Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Procedure Qualification Record

Caricato da

Dan ClarkeDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Procedure Qualification Record

Caricato da

Dan ClarkeCopyright:

Formati disponibili

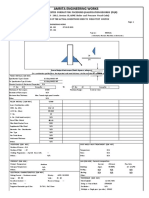

QW-483 SUGGESTED FORMAT FOR PROCEDURE QUALIFICATION RECORDS (PQR)

(See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code)

Record of the Actual Conditions Used to Weld Test Coupon

Company Name

Procedure Qualification Record No. Date

WPS No.

Welding Process (es)

Types (Manual, Automatic, Semi-auto)

JOINTS (QW-402)

Groove Design of Test Coupon (sketch, figure or reference)

(For combination qualifications, the deposited weld metal thickness shall be recorded for each filler metal and process used.)

BASE METALS (QW-403) POST WELD HEAT TREATMENT (QW-407)

Material Specification Temperature

Type or Grade or UNS Number Time

P No. Group No. to P No. Group No. Other

Thickness of Test Coupon

Diameter of Test Coupon

Maximum Pass Thickness

Other GAS (QW-408)

Percent Composition

FILLER METALS (QW-404) Gas (es) (Mixture) Flow Rate

Layer (combination welds) 1 2 3 Shielding

SFA Specification Trailing

AWS Classification Backing

Filler Metal F No. Other

Weld Metal Analysis A No.

Size of Filler Metal

Filer Metal Product Form ELECTRICAL CHARACTERISTICS (QW-409)

Supplemental Filler Metal Current

Electrode Flux Classification Polarity

Flux Type Amps Volts

Flux Trade Name Tungsten Electrode Size

Weld Metal Thickness Transfer Mode for GMAW (FCAW)

Other Other

POSITION (QW-405)

Position of Groove

Weld Progression (Uphill, Downhill) TECHNIQUE (QW-410)

Other Travel Speed

String or Weave Bead

Oscillation

PREHEAT (QW-406) Multipass or Singles Pass (per side)

Preheat Temperature Single or Multiple Electrodes

Interpass Temperature Other

Other

QW-483 (Back)

PQR No.

Tensile Test (QW-150)

Type of

Specimen Ultimate Ultimate

Width Thickness Area Failure &

No. Total Load Unit Stress

Location

Guided Bend Tests (QW-160)

Type and Figure No. Result

Toughness Tests (QW-170)

Specimen Notch Specimen Test

Impact Values Drop Weight Break

Number Location Size Temperature

Ft-lb or J % Shear Mils (in.) or mm (Yes/No)

Comments

Fillet Weld Test (QW-180)

Result- Satisfactory: Yes No Penetration into Parent Metal: Yes No

Macro - Results

Other Tests

Type of Test

Deposit Analysis

Other

Welders Name Clock No. Stamp No.

Tests Conducted by Laboratory Test Number

We certify that statements made in this record are correct and that the test welds were prepared, welded, and tested in accordance with the

Requirements of Section IX of the ASME Boiler and Pressure Vessel Code

Manufacturer or Contractor

Date Certified By

Potrebbero piacerti anche

- QW 483Documento2 pagineQW 483delta lab sangliNessuna valutazione finora

- WPQ Format - SMAWDocumento3 pagineWPQ Format - SMAWBalkishan DyavanapellyNessuna valutazione finora

- Amrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Documento3 pagineAmrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Balkishan DyavanapellyNessuna valutazione finora

- WPS PQR As Per IsDocumento3 pagineWPS PQR As Per Istarun kaushalNessuna valutazione finora

- PQR Asme Template EDITABLEDocumento6 paginePQR Asme Template EDITABLErcpretoriusNessuna valutazione finora

- Welding Procedure Specification (WPS) Yes PREQUALIFIED - QUALIFIED BY TESTING - or Procedure Qualification Records (PQR) YesDocumento1 paginaWelding Procedure Specification (WPS) Yes PREQUALIFIED - QUALIFIED BY TESTING - or Procedure Qualification Records (PQR) YesmashkhalilbabaNessuna valutazione finora

- QW-482 201.1Documento2 pagineQW-482 201.1Barwin CruzNessuna valutazione finora

- ASME 9 - CalculatorDocumento2 pagineASME 9 - CalculatorEmel Besir100% (1)

- Wps 7018 SmawDocumento1 paginaWps 7018 SmawErick VazquezNessuna valutazione finora

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Documento8 pagineQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad HannanNessuna valutazione finora

- WPQ-1083 3G PDFDocumento2 pagineWPQ-1083 3G PDFduendex360100% (1)

- WPS Updated PDFDocumento2 pagineWPS Updated PDFRaja Muaz Ahmad KhanNessuna valutazione finora

- WPQR2Documento3 pagineWPQR2Thanasis KyrgiazoglouNessuna valutazione finora

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocumento1 paginaD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1Nessuna valutazione finora

- WPS SampleDocumento6 pagineWPS SampleAshishNessuna valutazione finora

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocumento3 pagineWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNessuna valutazione finora

- 170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQDocumento4 pagine170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQMuhammad Fitransyah Syamsuar PutraNessuna valutazione finora

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Documento1 paginaQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Nessuna valutazione finora

- PQR & WPQ Standard Testing Parameter WorksheetDocumento4 paginePQR & WPQ Standard Testing Parameter WorksheetcosmicbunnyNessuna valutazione finora

- PQR Sample PrintoutDocumento2 paginePQR Sample PrintoutDhewo Rachmad Yansyah100% (3)

- Welding Procedure Specification For GTAWDocumento9 pagineWelding Procedure Specification For GTAWraja reyhanNessuna valutazione finora

- Procedure Qualification Record (PQR) FormDocumento1 paginaProcedure Qualification Record (PQR) FormEarl HarbertNessuna valutazione finora

- EFR-190719-PQR-01 - Shell Vertical-Horizontal PDFDocumento11 pagineEFR-190719-PQR-01 - Shell Vertical-Horizontal PDFIonut FloricaNessuna valutazione finora

- Wps For Steel RodsDocumento5 pagineWps For Steel RodsHamid MansouriNessuna valutazione finora

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocumento5 pagineQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.Nessuna valutazione finora

- Format WPQDocumento2 pagineFormat WPQAkash Singh TomarNessuna valutazione finora

- Poposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015Documento12 paginePoposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015MulPXNessuna valutazione finora

- PQR 01 PDFDocumento2 paginePQR 01 PDFVijay BhaleraoNessuna valutazione finora

- PQR Template (Asme)Documento2 paginePQR Template (Asme)jok1974Nessuna valutazione finora

- SMAW DuniDocumento4 pagineSMAW DuniMuhammad Fitransyah Syamsuar PutraNessuna valutazione finora

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTDocumento5 pagineHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTVKT TiwariNessuna valutazione finora

- WPQT SawDocumento2 pagineWPQT Sawkiran144Nessuna valutazione finora

- 004 Gtaw P5aDocumento16 pagine004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- WPQ Template (Asme Ix) No LogoDocumento4 pagineWPQ Template (Asme Ix) No LogorcpretoriusNessuna valutazione finora

- WPS API1104 A516 GR 70Documento1 paginaWPS API1104 A516 GR 70Erick HoganNessuna valutazione finora

- GTL WPSDocumento6 pagineGTL WPSYoucef ChorfaNessuna valutazione finora

- Juta Bumi Kapital Sdn. BHD: Doc. No. Revision NoDocumento2 pagineJuta Bumi Kapital Sdn. BHD: Doc. No. Revision NoSong Kiet ChooNessuna valutazione finora

- WOPQ Form English1Documento2 pagineWOPQ Form English1oaperuchenaNessuna valutazione finora

- Gtaw Smaw 6 Inch 6G CSDocumento1 paginaGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- Aws d1.5 PQRDocumento2 pagineAws d1.5 PQRjacquesmayolNessuna valutazione finora

- WPS - 023Documento10 pagineWPS - 023MAT-LION0% (1)

- Welding Report For Tank 1Documento1 paginaWelding Report For Tank 1Rifki HasyaNessuna valutazione finora

- WPS RegisterDocumento2 pagineWPS RegisterdaveswinburneNessuna valutazione finora

- Wps GT 9b Cvn90 Rev 1 PDFDocumento6 pagineWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNessuna valutazione finora

- Butt JointsDocumento21 pagineButt JointsRaj1-23Nessuna valutazione finora

- Joints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateDocumento3 pagineJoints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateAmjad PathanNessuna valutazione finora

- WPS 316 L PDFDocumento4 pagineWPS 316 L PDFIrinaNessuna valutazione finora

- WPS Format For ASME IX - PQR-AllDocumento3 pagineWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocumento2 pagineASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNessuna valutazione finora

- WPS Format For Asme Ix - Wps - Gtaw - OverlayDocumento1 paginaWPS Format For Asme Ix - Wps - Gtaw - OverlayThe Welding Inspections Community100% (1)

- GMAWDocumento12 pagineGMAWsushant47Nessuna valutazione finora

- ASME Section IX Welding Procedure Qualification: Antonius P. BramonoDocumento50 pagineASME Section IX Welding Procedure Qualification: Antonius P. BramonoHAKANNessuna valutazione finora

- WPS 2014-002 006 - 6G PipeDocumento3 pagineWPS 2014-002 006 - 6G PipejeswinNessuna valutazione finora

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Documento1 paginaQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)ventas ventasNessuna valutazione finora

- QW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Documento1 paginaQW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Deepanshu KhatriNessuna valutazione finora

- QW-484A (WPQ) GTAW 4MM FilletDocumento2 pagineQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- WPQ PDFDocumento0 pagineWPQ PDFstanleyNessuna valutazione finora

- SC PTSS PQRDocumento3 pagineSC PTSS PQRprayogaNessuna valutazione finora

- Suggested Format PQRDocumento2 pagineSuggested Format PQRAngel RebolloNessuna valutazione finora

- Fillet Inspection SheetDocumento2 pagineFillet Inspection SheetShankey JAlanNessuna valutazione finora

- Canadian Red AleDocumento1 paginaCanadian Red AleDan ClarkeNessuna valutazione finora

- Instruction Sheets Shimano Quick Fix Baitcasting ReelsDocumento2 pagineInstruction Sheets Shimano Quick Fix Baitcasting ReelsDan ClarkeNessuna valutazione finora

- 113 EDDY CURRENT INSPECTION OF TWISTED TUBE HEAT EXCHANGERS AND FIELD TEST RESULTS - TimothyRushDocumento25 pagine113 EDDY CURRENT INSPECTION OF TWISTED TUBE HEAT EXCHANGERS AND FIELD TEST RESULTS - TimothyRushDan ClarkeNessuna valutazione finora

- Insp CalculationDocumento20 pagineInsp CalculationAbu Huraira100% (2)

- Pipe Schedule ImperialDocumento1 paginaPipe Schedule ImperialDan ClarkeNessuna valutazione finora

- Butter ChickenDocumento1 paginaButter ChickenDan ClarkeNessuna valutazione finora

- S-Mart Gasket TypesDocumento8 pagineS-Mart Gasket TypesdjvhNessuna valutazione finora

- 64 Save Time and Cost For Turnarounds Using Phased Array Technology - Terry WebbDocumento21 pagine64 Save Time and Cost For Turnarounds Using Phased Array Technology - Terry WebbDan ClarkeNessuna valutazione finora

- Blueberry Cream AleDocumento1 paginaBlueberry Cream AleDan ClarkeNessuna valutazione finora

- Greyloc InstructionsDocumento16 pagineGreyloc InstructionsDan ClarkeNessuna valutazione finora

- 43 Risk Assessment of Onshore Tanks - Christopher PerezDocumento15 pagine43 Risk Assessment of Onshore Tanks - Christopher PerezDan ClarkeNessuna valutazione finora

- All-Weather Morris Chair PlansDocumento7 pagineAll-Weather Morris Chair PlansrelbuhmNessuna valutazione finora

- 24 Synergy For Success The Unit Inspector and The Turnaround Organization - Dana BahamDocumento12 pagine24 Synergy For Success The Unit Inspector and The Turnaround Organization - Dana BahamDan ClarkeNessuna valutazione finora

- Instruction Sheets Shimano Quick Fix Baitcasting ReelsDocumento2 pagineInstruction Sheets Shimano Quick Fix Baitcasting ReelsDan ClarkeNessuna valutazione finora

- Reclining Lounge ChairDocumento5 pagineReclining Lounge ChairDan ClarkeNessuna valutazione finora

- ASTM A194 NutsDocumento13 pagineASTM A194 NutsDan ClarkeNessuna valutazione finora

- DA Tank OperationDocumento48 pagineDA Tank OperationDan ClarkeNessuna valutazione finora

- Coating FailuresDocumento17 pagineCoating FailuresDan ClarkeNessuna valutazione finora

- Homelite Chain Saw Repair Manual Covers 42 Different ModelsDocumento2 pagineHomelite Chain Saw Repair Manual Covers 42 Different ModelsDan ClarkeNessuna valutazione finora

- Homelite Condenser TesterDocumento3 pagineHomelite Condenser TesterDan ClarkeNessuna valutazione finora

- Product Name: Product Code:: Page 1 of 10Documento10 pagineProduct Name: Product Code:: Page 1 of 10Dan ClarkeNessuna valutazione finora

- Basic CabinetmakingDocumento40 pagineBasic Cabinetmakingmartym100% (1)

- 5928cabin PDFDocumento4 pagine5928cabin PDFDan ClarkeNessuna valutazione finora

- Tecumseh Service Repair Manual VH80 VH100 HH80 HH100 HH120 Oh120 Oh140 Oh160 Oh180 8HP Thru 18HP Cast Iron Engines 691462a PDFDocumento78 pagineTecumseh Service Repair Manual VH80 VH100 HH80 HH100 HH120 Oh120 Oh140 Oh160 Oh180 8HP Thru 18HP Cast Iron Engines 691462a PDFDan Clarke75% (4)

- Greyloc InstructionsDocumento16 pagineGreyloc InstructionsDan ClarkeNessuna valutazione finora

- Pipe Schedule ImperialDocumento1 paginaPipe Schedule ImperialDan ClarkeNessuna valutazione finora

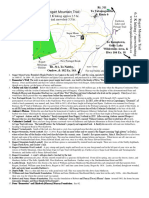

- Rogart Mountain Map and Legend One PagerDocumento1 paginaRogart Mountain Map and Legend One PagerDan ClarkeNessuna valutazione finora

- Y-1 Yoke Kit ManualDocumento14 pagineY-1 Yoke Kit ManualDan ClarkeNessuna valutazione finora

- 570 Sample Questions Rev 061815Documento2 pagine570 Sample Questions Rev 061815Amal KaNessuna valutazione finora

- 06 Tackling Competency - Nick MarxDocumento32 pagine06 Tackling Competency - Nick MarxDan ClarkeNessuna valutazione finora

- CHAPTER 17-Antenna FundamentalsDocumento31 pagineCHAPTER 17-Antenna FundamentalsDanielle TioNessuna valutazione finora

- EXPT. 1 Common Laboratory OperationsDocumento8 pagineEXPT. 1 Common Laboratory Operationsjazzmin dulceNessuna valutazione finora

- Astm D5797Documento2 pagineAstm D5797Jose RacancojNessuna valutazione finora

- APPSC Municipal AE SyllabusDocumento4 pagineAPPSC Municipal AE SyllabusPrasanna KumarNessuna valutazione finora

- IOTDocumento6 pagineIOTKaze KazeNessuna valutazione finora

- Nuclear Physics Interview Questions and Answers 830 PDFDocumento7 pagineNuclear Physics Interview Questions and Answers 830 PDFpeterjo raveloNessuna valutazione finora

- NBC Protection SystemDocumento39 pagineNBC Protection Systembiruk1Nessuna valutazione finora

- SMA FLX InstallationGuide-XXDocumento248 pagineSMA FLX InstallationGuide-XXAnonymous smdEgZN2IeNessuna valutazione finora

- Transfer Station PDFDocumento2 pagineTransfer Station PDFgernNessuna valutazione finora

- ACE - 66kV GIS 03.09.2022Documento236 pagineACE - 66kV GIS 03.09.2022Chandan KumarNessuna valutazione finora

- IB Physics Topic 2Documento18 pagineIB Physics Topic 2wee100% (1)

- Chapter 4 Psychomentry, Humidification and DehumidificationDocumento14 pagineChapter 4 Psychomentry, Humidification and DehumidificationNurshaqina SufianNessuna valutazione finora

- A Working Guide To Shell-and-Tube Heat ExchangersDocumento642 pagineA Working Guide To Shell-and-Tube Heat ExchangersSiva baalan80% (5)

- CE F311 Design of Concrete Structures: BITS PilaniDocumento50 pagineCE F311 Design of Concrete Structures: BITS Pilanijs kalyana ramaNessuna valutazione finora

- Chapter 9 Electronic (Student)Documento30 pagineChapter 9 Electronic (Student)林柄洲Nessuna valutazione finora

- 8 The Application of Deep Sea Water PDFDocumento7 pagine8 The Application of Deep Sea Water PDFGraci AngelNessuna valutazione finora

- 4.0 User Manual For TBS Sensors v6Documento18 pagine4.0 User Manual For TBS Sensors v6Alexandre MandettaNessuna valutazione finora

- 3 Ortloff NGL LPG and Sulfur Recovery TechnologiesDocumento47 pagine3 Ortloff NGL LPG and Sulfur Recovery TechnologiesYanto Hasudungan LumbantobingNessuna valutazione finora

- 2800 Series: 2806C-E16TAG2Documento2 pagine2800 Series: 2806C-E16TAG2Tony LiNessuna valutazione finora

- Guide To Submersible Well Pump Selection: 1. Well Capacity 6. 2-WIRE VS. 3-WIREDocumento1 paginaGuide To Submersible Well Pump Selection: 1. Well Capacity 6. 2-WIRE VS. 3-WIREBassel El Sayed AliNessuna valutazione finora

- 005 - Fuel Design Requirements - Al ManzerDocumento26 pagine005 - Fuel Design Requirements - Al ManzerGeorge CălinNessuna valutazione finora

- Kirlosker Pump Selection Models PDFDocumento36 pagineKirlosker Pump Selection Models PDFgarimaNessuna valutazione finora

- I B.tech II Semester (MR15 Regulations) II Mid Examination - ECAS (EEE)Documento13 pagineI B.tech II Semester (MR15 Regulations) II Mid Examination - ECAS (EEE)arunkumarmurugesan88Nessuna valutazione finora

- Katalogas enDocumento20 pagineKatalogas enEman AdelNessuna valutazione finora

- Maintenance Guide: SINO Series Electrolyte AnalyzerDocumento18 pagineMaintenance Guide: SINO Series Electrolyte AnalyzerRoniiNessuna valutazione finora

- Cobar 1540 Ross Garling Hydraulic MiningDocumento26 pagineCobar 1540 Ross Garling Hydraulic MiningAbyzhar AlpasyahNessuna valutazione finora

- Crude Oil As Say ManualDocumento42 pagineCrude Oil As Say Manualsakthi service EngrNessuna valutazione finora

- Operating Instructions and Owner'S Manual Mr. Heater HeatstarDocumento8 pagineOperating Instructions and Owner'S Manual Mr. Heater HeatstarcjmNessuna valutazione finora

- Transformer Cooling MethodsDocumento4 pagineTransformer Cooling MethodsZappa VaiNessuna valutazione finora

- 1.7 Financial ManagementDocumento26 pagine1.7 Financial ManagementEngr Mohammed UsmaniaNessuna valutazione finora