Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Scania Connector Guide

Caricato da

eko sunaryoDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Scania Connector Guide

Caricato da

eko sunaryoCopyright:

Formati disponibili

16:06-11/C

Issue 3 en

C, Connectors

133 481

Scania CV AB 2004, Sweden

1 714 299

Contents

Contents

Component Page Picture

General 3

ABS / MCP 4

133481

AMP Mate'n Lock 6

102 197

Cannon Sure seal 8

102 193

Coni 10

102 195

Deutsch series DT 12

102 192

DIN 14

Tachograph 18

133 486

Pipa 20

115 807

Cab / Chassis 22

102 196

C56 24

16 1085

Scania CV AB 2004, Sweden

2 16:06-11/C

General

General

The electrical system on a Scania chassis The connectors are designed to tolerate a certain

contains a large number of connectors. These amount of vibration, heat, moisture, etc.

connectors together represent thousands of However, they may be easily damaged by

connection points. incorrect handling. Damage is frequently caused

by high current, moisture and incorrect

Most connectors are marked with a code dismantling.

number. This code number consists of the letter

C and a serial number - C1, C2...C265 etc. It is extremely important to use the correct tool

when working on cable terminals.

Connectors for electrical components such as

solenoid valves, electric motors etc do not have

this C marking. They are instead marked with

the same code number as the connected

component, e.g. V1, M2 etc.

There are a number of different types of

connectors, and they can have up to

70 terminals. The cable terminals can be either

round or flat and there are different grades:

Tin-plated phosphor-bronze, brass-plated and

gold-plated. The latter is used in electronic

circuits where high conductivity is required.

Scania CV AB 2004, Sweden

16:06-11/C 3

C ABS / MCP

C (ABS / MCP)

133 481

Cable terminals

2.8 mm cable terminal

Function

The connector is intended for cab environments

and is available in different configurations.

The cable terminals in the connector are secured 21-pin

via a secondary and primary locking feature.

Description

Crimping to cable 6-pin

• Crimp the cable terminal to the cable using

a press tool.

Scania CV AB 2004, Sweden

4 16:06-11/C

C ABS / MCP

Cable terminal/area Tools

Flat pin sleeve 0.5-1.5 mm 99 491 B

Flat pin sleeve 1.5-2.5 mm 99 493 B

Flat pin sleeve 2.6-4.0 mm 99 493 C

Flat pin 0.5-1.0 mm 99 491 A

Flat pin 1.5/2.5 mm 99 492 A/B

Secondary lock, Male

1 Release the secondary lock by pushing the

upper part slightly forwards approximately

1 mm. Use, for example, a ballpoint pen.

Secondary lock, Female

1 Release the secondary lock on the female

part by releasing the lock on the side with a

screwdriver and then pulling out the entire

lock.

Primary lock

Note: Push in the cable terminal using the cable

in order to make it easier to release the primary

lock.

2 Insert tool 588 192 into the connector to

release the primary lock. Then carefully pull 588192

on the cable on the other side to release the

cable terminal.

133 482

Scania CV AB 2004, Sweden

16:06-11/C 5

C AMP Mate´n Lock

C (AMP Mate'n

Lock)

102 197

Left: Female

Right: Male

Cable terminals

3.5 mm round pin

Function

The connector is intended for cab environments

and is available in 2, 3, 9 and 12 pin

configurations.

The round pins are rated for currents up to 10 A.

High contact pressure in combination with round

pins provides high vibration endurance and good

electrical performance.

Connectors for round pins, rear view

Scania CV AB 2004, Sweden

6 16:06-11/C

C AMP Mate´n Lock

Description

Crimping to cable

• Crimp the terminal on to the cable using

press tool 588 201.

Removing cable terminals from the

connector

• Remove the cable terminals from the

connector using tool 588 191. Slip the tool

over the relevant cable terminal so that its

hooks disengage from the insulator.

Carefully pull out the cable with the cable

terminal.

Scania CV AB 2004, Sweden

16:06-11/C 7

C Cannon Sure Seal

C (Cannon Sure

seal)

102 193

Left: Male

Right: Female

Cable terminals

2 mm round pin

Function

The connector is designed for harsh

environments such as components on the

chassis.

The round pins are rated for currents up to 10 A.

The connector is waterproof when correctly

assembled. Assembly is, however, critical. The

connector does not have a built-in locking

feature and thus some form of holders should

always be used to secure the connector halves.

The cable terminals have no distinct positions,

which means that great care is required when

they are assembled. If the cable terminals are

assembled incorrectly, they may be damaged

when connection is made.

Upper part = round sleeves

Lower part = round pins

Scania CV AB 2004, Sweden

8 16:06-11/C

C Cannon Sure Seal

Description

Crimping to cable

• Crimp the cable terminal onto the cable

using press tool 588 203 or 588 202.

• Use press tool 588 203 for a cable area of

0.5-1.0 mm².

• Use press tool 588 202 for a cable area of

0.8-1.5 mm².

Removing cable terminals from the

connector

1 Push out the cable terminals using tool

588 190.

2 Push out the cable sleeves using tool

588 194.

Fitting cable terminals in the connector

• Fit the cable terminals in the connector

using tool 588 193.

Scania CV AB 2004, Sweden

16:06-11/C 9

C Coni

C (Coni)

102 195

Left: Female

Right: Male

Cable terminals

1.2 mm round pin

Function

The connector is designed for cab environments.

The round pins are rated for currents up to 8 A.

The connector has good vibration endurance and

can be used in a properly protected environment.

The connector is not sealed.

Scania CV AB 2004, Sweden

10 16:06-11/C

C Coni

Description

Crimping to cable

• Crimp the terminal on to thin-walled cables

using press tool 588 202.

Removing cable terminals from the

connector

• Remove the cable terminals from the

connector using tool 588 209. Slip the tool

over the relevant cable terminal and cable

sleeve so that its hooks disengage from the

insulator. Pull out the cable carefully.

Scania CV AB 2004, Sweden

16:06-11/C 11

C Deutsch series DT

C (Deutsch series

DT)

102 192

Left: Female

Right: Male

Cable terminals

1,5 mm round pin

Function

The connector is designed for harsh

environments such as the engine and is available

in 2, 3, 4, 6 and 12 pin configurations.

The round pins are rated for currents up to 10 A.

The cable terminals in the connector are secured

via a secondary and primary locking feature.

The connector is waterproof but bending close to

the seal should be avoided. Do not secure the

connector cables with clips closer than 60 mm 3-pin

from the connector.

Description 8-pin

Crimping to cable

• Crimp the terminal on to thin-walled cables

using press tool 99 496.

Scania CV AB 2004, Sweden

12 16:06-11/C

C Deutsch series DT

Secondary lock, Female

1 Release the secondary lock by placing tool

588 214 in the slot, turning the tool

90 degrees and then pulling out the lock

which may be firmly fitted. Be careful not to

lose the lock.

Secondary lock, Male

1 Release the secondary lock by removing the

cover using a screwdriver.

Primary lock

1 Insert tool 588 214 into the connector to

release the primary lock by bending the lock

which secures the cable terminal in place. At

the same time, pull out the cable with the

cable terminal backwards through the seal.

Note: Fit sealing plugs in connections which are

not used.

Female Male

Fitting the secondary lock in the connector

• The secondary lock may be coded when

fitted.

Scania CV AB 2004, Sweden

16:06-11/C 13

C DIN

Configuration 1

C (DIN)

Configurations 1 and 2

Left: Rear

Right: Front

Configuration 2

Left: Rear

Right: Front

Cable terminals

Square sleeve for round pin Configuration 1

2.5 mm round pin Configuration 2, 4-pin

1.5 mm round pin Configuration 2, 7-pin

Function

The connector is intended for use in exposed

connections such as on engines and control unit

connections in chassis frames.

The connector is available in 4 and 7 pin

configurations, and in an old 4 pin configuration

with square pins.

The cable terminals have distinct positions.

7-pin

4-pin

Scania CV AB 2004, Sweden

14 16:06-11/C

C DIN

Description

Crimping to cable

Use press tool 588 204 for cable terminals on

configuration 1 connectors.

Use press tool 588 203 or 99 491 for cable

terminals for configuration 2 connectors and

with a cable area of 0.5-1.0 mm.

Use press tool 99 494 for cable terminals for

configuration 2 connectors and with a cable area

of 1.5-2.5 mm.

Use press tool 99 496 for cable terminals for

configuration 2 connectors and with a cable area

of 4 mm.

1 Slip the specified seal on to the cable.

2 Strip the end of the cable and push the rubber

seal forwards until it is 1 mm from the seal

edge.

3 Position the cable terminal in press

tool 588 204, and crimp the cable terminal

securely in place.

4 Pass the cable and the seal into the press

tool. Crimp the connection until the tool

releases.

Scania CV AB 2004, Sweden

16:06-11/C 15

C DIN

Removing cable terminals on newer type

connectors

Note: Push in the cable terminal using the cable

in order to make it easier to release the primary

lock.

• 4-pin: Insert tool 588 210 to release the lock

on the connector. Pull out the cable

terminal.

• 7-pin: Insert tool 588 209 to release the lock

on the connector. Pull out the cable

terminal.

Removing cable terminals on older type

connectors

Note: Push in the cable terminal using the cable

in order to make it easier to release the primary

lock.

• Press tool 588 196 carefully into the cross.

Remove the tool, rotate it a quarter of a turn

and press it in again. Pull out the cable

terminal.

There are four holes around the cable terminal

but only two locks. It is therefore necessary to

insert the tool into all the holes in order to try to

pull out the cable terminal.

Scania CV AB 2004, Sweden

16 16:06-11/C

C DIN

Fitting cable terminals and sealing plugs in

connectors

1 Make sure that the terminal hooks are intact.

Gently press the cable terminal into the

insulator until it engages.

2 Secure the cable with plastic strip around the

insulator centre pin, if available.

3 Insert the sealing plug 1-3 mm from the

edge as shown.

114 380

1−3

Scania CV AB 2004, Sweden

16:06-11/C 17

C Tachograph

C (Tachograph)

133 483

133 486

Left: 8-pin

Right: 16-pin

Cable terminals

Flat cable terminal

Function

The connector is intended for cab environments

and is available in 8 and 16 pin configurations.

The cable terminals in the connector are locked

via a secondary and primary locking feature.

Scania CV AB 2004, Sweden

18 16:06-11/C

C Tachograph

Description

Crimping to cable

• Crimp the cable terminal onto the cable

using press tool 588 203 or 588 206.

Secondary lock

• 8-pin: Release the secondary lock on the

connector using a small screwdriver by

carefully releasing the two side covers

which are fitted with plastic hinges.

133 484

• 16-pin: Release the secondary lock on the

connector by pushing the upper part

1-1.5 mm to the side.

01/B

133 665

133 487

Primary lock

Note: Push in the cable terminal using the cable

in order to make it easier to release the primary

lock.

• Insert tool 588 197 into the connector to

release the primary lock. Then carefully pull

588197

on the cable on the other side to release the

cable terminal. 588197

04

/B

0 1/ B

133 488

133 485

Scania CV AB 2004, Sweden

16:06-11/C 19

C Pipa

C (Pipa)

115 807

Cable terminals

Round pins

Function

The connector is intended for harsh

environments and is used for solenoid valves,

various sensors and confirmation switches.

The cable terminals are rated for currents up to

10 A.

Be careful when tightening the cap nut. The

material settles due to the pressure from the cap

nut at temperatures above 70°C, causing leakage.

When the connector is repeatedly assembled/

dismantled there is a risk of breaking the cable

terminals.

Scania CV AB 2004, Sweden

20 16:06-11/C

C Pipa

Description

Note: The connector with wiring is available as

a spare part.

Renewing cable terminals and connectors

1 The cable terminals are not removed from

the connector. The complete connector is

renewed. Make sure that the cable is not

supplied with voltage, then cut it

immediately behind the connector.

2 Strip off approximately 7 cm of the outer

cable sheath and slip a 5 cm long shrinking

tubing on to it. It must be possible to slip the

shrinking tubing on to the rear end of the

connector.

3 Press in pipe tool 98 683 from the front end

of the new connector. Push the cable into the

connector and the tool from the other side.

4 Extract the tool and make sure the cable is

pulled along.

5 Strip the cable and crimp on a new cable

terminal using press tool 588 203. Press the

cable terminal into the connector and at the

same time gently pull on the cable.

6 Slip on the shrinking tubing and heat it so

that it seals between the cable sheath and the

connector.

Scania CV AB 2004, Sweden

16:06-11/C 21

C Cab / Chassis

C (Cab / Chassis)

102 196

Left: Female

Right: Male

Connector

6 and 17 pin: The connectors are coded for their

specific location. For service, only code 0 is

available, which fits all locations.

Cable terminals

Cable terminals and cable sleeves are available in

phosphor-bronze in several variants depending on

the cross section of the cable to be connected.

Function

The connector is intended for cab environments

and is used in the cross-over between the cab

and chassis. The male part is also used as a

connector in the central electric unit.

The cable terminals are rated for currents up to

10 A.

The connector is sensitive to vibration. To

endure vibration, the wiring has to be fixed in a

secure way.

The cable terminals are secured via a secondary

locking feature.

Scania CV AB 2004, Sweden

22 16:06-11/C

C Cab / Chassis

Description

Crimping to cable

• Crimp the cable terminal onto the cable

using press tool 588 202 or 588 205.

Removing cable terminals from the

connector

Note: The cable terminal lock is easily

damaged.

1 Open the cable terminal lock by prying it

out approximately 3 mm.

2 Remove the sleeve section lock entirely.

116 355

3 Push out the cable terminal using tool

588 197.

4 Push out the cable sleeve using tool

588 198.

Scania CV AB 2004, Sweden

16:06-11/C 23

C56

C56

16 1085

Wiring Diagram

Connection diagram Symbol

Truck LHD: 16:02-01

C56

Truck RHD: 16:02-01 1 5

2 A 6

Bus: 16:52-10 3

4

7

4

1 5

2 B 6

3 7

1 5

2 C 6

3 7

4 4

1 5

2 D 6

3 7

1 5

2 E 6

3 7

4 4

1 5

2 F 6

3 7

1 5

2 G 6

3 7

4 4

1 5

2 J 6

3 7

5 1

6 2

7

M P 3

5 1

6 2

N R 3

7

5 1

6 2

7

O S 3

DIA

1−1 L 6−1

1−2 K 6−2

2−1 7−1

2−2 7−2

3−1 8−1

3−2 8−2

4−1 9−1

4−2 9−2

5−1 10−1

5−2 10−2

CAN

1−1 L 4−1

1−2 H 4−2

2−1 5−1

2−2 5−2

16 1018

3−1

120a

3−2

Scania CV AB 2004, Sweden

24 16:06-11/C

C56

Function

Parts of the connection block appear in a

number of different wiring diagrams. See the

diagram for each piece of optional equipment.

C56 is located inside of the central electric unit

P2 and consists of three different functional

parts. The first part, at the far left on the

connection block, has ten cable terminals for

CAN communication connections. Each CAN

signal requires two cable terminals. One

terminal for low signal -5V and one for high

signal +5V.

The second functional part consists of 20 cable

terminals for diagnostics cables. Each diagnostic

signal requires two cable terminals. One for

K diagnostics and one for L diagnostics.

The third functional part consists of fourteen

groups of cable terminals, A - S. The groups A

to J each have 7 cable terminals. The groups M

to S each have three cable terminals. Groups K

and L are not used so as to avoid confusion with

cables for K and L diagnostics.

Scania CV AB 2004, Sweden

16:06-11/C 25

Scania CV AB 2004, Sweden

26 16:06-11/C

Potrebbero piacerti anche

- Opisanie KomponentovDocumento299 pagineOpisanie KomponentovuserNessuna valutazione finora

- Wiring Diagrams Manual: For BusesDocumento46 pagineWiring Diagrams Manual: For BusesModestasNessuna valutazione finora

- Damper For Range Gear Changing GR801-900, GRS890-900 Work DescriptionDocumento8 pagineDamper For Range Gear Changing GR801-900, GRS890-900 Work DescriptionfugegaNessuna valutazione finora

- Retrofitting Alarm and Theft Protection, VPS: Issue 1Documento36 pagineRetrofitting Alarm and Theft Protection, VPS: Issue 1ruanNessuna valutazione finora

- Electric ComponentDocumento299 pagineElectric ComponentHari100% (1)

- ELC Work DescriptionDocumento36 pagineELC Work DescriptionHari100% (1)

- Spare Parts Catalog: 16 S 151 IT Material Number: 1315.041.719 Current Date: 29.10.2013Documento94 pagineSpare Parts Catalog: 16 S 151 IT Material Number: 1315.041.719 Current Date: 29.10.2013Муслим КадралиевNessuna valutazione finora

- WSM 0003159 ru-RUDocumento134 pagineWSM 0003159 ru-RUCleiton aviNessuna valutazione finora

- enDocumento23 pagineenuser100% (3)

- Scania P, G, S and R Series Workshop Manual - Removing The GearboxDocumento16 pagineScania P, G, S and R Series Workshop Manual - Removing The GearboxEva Apriana100% (1)

- SCANIA Suspension BT200 Work DescDocumento32 pagineSCANIA Suspension BT200 Work DescHeri Suryo0% (1)

- Station3-Cab Chassis Electrics Suspension and Steering PDFDocumento61 pagineStation3-Cab Chassis Electrics Suspension and Steering PDFjose breno vieira silva100% (4)

- P11X24EN Scania Opticruise and Retarder Tcm40 280864Documento6 pagineP11X24EN Scania Opticruise and Retarder Tcm40 280864Ionut LefterNessuna valutazione finora

- Electrical System 11: © Scania CV AB 2003Documento32 pagineElectrical System 11: © Scania CV AB 2003Laurenţiu Alin ŢiglişNessuna valutazione finora

- Wartungsanweisungen Für Gruppe 7-9 P-, G-, R - Und T-SerieDocumento24 pagineWartungsanweisungen Für Gruppe 7-9 P-, G-, R - Und T-SerieWeber BennyNessuna valutazione finora

- Munication Area Network (CAN) TerbaruDocumento19 pagineMunication Area Network (CAN) TerbaruKurniawan -Nessuna valutazione finora

- Electrical System: Installation Instructions - Industrial EnginesDocumento33 pagineElectrical System: Installation Instructions - Industrial Enginesjhonatan_silveira_8100% (2)

- Communication ErrorDocumento24 pagineCommunication Errorali wardanaNessuna valutazione finora

- Clutch Controol p360Documento15 pagineClutch Controol p360andi maryantoNessuna valutazione finora

- WSM 0000546 01Documento20 pagineWSM 0000546 01Omar ScaniaNessuna valutazione finora

- Air Suspention Work DescriptionDocumento52 pagineAir Suspention Work DescriptionHari100% (1)

- Scania ABS 6x4 A/B Pneumatic DiagramDocumento13 pagineScania ABS 6x4 A/B Pneumatic DiagramHari100% (1)

- Important Information: Operator's Manual DC9 EMS With S6/PDE Industrial EngineDocumento60 pagineImportant Information: Operator's Manual DC9 EMS With S6/PDE Industrial Enginemmmm100% (1)

- BBM en-GB 2015.4Documento476 pagineBBM en-GB 2015.4Topo Susilo100% (2)

- Scania Truck Sms Fault Codes DTCDocumento11 pagineScania Truck Sms Fault Codes DTCSurafel Abebe100% (1)

- CALIBRACIONDocumento65 pagineCALIBRACIONNuñez JesusNessuna valutazione finora

- Scania Heating & VentilationDocumento36 pagineScania Heating & VentilationIan Muhammad0% (1)

- Issue 4: © Scania CV AB 2003, SwedenDocumento56 pagineIssue 4: © Scania CV AB 2003, SwedenHari100% (2)

- GMS, Gear Box Managemnet SystemDocumento32 pagineGMS, Gear Box Managemnet SystemTomi Ananda PradistyNessuna valutazione finora

- GT2500133-V1 Door Brake Function SB enDocumento26 pagineGT2500133-V1 Door Brake Function SB enJose Carlos da SilvaNessuna valutazione finora

- KoordinatorDocumento31 pagineKoordinatorSaid Daden100% (2)

- Auxiliary Heater Operation Unit CTT D1LC and D1LCC: Issue 1Documento35 pagineAuxiliary Heater Operation Unit CTT D1LC and D1LCC: Issue 1Dusan Masle100% (1)

- Switch General InformationDocumento40 pagineSwitch General InformationmbpajaNessuna valutazione finora

- Brake Management System: Issue 1.2 Sheet 7 en-GBDocumento1 paginaBrake Management System: Issue 1.2 Sheet 7 en-GBkumbrovNessuna valutazione finora

- Scania Sops RedaktorDocumento7 pagineScania Sops Redaktorscania100% (2)

- Remove Unit InjectorDocumento55 pagineRemove Unit InjectorГеоргий222Nessuna valutazione finora

- Scania Ralentizador 100507 PDFDocumento39 pagineScania Ralentizador 100507 PDFGermainCampillayNessuna valutazione finora

- BWM - 0000388 - 01 - PTO OverviewsDocumento14 pagineBWM - 0000388 - 01 - PTO OverviewsNoeRtjahya AhmadNessuna valutazione finora

- Connector C449 - Functions For Automatic Gearbox and Trailer Connection General InformationDocumento3 pagineConnector C449 - Functions For Automatic Gearbox and Trailer Connection General InformationmbpajaNessuna valutazione finora

- Fuel Injection PDFDocumento11 pagineFuel Injection PDFscaniaNessuna valutazione finora

- ICL2, Instriment ClusterDocumento12 pagineICL2, Instriment ClusterKhairuddin KhairuddinNessuna valutazione finora

- How to Use Cookies and Privacy Settings on This SiteDocumento145 pagineHow to Use Cookies and Privacy Settings on This SiteBota NicusorNessuna valutazione finora

- GR 875 FungsiDocumento2 pagineGR 875 FungsiHariNessuna valutazione finora

- enDocumento30 pagineenRegistr RegistrNessuna valutazione finora

- Scania P, G, R, T Series Workshop Manual - Removing The Reductant Main UnitDocumento1 paginaScania P, G, R, T Series Workshop Manual - Removing The Reductant Main Unitmusharrf100% (1)

- EUROPART Inter Catalog Scania Truck 2017 ENDocumento356 pagineEUROPART Inter Catalog Scania Truck 2017 ENHeru susantoNessuna valutazione finora

- GMS, Gear Box Managemnet SystemDocumento32 pagineGMS, Gear Box Managemnet SystemKhairuddin KhairuddinNessuna valutazione finora

- Trouble Shoot ScaniaDocumento77 pagineTrouble Shoot ScaniaTjoa Gin Hao75% (4)

- XCOM User GuideDocumento33 pagineXCOM User GuideAnonymous ljkiyqJt8MNessuna valutazione finora

- Wiring Diagram HandbookDocumento168 pagineWiring Diagram Handbookluis meza100% (3)

- Electrical Components Bus: Edition 1Documento98 pagineElectrical Components Bus: Edition 1Truck Bus Electronica100% (1)

- Consumable Parts ScaniaDocumento224 pagineConsumable Parts ScaniaAhmad HisyamNessuna valutazione finora

- en PDFDocumento44 pagineen PDFAlex Renne Chambi100% (1)

- Cable Harness Connections For Additional Switches Cable Harness For Additional SwitchesDocumento4 pagineCable Harness Connections For Additional Switches Cable Harness For Additional Switchesmbpaja100% (1)

- Wartungsanweisungen Für Gruppe 1-3 P-, G-, R - Und T-SerieDocumento173 pagineWartungsanweisungen Für Gruppe 1-3 P-, G-, R - Und T-SerieWeber BennyNessuna valutazione finora

- Pnumatic BrakeDocumento19 paginePnumatic BrakeClovis100% (1)

- Fuel System With Unit Injector PDE and EDC MS6: Issue 2Documento60 pagineFuel System With Unit Injector PDE and EDC MS6: Issue 2Musharraf KhanNessuna valutazione finora

- 11 Building Block PDFDocumento18 pagine11 Building Block PDFeko sunaryoNessuna valutazione finora

- 11 Building Block PDFDocumento18 pagine11 Building Block PDFeko sunaryoNessuna valutazione finora

- Electrical System: Service Data AlternatorDocumento22 pagineElectrical System: Service Data Alternatoreko sunaryoNessuna valutazione finora

- Sub Bab IB Bipolar Junction TransistorDocumento14 pagineSub Bab IB Bipolar Junction Transistoreko sunaryoNessuna valutazione finora

- Weapons of The Waffen-SS - From Small Arms To TanksDocumento1 paginaWeapons of The Waffen-SS - From Small Arms To Tankseko sunaryoNessuna valutazione finora

- (Shrinked) - Marketing Winch Presentation (Introduction)Documento15 pagine(Shrinked) - Marketing Winch Presentation (Introduction)eko sunaryoNessuna valutazione finora

- QA_2 FIP Electric Governor Inspection ReportDocumento1 paginaQA_2 FIP Electric Governor Inspection Reporteko sunaryo100% (1)

- Maintenance For NK-550VRDocumento14 pagineMaintenance For NK-550VReko sunaryoNessuna valutazione finora

- Assembly Fip Electical: JakartaDocumento5 pagineAssembly Fip Electical: Jakartaeko sunaryoNessuna valutazione finora

- Performance DataDocumento1 paginaPerformance Dataeko sunaryoNessuna valutazione finora

- CurvaDocumento1 paginaCurvaeko sunaryoNessuna valutazione finora

- CanDocumento17 pagineCaneko sunaryoNessuna valutazione finora

- Trouble Code Indication Procedure Trouble Code Erasure ProcedureDocumento2 pagineTrouble Code Indication Procedure Trouble Code Erasure Procedureeko sunaryoNessuna valutazione finora

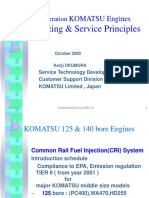

- New Generation KOMATSU Engines: Establishing a Global Service Network for Common Rail TechnologyDocumento18 pagineNew Generation KOMATSU Engines: Establishing a Global Service Network for Common Rail Technologyeko sunaryoNessuna valutazione finora

- 10 IC ApplicationDocumento18 pagine10 IC Applicationeko sunaryoNessuna valutazione finora

- PLC Roc F9 C9Documento10 paginePLC Roc F9 C9eko sunaryoNessuna valutazione finora

- 3.3 E-OLSS Control ValveDocumento12 pagine3.3 E-OLSS Control Valveeko sunaryo100% (1)

- CRI Pump & ControllerDocumento5 pagineCRI Pump & Controllereko sunaryo100% (1)

- CatSEBU7502 05 EnglishDocumento122 pagineCatSEBU7502 05 Englisheko sunaryo100% (1)

- CRI Test Harness PDFDocumento2 pagineCRI Test Harness PDFeko sunaryoNessuna valutazione finora

- TI 07 006 DF AdjustmentDocumento12 pagineTI 07 006 DF Adjustmenteko sunaryoNessuna valutazione finora

- Testing & Adjusting: SAA6D140/125-CRIDocumento20 pagineTesting & Adjusting: SAA6D140/125-CRIeko sunaryo100% (1)

- BR 1Documento66 pagineBR 1eko sunaryoNessuna valutazione finora

- Compressor X Ah 4 P To EnglishDocumento23 pagineCompressor X Ah 4 P To Englisheko sunaryoNessuna valutazione finora

- Ea PDFDocumento5 pagineEa PDFeko sunaryoNessuna valutazione finora

- Atlas Copco ROC F9-TH System DescriptionDocumento87 pagineAtlas Copco ROC F9-TH System Descriptioneko sunaryo100% (2)

- CatSEBU7457!01!01 EnglishDocumento126 pagineCatSEBU7457!01!01 Englisheko sunaryoNessuna valutazione finora

- 9852 1707 01a Operator's Instructions ROC F9Documento164 pagine9852 1707 01a Operator's Instructions ROC F9eko sunaryo75% (4)

- Product Catalogue - RotaryDocumento36 pagineProduct Catalogue - Rotaryeko sunaryoNessuna valutazione finora

- 9852 1696 01 Maintenance Schedules ROC F7Documento53 pagine9852 1696 01 Maintenance Schedules ROC F7eko sunaryo100% (2)

- Overview of Quality Gurus Deming, Juran, Crosby, Imai, Feigenbaum & Their ContributionsDocumento11 pagineOverview of Quality Gurus Deming, Juran, Crosby, Imai, Feigenbaum & Their ContributionsVenkatesh RadhakrishnanNessuna valutazione finora

- Module 2Documento42 pagineModule 2DhananjayaNessuna valutazione finora

- Miami Police File The O'Nell Case - Clemen Gina D. BDocumento30 pagineMiami Police File The O'Nell Case - Clemen Gina D. Barda15biceNessuna valutazione finora

- ER DiagramDocumento23 pagineER Diagramapi-2757091480% (20)

- Micropolar Fluid Flow Near The Stagnation On A Vertical Plate With Prescribed Wall Heat Flux in Presence of Magnetic FieldDocumento8 pagineMicropolar Fluid Flow Near The Stagnation On A Vertical Plate With Prescribed Wall Heat Flux in Presence of Magnetic FieldIJBSS,ISSN:2319-2968Nessuna valutazione finora

- 2016 Mustang WiringDocumento9 pagine2016 Mustang WiringRuben TeixeiraNessuna valutazione finora

- TransistorDocumento1 paginaTransistorXhaNessuna valutazione finora

- SEMICONDUCTORS AssignmentDocumento8 pagineSEMICONDUCTORS AssignmentMaryam MuneebNessuna valutazione finora

- Username: Password:: 4193 Votes 9 Days OldDocumento6 pagineUsername: Password:: 4193 Votes 9 Days OldΘώμηΜπουμπαρηNessuna valutazione finora

- Inventarisasi Data Kondisi Jalan Ke Dalam Aplikasi Sistem Informasi Geografis (Sig)Documento10 pagineInventarisasi Data Kondisi Jalan Ke Dalam Aplikasi Sistem Informasi Geografis (Sig)Wiro SablengNessuna valutazione finora

- Condy LatorDocumento11 pagineCondy LatorrekabiNessuna valutazione finora

- Modern Indian HistoryDocumento146 pagineModern Indian HistoryJohn BoscoNessuna valutazione finora

- Give Five Examples Each of Nature Having Reflection Symmetry and Radial Symmetry Reflection Symmetry Radial Symmetry Butterfly StarfishDocumento12 pagineGive Five Examples Each of Nature Having Reflection Symmetry and Radial Symmetry Reflection Symmetry Radial Symmetry Butterfly StarfishANNA MARY GINTORONessuna valutazione finora

- Unit 1 - Introduction To BankingDocumento17 pagineUnit 1 - Introduction To Bankingc08Nessuna valutazione finora

- 2.4 Avogadro's Hypothesis+ Equivalent MassesDocumento12 pagine2.4 Avogadro's Hypothesis+ Equivalent MassesSantosh MandalNessuna valutazione finora

- New Brunswick CDS - 2020-2021Documento31 pagineNew Brunswick CDS - 2020-2021sonukakandhe007Nessuna valutazione finora

- Steps To Configure Linux For Oracle 9i Installation: 1. Change Kernel ParametersDocumento5 pagineSteps To Configure Linux For Oracle 9i Installation: 1. Change Kernel ParametersruhelanikNessuna valutazione finora

- Newcomers Guide To The Canadian Job MarketDocumento47 pagineNewcomers Guide To The Canadian Job MarketSS NairNessuna valutazione finora

- Hawk Technology Systems v. NCLDocumento6 pagineHawk Technology Systems v. NCLPriorSmartNessuna valutazione finora

- Victron MultiPlus 48 1200-13-16 Datasheet enDocumento1 paginaVictron MultiPlus 48 1200-13-16 Datasheet enBAHJARI AMINENessuna valutazione finora

- Afu 08504 - International Capital Bdgeting - Tutorial QuestionsDocumento4 pagineAfu 08504 - International Capital Bdgeting - Tutorial QuestionsHashim SaidNessuna valutazione finora

- Mechanics of Deformable BodiesDocumento21 pagineMechanics of Deformable BodiesVarun. hrNessuna valutazione finora

- Modified Release Drug ProductsDocumento58 pagineModified Release Drug Productsmailtorubal2573100% (2)

- Weekly Choice - Section B - February 16, 2012Documento10 pagineWeekly Choice - Section B - February 16, 2012Baragrey DaveNessuna valutazione finora

- AE-Electrical LMRC PDFDocumento26 pagineAE-Electrical LMRC PDFDeepak GautamNessuna valutazione finora

- JSA - 0026 Chipping & Granite cutting and lying Work At PB-19Documento2 pagineJSA - 0026 Chipping & Granite cutting and lying Work At PB-19Koneti JanardhanaraoNessuna valutazione finora

- Daftar PustakaDocumento4 pagineDaftar PustakaRamli UsmanNessuna valutazione finora

- Ramdump Memshare GPS 2019-04-01 09-39-17 PropsDocumento11 pagineRamdump Memshare GPS 2019-04-01 09-39-17 PropsArdillaNessuna valutazione finora

- Standard Deviation IntroductionDocumento3 pagineStandard Deviation IntroductionShyam ShresthaNessuna valutazione finora

- Ch07 Spread Footings - Geotech Ultimate Limit StatesDocumento49 pagineCh07 Spread Footings - Geotech Ultimate Limit StatesVaibhav SharmaNessuna valutazione finora