Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

P921 PDF

Caricato da

Farhan ShahTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

P921 PDF

Caricato da

Farhan ShahCopyright:

Formati disponibili

P92x

VOLTAGE & FREQUENCY RELAYS

P921 Software Version V4 to V6.C

P922 Software Version V4 to V6.C

P923 Software Version V4 to V6.E

Technical Data Sheet

P92X/EN TD/A12

This Document does not replace the Technical Manual

P920 Technical Data Sheet 2

MiCOM P92x range of relays provide reliable and Integrated with 3 independent phase over voltage and phase

high performance voltage and frequency under voltage thresholds, MiCOM P921, P922 and P923

protection. relays provide effective voltage protection for typical

applications like protection of motors, generators., etc. The

Versatile application and integration of protection configurable detection logic (AND, OR) can also indicate the

functions with automation, control and absence of voltage, when the under voltage protection is used.

measurement functions, combined with reduced

maintenance, makes P92x relays an optimal and

The 3 zero-sequence over voltage thresholds available in

innovative choice.

P921, P22 & P923 relays can be applied :

A friendly, multi-lingual user interface with

programmable LEDs and logic equations, allows for > to detect earth faults at the neutral point of generators, as

simple and flexible applications on any type of the relays are insensitive to the 3rd harmonics

network. > to detect earth faults in high impedance earthed or

isolated electrical systems .

Connecting the relay to virtually any kind of Digital

Control System or SCADA is made possible by the The negative sequence over voltage protection provided by

wide range of updated communication protocols the P922 and P923 relays is designed to detect unbalanced

provided in P92x conditions it could therefore be used for motor, in which any

unbalance will lead to overheating and damage.

APPLICATION

The P922 and P923 relays integrate 6 frequency thresholds

The MiCOM P92x relays provide fast and accurate protection programmable as under or over frequency, which can be used

for use in numerous applications requiring voltage and for automated load shedding/load restoration.

frequency based protection elements. To suit different

application needs and provide optimum solution, following In addition, the P923 relays provide 6 thresholds of

models are available: instantaneous rate of change of frequency (df/dt) or average

measurements over a settable time interval.

P921: Voltage protection, 2 logic inputs, 4 outputs.

P922: Voltage and frequency protection, event and fault MANAGEMENT FUNCTIONS

records, disturbance recorder, 5 logic inputs, and 8 output

contacts. The protection functions in P92x complemented with a wide

P923 : Voltage and frequency protection (plus the rate of range of control, measurement, monitoring, post fault

change of frequency element df/dt), event and fault records, analysis and self-diagnostic features assist efficient

disturbance recorder, 5 logic inputs, 8 output contacts. management of the primary system. These include:

The relays can be ordered with one of the two voltage input > Programmable logic equation

range, to suit the application: > Programmable logic inputs and outputs

> Circuit breaker control

> 57V to 130V > Output contact latching

> 220V to 480V > Circuit breaker status

> Circuit breaker condition monitoring (in P922 & P923)

> 2 setting groups (in P922 & P923)

> True rms phase to phase, phase to neutral and residual

voltage measurement

> Frequency measurement

> Positive and negative sequence voltage measurement (in

P922 & P923)

> Rolling and peak value display (in P922 & P923)

> Sequence of event recording (in P922 & P923)

> Fault recording (in P922 & P923)

> Comprehensive disturbance recording (in P922 & P923)

> Frequency disturbance record (only in P923)

> Local and remote communication ports

> Programmable LEDs

> Multiple communication protocol options

> Password protection

> Power-up diagnostics and continuous self-monitoring of

relay.

> User friendly setting and analysis software (MiCOM S1)

P920 Technical Data Sheet 3

PROTECTION FUNCTIONS OVERVIEW P921 P922 P923

Configuration depending on the number

x x x

and type of voltage transformers

Phase-to-neutral or phase-to-phase voltage

x x x

protection

27 Phase under voltage (AND/OR logic) x x x

59 Phase over voltage (AND/OR logic) x x x

Settable hysteresis x x x

59N Zero-sequence over voltage x x x

47 Negative sequence over voltage - x x

27D Positive sequence under voltage - x x

81U/81 Under/over frequency

- x x

O

81R Rate of change of Frequency - - x

Inhibition of voltage & frequency protection functions - - -

Inhibition of timers(instantaneous forcing) - - -

Blocking logic x x x

Under voltage Blocking (settable for P923) - x x

Digital inputs 2 5 5

Output relays 4 8 8

Remote communication (RS485 port) x x x

Local communication (RS232 port) x x x

CONFIGURATION DEPENDING VOLTAGE PROTECTION

ON THE VT

For each of the voltage protection function listed below, an

instantaneous signal and a time delayed signal is available

MiCOM P921, P922 and P923 relays can be used in the

for each threshold.

following configurations:

For time-delayed signals, the first threshold of each function

> "3 phase-neutral VTs" or "3 phase-neutral VTs and 1

("low threshold") offers the choice between a definite timer and

residual VT":

an inverse timer, to which a reset timer can be assigned. The

> The voltage protection element can therefore operate

other thresholds only have one definite timer.

either from measured phase-to-neutral voltages, or from

phase-to-phase voltages which have been internally

calculated by the relay. Zero-sequence over voltage UNDER/OVERVOLTAGE

protection will always be available, the presence of the

residual VT is designed to display the true RMS value of Three thresholds are available for each function: each one can

the residual voltage. be independently activated or deactivated. If a threshold is

> "3 phase-phase VTs and 1 residual VT" or "2 phase- activated, it can be configured to detect:

phase VTs and 1 residual VT":

The voltage protection element can only operate from > an over voltage on the 3 simultaneous phases (logic

measured phase-to-phase voltages. If the residual VT is "AND") or on at least one of the phases (logic "OR") for

not connected, the zero-sequence over voltage protection the "Over voltage" function

will not be available. > an under voltage on the 3 simultaneous phases (absence

of voltage with the "AND" logic) or on at least one of the

RELAY SETTING USING MICOM S1 phases (logic "OR") for the "Under voltage" function

> The MiCOM P921, P922 and P923 relays provide a

programmable hysteresis (drop- out / pick-up ratio) as a

percentage of the under voltage and over voltage pick-up

values.

> The P923 provides a settable under voltage block of all

the protection and control elements based on the

frequency.

P920 Technical Data Sheet 4

ZERO-SEQUENCE OVERVOLTAGE LOGIC EQUATIONS

Three thresholds are available: each one can be

independently activated or deactivated. Depending on the VT

configuration, MiCOM P921, P922 and P923 relays will

operate from the zero sequence voltage, which is calculated

internally, or from the residual voltage, which is measured

directly.

NEGATIVE SEQUENCE

OVERVOLTAGE

Two thresholds are available: each one can be independently

activated or deactivated. This function is based on the

negative-sequence component of the voltage, which is

calculated internally and displayed on the screen of the front

panel: It is designed to detect any voltage unbalance condition.

INPUTS/OUTPUTS/ PROGRAMMABLE

POSITIVE SEQUENCE LEDs

UNDERVOLTAGE

All logic inputs, output contacts (excluding the RL0 changeover

Two thresholds are available: Each one can be output contact, dedicated to the "relay failed" function) and the

independently activated or deactivated. This function is based 4 LEDs of the MiCOM P921, P922 and P923 relays can be

on the positive phase sequence component of the voltage, programmed. This affects in particular all logic signals

which is calculated internally. (instantaneous, time delayed) in the relays which can be

combined with the different output contacts and LEDs. The

FREQUENCY PROTECTIONS output contacts can also be programmed to be latched.

The following frequency based protection functions are BLOCKING LOGIC

available. Frequency protection functions are inhibited below a

certain level of the measured secondary voltage (adjustable Operation of the different protection elements of P92x can be

level in P923). coordinated with other devices in the system. Two blocking

inputs are independently configurable. When active, they

UNDER/OVERFREQUENCY freeze the associated protection timers and when they drop-

off, they re-impose the initial value if the fault conditions are

still present.

Six thresholds are available: Each one can be configured to

detect an under or over frequency within the range [fn - 10Hz,

fn + 10Hz], where fn is the nominal frequency selected (50Hz SETTING GROUPS FOR PROTECTION

or 60Hz). A definite timer is assigned to each threshold. FUNCTIONS

RATE OF CHANGE OF FREQUENCY The MiCOM P922 and P923 relays have two independent

setting groups, which can be used to adapt the protection

Six thresholds are available: Each can be configured functions to different operating conditions. The two groups can

independently within the range [-10 Hz/s, +10 Hz/s]. be switched by activating a dedicated logic input, or by the

These functions are based on the calculation of the operator via the front panel, or locally (RS232 port) or remotely

instantaneous rate of change of frequency over a settable (RS485 port).The switch from one setting group to another will

integration time (number of cycles). only take effect if no protection or automation functions are

running, to prevent unwanted tripping.

PROGRAMMABLE LOGIC MEASUREMENTS

EQUATIONS

Depending on the configuration of the VTs connected to

MiCOM P921, P922 and P923 relays, the following values will

Two programmable logic equations (AND) are available with

be measured and displayed as true RMS values on the back-lit

P921 and P922 relays. Four programmable logic equations

screen:

(AND) are available with P923. A pick-up timer and a drop-off

timer can be assigned to each equation. These equations can

be programmed directly from the front panel of the relay.

P920 Technical Data Sheet 5

DISTURBANCE RECORDS

> phase-to-neutral voltages Ua, Ub, Uc

> phase-to-phase voltages Uab, Ubc, Uca Five disturbance records, each lasting 2.5 seconds, can be

> residual voltage Vo stored in non-volatile memory by MiCOM P922 and P923

> frequency. relays. The sampling frequency is fixed at 32 samples per

cycle. The event that triggers the recording can be configured:

In addition, the MiCOM P922 and P923 relays Instantaneous signals, time-delayed signals, or activation

calculate the following values internally: of a dedicated logic input.

> positive sequence voltage

> negative sequence voltage

FREQUENCY DISTURBANCE

> peak values of phase-to-neutral or phase-to-phase RECORDS

voltages

> rolling values of phase-to-neutral or phase-to-phase One frequency disturbance record, lasting 20 secs can be

voltages stored in non-volatile memory by the MiCOM P923 relay. The

sampling frequency is fixed at 1 sample per cycle. The

All measurements are available locally and remotely. mechanism that triggers the recording can be configured:

instantaneous or time delayed tripping, activation of a

LOGS AND RECORDS dedicated logic input or time delayed logic equation signal.

All event, fault and disturbance records are time-stamped to CIRCUIT BREAKER STATUS &

1ms by the internal real time clock. In the event of a loss of CONTROL

auxiliary power, a lithium battery is used to save the records,

the date and the time. Monitored at regular intervals, the With MiCOM P921, P922 and P923 relays, the circuit breaker

battery can be easily accessed from the front panel if it has to can be controlled manually via logic inputs (AUX1 and AUX2),

be replaced. with local or remote communication: the opening and closing

commands will therefore activate the programmed output

All records can be retrieved locally, using the MiCOM S1 contacts. The LEDs can be programmed to indicate the status

setting software (RS232 port), or remotely (RS485 port). of the circuit breaker.

EVENT RECORDS CIRCUIT BREAKER MAINTENANCE

Any change of state of logic inputs, output contacts or In addition to protecting and controlling the electrical network,

protection functions will be recorded in the non-volatile the P922 and P923 relays provide preventive and curative

memory of the MiCOM P922 and P923 relays, with a maintenance of the circuit breakers. The MiCOM P922 and

maximum of 75 events. When the memory is full, the oldest P923 relays monitor the opening / closing time of the circuit

events will be deleted, which will increase the storage capacity breaker and monitor the number of operations carried out. An

for more recent events. Each event can be retrieved locally to alarm is triggered as soon as the maximum opening or closing

a PC using the MiCOM S1 support software through front time, or the maximum permitted number of operations is

RS232 port or remotely using the rear RS485 port. exceeded.

DISTURBANCE RECORD ANALYSIS

FAULT RECORDS

The MiCOM P922 and P923 relays can store the last 5 faults

that have occurred in non-volatile memory. Each record

provides the following information:

> date and time of fault

> origin of fault (under voltage, etc.)

> faulted phase(s)

> magnitude of the quantity which lead to the fault

> magnitude of phase-to-neutral or phase-to-phase

voltages

> magnitude of the zero-sequence voltage (if available)

P920 Technical Data Sheet 6

COMMUNICATIONS USER INTERFACE

Two communication ports are available on MiCOM P921, The user interface for MiCOM P921, P922 and P923 relays

P922 and P923 relays: A rear RS485 port for remote comprises:

communication and a local front RS232 port for local > back-lit, 2 x 16 characters LCD display,

communication. A MiCOM S1 software provided for relay > four dedicated LEDs to provide information such as

setting, record retrieving and analysis is fully Windows TM "Trip", "Alarm", "Warning" and "Relay Healthy"

compatible. This support Software allows easy setting of any > four programmable LEDs: Each one lights up when

MiCOM relay model including P92x. protection information is displayed, or if a logic input state

changes

> five tactile keys for scrolling through the menus and

REMOTE COMMUNICATION entering settings the pull-down structure of the menus

enables quick and easy access to required information

The P921, P922 and P923 relays can be ordered with any one > 1 key for reading and one for acknowledging alarms

of the following communication protocols.

HARDWARE & CASE

> MODBUS™

> IEC 60870-5-103 All the models of the MiCOM P92x range have a 4U

> Courier(K bus). draw out metal case, and can be flush-mounted in

> DNP3.0 switchboard or panel or rack-mounted. External connections

are made via MIDOS type terminal blocks. Each connection

The remote RS485 port can be connected to any SCADA or includes two 4.8 mm Faston and one M4 screw fixing.

digital control system to access settings, measurements and

alarms as well as all records.

BATTERY BOX

An optional external battery box type MiCOM E1 can be used

LOCAL COMMUNICATION

to set the relay without the need to provide an auxiliary supply.

The RS232 port on the front panel of MiCOM P921, P922 and

P923 relays has two functions: EXTERNAL BATTERRY BOX

> to download a software version to the relay (upgrade,

change the language setting, modify the remote

communication protocol, etc.)

> to connect a PC which has the setting software

COMMUNICATION INTERFACES

P920 Technical Data Sheet 7

TECHNICAL DATA TYPE TESTS

Insulation

MECHANICAL SPECIFICATIONS Per IEC 60255-5: 2000,

Insulation resistance > 100MW at 500Vdc

Design

(Using only electronic/brushless insulation tester).

Modular MiCOM Px2x platform relay:

P921, P922 & P923 – Case 20TE – 4U High Voltage (Dielectric) Withstand

Weight approx. 1.7 Kg (i) Per IEC 60255-5: 2000, 2 kV rms AC, 1 minute:

Mounting Between all case terminals connected together, and the case

earth, and between all terminals of independent ircuits (RS232

Rack or flush mounting.

ports excepted).

Connections 1kV rms AC for 1 minute, across open watchdog

Rear (double faxt on + M4 screw per connection) contacts.

Full draw-out with automatic CT shorting in the case of the

1kV rms AC for 1 minute, across open contacts of

relay.

changeover output relays.

Enclosure Protection

Impulse Voltage Withstand Test

Front Panel: IEC 529: IP 52 and IK 07

Rear connection: IP 10 Per IEC 60255-5: 2000

1.2 / 50 µs, peak value: 5 kV, 0.5J

Dimensions Between all terminals, and all terminals and case earth.

See dimensions diagram.

Electromagnetic Compatibility (EMC)

PC Interface

1 MHz Burst Disturbance Test

DIN 41652 connector (X6),

type D-Sub, 9-pin. IEC 61000-4-12, Class 3

ENVIRONMENTAL CONDITIONS Immunity to Electrostatic Discharge

Per IEC 60255-22-2: 1996, Class 3 and 4

Recommended Ambient temperature range

Electrical Fast Transient bursts

Per IEC 60255-6: 1988

IEC 60255-22-4 class 4.

Operating Temperature Range:

IEC 61000-4-4 class 4.

Continuous Withstand -25 to +55°C

Limit(Note 1) -25 to +70°C. Immunity to Radiated Electromagnetic field

Storage Temperature Range: -25 to +70°C IEC60255-22-3 class 3.

IEC61000-4-3 class 3.

Note 1: The upper limit is permissible for a single 6 hour

duration within any 24 hour period. Surge Immunity Test

IEC 61000-4-5, class 4.

Ambient Humidity Range

Per IEC 60068-2-3: 1969: Immunity to Conducted Disturbances Induced by Radio

56 days at 93% relative humidity and +40 °C Frequency Fields

Per IEC 60068-2-30: 1980: 4 IEC 61000-4-6, class 3.

Damp heat cyclic, six (12 + 12) hour cycles, 93% RH,

+25 to +55 °C Power Frequency Magnetic Field Immunity

IEC 61000-4-8, class V.

Solar Radiation

Avoid exposure of the front panel to direct solar radiation. EMC compliance

MECHANICAL ENVIRONMENT 89/336/EEC

93/31/EEC

Vibration Test Compliance with European Commission EMC Directive.

IEC 60255-21-1, class 2. Generic standards were used to establish conformity:

Shock and Bump Test EN50081-2: 1994

IEC 60255-21-2, class 1. EN60952-2: 1995

Per IEC 60529: 1989

Seismic Test

IP 52 Protection (front panel) against dust and dripping water,

IEC 60255-21-3, Class 2. IPx2 except P741 – Protected against vertically falling drops of

PRODUCT SAFETY water with the product in 4 fixed positions of 15° tilt with a flow

rate of 3mm/minute for 2.5 minutes.

72/23/EEC

Compliance with European Commission Low Voltage

Directive. Compliance is demonstrated by reference to generic

safety standards:

EN61010-1: 1993/A2: 1995

EN60950: 1992/A11: 1997

P920 Technical Data Sheet 8

RATINGS BURDENS

Voltages Voltage circuits

Nominal voltage Operating range REFERENCE VOLTAGE (VN)

57 – 130Vph - ph eff 5 to 260Vph - ph eff

220 – 480Vph - ph eff 20 to 960Vph - ph eff VN = 57 – 130V <0,25 VA

VN = 220 – 480V <0,36 VA

Duration

Thermal withstand (Vn = 57V … 130V) Auxiliary supply

Continuous 260Vph - ph eff

10 seconds 300Vph - ph eff Nominal* : 3W

* Nominal is with 50% of the optos energised and one relay

Thermal withstand (Vn = 220V … 480V) per card energised

Continuous 960Vph - ph eff

10 seconds 1300Vph - ph eff

Optically-isolated inputs

Auxiliary voltage Reference voltage Current (per logic input)

Nominal ranges 24… 60 Vdc 24… 60VDC 10mA

Operating ranges 19…72 V (Vdc) 48… 125 VDC 5mA

Nominal ranges 48… 150 Vdc 130… 250VDC 2.5mA

Operating ranges 38…180 V (Vdc)

Nominal ranges 130… 250 Vdc / 100… 250 Vac, 50/60 Hz

PROTECTION SETTING RANGES

Operating ranges 104… 300 V (Vdc)

88… 300 V (Vac) UNDERVOLTAGE (ANSI CODE 27)

Frequency Threshold settings (secondary values)

Nominal value 50Hz > Nominal voltage range : 57 – 130V

Operating range 40 – 60 Hz

Nominal value 60Hz V<= Voltage Set 0.5…130.0V

Operating range 50 – 70 Hz V<<= Voltage Set 0.5…130.0V

Logic inputs V<<<= Voltage Set 0.5…130.0V

All the logic inputs are optically-isolated and independent :

MiCOM P921 relay has 2 logic inputs > Nominal voltage range : 220 – 480V

MiCOM P922-P923 relays have 5 logic inputs. V<= Voltage Set 20.0…480.0V (by step: 0.5V)

Energization of the logic inputs is realised with a DC or AC V<<= Voltage Set 20.0…480.0V (by step: 0.5V)

auxiliary voltage.

V<<<= Voltage Set 20.0…480.0V (by step: 0.5V)

Logical « ON »

CORTEC Aux. voltage : Min Time delay settings

code Voltage Min

nominal current Each voltage element is associated to an independent time

range voltage

ranges (mA) delay.

A 24-60Vdc 19-60Vdc 15 Vdc 3,35 mA

Each measuring element time delay can be blocked by the

F 48-150Vdc 32-50Vdc 25 Vdc 3,35 mA operation of a user defined logic (optical isolated) input (see

M 130-250Vdc 48-250Vdc 38 Vdc 2,20 mA “Blocking logic1” or “Blocking logic2” functions).

100-250Vac

Element Time delay type

Logic input recognition time = 5 ms

1st stage Definite Time (DT) or IDMT

Output Relay Contacts

The output contacts of the MiCOM P921-P922-P923 relays are 2nd stage DT

AgCdO dry contacts. 3rd stage DT

Make and carry : 30A for 3s

Carry : 5A continuous

Break : DC : 50W resistive

DC : 25W inductive (L/R = 40ms)

AC : 1250VA

AC : 1250 VA inductive (cos ϕ = 0.5)

Maxima : 5A and 300V

Loaded contact : 10 000 operation minimum

Unloaded contact : 100 000 operation minimum

Operation time < 7 ms

P920 Technical Data Sheet 9

Inverse Time Delay Characteristic

Inverse Time Delay Characteristic

The inverse characteristic is defined by the following formula :

The inverse characteristic is defined by the following formula :

⎛ ⎞ ⎛ ⎞

⎜ ⎟ ⎜ ⎟

TMS ⎟ ⎜ TMS ⎟

t= ⎜ t=

⎜ V ⎟ ⎜ V ⎟

−1⎟ ⎜ −1⎟

⎜ ⎝ Vs ⎠

⎝ Vs ⎠

where :

where :

t = operating time in seconds

t = operating time in seconds TMS = time Multiplier Setting

TMS = time Multiplier Setting V = applied input voltage

V = applied input voltage Vs = relay setting voltage

Vs = relay setting voltage

V

V

NOTE : this equation is only valid for ratio< than 0.95 Vs ratio > than 1.1

Vs NOTE : this equation is only valid for

TMS 0.5…100.0 (by step: 0.5)

TMS 0.5…100.0 (by step: 0.5)

TRESET (only DT) 0.00… 100.00s

TRESET (only DT) 0.00…100.00s

When the V> is associated with IDMT curve, the recommended

maximum setting value should be less or equal to max. setting

Definite time delay characteristics range divided by 20.

tV< 0.00… 599.00s

tV<< 0.00… 599.00s Definite time delay characteristics

tV<<< 0.00… 599.00s tV> 0.00… 599.00s

Hysteresis tV>> 0.00… 599.00s

Hysteresis 1.02… 1.05% tV>>> 0.00… 599.00s

NOTE : this range is a percentage value of the pickup value of Hysteresis

the undervoltage elements Hysteresis 0.95… 0.98%

OVERVOLTAGE (ANSI CODE 59) NOTE : this range is a percentage value of the pickup value of

the overvoltage elements

Threshold settings (secondary values)

> Nominal voltage range : 57 – 130V RESIDUAL OVERVOLTAGE / NEUTRAL

DISPLACEMENT (ANSI CODE 59N)

V>= Voltage Set 0.5…200.0V

V>>= Voltage Set 0.5…260.0V Threshold settings (secondary values)

V>>>= Voltage Set 0.5…260.0V > Nominal voltage range : 57 – 130V

> Nominal voltage range : 220 – 480V V0> Voltage set 0.5… 130.0V

V>= Voltage Set 20.0… 720.0V (by step: 0.5V) V0>> Voltage set 0.5… 130.0V

V>>= Voltage Set 20.0… 960.0V (by step: 0.5V) V0>>> Voltage set 0.5… 130.0V

V>>>= Voltage Set 20.0… 960.0V (by step: 0.5V)

> Nominal voltage range : 220 – 480V

Time delay settings

V0> Voltage set 2.0… 480.0V (by step: 0.5V)

Each voltage element is associated to an independent time

V0>> Voltage set 2.0… 480.0V (by step: 0.5V)

delay.

Each measuring element time delay can be blocked by the V0>>> Voltage set 2.0… 480.0V (by step: 0.5V)

operation of a user defined logic (optical isolated) input (see

“Blocking logic1” or “Blocking logic2” functions).

Element Time delay type

1st stage Definite Time (DT) or IDMT

2nd stage DT

3rd stage DT

P920 Technical Data Sheet 10

Time delay settings

Time delay settings

Each voltage element is associated to an independent time

Each voltage element is associated to an independent time delay.

delay.

Each measuring element time delay can be blocked by the

Each measuring element time delay can be blocked by the operation of a user defined logic (optical isolated) input (see

operation of a user defined logic (optical isolated) input (see “Blocking logic1” or “Blocking logic2” functions).

“Blocking logic1” or “Blocking logic2” functions).

Element Time delay type

Element Time delay type

1st stage Definite Time (DT) or IDMT

1st stage Definite Time (DT) or IDMT

2nd stage DT

2nd stage DT

3rd stage DT Inverse Time Delay Characteristic

The inverse characteristic is defined by the following formula :

Inverse Time Delay Characteristic

The inverse characteristic is defined by the following formula : ⎛ ⎞

⎜ ⎟

⎛ ⎞ ⎜ TMS ⎟

⎜ ⎟ t=⎜ ⎟

⎜ TMS ⎟

t=⎜ ⎜ V2 − 1 ⎟

⎟ ⎜ V ⎟

⎜ V0 − 1 ⎟ ⎝ S ⎠

⎜ V ⎟

⎝ S ⎠ where :

t = operating time in seconds

where :

TMS = time Multiplier Setting

t = operating time in seconds V2 = applied input voltage

TMS = time Multiplier Setting Vs = relay setting voltage

V0 = applied input voltage

Vs = relay setting voltage TMS 0,5… 100.0 (by step: 0.5)

tRESET (only DT) 0.00… 100.00s

TMS 0,5… 100.0 (by step: 0.5)

TRESET (only DT) 0.00… 100.00s Definite time delay characteristics

Definite time delay characteristics tV2> 0.00… 599.00s

tV2>> 0.00… 599.00s

tV0> 0.00… 599.00s

tV0>> 0.00… 599.00s Hysteresis

tV0>>> 0.00… 599.00s Hysteresis fixed 95%

When the V2> is associated with IDMT curve, the

Hysteresis

recommended maximum setting value should be less or equal

Hysteresis fixed 95% to max. withstand voltage of the VT inputs divided by 20.

When the V0> is associated with IDMT curve, the

recommended maximum setting value should be less or equal

to max. withstand voltage of the VT inputs divided by 20. POSITIVE SEQUENCE UNDERVOLTAGE

(ANSI CODE 27D) ONLY P922 & P923

Threshold settings (secondary values)

NEGATIVE SEQUENCE OVERVOLTAGE

(ANSI CODE 47) ONLY P922 & P923 > Nominal voltage range : 57 – 130V

V1< Voltage set 5.0… 130.0V

Threshold settings (secondary values)

> Nominal voltage range : 57 – 130V V1<< Voltage set 5.0… 130.0V

V2> Voltage set 5.0… 200.0V > Nominal voltage range : 220 – 480V

V2>> Voltage set 5.0… 200.0V V1< Voltage set 20.0… 480.0V (by step: 0.5)

> Nominal voltage range: 220 – 480V V1<< Voltage set 20.0… 480.0V (by step: 0.5)

V2> Voltage set 20.0… 720.0V (by step: 0.5)

V2>> Voltage set 20.0… 720.0V (by step: 0.5)

P920 Technical Data Sheet 11

Time delay settings RATE OF CHANGE OF FREQUENCY

(ANSI CODES 81R) ONLY P923

Each voltage element is associated to an independent time

delay. Threshold settings

Each measuring element time delay can be blocked by the

Setting Range Step Size

operation of a user defined logic (optical isolated) input (see

“Blocking logic1” or “Blocking logic2” functions). df/dt1 threshold –10 Hz/s, +10 Hz/s 0.1 Hz/s

Element Time delay type df/dt2 threshold –10 Hz/s, +10 Hz/s 0.1 Hz/s

1st stage Definite Time (DT) or IDMT df/dt3 threshold –10 Hz/s, +10 Hz/s 0.1 Hz/s

2nd stage DT df/dt4 threshold –10 Hz/s, +10 Hz/s 0.1 Hz/s

Inverse Time Delay Characteristic df/dt5 threshold –10 Hz/s, +10 Hz/s 0.1 Hz/s

The inverse characteristic is defined by the following formula : df/dt6 threshold –10 Hz/s, +10 Hz/s 0.1 Hz/s

⎛ ⎞

⎜ ⎟ Integration time

⎜ TMS ⎟ Setting Range Step Size

t=⎜ ⎟ cycle number 1 – 200 1 cycle

⎜ V1 − 1 ⎟

⎜ V ⎟ Validation number of protection

⎝ S ⎠ Setting Range Step Size

where :

Validation 2 or 4 2

t = operating time in seconds

TMS = time Multiplier Setting

V1 = applied input voltage UNDER VOLTAGE BLOCKING

Vs = relay setting voltage > Nominal voltage range : 57-130V

TMS 0,5… 100.0 (by step: 0.5) protection block 5.0… 130.0V

tRESET (only DT) 0.00… 100.00s

> Nominal voltage range : 220-480V

Definite time delay characteristics protection block 20.0… 480.0V

tV1< 0.00… 599.00s

NOTE : For P922S the under voltage blocking threshold is

tV1<< 0.00… 599.00s fixed to 10% of the nominal setting voltage range.

Hysteresis

Hysteresis fixed 105% MEASUREMENT AND RECORDS

SETTINGS

The measured values are displayed on the LCD of the relay ;

UNDER/OVERFREQUENCY th

they are true RMS values (up to the 10 harmonic) and are

(ANSI CODES 81U/81O) ONLY P922 & P923 primary values.

They can also be read through the communication ports

Setting Range Step Size (RS232 or RS485).

F1 threshold Fn – 10Hz, Fn + 10Hz 0.01 Hz

DISTURBANCE RECORD (P922 AND P923)

tF1 (definite time delay) 0.00… 599.00s 0.01s The MiCOM P922-P923 is able to store up to 5 records of 2.5s

F2 threshold Fn – 10Hz, Fn + 10Hz 0.01 Hz each.

tF2 (definite time delay) 0.00… 599.00s 0.01s Pre – time 0.01… 2.50s

F3 threshold Fn – 10Hz, Fn + 10Hz 0.01 Hz Post – time 0.01… 2.50s

tF3 (definite time delay) 0.00… 599.00s 0.01s Sample rate 32 samples/cycle Fixed

F4 threshold Fn – 10Hz, Fn + 10Hz 0.01 Hz Digital signals Logic inputs and output contacts status

tF4 (definite time delay) 0.00… 599.00s 0.01s Trigger logic Power on of the MiCOM relay,

F5 threshold Fn – 10Hz, Fn + 10Hz 0.01 Hz Any selected protection alarm or trip,

Dedicated logic input,

tF5 (definite time delay) 0.00… 599s.00 0.01s

Remote command.

F6 threshold Fn – 10Hz, Fn + 10Hz 0.01 Hz

NOTE : if both post- and pre-time are set equal to 2.5s, the

tF6 (definite time delay) 0.00… 599.00s 0.01s pre-time will be priority and equal to 2.5s. The post-

time will then be equal to 0s.

Where : Fn : nominal frequency

P920 Technical Data Sheet 12

FREQUENCY DISTURBANCE RECORD CIRCUIT BREAKER CONDITION MONITORING

(P923 ONLY)

Nb. Operations Alarm 0… 50000

The MiCOM P923 is able to store one record of 20s.

Open time alarm 0.1… 5.0s

Pre – time 5s (fixed) Close time alarm 0.1… 5.0s

Post – time 15s (fixed)

Sample rate 1 sample/cycle (fixed) LOGIC EQUATIONS

Digital signals Logic inputs and output contacts status 2 or 4 logic equations are available.

The associated timers are :

Trigger logic Instantaneous or time delayed tripping,

Dedicated logic input,

tOPERATE 0.0… 3600.0s

Logic equation,

Remote command. tRESET 0.0… 3600.0s

COMMUNICATIONS VT RATIOS

The primary and secondary rating can be independently set for

FRONT PORT (RS232)

each set of VT inputs, for example the residual VT ratio can be

Front port Communication Parameters (Fixed) different to that used for the phase voltages.

Protocol Modbus RTU

Voltage ranges Primary Secondary

Address To be specified in the

« COMMUNICATIONS » menu of the 57 – 130V 0,1 – 100kV 57 – 130V

relay step = 0.01kV step = 0.1V

Messages format IEC60870FT1.2 220 – 480V 220 – 480V 220 – 480V

step = 10V step = 10V

Baud rate 19200 bits/s

Parity Without

ACCURACY

Stop bits 1 If no range is specified for the validity of the accuracy, then the

Data bits 8 specified accuracy shall be valid over the full setting range.

REAR PORT (RS485) REFERENCE CONDITIONS

Rear port settings Setting options Setting available Quantity Reference Test tolerance

for: conditions

Remote address 0 - 255 (step = 1) IEC / Kbus-Courier General

/ Modbus RTU

Ambient temperature 20 °C ±2°C

Baud rate 9 600 or 19 200 bits/s IEC

Atmospheric pressure 86kPa to 106kPa -

Baud rate 300, 600, 1200, 2400, Modbus

Relative humidity 45 to 75 % -

4800, 9600, 19 200 or

38 400 bits/s

Baud rate 64000 bits/s Kbus Input energising quantity

Parity “Even”, “Odd” or Modbus RTU Voltage Vn ±5%

“Without”

Frequency 50 or 60Hz ±0.5%

Stop bits 0 or 1 or 2 Modbus RTU

Auxiliary supply DC 48V or 110V ±5%

AC 63.5V or 110V

CONTROL FUNCTIONS SETTINGS MEASUREMENTS ACCURACY

CIRCUIT BREAKER STATE MONITORING Quantity Range Accuracy

The MiCOM P921-P922-P923 relays monitor the state of the

circuit breaker using either 52a and/or 52b signals. Voltage Vn ±2%

Frequency 40 - 70Hz ±10mHz

CIRCUIT BREAKER CONTROL

It is possible to control the circuit breaker via the communication

(RS232 or RS485 links).

Close pulse time 0.10… 5.00s (by step: 0.05)

Trip pulse time 0.10… 5.00s (by step: 0.05)

P920 Technical Data Sheet 13

PROTECTION ACCURACY

Functions Range Operate Reset Timer Accuracy

Undervoltage 5-130V (range 1) DT : Vs ±2% (1.02-1.05) Voperate Greater of 2% or 20ms

protection 20-480V (range 2) IDMT : Voperate = ±2% Greater of 5% or 40ms

(V<, V<< and 0.95Vs ±2%

V<<<)

Overvoltage 0.5-260V (range 1) DT : Vs ±2% (0.95-0.98) Voperate Greater of 2% or 20ms

protection 20-960V (range 2) IDMT : Voperate = ±2% Greater of 5% or 40ms

(V>, V>> and 1.1Vs ±2%

V>>>)

Residual 0.5-130V (range 1) DT : Vs ±2% 0.95 Voperate ±2% Greater of 2% or 20ms

voltage 2-480V (range 2) IDMT : Voperate = Greater of 5% or 40ms

protection 1.1Vs ±2%

(V0>, V0>> (if direct

and V0>>>) measurement)

Under/Over 40 – 70Hz DT : fs ±10mHz fs ±50mHz Greater of 2% or 20ms

frequency

NOTE : For residual voltage protection :

– 0.5V → 4V (range 1) :

hysteresis = Voperate – 0.2V

– 2V → 16V (range 2) :

hysteresis = Voperate – 0.8V

The instantaneous operating time for

under/over frequency is 50 ms (minimum).

The instantaneous operating time for

under/over voltage is ≤ 30 ms.

No additional errors will be incurred for any

of the following influencing quantities.

Environmental Operative range (typical only)

Temperature -25°C to +55°C

Mechanical According to :

(Vibration, Shock, IEC 60255-21-1:1988

Bump, Seismic) IEC 60255-21-2:1988

IEC 60255-21-3:1995

Electrical Operative range

Frequency 40 Hz to 70 Hz

Harmonics (single) 5% over the range 2nd to 17th

Auxiliary voltage range 0.8 LV to 1.2 HV (dc)

0.8 LV to 1.1 HV (ac)

Aux. supply ripple 12% Vn with a frequency of 2.fn

Power off withstand 50 ms

P920 Technical Data Sheet 14

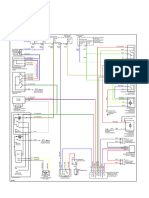

CONNECTION DIAGRAMS

3VTs CONFIGURATION (Phase-Neutral)

33 37

+ 35 Watchdog

Power supply WD

C B -

34 36

Phase rotation 6 Output contacts programmable

4

RL1 RL1

2

12

MiCOM P92* RL2

10

8

RL2

41 16

RL3 14 RL3

42 20

43

RL4 18 RL4

44 3

45 RL5 1 RL5

7

46 RL6 5 RL6

49

See note 1

9

50 RL7 11 RL7

13

RL8 15 RL8

Programmable inputs : +

22 LEDs

_

EL1 24 4 programmable LEDs

26

+

EL2 _

28

17 Earth

+

EL3 _ 29 connection

19 -

21 * 30

+

EL4 _

See note 2 31

23 + Communication port RS485

25

+

EL5 _

27

32 _

(* System end resistance.

For last relay, connect 30 and 32 together).

Notes :

(1) Additional hardware for MiCOM P922 and P923 relay

(2) Additional hardware for MiCOM P922 and P923 relay

Scheme representing MiCOM relay off

P0389ENa

P920 Technical Data Sheet 15

3VTs CONFIGURATION (Phase-Neutral) + residual voltage

33 37

Power + 35 Watchdog

supply WD

C B -

34 36

Phase rotation 6 Output contacts (programmable) :

4

RL1 RL1

2

12

10 RL2

RL2

8

41 16

RL3 14 RL3

42 20

43

RL4 18 RL4

44 3

45 RL5 1 RL5

7

46 RL6 5 RL6

49

See note 1

9

RL7 11 RL7

50

13

RL8 15 RL8

Programmable inputs : +

22 LEDs

_

EL1

24 4 programmable LEDs

26

+

EL2 _

28

17 Earth

+

EL3 _ 29 connection

19 -

* 30

21 *

+

EL4 _ See note 2 31

23 + Communication port RS485

25

+

EL5 _

27

32 _

(* System end resistance.

For last relay, connect 30 and 32 together)

Notes :

(1) Additional hardware for MiCOM P922 and P923 relay

(2) Additional hardware for MiCOM P922 and P923 relay

Scheme representing MiCOM relay off P0390ENa

P920 Technical Data Sheet 16

2VTs CONFIGURATION + residual voltage

33 37

Power + 35 Watchdog

supply WD

C B -

34 36

Phase rotation 6 Output contacts (programmable) :

4

RL1 RL1

2

12

10 RL2

RL2

41 8

42 16

43 RL3 14 RL3

20

44

45 RL4 18 RL4

3

46 RL5 1 RL5

49

7

RL6 5 RL6

50

See note 1

9

RL7 11 RL7

13

RL8 15 RL8

Programmable inputs : +

22 LEDs

EL1 _

24

26 4 programmable LEDs

+

EL2 _

28

17 Earth

+

EL3 _ 29 connection

19 -

* 30

21

+

*

EL4 _ See note 2 31

23 + Communication port RS485

25

+

EL5 _

27

32 _

(* System end resistance.

For last relay, connect 30 and 32 together)

Notes :

(1) Additional hardware for MiCOM P922 and P923 relay

(2) Additional hardware for MiCOM P922 and P923 relay

Scheme representing MiCOM relay off

P0392ENa

P920 Technical Data Sheet 17

LV connection for P92x (220-480V range)

33 37

Power + 35 Watchdog

supply WD

C B -

34 36

Phase rotation 6 Output contacts (programmable) :

4

RL1 RL1

A B C

2

12

10 RL2

RL2

41 8

42 16

43 RL3 RL3

14

20

44

45 RL4 18 RL4

3

46 RL5 1 RL5

49

7

RL6 5 RL6

50

See note 1

9

RL7 11 RL7

13

RL8 15 RL8

Programmable inputs : +

22 LEDs

_

EL1

24

26 4 programmable LEDs

+

EL2 _

28

17 Earth

+

EL3 _ 29 connection

19 -

21

+

** 30

EL4 _

See note 2 31

23 +

25 Communication port RS485

+

EL5 _

27

32 _

(* System end resistance.

Notes : For last relay, connect 30 and 32 together)

(1) Additional hardware for MiCOM P922 and P923 relay

(2) Additional hardware for MiCOM P922 and P923 relay

Scheme representing MiCOM relay off

A

33 37

Power + 35 Watchdog

supply WD

C B -

34 36

Phase rotation 6 Output contacts (programmable) :

4

RL1 RL1

2

12

10 RL2

RL2

41 8

42 16

43 RL3 RL3

14

20

44

45 RL4 18 RL4

3

46 RL5 1 RL5

49

7

RL6 5 RL6

50

See note 1

9

RL7 11 RL7

N A B C

13

RL8 15 RL8

Programmable inputs : +

22 LEDs

EL1 _

24

26 4 programmable LEDs

+

EL2 _

28

17 Earth

+

EL3 _ 29 connection

19 -

21

+

** 30

EL4 _ See note 2 31

23 + Communication port RS485

25

+

EL5 _

27

32 _

(* System end resistance.

Notes : For last relay, connect 30 and 32 together)

(1) Additional hardware for MiCOM P922 and P923 relay

(2) Additional hardware for MiCOM P922 and P923 relay

Scheme representing MiCOM relay off P0393ENa

P920 Technical Data Sheet 18

CASES & DIMENSIONS

39 39

97 26 26

Dimensions

in mm.

168 158

Panel cut-out

Flush mounting fixing details

4 holes Ø 3.4 49.5 49.5 4 holes Ø 4.4 (M4 screw)

103 25.1 226

MiCOM P921

VA = 214.50 A

Trip

Ala rm e

Equip. fail

Auxiliary

177 151.2 max.

supply

AUX. 1

AUX. 2

AUX. 3

AUX. 4

Flush mounting

P0395ENb

MiCOM P921, P922 & P923 – 4U 20TE

P920 Technical Data Sheet 19

MiCOM P920

GUIDE FORM SPECIFICATION

The voltage and frequency protections have to be of

entirely numerical technology and in a 4U draw out

metal case.

The following functions have to be available:

> 3 independent phase overvoltage thresholds

(instantaneous and time-delayed - ANSI 59 code)

> 3 independent phase undervoltage thresholds

(instantaneous and time-delayed - ANSI 27 code)

> Settable Hysteresis thresholds for Undervoltage

and Overvoltage functions

> 3 independent zero-sequence overvoltage

thresholds (instantaneous and time-delayed -

ANSI 59N code)

> programmable logic equations

> Programmable I/O

> Relay latching (ANSI 86 code)

> Display of true RMS values

> 2 setting groups

> An RS485 rear port compatible with the following

protocols: MODBUS™, Courier, IEC 60870-5-103,

DNP3.0

> Records of the last 75 events, time-stamped to

1ms

> Data records relating to the last 5 faults

> Disturbance recorder with storage of 5 records,

each lasting 2.5 seconds, 32 samples per cycle

For frequency protection, the following functions have

to be added:

> 2 independent negative sequence phase

overvoltage thresholds (instantaneous and time-

delayed - ANSI 47 code)

> 2 independent positive sequence phase

undervoltage thresholds (instantaneous and time-

delayed - ANSI 27D code)

> Settable Hysteresis thresholds for Undervoltage

and Overvoltage functions.

> 6 independent over/underfrequency thresholds

(instantaneous and time-delayed - ANSI 81U/81O

codes)

For rate of change of frequency, the following functions

have to be added:

> 6 independent rate of change of frequency

thresholds - ANSI 81R codes

> 1 adjustable undervoltage Blocking threshold

> 4 programmable logic equations

The user interface must include the following elements:

> A 32-character alphanumeric back-lit LCD display

> An RS232 front port compatible with application

software and PC setting software

> Programmable LEDs with customised labelling

P920 Technical Data Sheet 20

ORDERING INFORMATION

MiCOM P92x - Voltage Protection Relays

P92 0 1

Relay Type

Voltage Relay 1

Voltage/Frequency relay 2

Voltage/Frequency relay with (df / dt) relay 3

Voltage Inputs

57 - 130 V A

220 - 480 V B

Application

Standard S

Auxiliary Supply Voltage

24 - 60Vdc A

48 - 150Vdc F

130 - 250Vdc / 100 - 250Vac M

48 - 150Vdc with 48 - 150 Vdc digital inputs voltage (special EA) T

130 - 250Vdc with 130 - 250 Vdc digital inputs voltage (special EA) U

125 - 250Vdc / 100 - 250Vac with 95 - 150 Vdc digital inputs voltage (special application) H

Communications protocol options

Modbus 1

K-bus / Courier 2

IEC 60870-5-103 3

DNP3.0 4

User interface language options (see note 1)

French 0

English 1

Spanish 2

German 3

Italian 4

Russian 5

Polish 6

Portuguese (NOT YET AVAILABLE !) 7

Dutch (NOT YET AVAILABLE for P923 !) 8

Czech A

Hungarian (NOT YET AVAILABLE !) B

Case Type

Flush and/or panel mounted only 1

Note 1: Contact us for language availability

P920 Technical Data Sheet 21

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- 740B Transmission Electronic SystemDocumento6 pagine740B Transmission Electronic SystemRajan Mullappilly100% (4)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- IEC 62271 - EN - 2003-10-27 - HandoutDocumento18 pagineIEC 62271 - EN - 2003-10-27 - HandoutFarhan ShahNessuna valutazione finora

- Samsung Ue49nu7172u Uwx80Documento104 pagineSamsung Ue49nu7172u Uwx80kevinalleinNessuna valutazione finora

- IEC 62271-200 SwitchgearDocumento22 pagineIEC 62271-200 SwitchgearFarhan Shah100% (7)

- Preparing Group 1 RS2000 Rally CarsDocumento6 paginePreparing Group 1 RS2000 Rally CarsPhilip RiddlesNessuna valutazione finora

- MA5616 V800R311C01 Environment Monitoring 01Documento121 pagineMA5616 V800R311C01 Environment Monitoring 01Alvaro Cue100% (1)

- Ep 3Documento18 pagineEp 3MancamiaicuruNessuna valutazione finora

- Ml30e100 PDFDocumento2 pagineMl30e100 PDFFarhan ShahNessuna valutazione finora

- ECT191 Fuzzy LogicDocumento32 pagineECT191 Fuzzy LogicBernardMightNessuna valutazione finora

- Valve Selection and Sizing: Section of Engineering Manual of Automatic Control 77-1100Documento20 pagineValve Selection and Sizing: Section of Engineering Manual of Automatic Control 77-1100intequabNessuna valutazione finora

- Lightning and HV Electrical Installations PDFDocumento24 pagineLightning and HV Electrical Installations PDFRiazAhmedNessuna valutazione finora

- E&DPlanDocumento8 pagineE&DPlanFarhan ShahNessuna valutazione finora

- Cable Capacity Table for PVC Insulated WiresDocumento1 paginaCable Capacity Table for PVC Insulated WiresFarhan ShahNessuna valutazione finora

- Cti PDFDocumento5 pagineCti PDFFarhan ShahNessuna valutazione finora

- Power capacitor bank componentsDocumento1 paginaPower capacitor bank componentsFarhan ShahNessuna valutazione finora

- Analysis of Networks Using Symmetrical ComponentsDocumento33 pagineAnalysis of Networks Using Symmetrical ComponentsashawishNessuna valutazione finora

- Busbar Selection TabelDocumento1 paginaBusbar Selection TabelFarhan ShahNessuna valutazione finora

- New Cable ChartDocumento1 paginaNew Cable ChartFarhan ShahNessuna valutazione finora

- Power capacitor bank componentsDocumento1 paginaPower capacitor bank componentsFarhan ShahNessuna valutazione finora

- Insideiec04 eDocumento36 pagineInsideiec04 eFarhan ShahNessuna valutazione finora

- Services PDFDocumento4 pagineServices PDFFarhan ShahNessuna valutazione finora

- Specifications For: 11Kv Pad Mounted SwitchDocumento8 pagineSpecifications For: 11Kv Pad Mounted SwitchFarhan ShahNessuna valutazione finora

- Portable Device For PD MeasurementDocumento52 paginePortable Device For PD MeasurementFarhan ShahNessuna valutazione finora

- Pirelli PDFDocumento24 paginePirelli PDFFarhan ShahNessuna valutazione finora

- IEC61850 Message StatusDocumento6 pagineIEC61850 Message StatustonytomsonNessuna valutazione finora

- 7SJ80xx Manual A1 V040005 Us PDFDocumento514 pagine7SJ80xx Manual A1 V040005 Us PDFFarhan ShahNessuna valutazione finora

- E&DPlan0708 1Documento80 pagineE&DPlan0708 1Farhan ShahNessuna valutazione finora

- TF Testing RecommendationDocumento4 pagineTF Testing RecommendationFarhan ShahNessuna valutazione finora

- 8PT112 WiresDocumento4 pagine8PT112 WiresFarhan ShahNessuna valutazione finora

- The New IECDocumento10 pagineThe New IECFarhan ShahNessuna valutazione finora

- Latest Iec Vs Siemens SGDocumento36 pagineLatest Iec Vs Siemens SGFarhan ShahNessuna valutazione finora

- Transients On Secondary Equipment in MV Switchgear InstallationsDocumento6 pagineTransients On Secondary Equipment in MV Switchgear InstallationsFarhan ShahNessuna valutazione finora

- Damping ResistorDocumento8 pagineDamping ResistorFarhan ShahNessuna valutazione finora

- Vortrag - WandlerJun 04Documento13 pagineVortrag - WandlerJun 04Farhan ShahNessuna valutazione finora

- TH-A35 TH-A32: DVD Digital Theater SystemDocumento65 pagineTH-A35 TH-A32: DVD Digital Theater SystemEl Tio Del TamborNessuna valutazione finora

- Aw033 Gpe Motor StarterDocumento4 pagineAw033 Gpe Motor Startermzaid1979Nessuna valutazione finora

- Shift and Throttle Control CablesDocumento21 pagineShift and Throttle Control CablesrfffffNessuna valutazione finora

- Medical Equipment and SuppliesDocumento2 pagineMedical Equipment and SuppliesJanna FabiaNessuna valutazione finora

- Catalogo XMDocumento42 pagineCatalogo XMAlejandro Saco HerreraNessuna valutazione finora

- Differences Related To Computer MaintenanceDocumento5 pagineDifferences Related To Computer MaintenanceAlpesh ThesiyaNessuna valutazione finora

- GP Electronic Wiring DiagramDocumento2 pagineGP Electronic Wiring DiagramRamon Thales DomeniconiNessuna valutazione finora

- CoBra Hardware Manual Rev.1.0Documento63 pagineCoBra Hardware Manual Rev.1.0Cristian CotetNessuna valutazione finora

- 2006-2011 Yaris Aftermarket Fog Light Switch WiringDocumento3 pagine2006-2011 Yaris Aftermarket Fog Light Switch WiringPaolo Jan C. LimNessuna valutazione finora

- Technical Service Information: Automatic Transmission Service GroupDocumento3 pagineTechnical Service Information: Automatic Transmission Service GroupMarcos MontesNessuna valutazione finora

- InflightRefueling HIFR FlyerDocumento2 pagineInflightRefueling HIFR FlyerMone MostafaNessuna valutazione finora

- CIS for Epson C79 - Easy Printer Ink InstallationDocumento7 pagineCIS for Epson C79 - Easy Printer Ink InstallationMuhammad Syafi'i MahjuriNessuna valutazione finora

- Underwater PelletiserDocumento2 pagineUnderwater PelletiserTuesou MachereNessuna valutazione finora

- XS630B1MBL2 inductive sensor product data sheetDocumento2 pagineXS630B1MBL2 inductive sensor product data sheetRenato Antonio Zenteno TapiaNessuna valutazione finora

- National Plumbing Code QuizDocumento8 pagineNational Plumbing Code QuizJohn Kenedy Hernandez CasapaoNessuna valutazione finora

- Tle10 Ict Technicaldrafting q4 Mod2 Draftingmechanicallayoutanddetailsusingcad (2) v4Documento22 pagineTle10 Ict Technicaldrafting q4 Mod2 Draftingmechanicallayoutanddetailsusingcad (2) v4Mark Anthony RobleNessuna valutazione finora

- Montageanleitung Cycle R: Art.-Nr. 07986-996Documento14 pagineMontageanleitung Cycle R: Art.-Nr. 07986-996Beth KananiaNessuna valutazione finora

- Nfpa 12 2018 12Documento1 paginaNfpa 12 2018 12Sundar RzNessuna valutazione finora

- Electronics Quiz 1Documento2 pagineElectronics Quiz 1Dave AllenNessuna valutazione finora

- UF Physical Plant Division Motor Vehicle Inspection ManualDocumento9 pagineUF Physical Plant Division Motor Vehicle Inspection ManualAsad KhanNessuna valutazione finora

- Surge Arrester - Wikipedia, The Free EncyclopediaDocumento2 pagineSurge Arrester - Wikipedia, The Free EncyclopediaMuhammad Nico PermanaNessuna valutazione finora

- Co2 Dragster SpecsDocumento3 pagineCo2 Dragster Specsapi-233611534Nessuna valutazione finora

- 01 - SWG - Automatic Transfer Switches - (1.23 - 1.24)Documento2 pagine01 - SWG - Automatic Transfer Switches - (1.23 - 1.24)ThilinaNessuna valutazione finora

- +05C001951 - CHI - ENG - Rel - 1-1 - PGDx7 SmartDocumento2 pagine+05C001951 - CHI - ENG - Rel - 1-1 - PGDx7 SmartP K pandianNessuna valutazione finora

- All Wiring Diagrams For Nissan Sentra CA 2002Documento63 pagineAll Wiring Diagrams For Nissan Sentra CA 2002tellossaposNessuna valutazione finora

- Catalogue 2016Documento68 pagineCatalogue 2016Abenezer BirhanuNessuna valutazione finora