Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fluid Machinery Course

Caricato da

Sudeesh SudevanTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Fluid Machinery Course

Caricato da

Sudeesh SudevanCopyright:

Formati disponibili

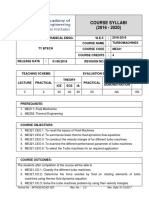

Course No.

Course Name L-T-P-Credits Year of Introduction

ME206 FLUID MACHINERY 2-1-0-3 2016

Prerequisite: ME203 Mechanics of Fluids

Course Objectives:

1. To acquire knowledge on hydraulic machines such as pumps and turbines

2. To understand the working of air compressors and do the analysis

Syllabus

Impact of jets, Hydraulic Turbines, Rotary motion of liquids, Rotodynamic pumps, Positive

displacement pumps, , Compressors

Expected outcome: At the end of the course the students will be able to

1. Discuss the characteristics of centrifugal pump and reciprocating pumps

2. Calculate forces and work done by a jet on fixed or moving plate and curved plates

3. Know the working of turbines and select the type of turbine for an application.

4. Do the analysis of air compressors and select the suitable one for a specific application

Text Books:

1. Som, Introduction to Fluid Mechanics and Fluid Machines ,McGraw Hill Education India 2011

www.ktustudents.in

2. Bansal R. K., A Textbook of Fluid Mechanics and Hydraulic Machines, Laxmi

Publications,2005.

Reference Books:

1. Cengel Y. A. and J. M. Cimbala, Fluid Mechanics, Tata McGraw Hill, 2013

2. Yahya S. M, Fans, Blower and Compressor, Tata McGraw Hill, 2005.

3. Shepherd D. G, Principles of Turbo Machinery, Macmillan, 1969.

4. Stepanoff A. J, Centrifugal and Axial Flow Pumps, John Wiley & Sons, 1991.

5. Rajput R. K, Fluid Mechanics and Hydraulic Machines, S. Chand & Co.,2006.

6. Subramanya, Fluid mechanics and hydraulic machines, 1e McGraw Hill Education

India,2010

To get more study materials click here> www.ktustudents.in

Course Plan

Sem.

Module Contents Hours Exam

Marks

Impact of jets: Introduction to hydrodynamic thrust of jet on a fixed and

moving surface (flat and curve),– Series of vanes - work done and

efficiency

Hydraulic Turbines : Impulse and Reaction Turbines – Degree of

I reaction – Pelton Wheel – Constructional features - Velocity triangles 7 15%

– Euler’s equation – Speed ratio, jet ratio and work done , losses and

efficiencies, design of Pelton wheel – Inward and outward flow

reaction turbines- Francis Turbine – Constructional features – Velocity

triangles, work done and efficiencies.

Axial flow turbine (Kaplan) Constructional features – Velocity

triangles- work done and efficiencies – Characteristic curves of

II turbines – theory of draft tubes – surge tanks – Cavitation in turbines –

Governing of turbines – Specific speed of turbine , Type Number– 7 15%

Characteristic curves, scale Laws – Unit speed – Unit discharge and

unit power.

www.ktustudents.in FIRST INTERNAL EXAM

Rotary motion of liquids – free, forced and spiral vortex flows

Rotodynamic pumps- centrifugal pump impeller types,-velocity

triangles-manometric head- work, efficiency and losses, H-Q

characteristic, typical flow system characteristics, operating point of a 7

III pump. Cavitation in centrifugal pumps- NPSH required and available- 15%

Type number-Pumps in series and parallel operations. Performance

characteristics- Specific speed-Shape numbers – Impeller shapes based

on shape numbers.

Positive displacement pumps- reciprocating pump – Single acting and

double acting- slip, negative slip and work required and efficiency-

indicator diagram- acceleration head - effect of acceleration and

friction on indicator diagram – speed calculation- Air vessels and their 7

IV purposes, saving in work done to air vessels multi cylinder pumps. 15%

Multistage pumps-selection of pumps-pumping devices-hydraulic ram,

Accumulator, Intensifier, Jet pumps, gear pumps, vane pump and lobe

pump.

SECOND INTERNAL EXAM

Compressors: classification of compressors, reciprocating

compressor-single stage compressor, equation for work with and 7

V 20%

without clearance volume, efficiencies, multistage compressor,

intercooler, free air delivered (FAD)

Centrifugal compressor-working, velocity diagram, work done, power

required, width of blades of impeller and diffuser, isentropic

efficiency, slip factor and pressure coefficient, surging and chocking. 7

VI Axial flow compressors:- working, velocity diagram, degree of 20%

reaction, performance. Roots blower, vane compressor, screw

compressor.

To get more study materials click here> www.ktustudents.in

END SEMESTER EXAM

Question Paper Pattern

Total marks: 100, Time: 3 hrs

The question paper should consist of three parts

Part A

4 questions uniformly covering modules I and II. Each question carries 10 marks

Students will have to answer any three questions out of 4 (3X10 marks =30 marks)

Part B

4 questions uniformly covering modules III and IV. Each question carries 10 marks

Students will have to answer any three questions out of 4 (3X10 marks =30 marks)

Part C

6 questions uniformly covering modules V and VI. Each question carries 10 marks

Students will have to answer any four questions out of 6 (4X10 marks =40 marks)

Note: In all parts, each question can have a maximum of four sub questions, if needed.

www.ktustudents.in

To get more study materials click here> www.ktustudents.in

Potrebbero piacerti anche

- ME 206 Fluid Machinery PDFDocumento3 pagineME 206 Fluid Machinery PDFnandan144Nessuna valutazione finora

- ME 206 Fluid MachineryDocumento3 pagineME 206 Fluid MachineryMohammed Asif NNessuna valutazione finora

- Wa0094Documento3 pagineWa0094VIGNESH RAJNessuna valutazione finora

- Hydraulic Machines and SystemsDocumento2 pagineHydraulic Machines and SystemsKARTHIK RAJASHEKARNessuna valutazione finora

- 18 Me 3-1Documento20 pagine18 Me 3-1Ashok KumarNessuna valutazione finora

- Ee010 306 (Me) Mechanical TechnologyDocumento2 pagineEe010 306 (Me) Mechanical TechnologyBrandon AllenNessuna valutazione finora

- New Scheme Based On AICTE Flexible CurriculaDocumento13 pagineNew Scheme Based On AICTE Flexible Curricularohit choudharyNessuna valutazione finora

- NalsDocumento148 pagineNalsKartik BhararaNessuna valutazione finora

- Fluid Mechanics and MachineryDocumento1 paginaFluid Mechanics and Machineryபாலரத்தினம் தமிழன்Nessuna valutazione finora

- Hydraulics and Hydraulic Machinery CourseDocumento3 pagineHydraulics and Hydraulic Machinery CoursealejodanyNessuna valutazione finora

- Chhattisgarh Swami Vivekanand TechnicalDocumento8 pagineChhattisgarh Swami Vivekanand TechnicalLakshminarayana ChNessuna valutazione finora

- Fluid Power EngineeringDocumento2 pagineFluid Power EngineeringBhavesh PipaliyaNessuna valutazione finora

- TE - Turbomachinery - IA 2 Syllabus and Question BankDocumento2 pagineTE - Turbomachinery - IA 2 Syllabus and Question Banktodankarpratham15Nessuna valutazione finora

- Course Plan - Turbo MachineryDocumento4 pagineCourse Plan - Turbo MachineryAMIT PRAJAPATINessuna valutazione finora

- GTU Fluid Power Engineering SyllabusDocumento3 pagineGTU Fluid Power Engineering SyllabusKrupal VithlaniNessuna valutazione finora

- Mech V Turbo Machines (10me56) NotesDocumento79 pagineMech V Turbo Machines (10me56) NotesPraveen D Jadhav100% (4)

- Thermal Turbo MachineryDocumento2 pagineThermal Turbo MachinerymechmuruganNessuna valutazione finora

- Turbomachine SyllabusDocumento6 pagineTurbomachine Syllabussuhas_SCEMNessuna valutazione finora

- AE6404 PROPUSION-I BackupDocumento18 pagineAE6404 PROPUSION-I Backupkdastro009Nessuna valutazione finora

- ME200-Fluid Mechanics and MachineryDocumento3 pagineME200-Fluid Mechanics and Machinerynandan144Nessuna valutazione finora

- FTM SyllabusDocumento3 pagineFTM SyllabusQwer QwerNessuna valutazione finora

- Turbo Machines Lesson PlanDocumento3 pagineTurbo Machines Lesson PlanHemanth KumarNessuna valutazione finora

- Ce6451 Fluid Mechanics and Machinery L T P C 3 0 0 3: ObjectivesDocumento3 pagineCe6451 Fluid Mechanics and Machinery L T P C 3 0 0 3: Objectiveskumar kmNessuna valutazione finora

- EE205 DC Machines N TransformersDocumento2 pagineEE205 DC Machines N TransformersAshik AhmedNessuna valutazione finora

- JNTU Thermal Engineering Course OverviewDocumento2 pagineJNTU Thermal Engineering Course OverviewT Hari PrasadNessuna valutazione finora

- EE205 DC Machines N TransformersDocumento2 pagineEE205 DC Machines N TransformersGautam S BNessuna valutazione finora

- ELEMENTS OF MECHANICAL ENGINEERING AND HYDRAULICSDocumento5 pagineELEMENTS OF MECHANICAL ENGINEERING AND HYDRAULICSnavitgmNessuna valutazione finora

- Final Revised ME342 TurbomachinesDocumento4 pagineFinal Revised ME342 TurbomachinesNikhil SatbhaiNessuna valutazione finora

- Applied Hydraulics and Fluid MachineryDocumento2 pagineApplied Hydraulics and Fluid MachinerySathishkumar PalanippanNessuna valutazione finora

- ATD SyllabusDocumento3 pagineATD Syllabusprashanth prabhuNessuna valutazione finora

- Thermal Engineering Course OverviewDocumento3 pagineThermal Engineering Course OverviewneerubandaNessuna valutazione finora

- Syllabus-MDU-ME 5 Sem FDocumento13 pagineSyllabus-MDU-ME 5 Sem Fraul2speedNessuna valutazione finora

- For Questions, Notes, Syllabus & Results: Ae8404 Propulsion - IDocumento1 paginaFor Questions, Notes, Syllabus & Results: Ae8404 Propulsion - ISanjay KumarNessuna valutazione finora

- Piston Engine Course NotesDocumento157 paginePiston Engine Course NotesKelton WadeNessuna valutazione finora

- Turbo Machinery SyllabusDocumento1 paginaTurbo Machinery SyllabusjaihogoluNessuna valutazione finora

- 18F46-DOMI of Rotating Equipment Level 1Documento3 pagine18F46-DOMI of Rotating Equipment Level 1ehabwardaNessuna valutazione finora

- S4 Mechanical SyllabusDocumento8 pagineS4 Mechanical SyllabusJinu MadhavanNessuna valutazione finora

- Turbo Machines NotesDocumento79 pagineTurbo Machines NoteschawarepNessuna valutazione finora

- 7th Semester Mechanical Engineering Syllabus (MG University)Documento13 pagine7th Semester Mechanical Engineering Syllabus (MG University)Amit CherianNessuna valutazione finora

- FLUID MECHANICS - II: Dimensional Analysis & Hydraulic MachinesDocumento3 pagineFLUID MECHANICS - II: Dimensional Analysis & Hydraulic MachinesPalaka RahulNessuna valutazione finora

- Fourth 1 PDFDocumento23 pagineFourth 1 PDFMathews P RejiNessuna valutazione finora

- Me-301 F Dynamics of MachinesDocumento12 pagineMe-301 F Dynamics of MachinesRaj KumarNessuna valutazione finora

- Fluid Mechanics and Machinery Course HandoutDocumento3 pagineFluid Mechanics and Machinery Course HandoutMohanraj SubramaniNessuna valutazione finora

- ME321 Turbomachines 2020Documento4 pagineME321 Turbomachines 2020Ashish DaundkarNessuna valutazione finora

- Fluid Mechanics and MachineryDocumento1 paginaFluid Mechanics and MachinerygocoolonNessuna valutazione finora

- ME200-Fluid Mechanics and MachineryDocumento3 pagineME200-Fluid Mechanics and MachineryvishnuNessuna valutazione finora

- Fluid Machinery & Fluid PowerDocumento3 pagineFluid Machinery & Fluid Poweras2faasbujsacNessuna valutazione finora

- AU401 Automotive System DesignDocumento2 pagineAU401 Automotive System DesignAJIN ELIAS ALEXNessuna valutazione finora

- Gujarat Technological University: Mechanical Engineering (19) SUBJECT CODE: 2151902Documento54 pagineGujarat Technological University: Mechanical Engineering (19) SUBJECT CODE: 2151902Rameshbhai DabhiNessuna valutazione finora

- Fluid Mechanics and Hydraulic Machines CourseDocumento3 pagineFluid Mechanics and Hydraulic Machines CourseAbdul Rauf Noohani100% (1)

- MGM SyllabusDocumento4 pagineMGM SyllabusKshirsagar Sandeep Popat me16d040Nessuna valutazione finora

- Lab Manual Hydraulics and Pneumatics .Documento56 pagineLab Manual Hydraulics and Pneumatics .Aniket ChavanNessuna valutazione finora

- Sucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingDa EverandSucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingValutazione: 5 su 5 stelle5/5 (9)

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.Da EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.Nessuna valutazione finora

- Tribological Processes in the Valve Train Systems with Lightweight Valves: New Research and ModellingDa EverandTribological Processes in the Valve Train Systems with Lightweight Valves: New Research and ModellingValutazione: 1.5 su 5 stelle1.5/5 (2)

- Major Process Equipment Maintenance and RepairDa EverandMajor Process Equipment Maintenance and RepairValutazione: 4 su 5 stelle4/5 (4)

- Turbine Thermal Appraisal: A Spreadsheet ApproachDa EverandTurbine Thermal Appraisal: A Spreadsheet ApproachNessuna valutazione finora

- Module 2 Ethics Morals and ValuesDocumento44 pagineModule 2 Ethics Morals and ValuesSudeesh SudevanNessuna valutazione finora

- Grinding MachinesDocumento34 pagineGrinding MachinesSudeesh SudevanNessuna valutazione finora

- 1.mechanics of MachineryDocumento12 pagine1.mechanics of Machineryram jrpsNessuna valutazione finora

- Reciprocating PumpDocumento43 pagineReciprocating PumpSudeesh SudevanNessuna valutazione finora

- Syllabus MET203Documento12 pagineSyllabus MET203Sudeesh SudevanNessuna valutazione finora

- Stress Diary Scenario Worked Example and Blank TemplateDocumento6 pagineStress Diary Scenario Worked Example and Blank TemplateKavithaNessuna valutazione finora

- Stress Diary Scenario Worked Example and Blank TemplateDocumento6 pagineStress Diary Scenario Worked Example and Blank TemplateKavithaNessuna valutazione finora

- Francis TurbineDocumento34 pagineFrancis TurbinevishalNessuna valutazione finora

- Fifth Semester Mechanical Engineering Internal Test I - September 2018 Ee 311 - Electrical Drives and Control For AutomationDocumento1 paginaFifth Semester Mechanical Engineering Internal Test I - September 2018 Ee 311 - Electrical Drives and Control For AutomationSudeesh SudevanNessuna valutazione finora

- ME404 - Industrial Engineering: Module-IIIDocumento16 pagineME404 - Industrial Engineering: Module-IIISudeesh SudevanNessuna valutazione finora

- Sequencing and Scheduling - An Overview: Chapter-IiDocumento14 pagineSequencing and Scheduling - An Overview: Chapter-IiSudeesh SudevanNessuna valutazione finora

- 08 802 Industrial Engineering 2008 Scheme April 2014Documento2 pagine08 802 Industrial Engineering 2008 Scheme April 2014Sudeesh SudevanNessuna valutazione finora

- Apj Abdul Kalam Technological University Thiruvananthapuram, Kerala, INDIADocumento15 pagineApj Abdul Kalam Technological University Thiruvananthapuram, Kerala, INDIASudeesh SudevanNessuna valutazione finora

- 3.3 - 1.1 - Supply Chain ManagementDocumento1 pagina3.3 - 1.1 - Supply Chain ManagementSudeesh SudevanNessuna valutazione finora

- Lecture1428641930 PDFDocumento136 pagineLecture1428641930 PDFKrish PavanNessuna valutazione finora

- University of Kerala: Syllabus For Iv Semester Mechanical EngineeringDocumento20 pagineUniversity of Kerala: Syllabus For Iv Semester Mechanical EngineeringRahul RetnakaranNessuna valutazione finora

- Operations Management Question Bank - Module 1Documento1 paginaOperations Management Question Bank - Module 1Sudeesh SudevanNessuna valutazione finora

- Quality CircleDocumento33 pagineQuality CircleSudeesh SudevanNessuna valutazione finora

- Matlab - Practice ProblemsDocumento5 pagineMatlab - Practice ProblemsSudeesh SudevanNessuna valutazione finora

- ME09 804 1st SeriesDocumento1 paginaME09 804 1st SeriesSudeesh SudevanNessuna valutazione finora

- Problem FormulationDocumento5 pagineProblem FormulationSudeesh SudevanNessuna valutazione finora

- Power Transmission: Components Used To Transmit Power: Gears, Belt, Clutch and BrakesDocumento17 paginePower Transmission: Components Used To Transmit Power: Gears, Belt, Clutch and Brakesrip111176Nessuna valutazione finora

- ME Fluid-Mechanics PDFDocumento48 pagineME Fluid-Mechanics PDFSudeesh SudevanNessuna valutazione finora

- Answer To Assignment 1 Questions: 1. (C) 2. (B) 3. (D) 4. (B) 5. (D) 6. (B) 7. (C)Documento2 pagineAnswer To Assignment 1 Questions: 1. (C) 2. (B) 3. (D) 4. (B) 5. (D) 6. (B) 7. (C)Sudeesh SudevanNessuna valutazione finora

- ME201 Mechanics of Solids Course SyllabusDocumento3 pagineME201 Mechanics of Solids Course SyllabusSudeesh SudevanNessuna valutazione finora

- Quality Question PaperDocumento1 paginaQuality Question PaperSudeesh SudevanNessuna valutazione finora

- ICSGT 2015 Submission 103 EditDocumento1 paginaICSGT 2015 Submission 103 EditSudeesh SudevanNessuna valutazione finora

- 6 Best IBPS Reasoning Preparation Tips To Follow This YearDocumento7 pagine6 Best IBPS Reasoning Preparation Tips To Follow This YearSudeesh SudevanNessuna valutazione finora

- Prestressed Concrete Structures 500 OqaDocumento90 paginePrestressed Concrete Structures 500 OqasanthiamuthaNessuna valutazione finora

- API 610 Centrifugal Pump Data SheetDocumento2 pagineAPI 610 Centrifugal Pump Data SheetjojagucaNessuna valutazione finora

- C6 Fluid Friction Measurement (Issue 2) PDFDocumento4 pagineC6 Fluid Friction Measurement (Issue 2) PDFdjafarNessuna valutazione finora

- Aga 3 - 2000 RevisionDocumento57 pagineAga 3 - 2000 RevisionAnonymous XV4AlTzUNessuna valutazione finora

- Design of SpringsDocumento80 pagineDesign of SpringsRohan SinghNessuna valutazione finora

- Simple Equilibrium Distillation Lab ReportDocumento6 pagineSimple Equilibrium Distillation Lab ReportFarahSyazwaniNessuna valutazione finora

- Natural Gas Physical PropertiesDocumento20 pagineNatural Gas Physical PropertiesMarco Antonio Pomahuali BravoNessuna valutazione finora

- Introduction SlidesDocumento23 pagineIntroduction SlidesMathiselvan GopalNessuna valutazione finora

- Hargreaves 2007Documento15 pagineHargreaves 2007Sam GonçalvesNessuna valutazione finora

- Seepage and StabilityDocumento6 pagineSeepage and StabilityChengHian Yap100% (2)

- Issues Using Welded Built-Up Box Columns Steel Moment FramesDocumento13 pagineIssues Using Welded Built-Up Box Columns Steel Moment Framesclam2014Nessuna valutazione finora

- 3-1. Hydraulic SystemDocumento35 pagine3-1. Hydraulic SystemSumitomo ExcavatorNessuna valutazione finora

- ConsolidationDocumento6 pagineConsolidationKanchana Randall100% (1)

- 5 - Unsteady Flow in Rivers Pp. 122-157Documento37 pagine5 - Unsteady Flow in Rivers Pp. 122-157Anonymous 87xpkIJ6CFNessuna valutazione finora

- Magnetic Induction and Electric Potential Solvers For Incompressible MD FlowsDocumento32 pagineMagnetic Induction and Electric Potential Solvers For Incompressible MD FlowsaryamesaNessuna valutazione finora

- Chapter 3 - Example 3Documento6 pagineChapter 3 - Example 3NIBEDITA DEYNessuna valutazione finora

- Appendix H PDFDocumento59 pagineAppendix H PDFarif_rubinNessuna valutazione finora

- Inside The Demon BoxDocumento64 pagineInside The Demon BoxWarren WhitneyNessuna valutazione finora

- DOME-2 Notes QPapers PDFDocumento305 pagineDOME-2 Notes QPapers PDFSumit KumarNessuna valutazione finora

- Three Dimensional Stress SolvedDocumento10 pagineThree Dimensional Stress SolvedSiva PrasadNessuna valutazione finora

- FMM Ques Bank With AnsDocumento3 pagineFMM Ques Bank With AnsAmal MechanicNessuna valutazione finora

- Ntroduction: Types of PressureDocumento17 pagineNtroduction: Types of PressureSophia VarshiniNessuna valutazione finora

- Spe 176089 MS PDFDocumento11 pagineSpe 176089 MS PDFatilio martinezNessuna valutazione finora

- 2.5 Piping Thermal Expansion and FlexibilityDocumento27 pagine2.5 Piping Thermal Expansion and FlexibilityJohn TinnerNessuna valutazione finora

- Vortex GeneratorsDocumento12 pagineVortex GeneratorsSatyajeet NayakNessuna valutazione finora

- Depressuring Study and Application On BP-A ProjectDocumento35 pagineDepressuring Study and Application On BP-A ProjectTruong Minh Hoang100% (6)

- Thermal Engineering-CondenserDocumento17 pagineThermal Engineering-CondenserJayNessuna valutazione finora

- Training Course Pipeliq Library: Raúl Avezuela RodríguezDocumento41 pagineTraining Course Pipeliq Library: Raúl Avezuela RodríguezrentboyrodriguezNessuna valutazione finora

- Physics Chapt 19Documento84 paginePhysics Chapt 19catlinmwagner0% (1)