Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

MT11596 PDF

Caricato da

berkahharianTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MT11596 PDF

Caricato da

berkahharianCopyright:

Formati disponibili

Sep-14-2017

ShinMaywa

MT11596

Customer: Approved Judged Dwg.

Project Name:

Tamaki Akamatsu

Calculate the "Required Reaction Force" for select the suitable model from shape of the tank,

tank volume, liquid condition and mixing purpose.

Decided the suitable model compared with the "Required Reaction Force" and its catalogue value.

1.Conditions ( ): estimated value

Tank name Wastewater Basin Mixing purpose Preventation of sedimentation

Tank vol. W×L×Water Depth =15.0 x 15.0 x 2.7 m = 608 [ m3]

Liquid Wastewater Solid - Particle Dia. -

Liquid Gravity (1.0) True specific gravity - Superficial specific gravity -

Viscosity (50) [mPa・s] pH (6~9) Cl- Density (1000) [mg/L]

Density 0.5 [%] Temperature (40)℃ Foreign Matter Refer to the note.

2.Check a required No. of the mixer

Required number of the mixer is calculated as devided number of tank is 1.

Mixing vol. Tank vol./Divided No. of tank = 608 / 1 = 608 [m3]

3.Calculation of Required Reaction Force

Calculate the required reaction force from shape of the tank, mixing purpose and liquid conditions using correction coefficient.

Correction coefficient name Offset Remarks

Rated mixing reaction force 618 Rated mixing reaction force required for mixing our standard tank

Tank shape coefficient C1 1.36 Value from the tank volume and shape

Sludge density coefficient C2 1.07 Value from the liquid quality

Flow velocity coefficient C3 1.0 Value from settle ability of sludge and installation method of equipment

Safety Factor α 1.0

Required Reaction Force(=Rated mixing reaction force×C1×C2×C3×α) =618 x 1.36 x 1.07 x 1.00 x 1.00=899 [N]

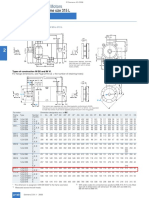

4.Selected Model

Select the following Mixer model to meet the required reaction force from our catalogues.

Q'ty 1 unit / tank Installation example:

Model SM50B-515 (w/ Flow Stabilizer)

Output 5.0 kW

Frequency 50 Hz

Reaction Force 900 N

Outer Dia. 525 mm

Propeller Material SUS316L

Oil Casing SCS14

Draft Ring SUS304L

Required Min. water level 1.2 [m] from the bottom

Required Min. opening dim. 0.8 x 1.2 [m]

●Notice for Installation & Operation

-Remove the foreign matter by screen to prevent

entwining with propeller.

-In case the above condition changed,

the model shall be changed.

-Make sure to keep required min. water level

during operation.

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Instructions For Installation, Operation and MaintenanceDocumento101 pagineInstructions For Installation, Operation and MaintenanceberkahharianNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- SKF Industrial Gearbox 2 2Documento2 pagineSKF Industrial Gearbox 2 2berkahharianNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- 1823 Chapter VDocumento10 pagine1823 Chapter VberkahharianNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- BoQ PlumbingDocumento30 pagineBoQ PlumbingberkahharianNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- 5e6b0pt Tunnel Fan Cat029 E0 Ed2Documento24 pagine5e6b0pt Tunnel Fan Cat029 E0 Ed2berkahharianNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Flender Tübingen Mixer Drives: Technical Data Agitator Drives ZR and DR Series in 8 SizesDocumento1 paginaFlender Tübingen Mixer Drives: Technical Data Agitator Drives ZR and DR Series in 8 SizesberkahharianNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Siemens 1LA7 Cat 130Documento1 paginaSiemens 1LA7 Cat 130berkahharianNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- II Test Running Record: 2.1 Vibration Data No LoadDocumento10 pagineII Test Running Record: 2.1 Vibration Data No LoadberkahharianNessuna valutazione finora

- Siemens 1LA7 Cat 48Documento1 paginaSiemens 1LA7 Cat 48berkahharianNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Siemens 1LA7 Cat 123Documento1 paginaSiemens 1LA7 Cat 123berkahharianNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- FCL Couplings: Chengdu Leno Machinery Co., LTDDocumento1 paginaFCL Couplings: Chengdu Leno Machinery Co., LTDjamblang_limNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- DRAIN TYPE FLUID COUPLING For Internal Combustion Engines KPTODocumento4 pagineDRAIN TYPE FLUID COUPLING For Internal Combustion Engines KPTOberkahharianNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Full Size Selection ChartDocumento88 pagineFull Size Selection ChartberkahharianNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Siemens 1LA7 Cat 40Documento1 paginaSiemens 1LA7 Cat 40berkahharianNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Taper Grip Bushing Installation Guide: Apply Thin Layer of Anti-Seize Paste To Male Threads of Bushing OnlyDocumento4 pagineTaper Grip Bushing Installation Guide: Apply Thin Layer of Anti-Seize Paste To Male Threads of Bushing OnlyberkahharianNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Loiskov Jednotky YDocumento44 pagineLoiskov Jednotky YberkahharianNessuna valutazione finora

- Installation Operation Maintenance Manual (Harvest Series)Documento36 pagineInstallation Operation Maintenance Manual (Harvest Series)berkahharianNessuna valutazione finora

- RMA4 Users Guide 09-27-2011Documento187 pagineRMA4 Users Guide 09-27-2011Athanasius Kurniawan Prasetyo AdiNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Momentum Transfer: Engr. Eric R. HalabasoDocumento32 pagineMomentum Transfer: Engr. Eric R. HalabasoClaire dela CruzNessuna valutazione finora

- Naval Architecture Syllabus PDFDocumento8 pagineNaval Architecture Syllabus PDFMahesh Kumar K BNessuna valutazione finora

- Modeling The Deformation of Earth Dam During An Earthquake: AbstractDocumento6 pagineModeling The Deformation of Earth Dam During An Earthquake: AbstractMahmoud. HlelaiNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Phreeqc 3 2013 ManualDocumento519 paginePhreeqc 3 2013 ManualpauloalpeNessuna valutazione finora

- Machine Protection USA Web PDFDocumento84 pagineMachine Protection USA Web PDFEren GünerNessuna valutazione finora

- Power System Engineering MaterialDocumento6 paginePower System Engineering MaterialAshok SainiNessuna valutazione finora

- Electron Diffraction Lab Report - KatzerDocumento7 pagineElectron Diffraction Lab Report - Katzerapi-489811472Nessuna valutazione finora

- Eberhardt (2015) ISRM Suggested Method Por Failure Criteria - Hoek-BrownDocumento13 pagineEberhardt (2015) ISRM Suggested Method Por Failure Criteria - Hoek-BrownSebastian Jorquera HenriquezNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Begin As Follows: To Compute An MPN and The 95% Confidence Limits On The Log of The MPN: Enter The Inoculum/tube in Column ADocumento1 paginaBegin As Follows: To Compute An MPN and The 95% Confidence Limits On The Log of The MPN: Enter The Inoculum/tube in Column AlailinayahNessuna valutazione finora

- DjekicDocumento110 pagineDjekicРаденко ОстојићNessuna valutazione finora

- Energy, Energy Transfer, and General Energy AnalysisDocumento23 pagineEnergy, Energy Transfer, and General Energy AnalysisBen RileyNessuna valutazione finora

- MS8910 Instruction ManualDocumento6 pagineMS8910 Instruction ManualAndre Fabiano JardimNessuna valutazione finora

- 3.3B Antenas PDFDocumento4 pagine3.3B Antenas PDFHéctor González DortaNessuna valutazione finora

- Ch. 9 (B) LecDocumento38 pagineCh. 9 (B) LecTom UlesNessuna valutazione finora

- Reinforced Concrete Structures R. Park T.paulayDocumento783 pagineReinforced Concrete Structures R. Park T.paulayMamet Edvant89% (9)

- Astm D2573 D2573M 18Documento4 pagineAstm D2573 D2573M 18deptrailaikieuNessuna valutazione finora

- Vortex Shedding Induced Vibrations of A Light MastDocumento15 pagineVortex Shedding Induced Vibrations of A Light MastDM2Nessuna valutazione finora

- Bmsee Ii Math Challenge!Documento32 pagineBmsee Ii Math Challenge!Venus Cadenas AscarezNessuna valutazione finora

- Resident Physics Lectures: Mammography X-Ray SystemDocumento42 pagineResident Physics Lectures: Mammography X-Ray SystemLajja Parikh PatelNessuna valutazione finora

- Ce2253 Applied Hydraulic Engg Qus Bank PDFDocumento13 pagineCe2253 Applied Hydraulic Engg Qus Bank PDFthamilarasuNessuna valutazione finora

- AstrochemistryDocumento2 pagineAstrochemistryjennifer_friedmann0% (1)

- 03 - Velocity Time GraphsDocumento33 pagine03 - Velocity Time GraphsWaqas AhmadNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- System of Linear InequalitiesDocumento7 pagineSystem of Linear InequalitiesDominic SavioNessuna valutazione finora

- SS Skyfr 000819 - 2Documento3 pagineSS Skyfr 000819 - 2Anonymous HfsLqoWlNessuna valutazione finora

- Sci 202 - Course GuideDocumento8 pagineSci 202 - Course GuideRicardo VelozNessuna valutazione finora

- Force Table: Instruction Manual and Experiment Guide For The PASCO Scientific Model ME-9447Documento18 pagineForce Table: Instruction Manual and Experiment Guide For The PASCO Scientific Model ME-9447joanally bagoyoNessuna valutazione finora

- Matlab For SHRT Circuit AnalysisDocumento6 pagineMatlab For SHRT Circuit AnalysisM B Hemanth KumarNessuna valutazione finora

- Boiler Feed Pump KSBDocumento9 pagineBoiler Feed Pump KSByogacruiseNessuna valutazione finora

- 4B-Velocity Profiles (2021)Documento18 pagine4B-Velocity Profiles (2021)ArinaAdilaNessuna valutazione finora