Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Assignment. Engr Essay

Caricato da

GopalDhakalCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Assignment. Engr Essay

Caricato da

GopalDhakalCopyright:

Formati disponibili

Comparative Study of R.C.

C and Steel Concrete Composite Structures

Mg.Gopal (VBEC-6) , Mg. Wai Yan Htun (VBEC-7)

ABSTRACT

Steel concrete composite construction has gained wide acceptance world wide as an alternative

to pure steel and pure concrete construction. The use of steel in construction industry is very low

in Myanmar compared to many developing countries. There is a great potential for increasing the

volume of steel in construction, especially in the current development needs and not using steel

as an alternative construction material and not using it where it is economical is a heavy loss for

the country. In this paper, some statistics from an engineering research article about the analysis

of four various multistoried commercial buildings, are brought.

Keywords- Composite beam, Composite column, Composite slab, R.C.C Structure.

1.INTRODUCTION

The word composite general in construction industry refers to steel-concrete composite

structure. The most important and most frequently encountered combination of construction

materials is that of steel and concrete, it has applications in multi-storey commercial buildings

and factories, as well as in bridges. These materials can be used in mixed structural systems, for

example concrete cores encircled by steel tubes, as well as in composite structures. Designing

composite systems of structural steel and reinforced concrete produces more efficient structures

when compared to designs using either material alone.

2. COMPOSITE MULTISTORIED BUILDINGS

2.1. COMPOSITE DECK SLAB

Composite floor system consists of steel beams, metal decking and concrete. They are

combined in a very efficient way so that the best properties of each material can be used to

optimize construction techniques. The most common arrangement found in composite floor

systems is a rolled or built-up steel beam connected to a formed steel deck and concrete slab.

2.2. COMPOSITE BEAM

In conventional composite construction, concrete slabs rest over steel beams and are

supported by them. Under load these two components act independently and a relative slip

occurs at the interface if there is no connection between them. With the help of a deliberate and

appropriate connection provided between them can be eliminated. In this case the steel beam and

the slab act as a “composite beam” and their action is similar to that of a monolithic Tee beam.

Shweta A. Wagh et al Int. Journal of Engineering Research and Applications

ISSN: 2248-9622, Vol.4, Issue 4(Version1), April 2014, pp.369-376

2.3. COMPOSITE COLUMN

A steel concrete composite column is a compression member, comprising either of a

concrete encased hot rolled steel section or a concrete filled hollow section of hot rolled steel. It

is generally used as a load bearing member in a composite framed structure. Composite members

are mainly subjected to compression and bending.

3. BOND OR ANCHORAGE TYPE

It is used to resist horizontal shear and to prevent separation of girder from the concrete

slab at the interface through bond. These connectors derived from the resistance through bond

and anchorage action.

4. COMPARATIVE ANALYSIS

This comparative study was done by Shweta A. Wagh and Dr. U.P. Waghe. They have

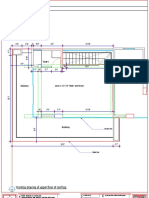

considered a commercial building. The plan dimension was 63.2mx29.5m. The study was carried

out on the same building plan for both R.C.C and Composite construction using STAAD.Pro.

The basic loading on both types of structures were kept same. The study had provided the

following comparison bar charts.

Fig.1: Comparison of deflection of a particular column

Fig.2: Comparison of SF of a particular column in X-direction

Fig.3: Comparison of BM of a particular column in Z-direction

Fig.4: Cost Comparison Bar Chart

4.Disccussion

From the analysis and comparison between the two structure types, the following conclusion can

be drawn out-

1. In case of a composite structural system because of the lesser magnitude of the beam end

forces and moments compared to an R.C.C system, one can use lighter section in a

composite structure.

2. Because of the lesser downward reaction in composite structure, one can use smaller size

of foundation.

3. Under earthquake consideration because of inherent ductility characteristics, steel-

concrete composite structure perform better than a R.C.C structure.

4. The cost comparison reveals that steel-concrete composite design structure is more

economical in case of high rise buildings and construction is speedy.

REFERENCES

1. Johnson R. P., Composite Structures of Steel and Concrete, Volume 1, Blackwell

Scientific Publications, UK, 2004.

2. Fisher J. w. Design of composite beams with formed metal deck. Eng. J,, amer, lnst ,Steel

Constr,7.88-96,July 1970.

3. Euro code 4, ―Design of composite steel and concrete structure, European committee

for standardization committee European de normalization europaisches committee fur

normung.

4. IS: 456(2000), ― Indian Standard Code of Practice for Plan and Reinforcement

Potrebbero piacerti anche

- Composite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)Da EverandComposite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)Valutazione: 4 su 5 stelle4/5 (10)

- RCC 1 PDFDocumento8 pagineRCC 1 PDFNgọc TuyênNessuna valutazione finora

- COMPOSITE MATERIALS SYLLABUSDocumento200 pagineCOMPOSITE MATERIALS SYLLABUSTaimoor NasserNessuna valutazione finora

- An Analytical and Comparitive Study of Composite and RCC Multi Storey BuildingsDocumento15 pagineAn Analytical and Comparitive Study of Composite and RCC Multi Storey BuildingsRakkeshKudullaNessuna valutazione finora

- Study of Seismic and Wind Effect On Multi Storey R.C.C. Steel and Composite BuildingDocumento6 pagineStudy of Seismic and Wind Effect On Multi Storey R.C.C. Steel and Composite BuildingAkshay DobleNessuna valutazione finora

- Seismic Analysis of RCC and Composite StructuresDocumento9 pagineSeismic Analysis of RCC and Composite Structuresvishnumani3011Nessuna valutazione finora

- RCC vs steel-composite building analysis cost comparisonDocumento5 pagineRCC vs steel-composite building analysis cost comparisondarsu NaikNessuna valutazione finora

- Jounal Composite 4Documento11 pagineJounal Composite 4barath kumarNessuna valutazione finora

- Composite Construction History ReviewDocumento22 pagineComposite Construction History Reviewsantosh bharathyNessuna valutazione finora

- IJRPR16287Documento6 pagineIJRPR16287B45Raj Kumar ThakurNessuna valutazione finora

- Analysis and Design of Multi-Storeyed Building by Steel Concrete Composite StructureDocumento9 pagineAnalysis and Design of Multi-Storeyed Building by Steel Concrete Composite StructureUsha EngineeringNessuna valutazione finora

- COMPARATIVE STUDY OF RCC STEEL AND COMPOSITE STRUCTURES FOR INDUSTRIAL BUILDING Ijariie10646Documento11 pagineCOMPARATIVE STUDY OF RCC STEEL AND COMPOSITE STRUCTURES FOR INDUSTRIAL BUILDING Ijariie10646NikhilARNessuna valutazione finora

- Comparative Study On Multi-Storey Structure of R.C.C and Composite MaterialDocumento5 pagineComparative Study On Multi-Storey Structure of R.C.C and Composite MaterialBasavarajBachihalNessuna valutazione finora

- Kamal - 2015 - Encased Beam With Variable Upper SteelDocumento8 pagineKamal - 2015 - Encased Beam With Variable Upper SteelRene Rodrigues O. SilvaNessuna valutazione finora

- Composite Cold-Formed Steel-Concrete Structural System Composite Cold-Formed Steel-Concrete Structural SystemDocumento27 pagineComposite Cold-Formed Steel-Concrete Structural System Composite Cold-Formed Steel-Concrete Structural SystemVladimirNessuna valutazione finora

- Comparative Study On Dynamic Analysis of Composite, RCC & Steel StructureDocumento8 pagineComparative Study On Dynamic Analysis of Composite, RCC & Steel StructureRajalakshmi JothivelNessuna valutazione finora

- Comparative Analysis of RCC and Steel-Concrete Composite Multistoried BuildingDocumento7 pagineComparative Analysis of RCC and Steel-Concrete Composite Multistoried BuildingAbhishek GuptaNessuna valutazione finora

- Comparing RCC, Steel and Composite Structures for 30-Storey BuildingDocumento6 pagineComparing RCC, Steel and Composite Structures for 30-Storey Buildingnvc_vishwanathanNessuna valutazione finora

- Analysis and Design of Multi-Storeyed Bu PDFDocumento8 pagineAnalysis and Design of Multi-Storeyed Bu PDFengyana engyyyNessuna valutazione finora

- Innovation in Composite ConstructionDocumento6 pagineInnovation in Composite ConstructionnicholasNessuna valutazione finora

- Objective/Scope: Arranged by Erkan SAMHÂL From SSEDTA (European Steel Computer Aided Learning), April 2005Documento12 pagineObjective/Scope: Arranged by Erkan SAMHÂL From SSEDTA (European Steel Computer Aided Learning), April 2005CIVIL ENGG. SVESNessuna valutazione finora

- Chapter Five Composite Structures (Concrete and Steel)Documento15 pagineChapter Five Composite Structures (Concrete and Steel)Assefa Nigussie100% (1)

- 7 El-Ghazouli, DowlingDocumento23 pagine7 El-Ghazouli, DowlingYap Wen KhongNessuna valutazione finora

- Advantages CFSTDocumento14 pagineAdvantages CFSTprajjwal patidarNessuna valutazione finora

- Steel-Concrete Composite Bridge DesignDocumento24 pagineSteel-Concrete Composite Bridge DesignSulabh BiswasNessuna valutazione finora

- Research On RC/SRC Column Systems: Gregory G Deierlein and Hiroshi NOGUCHIDocumento7 pagineResearch On RC/SRC Column Systems: Gregory G Deierlein and Hiroshi NOGUCHIKrishna MurariNessuna valutazione finora

- Comparison of Aisc 360 - 16 and Ec4 For The Prediction of Composite Column Capacity (#612280) - 795121Documento20 pagineComparison of Aisc 360 - 16 and Ec4 For The Prediction of Composite Column Capacity (#612280) - 795121mohamed alyozbakiNessuna valutazione finora

- 2.4 related literatureDocumento2 pagine2.4 related literatureqdalquiambaoNessuna valutazione finora

- Research On Application of Steel and Concrete Mixed Structure in High-Rise BuildingsDocumento7 pagineResearch On Application of Steel and Concrete Mixed Structure in High-Rise Buildingsrui yangruixiNessuna valutazione finora

- A Review On Concrete Filled Steel Tubes Column: December 2015Documento7 pagineA Review On Concrete Filled Steel Tubes Column: December 2015Dony DoanxNessuna valutazione finora

- Researchpaper Design Model of Built Up Stiffened Column Base Under Large Eccentric LoadDocumento10 pagineResearchpaper Design Model of Built Up Stiffened Column Base Under Large Eccentric LoadNishant GaurNessuna valutazione finora

- Hou 2016Documento12 pagineHou 2016Evonne LeeNessuna valutazione finora

- SCS Protective StructureDocumento18 pagineSCS Protective Structure안진호 / 학생 / 건설환경공학부Nessuna valutazione finora

- Experimental and Analytical Study On Fatigue Behavior of Composite Truss JointsDocumento17 pagineExperimental and Analytical Study On Fatigue Behavior of Composite Truss JointsOanh PhanNessuna valutazione finora

- Introduction To Composite ConstructionDocumento40 pagineIntroduction To Composite Constructionrameshbabu_1979100% (1)

- International Journal of EngineeringDocumento10 pagineInternational Journal of Engineeringparth daxiniNessuna valutazione finora

- Composite Steel-Concrete Construction For New Zealand: P. Chunhaviriyakul, G.A. MacraeDocumento30 pagineComposite Steel-Concrete Construction For New Zealand: P. Chunhaviriyakul, G.A. MacraeCIVIL ENGG. SVESNessuna valutazione finora

- Review On Performance Analysis of Steel Concrete Composite SectionDocumento3 pagineReview On Performance Analysis of Steel Concrete Composite SectionKaran SadhwaniNessuna valutazione finora

- A Review On Concrete Filled Steel Tubes Column: December 2015Documento7 pagineA Review On Concrete Filled Steel Tubes Column: December 2015Sushant WaghmareNessuna valutazione finora

- Steel Conc. Comp. ContDocumento35 pagineSteel Conc. Comp. ContDeepak SinghNessuna valutazione finora

- Composite Steel-Concrete Construction Review for New Zealand BuildingsDocumento30 pagineComposite Steel-Concrete Construction Review for New Zealand BuildingsBasil Baby-PisharathuNessuna valutazione finora

- Composite Construction MethoddDocumento13 pagineComposite Construction MethoddEditha BaniquedNessuna valutazione finora

- Experimental and Numerical Investigation On Full-Scale Tension-Only CBF Steel Beam Through FramesDocumento18 pagineExperimental and Numerical Investigation On Full-Scale Tension-Only CBF Steel Beam Through FramesponjoveNessuna valutazione finora

- Journal Article - Comparison RCC - CompositeDocumento6 pagineJournal Article - Comparison RCC - CompositeSri KayNessuna valutazione finora

- Numerical Analysis of Composite Steel Concrete Structural Shear Walls With Steel Encased ProfilesDocumento12 pagineNumerical Analysis of Composite Steel Concrete Structural Shear Walls With Steel Encased ProfilesAnonymous mcHqIfbnV1Nessuna valutazione finora

- Vayas2018 PDFDocumento42 pagineVayas2018 PDFDaniel JaraNessuna valutazione finora

- Concrete Filled Steel Tubular (CFST) Columns in Composite StructuresDocumento8 pagineConcrete Filled Steel Tubular (CFST) Columns in Composite Structuresashish SindhuNessuna valutazione finora

- Seismic Behavior of Steel-Concrete Composite Structures: December 2019Documento7 pagineSeismic Behavior of Steel-Concrete Composite Structures: December 2019Usha EngineeringNessuna valutazione finora

- Numerical Study of R.C. Beams Strengthening by External Steel PlateDocumento9 pagineNumerical Study of R.C. Beams Strengthening by External Steel PlateAJER JOURNALNessuna valutazione finora

- Experimental Study On Behaviour of Composite Column CFTDocumento7 pagineExperimental Study On Behaviour of Composite Column CFTnilkanthNessuna valutazione finora

- Journal of The South African Institution of Civil EngineeringDocumento15 pagineJournal of The South African Institution of Civil Engineeringkranthi142434Nessuna valutazione finora

- Limit State Response of Composite Columns and Beam-Columns Part I, Roberto Leon PDFDocumento18 pagineLimit State Response of Composite Columns and Beam-Columns Part I, Roberto Leon PDFHeriberto Bórquez UrquidyNessuna valutazione finora

- CH 1 - 5Documento70 pagineCH 1 - 5Abdul BariNessuna valutazione finora

- Design of Composite Slabs With Profiled Steel Deck PDFDocumento16 pagineDesign of Composite Slabs With Profiled Steel Deck PDFPanha MenhNessuna valutazione finora

- Composite Structure PDFDocumento73 pagineComposite Structure PDFsvn100% (1)

- Innovative hybrid coupled shear walls for seismic steel buildingsDocumento10 pagineInnovative hybrid coupled shear walls for seismic steel buildingsAkhil Nath P SNessuna valutazione finora

- Tall 758Documento21 pagineTall 758Mongkol JirawacharadetNessuna valutazione finora

- Composite Structures: Dr. Hesham Fawzy Shaabn Professor, Zagazig UniversityDocumento18 pagineComposite Structures: Dr. Hesham Fawzy Shaabn Professor, Zagazig UniversityMahmoud A SalamaNessuna valutazione finora

- 23 - Optimized Modeling and Design of Steel Frames in Different Seismic Zones Using Etabs SoftwareDocumento9 pagine23 - Optimized Modeling and Design of Steel Frames in Different Seismic Zones Using Etabs SoftwareSandy KavitakeNessuna valutazione finora

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesDa EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesNessuna valutazione finora

- Septic TANK DesignDocumento4 pagineSeptic TANK Designadnan88% (8)

- Assignment. Engr EssayDocumento4 pagineAssignment. Engr EssayGopalDhakalNessuna valutazione finora

- Assignment. Engr EssayDocumento4 pagineAssignment. Engr EssayGopalDhakalNessuna valutazione finora

- PresentationDocumento24 paginePresentationGopalDhakalNessuna valutazione finora

- Septic TanksDocumento1 paginaSeptic TanksGopalDhakalNessuna valutazione finora

- PresentationDocumento1 paginaPresentationGopalDhakalNessuna valutazione finora

- PresentationDocumento1 paginaPresentationGopalDhakalNessuna valutazione finora

- CE-632 Foundation Analysis and Design: Shallow FoundationsDocumento33 pagineCE-632 Foundation Analysis and Design: Shallow FoundationsMadhu SulaniyaNessuna valutazione finora

- Geo Polymer ConcreteDocumento17 pagineGeo Polymer ConcreteAshutosh RungtaNessuna valutazione finora

- Strength of Materials - Task 1. Chapter 4-IiDocumento4 pagineStrength of Materials - Task 1. Chapter 4-IiMilton CobaNessuna valutazione finora

- Henscha Phils. Inc.: Concrete Pouring ChecklistDocumento4 pagineHenscha Phils. Inc.: Concrete Pouring Checklistchester carpioNessuna valutazione finora

- Flier - Refresher Course On Prestressed Concrete DesignDocumento3 pagineFlier - Refresher Course On Prestressed Concrete DesignMano HarNessuna valutazione finora

- RZTQJSJ - 2 Static Force ProcedureDocumento12 pagineRZTQJSJ - 2 Static Force Procedurebsce.delossantos.rizza.mNessuna valutazione finora

- Modular Pipe Support SystemsDocumento49 pagineModular Pipe Support Systemsdepinfor lusofabrilNessuna valutazione finora

- Aci Manual of Concrete InspectionDocumento218 pagineAci Manual of Concrete InspectionRyan Lasaca100% (1)

- Carbonation resistance of industrial mortar coatingDocumento5 pagineCarbonation resistance of industrial mortar coatingViníciusNessuna valutazione finora

- Manpower Leveling and Pert CPM (Crashed) PDFDocumento2 pagineManpower Leveling and Pert CPM (Crashed) PDFJonathan Marvin Bacares DueNessuna valutazione finora

- Slab layout of penthouse roofDocumento2 pagineSlab layout of penthouse roofAbrarNessuna valutazione finora

- Drobac Stimac-Grandic - GNP2020Documento8 pagineDrobac Stimac-Grandic - GNP2020jug.drobacNessuna valutazione finora

- Coefficient of FrictionDocumento1 paginaCoefficient of FrictionLiladhar Ganesh DhobleNessuna valutazione finora

- Deep Basements & Cut & Cover - 2Documento113 pagineDeep Basements & Cut & Cover - 2bsitler100% (2)

- Rebar Steel Bar Detail For Grade 1Documento29 pagineRebar Steel Bar Detail For Grade 1talatzahoorNessuna valutazione finora

- A Comparative Study of Seismic Behavior of Structural Framing SystemsDocumento8 pagineA Comparative Study of Seismic Behavior of Structural Framing SystemsJashwin UllalNessuna valutazione finora

- Chapter Two 2.balconies, Loggias, Canopy and Terraces: Dire Dawa Poly Technical College Satellite ProgramDocumento12 pagineChapter Two 2.balconies, Loggias, Canopy and Terraces: Dire Dawa Poly Technical College Satellite ProgramTemesgen YohannesNessuna valutazione finora

- SubstructureDocumento35 pagineSubstructureMeghna AshokNessuna valutazione finora

- Estimate PDFDocumento3 pagineEstimate PDFAnu PathakNessuna valutazione finora

- Slump TestDocumento6 pagineSlump TestAngel MouriNessuna valutazione finora

- Sika Viscocrete 1003 Pds enDocumento2 pagineSika Viscocrete 1003 Pds enSambelteri SelorejoNessuna valutazione finora

- Flexural Strength of Concrete Beam Specimen: Laboratory Experiment NoDocumento7 pagineFlexural Strength of Concrete Beam Specimen: Laboratory Experiment NokeishasantiagoNessuna valutazione finora

- Cast-In-Place Concrete SpecificationsDocumento15 pagineCast-In-Place Concrete SpecificationsMark Roger II HuberitNessuna valutazione finora

- BLDG-section Chua 02Documento1 paginaBLDG-section Chua 02leslieNessuna valutazione finora

- Bid Addendum Report: 105 Road Division BiratnagarDocumento8 pagineBid Addendum Report: 105 Road Division Biratnagarnitish JhaNessuna valutazione finora

- Bending MomentDocumento4 pagineBending MomentNicholas TedjasukmanaNessuna valutazione finora

- Design For Structural Steel Work For Frame Industrial BuildingDocumento100 pagineDesign For Structural Steel Work For Frame Industrial BuildingNguywn DuongNessuna valutazione finora

- Amvic ICF Installation ManualDocumento136 pagineAmvic ICF Installation ManualdanNessuna valutazione finora

- Alufix Slab Formwork Tim PDFDocumento18 pagineAlufix Slab Formwork Tim PDFMae FalcunitinNessuna valutazione finora