Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Daily unloader checklist

Caricato da

Anonymous ahdhFMaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Daily unloader checklist

Caricato da

Anonymous ahdhFMaCopyright:

Formati disponibili

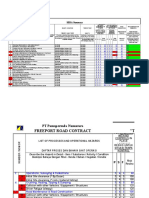

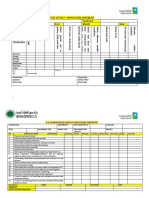

UNLOADER DAILY CHECK LIST Year: Month:

Main part Description Date 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

Check the wheel work & the accelerator for the operational noise and their fastening situation

Check the hydraulic & lubrication lines for leakage

General Principals

Fasten/replace loose or missed screw

Record some of the structure issues

Check the Oil condition of the hinge points, steel pully,steel guiding rollers and moulding mouth of the steel rope

Check the fastening & connection of the steel ropes replace worn or damage steel ropes if needed

check the worn components of the hinge pin and axle-shaft replace if it necessary

Grab bucket

Check grab working pulley wires are correct position.

Check grab hanging shackle condition.

Check grab wire guide small pulley (which locate top of the grab)properly touch & guide the wire

Elevating ,open & close mechanism Check the broken wire rope and repaired it Count broken wire rope & replace it if need

Disc break check the break lining and working conditions of the break disc, replace the break liner if necessary

Wire rope guiding pulley Check & count steel wires with broken wire rope. Replace if necessary.

Check the breaking condition

Check emergency push button working condition

Assistant maintenance crane on wrinch

room

check wire rope & its fixing

Check the stop position of the crane because it can touch the wire ropes

check the drive part (rail) of the crane. If there is a barrier clear it.

Crane drive mechanism Motor & check the crane driving motor gear box oil level .If low fill it.

gear box

Check the rail clamp hydraulic unit oil leval.If low top up

check the rubber mounting of the feeder if broken repair or replace

Check the feeder hanging bolt tightening condition if loosen tight it.

Vibrator feeder & hopper

check the feeder & hopper gap if it is not sufficient adjust it.

check hopper & feeder vibrator motors mounting & working condition if there abnormal repair it

Check the oil level of the tank

Hydraulic station Check the hopper gate,spilage gate & window gate hydraulic cylinder leakage

check the spillage gate clean condition. If there is some coal clean it.

Check the water tank water leval.If low level fill it.

Check the water leakage from lines & pump

water sprinkle system

Check the water motor condition (teperature,noice,etc) when it working.

Check the sprinkles condition .If there is blockage repaired it.

Check the wire bobbin break condition (abnormal sound,temperature,etc.)

Check the wire bobbin motor condition (abnormal sound,temperature,etc.)

Check the motor cooling fan working condition (abnormal sound,vibration,etc.)

Winch room

Check the gear box (3 numbers) oil level & gear wheel (through inspection door)

Check weather wire rope guiding pulley is correct position

Check wires are correctly wound to the bobin.If there is mismatch prepare it

Operator EPF Number

Potrebbero piacerti anche

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- KPI Submission (October)Documento3 pagineKPI Submission (October)Htoo Htoo KyawNessuna valutazione finora

- PM Inspection SheetDocumento4 paginePM Inspection SheetYogeshNessuna valutazione finora

- "Red" High (1) "Yellow" Medium (2) "Green" Low (3) : IllnessDocumento2 pagine"Red" High (1) "Yellow" Medium (2) "Green" Low (3) : IllnessBarb O'NeillNessuna valutazione finora

- IDI-FRM-HSE-32-01 Permit To Work - Electrical WorkDocumento1 paginaIDI-FRM-HSE-32-01 Permit To Work - Electrical Workaulia chaniaNessuna valutazione finora

- HSE PERFORMANCE MONITORING REPORTDocumento2 pagineHSE PERFORMANCE MONITORING REPORTRezza FahleviNessuna valutazione finora

- Rameshwer Lal Gadri - Safety KPIs For FY 2021-22Documento7 pagineRameshwer Lal Gadri - Safety KPIs For FY 2021-22Nikhil VaidyaNessuna valutazione finora

- HIRADocumento16 pagineHIRASAMEER JAVEDNessuna valutazione finora

- Hot - Work - Permit Form 10.20Documento2 pagineHot - Work - Permit Form 10.20Jixtha SaintNessuna valutazione finora

- Waste Inventory Sheet (Process Waste) : Name of Company/Production UnitDocumento2 pagineWaste Inventory Sheet (Process Waste) : Name of Company/Production UnitNur E Alam NuruNessuna valutazione finora

- SPC ME TT 0001 - Design - Basis - R PDFDocumento18 pagineSPC ME TT 0001 - Design - Basis - R PDFAnonymous ahdhFMa0% (1)

- BOQ 2 BedroomDocumento83 pagineBOQ 2 BedroomOgunfolaji Rasheed100% (1)

- HSE Program 2016 ReviewDocumento4 pagineHSE Program 2016 ReviewNurAjiNessuna valutazione finora

- Annual Safety Activity Plan of UAIL Site, Rev.-03Documento1 paginaAnnual Safety Activity Plan of UAIL Site, Rev.-03Sheikh AshfaqueNessuna valutazione finora

- Ind Swift Limited (Gbu) : Manpower Summary of (Company Name) As On 31.05.2010 (Permanent)Documento14 pagineInd Swift Limited (Gbu) : Manpower Summary of (Company Name) As On 31.05.2010 (Permanent)tarique1189040Nessuna valutazione finora

- Electroconvulsive Therapy: Presented By: Shweta Surwase F.Y. M.Sc. (Mental Health Nursing) MIMH, PuneDocumento48 pagineElectroconvulsive Therapy: Presented By: Shweta Surwase F.Y. M.Sc. (Mental Health Nursing) MIMH, PuneShweta KateNessuna valutazione finora

- Form-I-010 Welding Machine Inspection Form: Carry-In CertificateDocumento1 paginaForm-I-010 Welding Machine Inspection Form: Carry-In CertificateAdhy DarmawanNessuna valutazione finora

- Daily OHSE Report for Byte Bridge Data CentresDocumento1 paginaDaily OHSE Report for Byte Bridge Data CentresNavnath Ambre100% (1)

- Protective Equipment ChecklistDocumento5 pagineProtective Equipment ChecklistBuddy Lynn RadhikaNessuna valutazione finora

- Weekly safety report formDocumento6 pagineWeekly safety report formAnonymous PvknTD76Nessuna valutazione finora

- Safety InspectionDocumento45 pagineSafety InspectionKladees WorldNessuna valutazione finora

- HSE Weekly Statistic Mei 2021Documento8 pagineHSE Weekly Statistic Mei 2021Obie86 BahhierNessuna valutazione finora

- Pre-Use Welding ChecklistDocumento2 paginePre-Use Welding ChecklistNuno LopesNessuna valutazione finora

- Safety Harness and Lanyard Inspection GuideDocumento4 pagineSafety Harness and Lanyard Inspection GuideUlviyye ElesgerovaNessuna valutazione finora

- Railway Engineering 3Documento31 pagineRailway Engineering 3Sheikh UbaidNessuna valutazione finora

- Calculation Report Conveyor Structure T 1022 PDFDocumento29 pagineCalculation Report Conveyor Structure T 1022 PDFAnonymous ahdhFMaNessuna valutazione finora

- Calculation Report Conveyor Structure T 1022 PDFDocumento29 pagineCalculation Report Conveyor Structure T 1022 PDFAnonymous ahdhFMaNessuna valutazione finora

- Stop Work Report for Safety InterventionsDocumento1 paginaStop Work Report for Safety InterventionsRetselisitsoeNessuna valutazione finora

- DD3 Rig Monthly HSE Stats Sept 2013-1Documento21 pagineDD3 Rig Monthly HSE Stats Sept 2013-1Subhan Nur RamadhanNessuna valutazione finora

- Spraying TechniquesDocumento12 pagineSpraying TechniquesX800XLNessuna valutazione finora

- 1 Training For HAMTANTOTOR  RTGs PDFDocumento153 pagine1 Training For HAMTANTOTOR  RTGs PDFAnonymous ahdhFMaNessuna valutazione finora

- (Centrifugal Pump Calculation For DM PW Water To R-401Documento20 pagine(Centrifugal Pump Calculation For DM PW Water To R-401Ashish PawarNessuna valutazione finora

- Stringing, Welding and Coating Process.Documento3 pagineStringing, Welding and Coating Process.Beyar. ShNessuna valutazione finora

- Monthly HSE Performance ReportDocumento9 pagineMonthly HSE Performance ReportHemant HoneyNessuna valutazione finora

- OBGYN Form 3 Answers KeyDocumento2 pagineOBGYN Form 3 Answers KeyGrace0% (1)

- Check List HSEDocumento2 pagineCheck List HSEFernando Carrizales SánchezNessuna valutazione finora

- ASFP Launch Fire Risk PDFDocumento44 pagineASFP Launch Fire Risk PDFamarNessuna valutazione finora

- Hazard Identification 3-2-10Documento1 paginaHazard Identification 3-2-10slamet4riadiNessuna valutazione finora

- NSL Hollow Core Slabs 12jul16 - 2016 Edition PDFDocumento24 pagineNSL Hollow Core Slabs 12jul16 - 2016 Edition PDFjohnkoh9950% (2)

- LOTO ChecklistDocumento3 pagineLOTO ChecklistPutri UnaNessuna valutazione finora

- 2 Ptfi-Hira Forms 1 To 26Documento100 pagine2 Ptfi-Hira Forms 1 To 26Sitole S SiswantoNessuna valutazione finora

- Daily Report HSSE # 10 PDFDocumento4 pagineDaily Report HSSE # 10 PDFbisnisfendiNessuna valutazione finora

- Concrete Design Excel SheetDocumento16 pagineConcrete Design Excel SheetCleth Hiren Santos25% (4)

- Pre-use crane inspection checklistDocumento2 paginePre-use crane inspection checklistBeyar. Sh100% (2)

- Cumene ManufactringDocumento74 pagineCumene ManufactringTan JieSheng100% (1)

- Updated Checklist of TractorDocumento1 paginaUpdated Checklist of TractorparthaNessuna valutazione finora

- SOP - Movement of Light Vehicles in MinesDocumento6 pagineSOP - Movement of Light Vehicles in MinesMUHAMMAD KASHIF Siddiqi100% (1)

- Form Subcontractor Daily HSE Statistics ReportDocumento2 pagineForm Subcontractor Daily HSE Statistics ReportadityaNessuna valutazione finora

- SOP 4 - Coal Bed Leveling in PGPDocumento18 pagineSOP 4 - Coal Bed Leveling in PGPfaraz ahmedNessuna valutazione finora

- Waste Monitoring Flow Chart PicDocumento1 paginaWaste Monitoring Flow Chart PicDilip Kumar KNessuna valutazione finora

- JSA PRE-TEST UploadDocumento2 pagineJSA PRE-TEST UploadDenny Kurniawan PrawiraNessuna valutazione finora

- Personal Hygiene Checklist Month Supervisor in Charge: Prepared By: Approved byDocumento5 paginePersonal Hygiene Checklist Month Supervisor in Charge: Prepared By: Approved byLennon Tan Qin Ji100% (1)

- Akura - Hse Compliance (Tubular Inspection)Documento46 pagineAkura - Hse Compliance (Tubular Inspection)elvandiNessuna valutazione finora

- Toolbox Talk Risk Identification Card AreaDocumento21 pagineToolbox Talk Risk Identification Card AreaDheeraj Menon0% (1)

- HSE Training Matrix PDFDocumento3 pagineHSE Training Matrix PDFNizar KhalidNessuna valutazione finora

- Safe Use of Lifting Machines and Lifting TackleDocumento59 pagineSafe Use of Lifting Machines and Lifting TackleJakesNessuna valutazione finora

- 43 Equipment Erection (Static and Rotary)Documento5 pagine43 Equipment Erection (Static and Rotary)Hamza DhariwalNessuna valutazione finora

- Ensure sufficient natural and artificial lightingDocumento3 pagineEnsure sufficient natural and artificial lightingMohamed MounerNessuna valutazione finora

- Health: Key Performance Indicator Month of JANUARYDocumento1 paginaHealth: Key Performance Indicator Month of JANUARYSaddem Hadfi100% (1)

- Microsoft Word - Emergency-Evac-Drill-ReportDocumento3 pagineMicrosoft Word - Emergency-Evac-Drill-ReportAmal SalimNessuna valutazione finora

- 5 - HSE Statistics - Last 05 YearsDocumento1 pagina5 - HSE Statistics - Last 05 YearsMohammad Mokhtarul HaqueNessuna valutazione finora

- JSA of Charging UnitDocumento3 pagineJSA of Charging UnitMuhammad AliNessuna valutazione finora

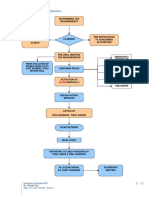

- Flow Chart For Fire Drill Operation:: Emerrgency ControllerDocumento1 paginaFlow Chart For Fire Drill Operation:: Emerrgency ControllerIwan Ms100% (2)

- Ppe Training Record: Department Occupation Type of Ppe Make/Model Name InitialsDocumento3 paginePpe Training Record: Department Occupation Type of Ppe Make/Model Name Initialsvlad100% (1)

- Rimal Global Technical Services LLC.: HSE Management System ProcedureDocumento1 paginaRimal Global Technical Services LLC.: HSE Management System ProcedureSreekumarNessuna valutazione finora

- Luffing Tower Crane Preshift InspectionDocumento1 paginaLuffing Tower Crane Preshift InspectionEdmond KeraNessuna valutazione finora

- Safety Daily Site Checklist Mastoura co-SA-1-12Documento12 pagineSafety Daily Site Checklist Mastoura co-SA-1-12LawrenceNessuna valutazione finora

- A Sample Preventative Maintenance Schedule PDFDocumento2 pagineA Sample Preventative Maintenance Schedule PDFreda100% (1)

- 14 JSA Excavation For Location Existing PipeDocumento5 pagine14 JSA Excavation For Location Existing PipeYosua SitumorangNessuna valutazione finora

- Part Submission WarrantDocumento4 paginePart Submission WarrantSam AnuNessuna valutazione finora

- Jsa Lifitng Gantry FabricationDocumento3 pagineJsa Lifitng Gantry FabricationOsiobe EwomazinoNessuna valutazione finora

- Working Safely With ForkliftsDocumento31 pagineWorking Safely With ForkliftsHari PrasathNessuna valutazione finora

- Proreka (M) Sdn Bhd CCCF and Safety ChartDocumento1 paginaProreka (M) Sdn Bhd CCCF and Safety Chartizi97Nessuna valutazione finora

- PT. NURMAN MITRA SENTOSA HSE REPORTDocumento4 paginePT. NURMAN MITRA SENTOSA HSE REPORTSigit WiyonoNessuna valutazione finora

- Daily maintenance checklist for LS crusherDocumento6 pagineDaily maintenance checklist for LS crusherlaxman JoshiNessuna valutazione finora

- BEAMCOL9 - Beam-Column Design Per AISC 9th Edition ASDDocumento5 pagineBEAMCOL9 - Beam-Column Design Per AISC 9th Edition ASDAnonymous ahdhFMaNessuna valutazione finora

- Technical Spec CablesDocumento1 paginaTechnical Spec CablesAnonymous ahdhFMaNessuna valutazione finora

- Powercore Dust Collectors: CPC & CPV SeriesDocumento16 paginePowercore Dust Collectors: CPC & CPV SeriesAnonymous ahdhFMaNessuna valutazione finora

- 7. General Arrangement DWG-GSU0901.00卸船机总图Documento1 pagina7. General Arrangement DWG-GSU0901.00卸船机总图Anonymous ahdhFMaNessuna valutazione finora

- Book Full PDFDocumento361 pagineBook Full PDFAnonymous ahdhFMaNessuna valutazione finora

- CRD-1 Conveyor Design ReportDocumento36 pagineCRD-1 Conveyor Design ReportSasmit RaiNessuna valutazione finora

- CRD-1 Conveyor Design ReportDocumento36 pagineCRD-1 Conveyor Design ReportSasmit RaiNessuna valutazione finora

- Basf Masteremaco s5400 TdsDocumento2 pagineBasf Masteremaco s5400 TdsAnonymous ahdhFMaNessuna valutazione finora

- Design Criteria 1 PDFDocumento17 pagineDesign Criteria 1 PDFAnonymous ahdhFMaNessuna valutazione finora

- Phase II Quality ManualDocumento148 paginePhase II Quality ManualAnonymous ahdhFMaNessuna valutazione finora

- Design Criteria 1 PDFDocumento17 pagineDesign Criteria 1 PDFAnonymous ahdhFMaNessuna valutazione finora

- Zp14-2252 Hambantota 2 RTG Mechanical DrawingDocumento22 pagineZp14-2252 Hambantota 2 RTG Mechanical DrawingAnonymous ahdhFMaNessuna valutazione finora

- Material Stainless Steel SS 316: Design Project DrawingsDocumento1 paginaMaterial Stainless Steel SS 316: Design Project DrawingsAnonymous ahdhFMaNessuna valutazione finora

- Hempadur Avantguard 750 1736g - Product DatasheetDocumento2 pagineHempadur Avantguard 750 1736g - Product DatasheetWisnu Wardhana0% (1)

- Report For Hydro-Test For Boiler No.3Documento2 pagineReport For Hydro-Test For Boiler No.3Anonymous ahdhFMaNessuna valutazione finora

- Technical Documents: Puttalam 1X300Mw Coal-Fired Power Plant ProjectDocumento8 pagineTechnical Documents: Puttalam 1X300Mw Coal-Fired Power Plant ProjectAnonymous ahdhFMaNessuna valutazione finora

- Nivena Sitha-Http-Dahamvila-Blogspot-ComDocumento146 pagineNivena Sitha-Http-Dahamvila-Blogspot-ComDaham Vila BlogspotNessuna valutazione finora

- Anhui Vocational and Technical College of Mining: Graduation Project (Thesis)Documento27 pagineAnhui Vocational and Technical College of Mining: Graduation Project (Thesis)Anonymous ahdhFMaNessuna valutazione finora

- 102Documento5 pagine102Anonymous ahdhFMaNessuna valutazione finora

- Technical Documents: Puttalam 1X300Mw Coal-Fired Power Plant ProjectDocumento49 pagineTechnical Documents: Puttalam 1X300Mw Coal-Fired Power Plant ProjectAnonymous ahdhFMaNessuna valutazione finora

- Technical Documents: Puttalam 1X300Mw Coal-Fired Power Plant ProjectDocumento20 pagineTechnical Documents: Puttalam 1X300Mw Coal-Fired Power Plant ProjectAnonymous ahdhFMaNessuna valutazione finora

- 3 Ps A Js:sfha FFP RSL Fhfok JsoshDocumento12 pagine3 Ps A Js:sfha FFP RSL Fhfok Jsoshsonaliforex1Nessuna valutazione finora

- Unmadini - Daham Vila - Http://dahamvila - Blogspot.comDocumento103 pagineUnmadini - Daham Vila - Http://dahamvila - Blogspot.comDaham Vila BlogspotNessuna valutazione finora

- Budusasaune Hita Alawa.Documento107 pagineBudusasaune Hita Alawa.njk19Nessuna valutazione finora

- Microfinance in SomaliaDocumento11 pagineMicrofinance in Somaliaabdulfatah.diriNessuna valutazione finora

- Single Point Earthing and Equipotential Planes for Sensitive Electronic EquipmentDocumento30 pagineSingle Point Earthing and Equipotential Planes for Sensitive Electronic EquipmentDeepak GuptaNessuna valutazione finora

- Bharat Heavy Electricals LimitedDocumento19 pagineBharat Heavy Electricals LimitedChandreshDharDubeyNessuna valutazione finora

- Question-7 MA CompreviewDocumento18 pagineQuestion-7 MA CompreviewBrigham JervosoNessuna valutazione finora

- Report on internship at JDS TransformersDocumento50 pagineReport on internship at JDS TransformersSachinNessuna valutazione finora

- Unit 4 Out WorldDocumento45 pagineUnit 4 Out WorldKhánh Nguyễn100% (2)

- LC Passive Wireless Sensors Toward A Wireless Sensing Platform: Status, Prospects, and ChallengesDocumento20 pagineLC Passive Wireless Sensors Toward A Wireless Sensing Platform: Status, Prospects, and ChallengesCristian David Merchan VegaNessuna valutazione finora

- Silo Surface Area CalculationDocumento3 pagineSilo Surface Area CalculationVIC EngineersNessuna valutazione finora

- Sample/Pre-Board Paper 14 Class X Term 1 Exam Nov - Dec 2021 English Language and Literature (Code 184)Documento5 pagineSample/Pre-Board Paper 14 Class X Term 1 Exam Nov - Dec 2021 English Language and Literature (Code 184)parmila raniNessuna valutazione finora

- Your First ProgramDocumento7 pagineYour First ProgramJosephat MugumbaNessuna valutazione finora

- Shortcuts and Quick Tips To Solve CAT MBA Quantitative Questions CAT, Entrance Exams, MBA - iHelpStudyDocumento21 pagineShortcuts and Quick Tips To Solve CAT MBA Quantitative Questions CAT, Entrance Exams, MBA - iHelpStudySofi DinendranNessuna valutazione finora

- Brother Printer GT-782Documento126 pagineBrother Printer GT-782vitprint22Nessuna valutazione finora

- The Redpoll: Costa Rica and Panama: Land of Birds and CoffeeDocumento6 pagineThe Redpoll: Costa Rica and Panama: Land of Birds and CoffeeArctic Audubon SocietyNessuna valutazione finora

- Complete Blood Count (CBC) Normal Laboratory Study Values: DefinitionDocumento6 pagineComplete Blood Count (CBC) Normal Laboratory Study Values: DefinitionGlare RhayneNessuna valutazione finora

- Protein Significance Analysis Tools for Proteomics ExperimentsDocumento47 pagineProtein Significance Analysis Tools for Proteomics ExperimentsGisele WiezelNessuna valutazione finora

- Chevrolet 2005 Uplander Electrical Wiring DiagramDocumento62 pagineChevrolet 2005 Uplander Electrical Wiring Diagramromain.richertNessuna valutazione finora

- BackIntelligence Herniated Disc ExercisesDocumento9 pagineBackIntelligence Herniated Disc Exercisesswaminathan1Nessuna valutazione finora

- Solah (Prayer in Islam)Documento22 pagineSolah (Prayer in Islam)Anif Ilham IsmailNessuna valutazione finora

- 2 13 Ionisation EnergiesDocumento6 pagine2 13 Ionisation EnergiesRobertLiu100% (2)

- DMAE Powder Safety Data SheetDocumento3 pagineDMAE Powder Safety Data SheetAInhoaNessuna valutazione finora

- Cash Valve Product OverviewDocumento16 pagineCash Valve Product OverviewestebanNessuna valutazione finora