figure 10, connection design can be used to achieve a safe and efficient

the connections for this W24x55 beam have the same strength design. They are also an area where missing or misleading

and have a differential cost of $ 10 for fabrication. But, includ- information can lead to drastically unsafe connections or

ing erection, the single angle beam costs approximately $25 connections which are grossly over-designed.

less than the double clip beam. For a 30-story building, 200

COPE 2 x 6lU COPE 2\ x 8''i

3 3

COPE l '« X 7 '4

r W18 x 35

CAPACITY

= 49 KIPS

W30 x 173 BOLTS A325N3'4 0

/

Fig. 5. Section AA of Figure 4 W10x22 to carry

Fig. 3. Normal full depth connection. V2 UDL = 61.8 kips reaction each end.

ENGINEERS NOTE: DESIGN BEAM END CONNECTIONS COPE 2 x 61' COPE 2% x 8''i

FOR AXIAL FORCES SHOWN ON PLANS

1

24-6 ^, 24-6 =U li=

W10 x 22

r* • 1

• 4

[ DOLT

r* •4

-] —/\^ /A\ •4

• -j

x

'J PL

\'3C> x 170 W36

1 " 1 .vu I

r I

L

W12«96 1*8$*) i

" ' \ p

p

£3«3>'2(*3SK) TYP THIS BAT D

WT6"I8&75 K UN0)TYPTHIS BAY

Fig. 6. Section AA of Figure 4 W10x22 to carry maximum

Fig. 4. Ambiguous forces for connection design. uncoped shear capacity of 35.4 kips as reactions at each end.

134 ENGINEERING JOURNAL / FOURTH QUARTER / 1995

Art and Science the resultant forces on the gusset edges for a wide variety of

Figure 13 shows a bracing connection design method which gusset edge support conditions are seen to fall within the

satisfies all of the requirements for equilibrium for the gusset, envelopes shown. The edge resultants appear to intersect with

the beam, and the column. It includes consideration of all the line of action of the brace at a point on this line on the

eccentricities and it is simple to use because all forces acting other side of the working point (WP) from the gusset. Note

between the gusset and the beam and column are known that no couples were required in Figure 14. This data from

before the size of the gusset is known. It has been referred to Richard is the genesis of the author's development of what

as the KISS method by a detailer who was impressing upon has come to be called the Uniform Force Method (Thornton

his people the necessity of getting the shop drawings "out the 1991, 1992 and AISC 1992, 1994). The method is shown in

door." Thus, the sarcastic comment to "Keep It Simple, Stu- Figure 15A. Figure 15B shows a force distribution which

pid!," or use the KISS method. Unfortunately, while this captures the essence of the distributions given "fuzzily" in

method is a boon to the detailer, it is a bane to the fabricator Figure 14. In other words, a force structure is imposed on

and owner. It results in large and expensive connections. Also, Richard's data. In order to test the efficacy of this structure,

the engineer and owner do not like it when, if there are four the data of six full scale tests were filtered through it. The tests

gussets in a building panel, they almost meet at the center. were performed by Chakrabarti and Bjorhovde, (1983,1985)

Also, the load paths through this gusset, beam, and column and Gross and Cheok (1988, 1990). Typical test specimens

are very unnatural and inefficient as will be shown. are shown in Figures 16 and 17. The limit states considered

Beginning about 15 years ago, AISC began to address this in the filtering process are given in Tables 1 and 2. Table 3

problem with a research program at the University of Arizona. shows the results. For the Chakrabarti/Bjorhovde tests, excel-

This program resulted in published work by Richard (1986) lent agreement is achieved. The ratio of test capacity to

which contained figures similar to Figure 14. In this Figure, predicted capacity is close to but slightly larger than unity as

COPE 2 x 6%U COPE 2 \ x Bl't

,— 3.25 Wft

W21x68 v /

~r i i .i i r

25-0

V-

• * - BOLTS A32SN>'4 0

BEAM SeoiON Lc*o» RlACTlCNi C.o**cncki5

A

W36 x 170

* \

W36 x 230

IWoftM

"^FT

COMC.

hA

-&TAL

fclFS

ACTUAL

bps

fcUDL

k-e5

MIKI

"ROMS

DOUBLE. CLIPS

Of

(tori) " Rows

CAP

SINGLE CUP

CAP

1 UZ)*66 3Z3 o 82 41 i5 i | 81 | 6 | M6 •b | S2

BOLTS 7 8 0 A 325N, CUPS 4 X 3» 2 X 3 8

3*0

fe- 4

Fig. 7. Section AA of Figure 4 W10x22 to

carry 15 kip reaction each end. Fig. 9. Comparisons for beam 1 of Figure 8—uniform load.

SINGLE CLIPS DOUBLE CLIPS

W33X1I9

U24>55

(EH &i

$

T rvows 5AME. STKENGTM 4 ^ows

FABRICATION - $io PER BEAM LESS FOR SINGLE CUPS

W33xitg

ERECTION - $ 15 PER BEAM LESS FOR SINGLE CUPS

JL±. g-4 g-4 TOTAL COST REDUCTION $ 2 5 PER B E A M USING SINGLE CLIPS

Fig. 8. Partial plan of industrial building floor. Fig. 10. Cost comparison same strength single and double clips.

ENGINEERING JOURNAL / FOURTH QUARTER / 1995 135

Table 1. Table 2.

Limit State Identification for Bracing Connections Limit States Considered for Each Interface

of Bracing Connections

Limit State Type Limit State Number

Connection Connection Limit

Bolt Shear Fracture 1 Interface Element States

Bolt Shear/Tension Fracture 2

Whitmore Yield 3 Brace to Gusset Bolts to Gusset 1

Whitmore Buckling 4 (A) Gusset 3,4,5,6

Tearout Fracture 5 Bolts to Brace 1

Bearing 6 Brace 5,6,7,8

Gross Section Yield 7 Splice plates or WTs 5,6,7,8

Net Section Fracture 8

Fillet Weld Fracture 9 Gusset to Beam Gusset 7

Beam Web Yield (beyond k distance) 10 (B) Fillet Weld 9

Bending (including Prying Action) Yield 11 Beam Web 10

Bending (including Prying Action) Fracture 12

Gusset to Column Bolts to Gusset 1

(C) Fillet Weld to Gusset 9

Gusset 6,7,8

is desired. The agreement for the Gross/Cheok tests is not as Bolts to Column 2

good, but the method is clearly conservative. The reason for Clip Angles 6,7,8,11,12

the poorer agreement in this second series of tests is due to Column 6,11,12

frame action. The tests include it but the Uniform Force

Beam to Column Bolts to Beam Web 1

Method does not. Perhaps frame action can be included in Fillet Weld to Beam Web 9

(D)

some future design method, but for the present, the data Beam Web 6,7,8

available indicate that its neglect is conservative. Bolts to Column 2

Clip Angles 6,7,8,11,12

Column 6,11,12

An Example: The Kiss Method vs. the Uniform Force

1

Method See Figure 16 for Interface Identification

Figure 18 shows the design example. The column is a

W14x605, the beam a W18xl06, and the brace a W12x65 of using the KISS Method rather than the Uniform Force

with 450 kips. Figure 19 gives the completed designs for the Method would be (840 - 658) x 8 x 40 = $58,240. This is

KISS Method and the Uniform Force Method. A cost com- assuming one bay of single diagonal bracing on each of the

parison indicates that the KISS design costs $840 while that four faces. If two bays per face were used, the extra cost of

of the Uniform Force Method costs $658. Thus, the KISS the KISS Method would be about $116,000.

Method costs about 28 percent more in addition to being a The differences in size and cost between the KISS Method

much more intrusive (to ductwork, piping, etc.) connection. and the Uniform Force Method are apparent in Figure 19.

To see the effect on a project of using the KISS Method From a scientific point of view, the reason the KISS Method

rather than the Uniform Force Method, consider a 40 story gives a larger connection is due to inefficiency in force

building with eight bracing connections per story. If all these transmission. The beam to column connection (interface D)

connections were similar to those shown in Figure 18, the cost

COMPARISONS FOR BEAM V

"\ 1 1

J

l^EAM SeciiON Lo\OS RtAOICNS Coujecnc»J5 J

Rt*CT10N» C.OUKCTIOJ& 1 U~o~« Cowc. TOTAL ACTUM kUDL DOUBLE. C U P S SWGIE Clip

K>EAM Secnow Low*

SWGIE CLIP """in- MIKI (CAP HAX CAP CAP

U««*M COMC. TOTAL ACTUAL fcUDL DOUMJE. C U P S k*% kif» KIPS KIPS

" Rcws tors) ftrs) [

MIKI CAP MAX CAP CAP 1

*"Ar ton km KIPS KIPS

'Row* ftirs) (trs)

\Y |UJ3>H8 O 82 (64- ^82 114- 6 J I5Q- ( 9 1 ZIP1 8 9Z

1' U24*76 z 3Z 8Z 44 56 + 63 7 137 5 52

BOLTS 7 8 0 A 3 2 5 N . CLIPS 4 X 3 b X 3 8 BOLTS A 325N 7 ^ U N O , CLIPS 4 X 3-2 X 3 e

Fig. 11. Comparisons for beam 1 of Figure 8,

uniform and concentrated loads. Fig. 12. Comparisons for beam 2 of Figure 8.

136 ENGINEERING JOURNAL / FOURTH QUARTER / 1995

Table 3.

Comparison of Uniform Force Method Predicted with Test Results

Predicted Results Test Results

Test

Brace to Gusset to Gusset to Beam to Capacity

Gusset Beam Column Column Predicted Predicted Test Test

Test A B C D Capacity Failure Capacity Failure Predicted

Specimen (kips) (kips) (kips) (kips) (kips) Interface (kips) Interface Capacity

Chakrabarti / 142 184 216 152 142 A 143 A 1.01

Bjorhovde (3,5)1 (7) (5) (12) (3,5) (3,5) (5)

30°

142 182 164 210 142 A 148 A 1.04

Bjorhovde (3,5) (7) (5) (12) (3,5) (3,5) (5)

45°

Chakrabarti / 142 169 155 342 142 A 158 C 1.11

Bjorhovde (3,5) (7) (5) (12) (3,5) (3,5) (5)

60°

Gross / 73 212 67 149 67 C 116 A 1.73

Cheok (4) (7) (12) (9) (12) (12) (4)

No. 1

Gross / 78 77 143 NL2 77 B 138 A 1.79

Cheok (4) (7) (7) (7) (7) (4)

No. 2

Gross / 84 94 171 NL2 84 A 125 A 1.49

Cheok (4) (7) (7) (4) (4) (5)

No. 3

1

Limit state number from Table 1, typical

2

NL = No Limit; this part of connection does not carry any of brace load P

is not used to carry any of the brace force. This is why the to the right of the column at Point A? This unspecified force

KISS Method gives such a small beam to column connection is the "transfer force."

in Figure 19. To carry the load around this area, the large Faced with this situation, the fabricator can perform analy-

couples are required on the gusset edges. A simple way to ses as shown in Figures 21 and 22 for assumed simultaneous

judge efficiency of force transmission was given by Thornton and non-simultaneous loads. This results in possible transfer

(1992). It is a rough way to judge the "smoothness" of the forces varying from 223k to 23k. Without further information

load paths through the connection. The lower the efficiency from the engineer, the fabricator has no choice but to design

number, the better the connection. For the Uniform Force for 223k, which will be safe but very expensive. The connec-

Method, the efficiency of the connection of Figure 19 is 1.39 tion design strategy, based on ignorance, is shown in Fig-

while that of the KISS Method is 1.97. These results are ure 23!

similar to the differences in cost. Thus, the technically better This problem occurred on an actual job, and when the

method for design also yields a cheaper design. engineer realized our problem, told us the transfer force at

Point A was 30k (Figure 24) and proceeded to provide the TF

INFORMATION force at all ambiguous points on his drawings. Obviously,

The Uniform Force Method is probably the most efficient designing for 30 kips rather than 223 kips is much more

way to design bracing connections, but it must be supple- economical as well as being safe. It is a design based on

mented by information about what are referred to as transfer knowledge rather than ignorance.

forces or connection interface forces. These are sometimes For another example of an ambiguous situation, again

obvious by application of the "art" of load paths, but not consider Figure 4. This shows axial forces on the beams along

always. Also, the information given by the engineer can be with the engineer's note:

wrong regarding transfer forces even if it is right regarding

"Design beam end connections for axial loads

member forces.

shown on plans."

Figure 20 shows a typical ambiguous situation. How much

of the bracing forces to the left of the column are transferred The framing plan shown is from an actual job and is not a

ENGINEERING JOURNAL/FOURTH QUARTER/1995 137

partial plan, that is, no other beams frame to it other than those be unsafe, as in the second example. To reinforce the point

shown. So there are certain points, such as point A, where that the omission of transfer force data can lead to very serious

designing for the axial force makes no sense because there is design inadequacies is demonstrated in the next example.

no place for the 90k load to go. Figure 28 shows a partial elevation from an engineer's draw-

When the engineer was queried about this, he was annoyed ing. The notes on the drawings included one which is shown

and sent us a fax stating: "Design beam end connections for in Figure 28, i.e. "Design beam end connections for the axial

axial loads shown on plans." He repeated the note on his loads shown." Now, the axial loads shown are obviously from

drawing and was basically saying, "Do what you are told, the engineer's computerized frame analysis, design, and

dumb fabricator!" We said, "OK, that means at Point B we drawing production program. As such, they are member

design the beam to column connection for 20 kips, right?" He forces not connection interface or transfer forces. Consider

repeated his earlier fax. Now, at Point B, there happens to be point A. Here we are told to design the beam end connection

a brace with 85 kips in it and the engineer provided the usual (interface D of Figure 16) for the beam on the left for 160

detail of a wrap-around gusset as shown in Figure 25. So we kips, yet the opposing beam has only 20 kips as shown. What

sent a copy of Figure 25 showing how his note would be is happening at this point is that the brace force coming down

interpreted in this case. When he saw this, he finally paid the column is transferred directly to the beam through the

attention and said, no, he wanted 85 kips between the beam gusset to beam connection (interface B of Figure 16) and

and column as shown in Figure 26. We agreed that was right, never reaches the column. The beam to column connection

but that 90 kips at Point A was wrong. He agreed and changed should be designed for shear and 20 kips tension. Designing

his drawing to Figure 27, where the transfer forces are clear. for 160 kips tension is expensive and wrong. Now consider

These two examples show that unclear transfer forces are Point B. Here the brace passes from the upper left to the lower

sometimes uneconomical, as in the first example, but also can right. There are no axial member forces shown on either

T—fVn V p

M c «ve c

Ht /

W.P-, w.p.

-w.p

_>J—y

Fig. 13. The "KISS" method. Fig. 15A. The uniform force method.

W24M04 BEAM W24'1Q4 BEAM

1ST'

33" —J°V\^

C

*WI2* 65 COLUMN

COLUMN** <T * WI2«65 COLUMN X c <f

W24'I04 BEAM

Vc-fP Hc-^-P

Fig. 14. Gusset edge force resultant envelopes 45° working

point models (adapted from Richard, 1986). Fig. 15B. Force distributions for the uniform force method.

138 ENGINEERING JOURNAL / FOURTH QUARTER / 1995

beam, because the computer indicated no axial forces for Moment Connections

these beams. Therefore, the beam to column connections are Like shear connections, moment connections are well under-

designed for shear only. This is exactly what the detailer did stood. Here the problem is lack of information in the "released

in accordance with the above mentioned note, as seen in for construction" drawings which generally leads to expen-

Figure 29 (shown opposite hand). But it is wrong. What is sive (but safe) connections, but the main problem is that

happening here is that the brace force must be transferred member design should also have taken into consideration the

across the column from the left to right. The beam to column design of the connections. If this is not done light weight

connections (interface D) of both beams must be matched and columns will be chosen by the frame design software, but the

must carry the horizontal components of the brace forces. constructed cost of the structure will be high because of the

These are interface forces and not member forces. As such, connections.

they are calculated by no presently available computer soft- Columns, when part of an unbraced frame, are designed for

ware. The engineer was wrong to specify that beam end bending moment as well as axial force. The designer uses a

connections be designed for the member forces shown on the rigid frame analysis computer program, which also possibly

drawings. At point A this error causes the structure to be too does a code check using the beam column interaction equa-

expensive. At point B this error causes the structure to be tions or he performs the latter operation manually. What the

grossly unsafe. The only way to avoid this problem is for the designer generally does not consider in his column design is

engineer to work out the transfer forces and present them on the "panel zone" between the column and the transverse

the drawings. This has been done for the frame of Figure 28 framing beams and this can be a costly oversight.

in Figure 30. The resulting correct detail for point B is shown Figure 32 shows a Wl4x90 column 34-ft. long with fillet

in Figure 31 (opposite hand again). welded stiffeners and a same cost W 14x120 with no stiffen-

ers. However, if a W 14x99 column will work, a less expen-

352K

t WI4*605

Fig. 16. Chakrabarti/Bjorhovde test specimen. Fig. 18. Design example (see AISC1992 andAISC 1994).

tW14'605

DESIGN BY DESIGN BY

THE KISS METHOD THE UNIFORM FORCE METHOD

GUSSET 52X43', GUSSET 42X3 P,

Fig. 17. Gross/Cheok test specimen no. 1. Fig. 19. Comparison of designs.

ENGINEERING JOURNAL/ FOURTH QUARTER/1995 139

sive job will result. The W 14x120 also may be less expensive cost about the same as the stiffened W 14x90. Now, looking

if extra erection costs associated with beams framing to the at the sections between W14x90 and W14xl76, we see that

weak axis of the W14x90 due to the stiffeners are considered. we have available a W14x99, a W14xl09, a W14xl20,

Figure 33 shows the same W 14x90 column as Figure 32, but W14xl32, W14xl45, and a W14xl59, all of which will yield

here the designer has specified full penetration groove welds a less expensive design if they satisfy the beam column design

of the stiffeners to the column. This almost triples the cost of equations.

the stiffeners and means that an unstiffened W 14x176 will Figure 34 shows the "fabricator's nightmare" of stiffeners

\ /

W)4 \ W14 W14 / W

A / ' EL. ASSUME THE WORST - HOPE FOR THE BEST!

W10 W12 N V

WHEN IN DOUBT - MAKE IT STOUT!

L

VM W14 \ WJ

USE "BELT AND SUSPENDERS"

W14

^

WH WM WI4 w

Fig. 23. Connection design strategies based on ignorance.

*4

Fig. 20. Partial elevation—what is the transfer force at point At

TF = 223K

TF = 23K

Fig. 21. Simultaneous loads—same load Fig. 24. Partial elevation transfer force is 30 kips per engineer.

condition possible transfer forces.

ENGINKER'S NOTE: DESIGN BEAM END CONNECTIONS

FOR AXIAL LOADS SHOWN ON PLANS

TF « 107K

TF = 23K

±85K

TF = 20K

Fig. 22. Non-simultaneous loads—different load

conditions possible transfer forces. Fig. 25. Connection design forces based on engineers note.

140 ENGINEERING JOURNAL / FOURTH QUARTER / 1995

and doublers. A clean W14xl76 costs no more than the axial force, requires no stiffeners or doublers. Since 120-90

stiffened and doubled Wl4x90, and all of the W14 sections = 30 lbs, which is less than the 117 lbs from Figure 36, the

in between will give less expensive designs if they satisfy the W14xl20 is the more economical choice. As Figure 37

beam-column equations. shows, $204 is saved per connection. If there were 1,000

For the convenience of designers, Figure 35 gives the cost similar connections on the job, savings would be approxi-

in lbs. of steel for stiffeners and doublers, as well as the cost mately $204,000.

of column splices. Column weights can be increased by The stiffeners and doublers of the column cost studies

approximately the amounts shown here without increasing previously discussed are the result of requirements for beam-

costs because, as previously mentioned, the stiffeners and the to-column moment connections, especially when full-

doublers will tend to increase erection costs. (Note that erec- strength moment connections are specified, as in Figure 38

tion costs are not included in Figures 33 through 35.) for doublers. Since stiffeners and doublers can add significant

Figure 36 shows a design aid derived from the foregoing costs to a job, design engineers should not specify full-

information. Here the connection with the stiffeners and

doublers is given per tributary length of column. As an

Engineer's Note:

example of its use, Figure 37 presents a W24x55 framing to Design Beam End Connections for Axial Forces Shown

a column flange. The design moment is M = 212 k-ft, which

is just slightly less than the full strength moment of the

W24x55 (A36), which is 226 k-ft. The W14x90 column,

which is determined to be adequate for M = 212 k-ft. and the

design axial load, requires stiffeners and doublers. The

W 14x120, which is also adequate for the design moment and

+84K

±85K

Fig. 28. Partial elevation member forces.

TF « 85K. NOT 20K

Z- 6/L-

Fig. 26. Connection design forces are clear

because transfer forces are given.

WI2«96

^ - £ 3 - 3 « , 2 U 3 S K ) TYP THIS 8AY WT6-iefe75 K UNO)TYPTHIS BAY

Fig. 27. Connection design forces are clear. Fig. 29. Original detail—3/s-in. clip angles.

ENGINEERING JOURNAL/FOURTH QUARTER/1995 141

strength moment connections unless they are required by increase in column weight, to drastically reduce the stiffener

loads or codes, e.g. ductile moment resisting frames for high and doubler requirements. On one recent 30-story building, a

seismic loads. change from full moment connections to a design for actual

For wind loads and for conventional moment frames where loads combined with using Figure 39 for doublers reduced the

beams and columns are sized for stiffness (drift control) as number of locations where stiffeners and doublers were re-

much as for strength, full strength moment connections are quired to several dozen from 4,500 locations with an esti-

not required Even so, many design engineers will specify full mated cost savings of approximately $500,000.

strength moment connections, adding to the cost of a struc-

ture. CONCLUSION

Designing for actual loads has the potential, without any Many of the suggestions made in this paper can be considered

just good or "common" sense suggestions. In reality, common

sense is not so common when time, money, and reputation are

involved. In order for these suggestions to be effective, they

must be implemented as early as possible in order that the

owner reaps the benefits.

Construction in steel and alternate materials is very com-

petitive. The ideas suggested in this paper can help reduce the

cost of steel construction, perhaps enough to cause more jobs

to be built in steel.

ONE PAIR STIFFENERS = 300 lbs STEEL

(FILLET WELDS)

TYP»- X

k32 | ]

o 1 i1 1

ro

(TYP)

o o

r\jl ~xt\

ro rO

O

£

oj

-Kil 1

Fig. 30. Partial elevation transfer forces. -1

W14x90(A36) W14xl20(A36)

Fig. 32. Same cost stiffened and unstiffened

-7-6«*

column no transverse beams.

ONE PAIR STIFFENERS = 300 lbs STEEL

(FILLET WELDS)

TYP>-jf

9 K I f

r^ i S-PL' 2

(TYP>

o Oj

'M

ro

O

i1

W14x90(A36) W14xl76(A36)

Fig. 33. Same cost stiffened and unstiffened

Fig. 31. Revised detial—1 - in. end plate. columns no transverse beams.

142 ENGINEERING JOURNAL/ FOURTH QUARTER/ 1995

REFERENCES material costs have been revised to reflect 1995 prices for this

In addition to the specific references given below, much of paper.

this paper is abstracted from presentations given at the AISC 1. American Institute of Steel Construction, Manual of Steel

National Steel Construction Conferences in 1991 and 1992, Construction, Vol. II, Connections, ASD 9th Ed./LRFD 1st

and subsequently published in Modern Steel Construction Ed., pp. 7-105-7-170.

Magazine in the issues of February and June, 1992, The 2. American Institute of Steel Construction, 1994, Manual of

STORY HEIGHT 120

N

1 1

*/W

I /-PL2X7* KTe

i - P L V l l 4 X f-10 4

1 )M'2'

VALt&rrKII

o •f\ Al

0

VV14«W Column W 14x120 Column

B| SECTION A-A

•il pi] =*SS8M| SINCE 120-90 = 30 lbs < 117 lbs.

o] VALLEY'

SECTION 6-B SAVED 117-30 = 87 lbs/ft. X .20 SI/lb. = 17 S/ft.

W14x90(A36) W14xl76(A36)

THEREFORE. PER 12" OF COLUMN

FOUR D0UBLER PLATES \_ 9/sm

f t m ,. CTFFI

,bs b l t L L 17X12 = $204 SAVED

FOUR PAIRS STIFFENERS/ "

(FILLET WELDS) BUILDING WITH 1.000 LOCATIONS = $204,000 SAVED

Fig. 34. Same cost columns—no transverse beams. Fig. 37. Possible cost reduction with heavier clean columns.

RULES OF THUMB DOUBLER PLATES

COMMONLY SEEN REQUIREMENTS

O N E PAIR STIFFENERS * 300 lbs OF STEEL

(FILLET WELDED)

O N E PAIR STIFFENERS = 800 lbs. OF STEEL

("•

(FULL PENETRATION WELDED)

ONE PAIR DOUBLER PLATES = 800 lbs. OF STEEL

ONE DOUBLER PLATE * 400 lbs OF STEEL f

320Vl1+M2)

«*cn>- Fydbdc

ONE COLUMN SPUCE * 500 lbs OF STEEL M,*M2 FULL STRENGTH MOMENTS

Figure 35. Fig. 38. Design for the full strength of the beams.

DOUBLER rLATES

LoJSmoF CCUHN V c =• C O L U M N WIWO SHEAR

TRIBUT-KY TO FOOT uiru KJo XuaeeAat.

|C«***CTIOW WllTM wCosr OF'CLEAN-COLUMN ^2,

DoueLEKS

S>r»peHeRS

BO 10

12

14

140

117

100

240

200

171

16 88 150

4 STIFFENERS

18 78 133

2 DOUBIERS 20 70 120 ,

-^-<.76, F -^-[ ( M 1@ -M 2 ^^ lw+ M 2vA ) : (^)v c ]

No WEAK AXIS

BEAM CONNECTIONS

WILL OFTEN ELIMINATE DOUBLER REQUIREMENT

Fig. 36. Column selection design aid. Fig. 39. Design for actual loads.

ENGINEERING JOURNAL / FOURTH QUARTER / 1995 143

Steel Construction, Vol. II, Connections, LRFD 2nd Ed., tions," AISC Engineering Journal, 3rd Qtr., Vol. 7, 1990,

pp. 11-17-11-48. pp. 89-97.

3. Bjorhovde, Reidar and Chakrabarti, S. K., "Tests of Full 7. Richard, Ralph M., "Analysis of Large Bracing Connection

Size Gusset Plate Connections," ASCE Journal of Struc- Designs for Heavy Construction," Proceedings of the AISC

tural Engineering, Vol. I l l , No. 3, March, 1985, pp. 667- National Engineering Conference, Nashville, TN, June,

684. 1986, pp. 31-1-31-24.

4. Chakrabarti, Sekhar, K. and Bjorhovde, Reidar, Tests of 8. Thornton, W. A., "On the Analysis and Design of Bracing

Gusset Plate Connections, Department of Civil Engineer- Connections," Proceedings of the AISC National Steel

ing and Engineering Mechanics, University of Arizona, Construction Conference, Washington, D.C., June, 1991,

Tucson, 1983. pp. 26-1-26-33.

5. Gross, John and Cheok Geraldine, "Experimental Study of 9. Thornton, W. A., "Design for Cost Efficient Fabrication and

Gusseted Connections for Laterally Braced Steel Build- Construction," Constructional Steel Design—An Interna-

ings," National Institute of Standards and Technology Re- tional Guide, Edited by Dowling, Harding, and Bjorhovde,

port, NISTIR 89-3849, Gaithersburg, MD, November, Elsevier Applied Science, London and New York, pp.

1988. 845-854.

6. Gross, John L., "Experimental Study of Gusseted Connec-

144 ENGINEERING JOURNAL / FOURTH QUARTER / 1995

Potrebbero piacerti anche

- Connections Art, Science, and Information in The Quest For Economy and SafetyDocumento13 pagineConnections Art, Science, and Information in The Quest For Economy and SafetyDoctoreNessuna valutazione finora

- Why CTCDocumento15 pagineWhy CTCfaharaNessuna valutazione finora

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Documento2 pagineSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoNessuna valutazione finora

- Modern Steel Construction's MonthlyDocumento2 pagineModern Steel Construction's MonthlyapirakqNessuna valutazione finora

- The Constructable Structure in Steel: F. Maatje, ICCS BV, The Netherlands H.G.A. Evers, ICCS BV, The NetherlandsDocumento10 pagineThe Constructable Structure in Steel: F. Maatje, ICCS BV, The Netherlands H.G.A. Evers, ICCS BV, The NetherlandsTsiry Tsilavo RajaonaryNessuna valutazione finora

- ENZ - Issues With Residential Hold-Down SystemsDocumento5 pagineENZ - Issues With Residential Hold-Down SystemsNelson ChinNessuna valutazione finora

- 11.1.1 Connections in BuildingsDocumento12 pagine11.1.1 Connections in BuildingsNicoreac Monica PaulaNessuna valutazione finora

- A Practical Design Guide For Welded Connections Analysis and Design of Welded ConnectionsDocumento22 pagineA Practical Design Guide For Welded Connections Analysis and Design of Welded Connectionssherif ashrafNessuna valutazione finora

- End-Plate Moment Connections-Their Use and Misuse PDFDocumento3 pagineEnd-Plate Moment Connections-Their Use and Misuse PDFsaber javidNessuna valutazione finora

- 5-6 Strut and Tie Model and Yield Line Method PDFDocumento96 pagine5-6 Strut and Tie Model and Yield Line Method PDFAnonymous cKV7P2magXNessuna valutazione finora

- Edium-Voltage Able Accessories: Special FeatureDocumento5 pagineEdium-Voltage Able Accessories: Special FeatureMohamedHussein MohamedHusseinNessuna valutazione finora

- Rules of Thumb - Structural Engineering Other Technical Topics FAQ - Eng-TipsDocumento7 pagineRules of Thumb - Structural Engineering Other Technical Topics FAQ - Eng-Tipsnuwan01100% (1)

- AISC - Splice ConferenceDocumento4 pagineAISC - Splice ConferenceKamal HalawiNessuna valutazione finora

- Understanding and Meeting The ACI 318 11 App D Ductility Requirements A Design ExampleDocumento6 pagineUnderstanding and Meeting The ACI 318 11 App D Ductility Requirements A Design ExampleVishalNessuna valutazione finora

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You! SendDocumento2 pagineSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You! SendAndres CasadoNessuna valutazione finora

- A Practical Design Guide For Welded Connections Analysis and Design of Welded ConnectionsDocumento22 pagineA Practical Design Guide For Welded Connections Analysis and Design of Welded ConnectionsMukhtar HadiNessuna valutazione finora

- Erection of Precast Concrete: C. Donald Johnson'Documento9 pagineErection of Precast Concrete: C. Donald Johnson'josephbawaNessuna valutazione finora

- Designing For Flexibility and ReliabilityDocumento5 pagineDesigning For Flexibility and Reliabilityluat1983Nessuna valutazione finora

- Needham Connections PDFDocumento11 pagineNeedham Connections PDFjeddijNessuna valutazione finora

- Course Name: CE 3130: Steel Structures DesignDocumento25 pagineCourse Name: CE 3130: Steel Structures Designcarlomonsalve1Nessuna valutazione finora

- Modulo 4 CM 19 09 2020Documento25 pagineModulo 4 CM 19 09 2020carlomonsalve1Nessuna valutazione finora

- 98 Tips For Designing Structural SteelDocumento5 pagine98 Tips For Designing Structural Steelklynchelle100% (2)

- Rules of Thumb: Graduate Manual Design TipsDocumento10 pagineRules of Thumb: Graduate Manual Design TipsDebendra Dev KhanalNessuna valutazione finora

- Modeling Steel Ropes 2009Documento13 pagineModeling Steel Ropes 2009peter_001Nessuna valutazione finora

- AD 329 - Dealing With Connection Design in A 3D Frame AnalysisDocumento2 pagineAD 329 - Dealing With Connection Design in A 3D Frame Analysissymon ellimacNessuna valutazione finora

- Steel Beams With Web OpeningsDocumento17 pagineSteel Beams With Web OpeningspestfariaNessuna valutazione finora

- Welding SolutionsDocumento4 pagineWelding SolutionsDo XuanNessuna valutazione finora

- PCB Design For Fabrication IssuesDocumento45 paginePCB Design For Fabrication IssuesAndersonEmanuelOliveiraNessuna valutazione finora

- CH 7 Simple Beam End Connections-9-13Documento60 pagineCH 7 Simple Beam End Connections-9-13JakesNessuna valutazione finora

- Catalouge For Lenton CouplersDocumento18 pagineCatalouge For Lenton Couplerss.skumar1Nessuna valutazione finora

- Atkins On TaylorDocumento55 pagineAtkins On Taylorbogdanostin0% (1)

- Eng TipsDocumento7 pagineEng TipsCorrie Du PreezNessuna valutazione finora

- Differential Thread Riser Coupling For TLP and Platform Tieback ApplicationsDocumento10 pagineDifferential Thread Riser Coupling For TLP and Platform Tieback Applicationskkozak99Nessuna valutazione finora

- MB Structural Design Compendium May16Documento52 pagineMB Structural Design Compendium May16aldert_path100% (2)

- Designing With Steel Deck FormDocumento17 pagineDesigning With Steel Deck FormMaria Fabiana100% (2)

- Designing With Steel Form Deck: P.O. Box 25 Fox River Grove, IL 60021 Phone: (847) 458-4647 Fax: (847) 458-4648Documento17 pagineDesigning With Steel Form Deck: P.O. Box 25 Fox River Grove, IL 60021 Phone: (847) 458-4647 Fax: (847) 458-4648Iqbal AhmadNessuna valutazione finora

- What Design Engineers Should Know: Metal DeckDocumento2 pagineWhat Design Engineers Should Know: Metal DeckMagenta CamaclangNessuna valutazione finora

- Srividya College of Engineering and Technology Question BankDocumento6 pagineSrividya College of Engineering and Technology Question BankAravindNessuna valutazione finora

- ValueengrDocumento23 pagineValueengrredinezNessuna valutazione finora

- Connections For Steel Structures by John Mark (CISC - ICCA)Documento32 pagineConnections For Steel Structures by John Mark (CISC - ICCA)prabhu81100% (2)

- 2010v09 98 TipsDocumento6 pagine2010v09 98 Tipsvenkatesh19701Nessuna valutazione finora

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Documento2 pagineSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoNessuna valutazione finora

- Long Span Composite Beams: Steel Industry Guidance NotesDocumento2 pagineLong Span Composite Beams: Steel Industry Guidance NotesJasmine SmithNessuna valutazione finora

- Rules of Thumb For Steel StructuresDocumento5 pagineRules of Thumb For Steel StructuresLincs lincoln100% (1)

- Ultimate Strength of Tubular JointsDocumento18 pagineUltimate Strength of Tubular JointsAnonymous VNu3ODGavNessuna valutazione finora

- Cable Construction GuideDocumento9 pagineCable Construction GuideRaghdaa RaafatNessuna valutazione finora

- Bar Pullout Tests and Seismic Tests of Small-Headed Barsin Beam-Column JointsDocumento11 pagineBar Pullout Tests and Seismic Tests of Small-Headed Barsin Beam-Column JointsProfessor Dr. Nabeel Al-Bayati-Consultant EngineerNessuna valutazione finora

- Pre-Design of Semi-Rigid Joints in Steel Frames: January 1994Documento20 paginePre-Design of Semi-Rigid Joints in Steel Frames: January 1994Mohamed Gamal100% (1)

- 01 4 132Documento5 pagine01 4 132cmkohNessuna valutazione finora

- General: Portal Frame Design Tips Seminar ProceedingsDocumento21 pagineGeneral: Portal Frame Design Tips Seminar ProceedingsKesavan DhuraiNessuna valutazione finora

- Overhead Line DesignDocumento6 pagineOverhead Line DesignNazeeh MohammedNessuna valutazione finora

- Some Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910Da EverandSome Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910Nessuna valutazione finora

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsDa EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNessuna valutazione finora

- Reinforced Concrete Buildings: Behavior and DesignDa EverandReinforced Concrete Buildings: Behavior and DesignValutazione: 5 su 5 stelle5/5 (1)

- Weld Like a Pro: Beginning to Advanced TechniquesDa EverandWeld Like a Pro: Beginning to Advanced TechniquesValutazione: 4.5 su 5 stelle4.5/5 (6)

- Publication PDFDocumento52 paginePublication PDFSrinivasan NarasimhanNessuna valutazione finora

- Enter MM: Ft. InchesDocumento4 pagineEnter MM: Ft. InchesSrinivasan NarasimhanNessuna valutazione finora

- Question Paper Code:: Reg. No.Documento2 pagineQuestion Paper Code:: Reg. No.Srinivasan NarasimhanNessuna valutazione finora

- Chapter-Iii Seismic Design of Structures-Exploratory Study: GeneralDocumento8 pagineChapter-Iii Seismic Design of Structures-Exploratory Study: GeneralSrinivasan NarasimhanNessuna valutazione finora

- Soil Mechanics - Assignment 3Documento5 pagineSoil Mechanics - Assignment 3Srinivasan Narasimhan100% (3)

- Chapter-Iv Prime Design of Seismic Activities: GeneralDocumento10 pagineChapter-Iv Prime Design of Seismic Activities: GeneralSrinivasan NarasimhanNessuna valutazione finora

- Design ProjectDocumento61 pagineDesign ProjectSrinivasan NarasimhanNessuna valutazione finora

- Earthquake Load CalculationDocumento4 pagineEarthquake Load Calculationgendadeyu552625100% (1)

- Types of Precipitation: Grade 9 Geography - Unit 4 Lesson 6Documento3 pagineTypes of Precipitation: Grade 9 Geography - Unit 4 Lesson 6smaindoliyaNessuna valutazione finora

- The Future As Sci FI A New Cold War - Slavoj ZizekDocumento5 pagineThe Future As Sci FI A New Cold War - Slavoj ZizekpancakepunisherNessuna valutazione finora

- Koala 20161128Documento1 paginaKoala 20161128Ale VuNessuna valutazione finora

- Oracle Database Standard Edition 2: Affordable, Full-Featured Databas e For SMB CustomersDocumento4 pagineOracle Database Standard Edition 2: Affordable, Full-Featured Databas e For SMB Customersjoffo89Nessuna valutazione finora

- Gas Density CalculationDocumento2 pagineGas Density CalculationLuis SantosNessuna valutazione finora

- Third-Party LogisticsDocumento16 pagineThird-Party Logisticsdeepshetty100% (1)

- Lab #3Documento10 pagineLab #3Najmul Puda PappadamNessuna valutazione finora

- Zhong-Lin Lu, Barbara Dosher-Visual Psychophysics - From Laboratory To Theory-The MIT Press (2013)Documento465 pagineZhong-Lin Lu, Barbara Dosher-Visual Psychophysics - From Laboratory To Theory-The MIT Press (2013)IrinaNessuna valutazione finora

- DHAVAL Resume 1Documento3 pagineDHAVAL Resume 1garvi_gujaratNessuna valutazione finora

- Damodar Dharmananda Kosambi: Chalega-Better Than A Padma-This-That-Or-The-Other!Documento3 pagineDamodar Dharmananda Kosambi: Chalega-Better Than A Padma-This-That-Or-The-Other!Sanjiv BokilNessuna valutazione finora

- Introduction - The Impact of The Digital Revolution On Consumer BehaviorDocumento27 pagineIntroduction - The Impact of The Digital Revolution On Consumer Behavioramitliarliar0% (1)

- Ei GSM IcbDocumento11 pagineEi GSM IcbwimaxaaabglNessuna valutazione finora

- 3VA System Manual Communication en en-USDocumento278 pagine3VA System Manual Communication en en-UScraigjsandersonNessuna valutazione finora

- Parts of The Microscope Quiz PDFDocumento2 pagineParts of The Microscope Quiz PDFEnriele De GuzmanNessuna valutazione finora

- Quality of CG and Its Determinants Empirical Evidence From Listed Banks of BangladeshDocumento24 pagineQuality of CG and Its Determinants Empirical Evidence From Listed Banks of BangladeshShahebZadaAshikNessuna valutazione finora

- FKBI VI - ACED - 03 - Oktaviani Rita P Teti Rahmawati - Universitas KuninganDocumento8 pagineFKBI VI - ACED - 03 - Oktaviani Rita P Teti Rahmawati - Universitas KuninganAndriiNessuna valutazione finora

- Trainer Competency ModelDocumento4 pagineTrainer Competency ModelpattapuNessuna valutazione finora

- SPC 200 Manual 170246Documento371 pagineSPC 200 Manual 170246osamaaaaaNessuna valutazione finora

- Mentor Graphics Corporation, SystemVerilog-VHDL Assistant Reference Manual, Release v2018.2Documento454 pagineMentor Graphics Corporation, SystemVerilog-VHDL Assistant Reference Manual, Release v2018.2dupipiNessuna valutazione finora

- AgChem Summit 2018 Final Attendee ListDocumento2 pagineAgChem Summit 2018 Final Attendee ListVimarsha HSNessuna valutazione finora

- NCP-26 Construction Project Management TechniquesDocumento32 pagineNCP-26 Construction Project Management TechniquesVivek Rai100% (1)

- Areas Under Curves, Integration From A-Level Maths TutorDocumento8 pagineAreas Under Curves, Integration From A-Level Maths TutorA-level Maths TutorNessuna valutazione finora

- Managerial LEADERSHIP P WrightDocumento5 pagineManagerial LEADERSHIP P WrighttomorNessuna valutazione finora

- Batch Controller LH SeriesDocumento1 paginaBatch Controller LH SeriesakhlaquemdNessuna valutazione finora

- The Ouranos RiteDocumento5 pagineThe Ouranos RiteliebofreakNessuna valutazione finora

- Siwes Report CHISOM SAM ORJIDocumento41 pagineSiwes Report CHISOM SAM ORJISOMSKI1100% (2)

- Xfoil - Users - Manual 6.9 PDFDocumento38 pagineXfoil - Users - Manual 6.9 PDFSepideNessuna valutazione finora

- Loquendo TTS User GuideDocumento73 pagineLoquendo TTS User GuideNakedCityNessuna valutazione finora

- ELTJ (1990) Pyramid Discussions - JordanDocumento9 pagineELTJ (1990) Pyramid Discussions - Jordanmariangoud100% (2)

- Davos ProgramDocumento80 pagineDavos ProgramhamiltajNessuna valutazione finora