Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

22a-RSJ Runway Beam Check-Simply Supported-Hand Operated

Caricato da

Parthiban ArivazhaganTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

22a-RSJ Runway Beam Check-Simply Supported-Hand Operated

Caricato da

Parthiban ArivazhaganCopyright:

Formati disponibili

xc

g Proj: Admin

Ref :

Tel:d Date: 14/08/17

--------------------------------------------------------------------------------------------------------------------------------------------------------------------

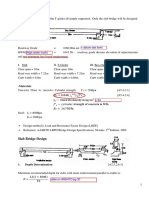

RSJ section runway beam check

Calculations in accordance with BS2853:1957. Note that stresses quoted are in N/mm2 with Imperial values shown in

brackets in tonf/in2

Length = 2500 mm

Beam support type - simply supported

Section size - 127x76x16.50 J

Steel grade - S275

Trolley details - type - hand operated

- number of wheels -2

- wheel centres - 300 mm

- wheel set-in - "0.5b"

Applied Safe Working Load (SWL) = 2 tonnes

(NOTE: This includes lifted load, lifting appliance weight, effort on handchains and other superimposed loads)

NOTE: Both section depth and width less than that suggested in the Table in Appendix A.

Design forces

The beam is simply supported. The design shear force is based on the trolley wheels at the support. The design bending

moment is based on the trolley wheels at midspan.

V =(SWL*9.81)+(wt/100*(L/1000)/2)

=(2*9.81)+(16.5/100*(2500/1000)/2)

=19.8 kN

M =(SWL*9.81*(L/1000)/4)+(wt/100*(L/1000)2/8)

=(2*9.81*(2500/1000)/4)+(16.5/100*(2500/1000)2/8)

=12.4 kNm

Applied stresses

The applied stresses are calculated including the additional factor identifed in clause 4a. For a hand operated trolley the loads

are increased by 10%.

Applied shear stress f = (V*103*1.1)/(D*t)

v

= (19.8*103*1.1)/(127*5.6)

= 30.6 N/mm2

( 1.98 tonf/in2 )

Longitudinal bending stress f = (M*106*1.1)/Z

1 xx

= (12.4*106*1.1)/89900

= 151.7 N/mm2

( 9.82 tonf/in2 )

The transverse bending stress is calculated in accordance with Appendix G. The constants C, K are obtained from Tables 3

1

and 4 respectively and the effective load W from the Safe Working Load. They have the following values; C = 1 , K = 1.4 and

1

W = 19.62 kN.

f = 1.4*C*W*103*1.1/(K *T2)

2 1

= 1.4*1*19.62*103*1.1/(1.4*(9.6)2)

= 234.2 N/mm2

( 15.16 tonf/in2 )

Allowable stresses

The beam is simply supported and the effective length = 2500 mm. Using S275 steel, the allowable shear stress is 100.4

N/mm2 ( 6.5 tonf/in2 ). The allowable longitudinal bending stress in tension is 162.2 N/mm 2 ( 10.5 tonf/in2 ) and the allowable

longitudinal bending stress in compression, with L/r = 147.1 and D/T = 13.2 , is 142.6 N/mm2 ( 9.23 tonf/in2 ).

yy

NOTE: Applied longitdudinal bending stress exceeds allowable compressive stress

NOTE: Combination of longitdudinal and transverse bending stress outside limits of Figure 6.

Deflection

The total deflection is calculated with the trolley in the centre of the span. The deflection due to the beam self weight is

= (5*(wt/100)*L4)/(384*205000*I )

b xx

= (5*(16.5/100)*(2500)4)/(384*205000*5710000)

= 0.1 mm

and due to the trolley is

= ((SWL*9.81*103)*L3)/(48*205000*I )

t xx

= ((2*9.81*103)*(2500)3)/(48*205000*5710000)

= 5.5 mm

and the total deflection is = +

tot b t

= 0.1+5.5

= 5.6 mm

NOTE: Actual deflection exceeds allowable deflection of L/500 ( 5 mm).

Section FAILS overall

Potrebbero piacerti anche

- Mitsubishi forklift manual pdf downloadDocumento3 pagineMitsubishi forklift manual pdf downloadDwi Putra33% (12)

- Design of Cantilever BeamDocumento23 pagineDesign of Cantilever Beamjs kalyana rama83% (12)

- Access Scaffolding CalculationDocumento8 pagineAccess Scaffolding CalculationOsama Tahir100% (3)

- Slab Design To BS 8110Documento11 pagineSlab Design To BS 8110Samuel Antobam100% (2)

- Design Gantry Girder Industrial Building CraneDocumento28 pagineDesign Gantry Girder Industrial Building Cranes_bharathkumar75% (12)

- Design of Grating For PlatformDocumento5 pagineDesign of Grating For PlatformKho C AhlNessuna valutazione finora

- Chequered-Plate CALCULATIONDocumento19 pagineChequered-Plate CALCULATIONRamuAlagappan100% (2)

- UC section runway beam design calculationsDocumento2 pagineUC section runway beam design calculationsParthiban ArivazhaganNessuna valutazione finora

- Stair CaseDocumento12 pagineStair Casevenkatesh19701Nessuna valutazione finora

- Design of A Slab Bridge On Abeya River A PDFDocumento13 pagineDesign of A Slab Bridge On Abeya River A PDFAbera Mamo Jaleta100% (1)

- M019 主機安裝圖HOLDING DOWN BOLTS OF MAIN ENGINE AND LINER ARRANGEMENTDocumento6 pagineM019 主機安裝圖HOLDING DOWN BOLTS OF MAIN ENGINE AND LINER ARRANGEMENTabu680530Nessuna valutazione finora

- SteelDocumento9 pagineSteelMohammedAlasaadNessuna valutazione finora

- Flexural Member DesignDocumento21 pagineFlexural Member Designbaraka100% (1)

- 10 - Structural Design of HCU - Example 2Documento11 pagine10 - Structural Design of HCU - Example 2Philip Lionel PeterNessuna valutazione finora

- Report 30 TonDocumento10 pagineReport 30 TonMARYANessuna valutazione finora

- Report 30 TonDocumento10 pagineReport 30 TonMARYANessuna valutazione finora

- Design of plate girder with corrugated webDocumento6 pagineDesign of plate girder with corrugated webSharad SaterneNessuna valutazione finora

- Beam Design CalculationsDocumento4 pagineBeam Design CalculationsVinod Achi VenugopalanNessuna valutazione finora

- Manyam Dr.s HouseDocumento33 pagineManyam Dr.s HouseDurga Rama Swamy KalvakolanuNessuna valutazione finora

- Manyam Dr.s House 2.5Documento33 pagineManyam Dr.s House 2.5Durga Rama Swamy KalvakolanuNessuna valutazione finora

- Composite Slab For Proposed Residential House-1Documento7 pagineComposite Slab For Proposed Residential House-1JosephNessuna valutazione finora

- Plate Girder DesignDocumento8 paginePlate Girder Designkalpanaadhi100% (1)

- Two Way SlabDocumento2 pagineTwo Way Slabrukesh104Nessuna valutazione finora

- Access Scaffolding CalculationDocumento8 pagineAccess Scaffolding CalculationSarah HaiderNessuna valutazione finora

- Timber Column Design To Bs5268-2:2002: Project Job RefDocumento2 pagineTimber Column Design To Bs5268-2:2002: Project Job RefZayyan RomjonNessuna valutazione finora

- Superstructure Analysis DesignDocumento25 pagineSuperstructure Analysis DesignskumaraNessuna valutazione finora

- Design of 75T Crane Girder for 10m SpanDocumento29 pagineDesign of 75T Crane Girder for 10m Spananbukgi100% (2)

- Design of FootingDocumento67 pagineDesign of FootingHarlene Marie M. Ilagan100% (1)

- Design of Isolated Square (Axially Loaded) Pad FootingDocumento7 pagineDesign of Isolated Square (Axially Loaded) Pad FootingNikhil100% (1)

- Connections 1 - Ch.5 Basic Principles - Exercise Solutions (196-214)Documento5 pagineConnections 1 - Ch.5 Basic Principles - Exercise Solutions (196-214)travis8zimmermannNessuna valutazione finora

- Materials: Slab Bridge DesignDocumento13 pagineMaterials: Slab Bridge DesignephremNessuna valutazione finora

- RC Corbel Design CON BSDocumento3 pagineRC Corbel Design CON BSMohd ShahrulmiziNessuna valutazione finora

- Anchor bolt sizing checkDocumento2 pagineAnchor bolt sizing checkmih150% (2)

- Design of Mullion For C W Wall System: Project NameDocumento3 pagineDesign of Mullion For C W Wall System: Project NameSales AlufacadesNessuna valutazione finora

- PurlinDocumento34 paginePurlinnaveenaeeNessuna valutazione finora

- CalculationDocumento10 pagineCalculationVIKRAM DESURKARNessuna valutazione finora

- Design stair waist slabDocumento11 pagineDesign stair waist slabJyoti PatilNessuna valutazione finora

- Design A Deck Type Plate Girder Railway Bridge For Single TractDocumento5 pagineDesign A Deck Type Plate Girder Railway Bridge For Single Tractjs kalyana rama57% (7)

- Example 2 Simply Supported Beam - Flanged Section PDFDocumento7 pagineExample 2 Simply Supported Beam - Flanged Section PDFWee Ren100% (1)

- NHAI Bridge Design StagingDocumento9 pagineNHAI Bridge Design StagingMasud AminNessuna valutazione finora

- Reinforced Concrete Slab Culvert DesignDocumento14 pagineReinforced Concrete Slab Culvert DesignManohar Manu100% (1)

- Base Plate DesignDocumento8 pagineBase Plate DesignANANDA D SNessuna valutazione finora

- Boiler CalculationDocumento67 pagineBoiler Calculationkeerthi dayarathnaNessuna valutazione finora

- Method of Design Cantilever ErectionDocumento62 pagineMethod of Design Cantilever Erectionzieq72Nessuna valutazione finora

- 4.5 - Design of DRS - Simply SupportedDocumento18 pagine4.5 - Design of DRS - Simply Supportedron thombareNessuna valutazione finora

- Desing of 200 Cubic Metre Reinforced Rectangular Clear Water Storage Tank For Rumphi Tank Geometry and DimensionsDocumento23 pagineDesing of 200 Cubic Metre Reinforced Rectangular Clear Water Storage Tank For Rumphi Tank Geometry and DimensionsWjz WjzNessuna valutazione finora

- FORMWORK DESIGNDocumento28 pagineFORMWORK DESIGNsubhananya50% (4)

- 10T SWL Spreader Bar R2-Fos2.0Documento8 pagine10T SWL Spreader Bar R2-Fos2.0Snr Designer JayaNessuna valutazione finora

- Structural Cals For UCWDocumento11 pagineStructural Cals For UCWShubham SoniNessuna valutazione finora

- Rekabentuk Anggota Lentur-Kayu1Documento13 pagineRekabentuk Anggota Lentur-Kayu1Ustaz Diq HalimNessuna valutazione finora

- Design of two-way reinforced concrete slabDocumento15 pagineDesign of two-way reinforced concrete slabMohammed Saleem Syed KhaderNessuna valutazione finora

- RC DesignDocumento11 pagineRC DesignZul FadzliNessuna valutazione finora

- Steel cable tray design and load calculationsDocumento6 pagineSteel cable tray design and load calculationsyusuf_jtNessuna valutazione finora

- Boiler CalcDocumento92 pagineBoiler CalcPrasanta Kumar BeheraNessuna valutazione finora

- Two Way SlabDocumento2 pagineTwo Way Slabrukesh104Nessuna valutazione finora

- Vertical MembersDocumento3 pagineVertical MembersARSENessuna valutazione finora

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresDa EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresValutazione: 4 su 5 stelle4/5 (1)

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationDa EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNessuna valutazione finora

- Web Content - Monorail-R2Documento2 pagineWeb Content - Monorail-R2Parthiban ArivazhaganNessuna valutazione finora

- UI Reinforcement DetailsDocumento3 pagineUI Reinforcement DetailsParthiban ArivazhaganNessuna valutazione finora

- 21a-Gutter-Downpipe Sizing Double Pitch Roof-True Half RoundDocumento2 pagine21a-Gutter-Downpipe Sizing Double Pitch Roof-True Half RoundParthiban ArivazhaganNessuna valutazione finora

- 21a-Gutter-Downpipe Sizing Double Pitch Roof-True Half RoundDocumento2 pagine21a-Gutter-Downpipe Sizing Double Pitch Roof-True Half RoundParthiban ArivazhaganNessuna valutazione finora

- 13a-Building Near Trees To NHBC STANDARDSDocumento1 pagina13a-Building Near Trees To NHBC STANDARDSParthiban ArivazhaganNessuna valutazione finora

- 45b-Floor Joits Type 01.PngDocumento7 pagine45b-Floor Joits Type 01.PngParthiban ArivazhaganNessuna valutazione finora

- 38a-Columns Axial Compression and Moments - PNGDocumento3 pagine38a-Columns Axial Compression and Moments - PNGParthiban ArivazhaganNessuna valutazione finora

- Minimum Pressure Case Stress AnalysisDocumento2 pagineMinimum Pressure Case Stress AnalysisParthiban ArivazhaganNessuna valutazione finora

- Crack Width Check BS5400 4Documento6 pagineCrack Width Check BS5400 4Parthiban ArivazhaganNessuna valutazione finora

- 22a-RSJ Runway Beam Check-Simply Supported-Hand OperatedDocumento2 pagine22a-RSJ Runway Beam Check-Simply Supported-Hand OperatedParthiban Arivazhagan100% (1)

- 21a-Gutter-Downpipe Sizing Double Pitch Roof-TrapezoidalDocumento3 pagine21a-Gutter-Downpipe Sizing Double Pitch Roof-TrapezoidalParthiban ArivazhaganNessuna valutazione finora

- 21a-Gutter-Downpipe Sizing Double Pitch Roof-True Half RoundDocumento2 pagine21a-Gutter-Downpipe Sizing Double Pitch Roof-True Half RoundParthiban ArivazhaganNessuna valutazione finora

- 22a-RSJ Runway Beam Check-Simply Supported-Hand OperatedDocumento2 pagine22a-RSJ Runway Beam Check-Simply Supported-Hand OperatedParthiban Arivazhagan100% (1)

- 45a-Columns Axial Force and Bending - PNGDocumento5 pagine45a-Columns Axial Force and Bending - PNGParthiban ArivazhaganNessuna valutazione finora

- 34e Trussed Beam - PNGDocumento3 pagine34e Trussed Beam - PNGParthiban ArivazhaganNessuna valutazione finora

- 34e Trussed Beam - PNGDocumento3 pagine34e Trussed Beam - PNGParthiban ArivazhaganNessuna valutazione finora

- 34d-Rafter or Sloping Beam-Roller at Lower Lever-With Depth and Width - PNGDocumento3 pagine34d-Rafter or Sloping Beam-Roller at Lower Lever-With Depth and Width - PNGParthiban ArivazhaganNessuna valutazione finora

- 34d-Rafter or Sloping Beam-Roller at Lower Lever - PNGDocumento3 pagine34d-Rafter or Sloping Beam-Roller at Lower Lever - PNGParthiban ArivazhaganNessuna valutazione finora

- 37a-Colums Axial Compression and Moments Type 03.PngDocumento4 pagine37a-Colums Axial Compression and Moments Type 03.PngParthiban ArivazhaganNessuna valutazione finora

- 39b-Columns Axial Compression Only - PNGDocumento2 pagine39b-Columns Axial Compression Only - PNGParthiban ArivazhaganNessuna valutazione finora

- 38j-Ties Axial Tension Only - PNGDocumento2 pagine38j-Ties Axial Tension Only - PNGParthiban ArivazhaganNessuna valutazione finora

- 37b-Columns Axial Compression Only Type 02.PngDocumento2 pagine37b-Columns Axial Compression Only Type 02.PngParthiban ArivazhaganNessuna valutazione finora

- 35c Floor Joists Medium Type A Notch Both Wet - PNGDocumento5 pagine35c Floor Joists Medium Type A Notch Both Wet - PNGParthiban ArivazhaganNessuna valutazione finora

- 37b-Columns Axial Compression Only Type 03.PngDocumento2 pagine37b-Columns Axial Compression Only Type 03.PngParthiban ArivazhaganNessuna valutazione finora

- 38i-Ties Axial Tension and Moments - PNGDocumento2 pagine38i-Ties Axial Tension and Moments - PNGParthiban ArivazhaganNessuna valutazione finora

- 35b Columns Axial Compression Only Single Nails Dry No Load Sharing - PNGDocumento2 pagine35b Columns Axial Compression Only Single Nails Dry No Load Sharing - PNGParthiban ArivazhaganNessuna valutazione finora

- 37c Floor Joists No Notch - PNGDocumento4 pagine37c Floor Joists No Notch - PNGParthiban ArivazhaganNessuna valutazione finora

- 30F-I Stability Check Bending Simply Supported Beams-On Bottom Flange - PNGDocumento3 pagine30F-I Stability Check Bending Simply Supported Beams-On Bottom Flange - PNGParthiban ArivazhaganNessuna valutazione finora

- 35c Floor Joists Long No Notch Dry - PNGDocumento5 pagine35c Floor Joists Long No Notch Dry - PNGParthiban ArivazhaganNessuna valutazione finora

- 35b Columns Axial Compression Only Spaced Screws or Bolts Wet Load Sharing - PNGDocumento3 pagine35b Columns Axial Compression Only Spaced Screws or Bolts Wet Load Sharing - PNGParthiban ArivazhaganNessuna valutazione finora

- En 808D Commissioning Guide 2013-09Documento98 pagineEn 808D Commissioning Guide 2013-09Sam eagle goodNessuna valutazione finora

- Bunker SiloDocumento3 pagineBunker SiloManju Civil PNessuna valutazione finora

- Phaser3300MFP Firmware Upgrade Instructions CWISDocumento2 paginePhaser3300MFP Firmware Upgrade Instructions CWISAlgenis De Leon RamirezNessuna valutazione finora

- 15 Suspensions PDFDocumento57 pagine15 Suspensions PDFSASWAT MISHRANessuna valutazione finora

- Char-Lynn (Eaton) - 158-2925-001 - Motion IndustriesDocumento2 pagineChar-Lynn (Eaton) - 158-2925-001 - Motion Industriesgeovane cardosoNessuna valutazione finora

- DirectX 11 Practical ProjectsDocumento64 pagineDirectX 11 Practical Projectszubair ansariNessuna valutazione finora

- Diesel Engine: Service Parts List ForDocumento49 pagineDiesel Engine: Service Parts List ForIgnacio OsorioNessuna valutazione finora

- MWD Log Quality & StandardsDocumento168 pagineMWD Log Quality & StandardsHamed Sadeghi100% (1)

- Conventional Smoke DetectorDocumento1 paginaConventional Smoke DetectorThan Htike AungNessuna valutazione finora

- Squeeze Cementing TechniquesDocumento22 pagineSqueeze Cementing TechniquesDoni KurniawanNessuna valutazione finora

- S Parameter Theory of Lossless BlockDocumento14 pagineS Parameter Theory of Lossless BlockthgnguyenNessuna valutazione finora

- Applications of The Infrared Thermography in The Energy Audit of Buildings - A ReviewDocumento14 pagineApplications of The Infrared Thermography in The Energy Audit of Buildings - A ReviewDian PsdNessuna valutazione finora

- Technical Information HANSA-FLEX Hose ConnectionsDocumento75 pagineTechnical Information HANSA-FLEX Hose ConnectionshorsanicuNessuna valutazione finora

- Standing Waves Worksheet SolutionsDocumento6 pagineStanding Waves Worksheet SolutionsMaher TrabelsiNessuna valutazione finora

- Manual de TallerDocumento252 pagineManual de TallerEdison RodriguezNessuna valutazione finora

- Cooling Tower PDFDocumento3 pagineCooling Tower PDFmaimslapNessuna valutazione finora

- Sound AttenuatorsDocumento24 pagineSound Attenuatorsadeel_akhtarNessuna valutazione finora

- Xiv 11.5.1 XcliDocumento704 pagineXiv 11.5.1 XcliMuthu LNessuna valutazione finora

- Phoenix Contact 3247055 enDocumento6 paginePhoenix Contact 3247055 enDGNessuna valutazione finora

- Trailblazer 28288123 PDFDocumento300 pagineTrailblazer 28288123 PDFkamote ka0% (1)

- Mount EFS Across VPCs and Availability ZonesDocumento12 pagineMount EFS Across VPCs and Availability Zonesbiswajit patrasecNessuna valutazione finora

- Multisite ErpDocumento5 pagineMultisite ErparavindhsekarNessuna valutazione finora

- Carbon Dioxide in RespirationDocumento1 paginaCarbon Dioxide in Respirationlolay01Nessuna valutazione finora

- Kali Linux For BeginnersDocumento13 pagineKali Linux For Beginnersnihal0% (1)

- Computer Aided Design Course Code: 3341904Documento7 pagineComputer Aided Design Course Code: 3341904Dhaval UpadhyayNessuna valutazione finora

- Haffmans DPT: Dew Point TesterDocumento2 pagineHaffmans DPT: Dew Point TesterLaura Elianne QuirogaNessuna valutazione finora

- EMF Test Report: Ericsson Street Macro 6701 B261 (FCC) : Rapport Utfärdad Av Ackrediterat ProvningslaboratoriumDocumento13 pagineEMF Test Report: Ericsson Street Macro 6701 B261 (FCC) : Rapport Utfärdad Av Ackrediterat Provningslaboratoriumiogdfgkldf iodflgdfNessuna valutazione finora

- Electrical Power Transmission & DistributionDocumento18 pagineElectrical Power Transmission & DistributionMd Saif KhanNessuna valutazione finora

- Construction Methodology for La Vella ResidencesDocumento16 pagineConstruction Methodology for La Vella ResidencesEugene Luna100% (1)